Multi-doping pomegranate-shaped solid electrolyte material and preparation method thereof

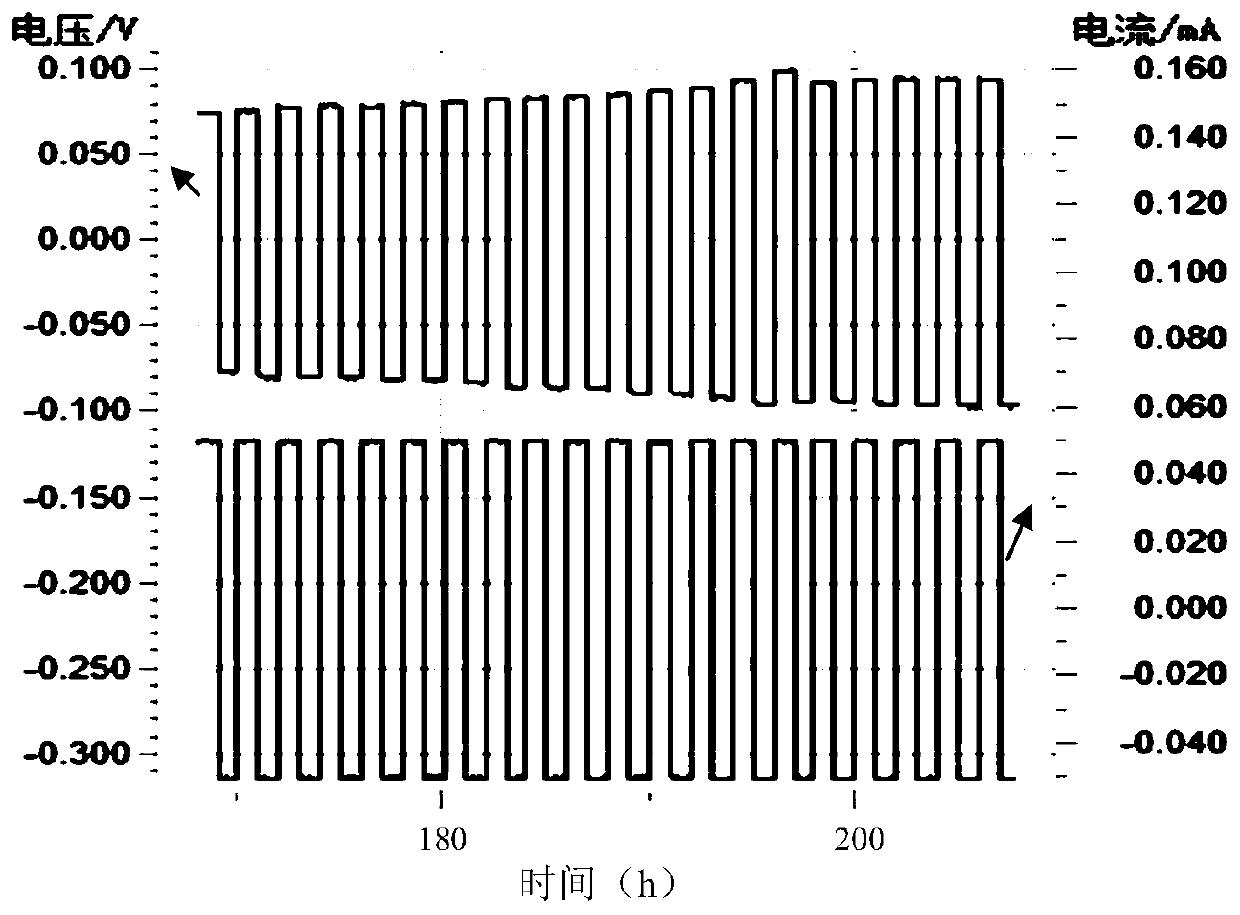

A solid electrolyte and garnet-type technology, which is applied in the field of multi-doped garnet-type solid electrolyte materials and their preparation, can solve the problems of harsh preparation conditions of solid electrolytes, and achieve reduced energy consumption, improved ion conductivity, and good electrical conductivity. The effect of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

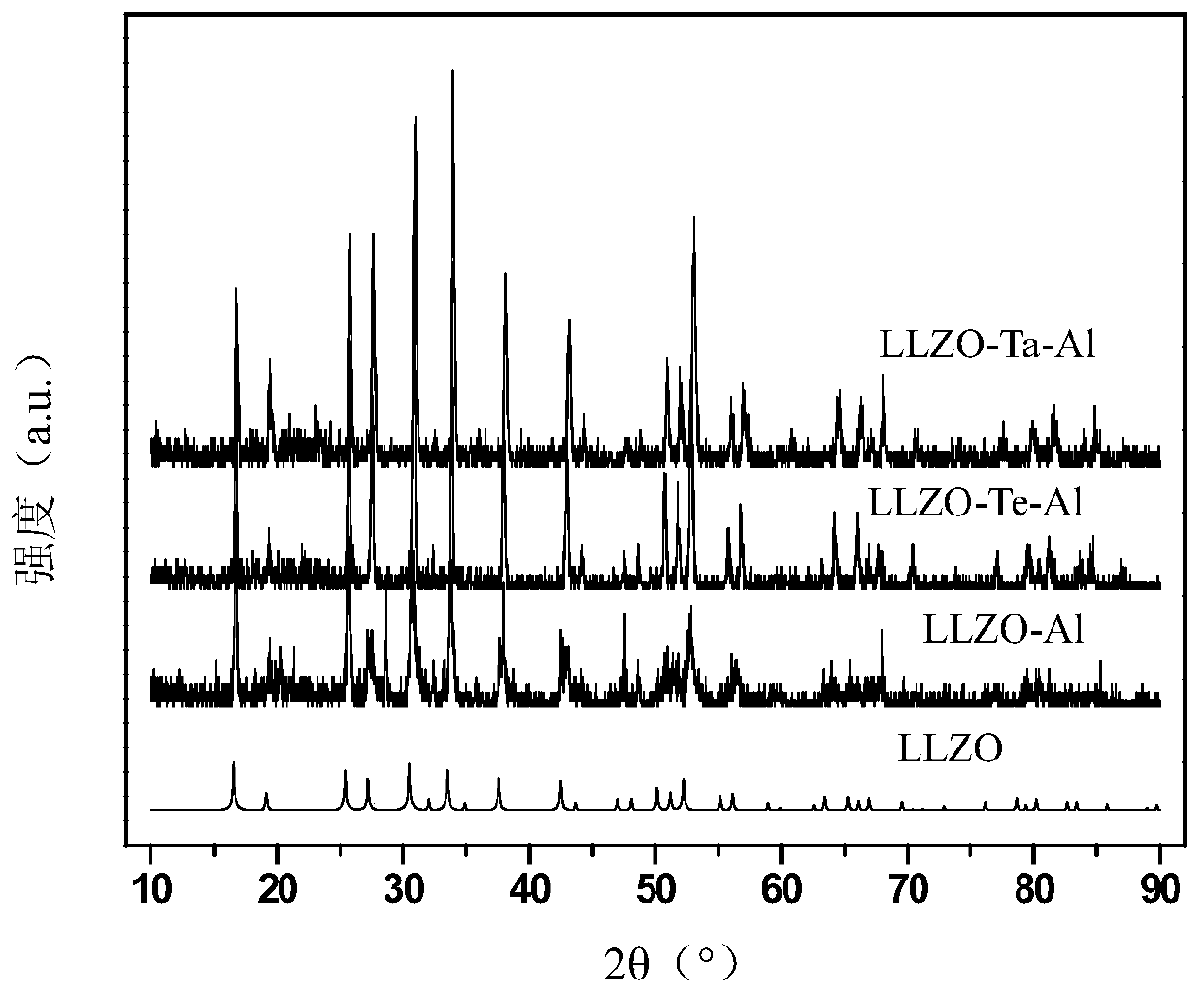

[0027] Embodiment 1 (comparative example)

[0028] Preparation of Al 2 o 3 -Li 7 La 3 Zr 2 o 12 Solid electrolyte material:

[0029] Weigh 2.33gLiOH·H according to the molar ratio of Li, La, Zr 7:3:2 2 O, 2.91gLa 2 o 3 , 1.46gZrO 2 , adding isopropanol as a dispersant for ball milling, material: zirconium balls: dispersant = 1:3:1 (mass ratio), ball milling at a speed of 500r / min for 6h, and then placed in a blast drying oven to dry at 60°C, A mixed powder is obtained. Put the mixed powder in a muffle furnace, raise the temperature to 800°C at a rate of 3°C / min, keep it at 800°C for 6 hours, take out the sample after cooling to room temperature with the furnace, add 0.005gAl 2 o 3Secondary ball milling for 6 hours to reduce the particle size of the solid powder to the micron level. After drying again, obtain the mother powder; take 5g of the mother powder, press the mother powder at a pressure of 250MPa, hold the pressure for 20min, and obtain LLZO tablets with a t...

Embodiment 2

[0032] Preparation of Al 2 o 3 -Li 6.8 La 3 Zr 1.9 Te 0.1 o 12 (Te is +6 valence in this embodiment) solid electrolyte material:

[0033] Choose LiOH·H 2 O, La 2 o 3 , ZrO 2 , TeO 2 、Al 2 o 3 As a raw material, weigh 2.24g LiOH·H according to the stoichiometric ratio 2 O, 2.88gLa 2 o 3 , 1.38g ZrO 2 , 0.09g TeO 2 , adding isopropanol as a dispersant for ball milling, material: zirconium balls: dispersant = 1:3:1, ball milling at a speed of 400r / min for 6h, and then placed in a blast drying oven at 60°C to obtain a mixed powder. Pre-fire the mixed powder in a muffle furnace at 600°C for 2h, add 0.007g Al 2 o 3 Secondary ball milling for 6 hours to reduce the particle size of the solid powder to the nanometer level. After drying again, 5 g of the mother powder was obtained. The mother powder was pressed into tablets with a pressure of 250 MPa to a thickness of 1 mm, and then placed in a muffle furnace at 3 ° C. Raise the temperature to 700°C at a rate of 1 / mi...

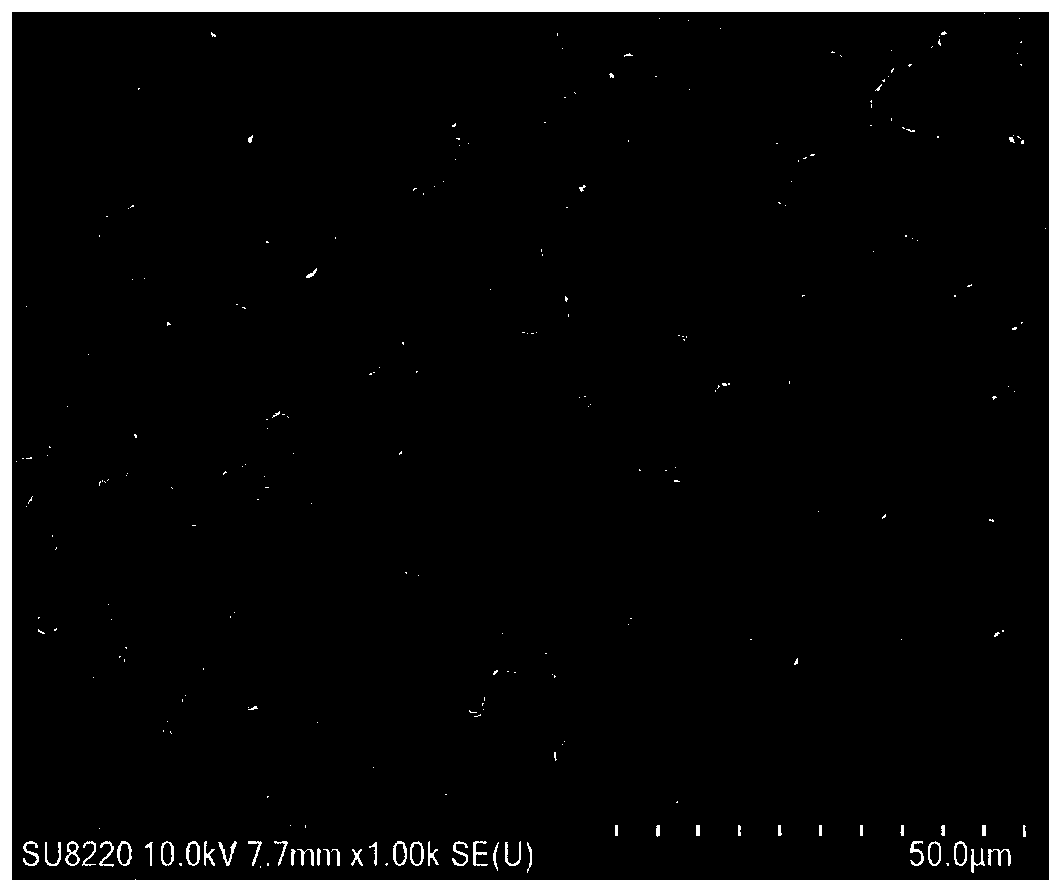

Embodiment 3

[0035] Preparation of Al 2 o 3 -Li 6.8 La 3 Zr 1.9 Te 0.1 o 12 The solid electrolyte material:

[0036] Weigh 4.48gLiOH·H according to the stoichiometric ratio 2 O, 5.76gLa 2 o 3 , 2.76gZrO 2 , 0.18gTeO 2 , adding isopropanol as a dispersant for ball milling, material: zirconium balls: dispersant = 1:6:1, ball milled at a speed of 500r / min for 12h, and then dried in a blast drying oven at 60°C to obtain a mixed powder. Put the mixed powder in a muffle furnace, pre-fire at 600°C for 2 hours, add 0.014g Al 2 o 3 Secondary ball milling for 12 hours to reduce the particle size of the solid powder to the micron level, and then dry again to obtain 10g of the mother powder, then press the mother powder into tablets with a pressure of 200MPa and a thickness of 1mm, and sinter in a muffle furnace at 700°C for 12 hours , making Al 2 o 3 -Li 6.8 La 3 Zr 1.9 Te 0.1 o 12 Cubic garnet type solid electrolyte sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com