Hydroxylated acrylic resin as well as preparation method and application thereof

A technology of hydroxy acrylic acid and hydroxy acrylate, applied in the coating and other directions, can solve the problems that the weather resistance of the coating film cannot be compared with that of the fluorocarbon coating, the reaction conditions of the fluorocarbon resin are harsh, and the curing of the paint film is difficult, and the production cost is reached. Low, high hardness, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

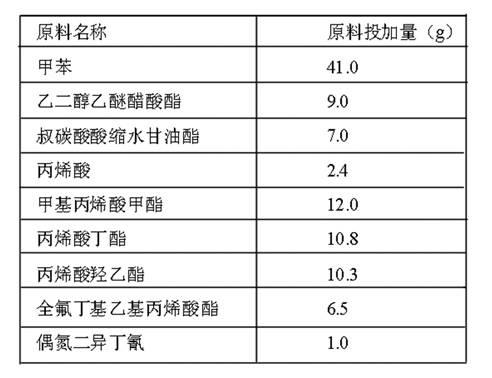

[0026] Raw material distribution table

[0027]

[0028] The whole reaction was carried out under the protection of nitrogen environment

[0029] (1) Add xylene, ethylene glycol ethyl ether acetate and glycidyl tertiary carbonic acid ester into the reactor according to the raw material dosage table, and raise the temperature to 155°C;

[0030] (2) Mix acrylic acid, methyl methacrylate, butyl acrylate, hydroxyethyl acrylate, perfluorobutyl ethyl acrylate and di-tert-butyl peroxide evenly, and add dropwise for 3.5 hours;

[0031] (3) Keep warm for 1.5 hours;

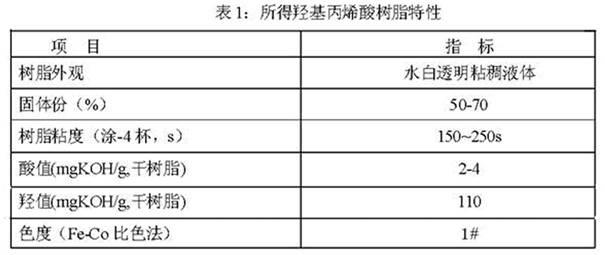

[0032] (4) Then cool down to 40°C and discharge to obtain a hydroxyacrylic resin with a molecular weight of 15,000. The properties of the obtained hydroxyacrylic resin are shown in Table 3.

[0033] Described hydroxyl acrylic resin is used as the application of coating raw material, and its concrete steps are as follows:

[0034] (1) Use xylene to adjust the viscosity of hydroxyacrylic resin, apply -4 cup and measure...

Embodiment 2

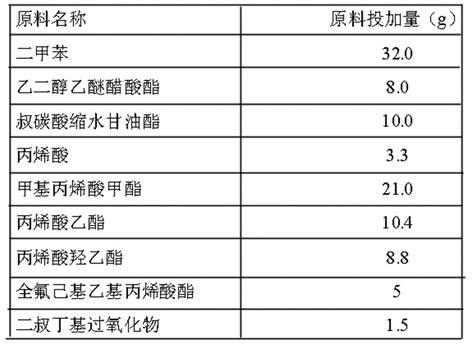

[0040] Raw material distribution table

[0041]

[0042] The whole reaction was carried out under the protection of nitrogen environment

[0043] (1) Add xylene, ethylene glycol ethyl ether acetate and glycidyl tertiary carbonic acid ester into the reactor according to the raw material dosage table, and raise the temperature to 150°C;

[0044] (2) Mix acrylic acid, methyl methacrylate, butyl acrylate, hydroxyethyl acrylate, perfluorobutyl ethyl acrylate and di-tert-butyl peroxide evenly, and add dropwise for 3.0 hours;

[0045] (3) Keep warm for 1.5 hours;

[0046] (4) Then cool down to 65°C and discharge to obtain a hydroxyacrylic resin with a molecular weight of 10,000. The properties of the obtained hydroxyacrylic resin are shown in Table 3.

[0047] Described hydroxyl acrylic resin is used as the application of coating raw material, and its concrete steps are as follows:

[0048] (1) Use xylene to adjust the viscosity of hydroxyacrylic resin, apply -4 cup for 90 seco...

Embodiment 3

[0054] Raw material distribution table

[0055]

[0056] The whole reaction was carried out under the protection of nitrogen environment

[0057] (1) Add xylene, ethylene glycol ethyl ether acetate and glycidyl tertiary carbonic acid ester into the reactor according to the raw material dosage table, and raise the temperature to 160°C;

[0058] (2) Mix acrylic acid, methyl methacrylate, butyl acrylate, hydroxyethyl acrylate, perfluorobutyl ethyl acrylate and di-tert-butyl peroxide evenly, and add dropwise for 4.0 hours;

[0059] (3) keep warm for 2.0 hours;

[0060] (4) Then cool down to 70°C and discharge to obtain a hydroxyacrylic resin with a molecular weight of 20,000. The properties of the obtained hydroxyacrylic resin are shown in Table 3.

[0061] Described hydroxyl acrylic resin is used as the application of coating raw material, and its concrete steps are as follows:

[0062] (1) Use xylene to adjust the viscosity of hydroxyacrylic resin, apply it to a -4 cup and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com