A low-loss high-strength microwave dielectric ceramic and its preparation method

A technology of microwave dielectric ceramics and high-intensity microwaves, applied in the field of electronic ceramics and its preparation, can solve the problems of low quality factor, unreachable processing strength, high dielectric constant, etc., and achieve high sintering temperature, low loss, and temperature coefficient of resonance frequency adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

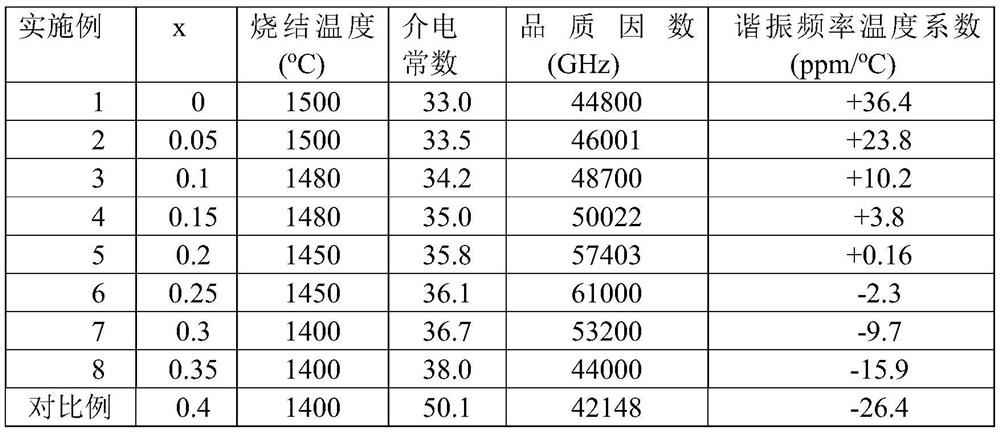

Examples

preparation example Construction

[0024] The present invention also provides a method for preparing low-loss high-strength microwave dielectric ceramics, comprising the following steps:

[0025] (1) TiO 2 and CaCO 3 According to the chemical formula CaTiO 3 The molar ratio of the corresponding elements in the ingredients, the TiO 2 and CaCO 3 After mixing, it is fully ball milled, dried and sieved after ball milling, and then put into a corundum crucible for roasting to obtain CaTiO 3 combination;

[0026] (2) will Sm 2 o 3 and Al 2 o 3 According to the chemical formula SmAlO 3 The molar ratio of the corresponding elements in the ingredients, the Sm 2 o 3 and Al 2 o 3 After mixing, it is fully ball milled, dried and sieved after ball milling, and then put into a corundum crucible for roasting to obtain SmAlO 3 combination;

[0027] (3) TiO 2 , CaCO 3 、Sm 2 o 3 、Al 2 o 3 According to the chemical formula CaSmAlTiO 6 The molar ratio of the corresponding elements in the ingredients, the TiO ...

Embodiment 1

[0036] The preparation method of the low-loss high-strength microwave dielectric ceramic of the present embodiment 1 comprises the following steps:

[0037] (1) TiO 2 and CaCO 3 According to the chemical formula CaTiO 3 The molar ratio of the corresponding elements in the ingredients, the TiO 2 and CaCO 3 After mixing, fully ball mill, dry and sieve after ball milling, then put it into a corundum crucible, and roast at 1100°C for 4 hours to obtain CaTiO 3 combination;

[0038] (2) TiO 2 , CaCO 3 、Sm 2 o 3 、Al 2 o 3 According to the chemical formula CaSmAlTiO 6 The molar ratio of the corresponding elements in the ingredients, the TiO 2 , CaCO 3 、Sm 2 o 3 、Al 2 o 3 After mixing, it is fully ball milled, dried and sieved after ball milling, then put into a corundum crucible, and roasted at 1100 ° C for 4 hours to obtain the chemical formula CaSmAlTiO 6 Compositions;

[0039] (4) CaTiO will be obtained 3 Composition and CaSmAlTiO 6 Composition according to che...

Embodiment 2

[0042] The preparation method of the low-loss high-strength microwave dielectric ceramic of the present embodiment 2 comprises the following steps:

[0043] (1) TiO 2 and CaCO 3 According to the chemical formula CaTiO 3 The molar ratio of the corresponding elements in the ingredients, the TiO 2 and CaCO 3 After mixing, fully ball mill, dry and sieve after ball milling, then put it into a corundum crucible, and roast at 1100°C for 4 hours to obtain CaTiO 3 combination;

[0044] (2) will Sm 2 o 3 and Al 2 o 3 According to the chemical formula SmAlO 3 The molar ratio of the corresponding elements in the ingredients, the Sm 2 o 3 and Al 2 o 3 After mixing, fully ball mill, dry and sieve after ball milling, then put it into a corundum crucible, and roast at 1100°C for 4h to obtain SmAlO 3 combination;

[0045] (3) TiO 2 , CaCO 3 、Sm 2 o 3 、Al 2 o 3 According to the chemical formula CaSmAlTiO 6 The molar ratio of the corresponding elements in the ingredients, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| quality factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com