A kind of microwave dielectric ceramic powder and its preparation method

A microwave dielectric ceramic and powder technology is applied in the field of microwave dielectric ceramic powder and its preparation, which can solve the problems of high price, limited application and promotion, etc., and achieve the effects of low cost, improved microstructure and low loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

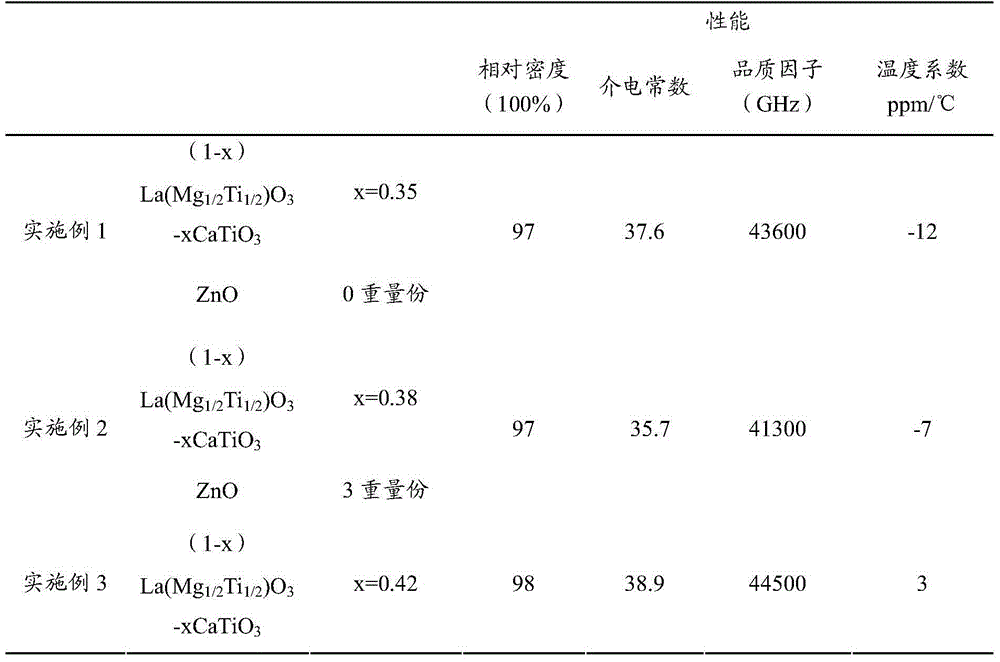

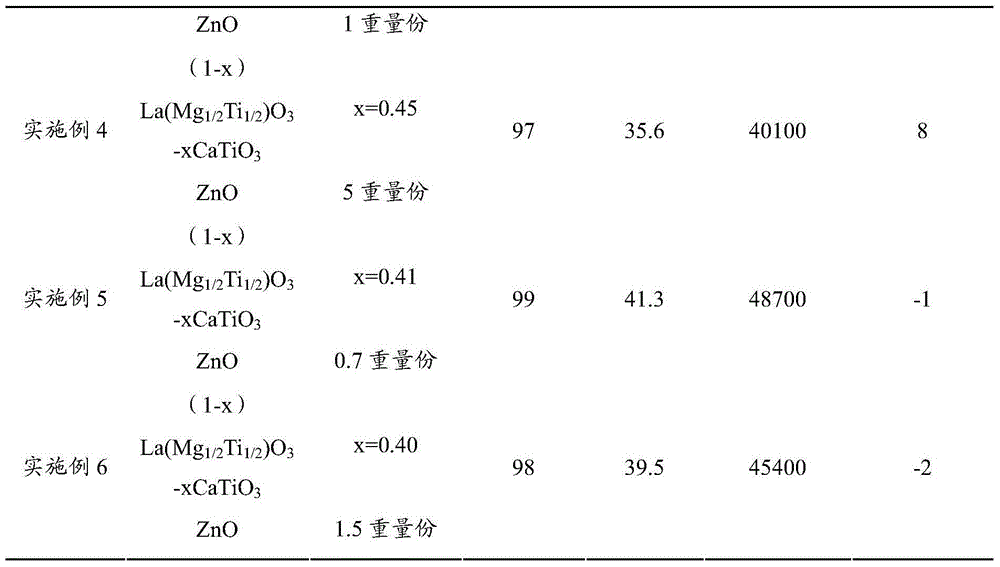

[0032] The present invention also provides a method for preparing the microwave dielectric ceramic powder, comprising: A) adding 95 to 100 parts by weight of (1-x)La(Mg 1 / 2 Ti 1 / 2 )O 3 -xCaTiO 3 It is mixed with 0-5 parts by weight of ZnO and ball-milled to obtain a microwave dielectric ceramic powder; wherein, x=0.35-0.45.

[0033] The (1-x)La(Mg 1 / 2 Ti 1 / 2 )O 3 -xCaTiO 3 The content of ZnO is the same as that described above, and will not be repeated here. The present invention has no special limitation on the sources of all raw materials, which can be commercially available or self-made.

[0034] The (1-x)La(Mg 1 / 2 Ti 1 / 2 )O 3 -xCaTiO 3 It is preferably prepared according to the following method: the molar ratio of the lanthanum-containing compound, the magnesium-containing compound, the titanium-containing compound and the calcium-containing compound according to the element lanthanum, magnesium, titanium and calcium is (1-x): 0.5 (1-x): [ 0.5(1-x)+x]:x ratio m...

Embodiment 1

[0045] 1.1 The molar ratio of lanthanum oxide, magnesium hydroxide, titanium oxide and calcium carbonate according to the element lanthanum, magnesium, titanium and calcium is (1-x): 0.5 (1-x): [0.5 (1-x) + x ]: mixed in the ratio of x, where x is 0.35, after mixing, add absolute ethanol as the medium to the ball mill jar for wet ball milling for 20 hours, then dry in an oven, keep at 1100°C for 6 hours to obtain ceramic powder 0.65La (Mg 1 / 2 Ti 1 / 2 )O 3 -0.35CaTiO 3 .

[0046] 1.2 The 0.65La (Mg 1 / 2 Ti 1 / 2 )O 3 -0.35CaTiO 3 Put it into a ball mill pot and use deionized water as the ball milling medium for ball milling for 22 hours, and dry in an oven to obtain a microwave dielectric ceramic powder.

Embodiment 2

[0048] 2.1 The molar ratio of lanthanum nitrate, magnesium oxide, titanium oxalate and calcium hydroxide according to the element lanthanum, magnesium, titanium and calcium is (1-x): 0.5 (1-x): [0.5 (1-x) + x ]: mixed in the ratio of x, where x is 0.38, after mixing, put deionized water as the medium into a ball mill tank for wet ball milling for 24 hours, then dry in an oven, and keep it at 1300°C for 1 hour to obtain ceramic powder 0.62La (Mg 1 / 2 Ti 1 / 2 )O 3 -0.38CaTiO 3 .

[0049] 2.2 The 0.62La (Mg 1 / 2 Ti 1 / 2 )O 3 -0.38CaTiO 3 It is mixed with 3 parts by weight of ZnO powder and added into a ball mill tank, using deionized water as the ball milling medium for ball milling for 22 hours, and dried in an oven to obtain a microwave dielectric ceramic powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality factor | aaaaa | aaaaa |

| resonant frequency temperature coefficient | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com