Cooker and preparation method thereof and cooking utensil

A technology of pots and pots, which is applied to special materials for cooking utensils, cooking utensils, kitchen utensils, etc., and can solve the problems of poor non-stickiness and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

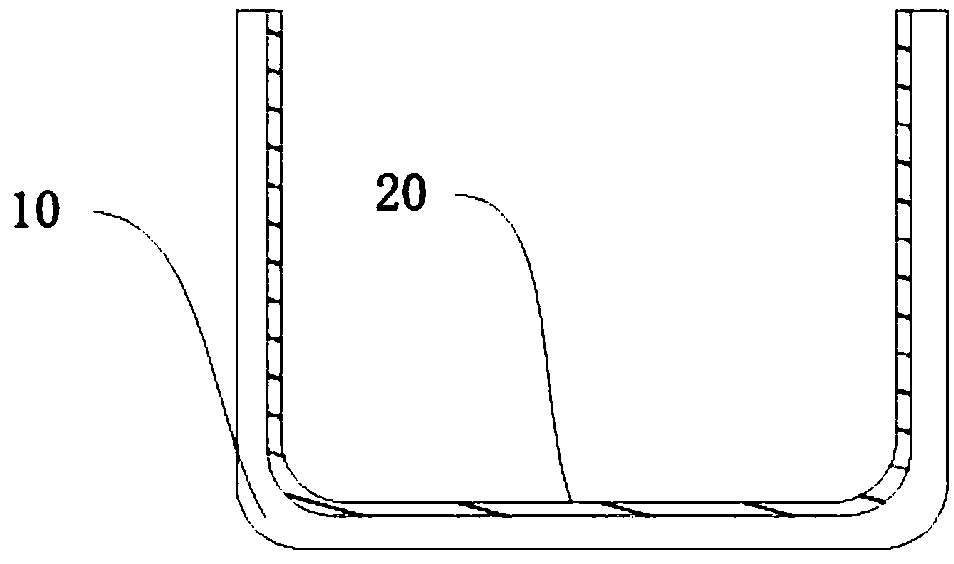

Image

Examples

Embodiment 1

[0060] The steps for preparing the pan include:

[0061] Step 1: Use pure aluminum, pure copper, pure iron, and pure chromium as raw materials, and make ingredients according to the atomic percentage of Al, Cu, Fe and Cr+Ti at 60:15:15:10;

[0062] Step 2: Put the weighed Al, Cu, Fe, (Cr+Ti) raw materials into the cleaned intermediate frequency induction furnace, place Fe and Cr at the bottom of the intermediate frequency induction furnace, heat up and melt, and pass through the whole process. Inertness is used as a protective gas during the smelting process or vacuuming, and the alloy ingot is cast after the alloy is completely melted and the slag is removed;

[0063] Step 3: CNC machining is used to process the alloy ingot obtained in Step 2 into the required target size;

[0064] Step 4: Clean the pot body;

[0065] Step 5: Using bias magnetron sputtering, coating under the following conditions,

[0066] Vacuum is 1.0x10 -2 Pa;

[0067] The power is 6kW;

[0068] The ...

Embodiment 2

[0075] The steps for preparing the pan include:

[0076] Step 1: Use pure aluminum, pure copper, pure iron, and pure chromium as raw materials, and make ingredients according to the atomic percentage of Al, Cu, Fe, and Cr+Ti at 70:15:5:10;

[0077] Step 2: Put the weighed Al, Cu, Fe, (Cr+Ti) raw materials into the cleaned intermediate frequency induction furnace, place Fe and Cr at the bottom of the intermediate frequency induction furnace, heat up and melt, and pass through the whole process. Inertness is used as a protective gas during the smelting process or vacuuming, and the alloy ingot is cast after the alloy is completely melted and the slag is removed;

[0078] Step 3: CNC machining is used to process the alloy ingot obtained in Step 2 into the required target size;

[0079] Step 4: Clean the pot body;

[0080] Step 5: Use bias multi-arc ion plating to perform coating under the following conditions,

[0081] Vacuum is 1.0x10 -3 Pa;

[0082] The power is 18kW;

[...

Embodiment 3

[0090] The steps for preparing the pan include:

[0091] Step 1: Use pure aluminum, pure copper, pure iron, and pure chromium as raw materials, and make ingredients according to the atomic percentage of Al, Cu, Fe and Cr+Ti at 65:15:10:10;

[0092] Step 2: Put the weighed Al, Cu, Fe, (Cr+Ti) raw materials into the cleaned intermediate frequency induction furnace, place Fe and Cr at the bottom of the intermediate frequency induction furnace, heat up and melt, and pass through the whole process. Inertness is used as a protective gas during the smelting process or vacuuming, and the alloy ingot is cast after the alloy is completely melted and the slag is removed;

[0093] Step 3: CNC machining is used to process the alloy ingot obtained in Step 2 into the required target size;

[0094] Step 4: Clean the pot body;

[0095] Step 5: Use bias multi-arc ion plating to perform coating under the following conditions,

[0096] The vacuum is 5.0x10 -2 Pa;

[0097] The power is 12kW; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| voidage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com