Low-temperature co-fired Li2MgTi3O8 microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic and low-temperature co-firing technology, applied in ceramics, inorganic insulators, etc., can solve the problems of insufficient comprehensive performance, adverse effects, low quality factor Q×f, etc., and achieve excellent microwave performance, stable and reliable performance, chemical Simple effect of composition and preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

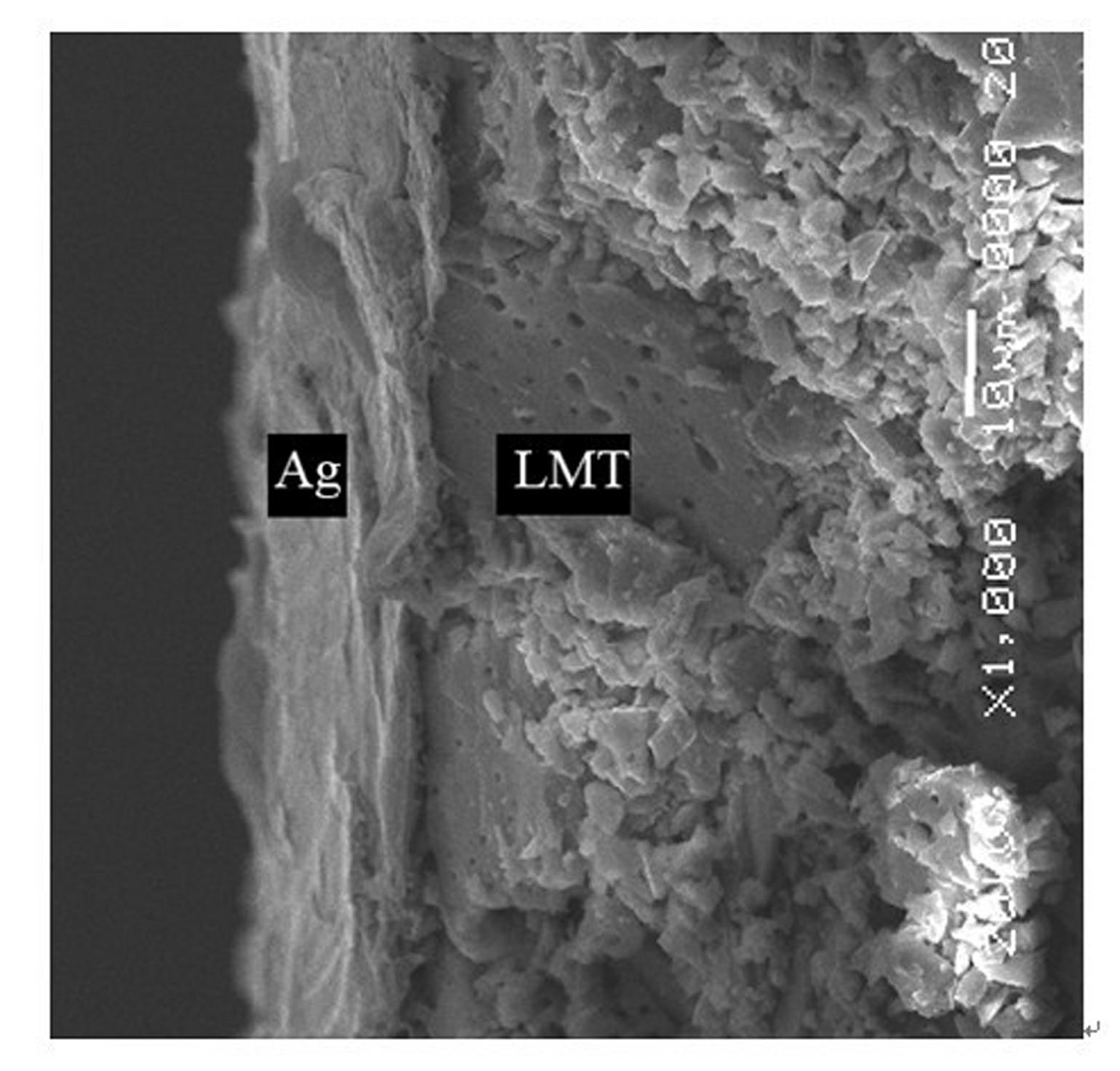

Image

Examples

Embodiment 1

[0023] A method for preparing a low-temperature co-fired lithium-magnesium-titanium microwave dielectric ceramic material, in which LMB glass powder is added to the composition.

[0024] 1) Synthesis of Li 2 MgTi 3 o 8 : Li 2 CO 3 (purity>97.5%), (MgCO 3 ) 4 Mg(OH) 2 ·5HO 2 and TiO 2 (purity ≥ 99%) as raw material, according to the molar ratio Li 2 CO 3 :MgO:TiO 2 = 1:1:3 Weigh the material, mix the prepared material with absolute alcohol as the medium, ball mill and mix for 24 h, dry and sieve, and then synthesize Li at 900 °C for 4 h 2 MgTi 3 o 8 main powder.

[0025] 2) Preparation of LMB glass powder: with Li 2 CO 3 (purity ≥ 97.5%), (MgCO 3 ) 4 Mg(OH) 2 ·5HO 2 and H 3 BO 3(purity ≥ 99%) as raw material, according to aLi 2 O+ bMgO +cB 2 o 3 Carry out batching, wherein a=30%, b=10%, c=60% by mole percentage. Keep the batch material at 950°C for 1 hour, then pour it into cold water to form glass slag, and get D through ball milling 50 =5μm LMB glas...

Embodiment 2

[0028] A method for preparing a low-temperature co-fired lithium-magnesium-titanium microwave dielectric ceramic material, in which LMB glass powder is added to the composition.

[0029] 1) Synthesis of Li 2 MgTi 3 o 8 : Li 2 CO 3 (purity ≥ 97.5%), (MgCO 3 ) 4 Mg(OH) 2 ·5HO 2 and TiO 2 (purity ≥ 99%) as raw material, according to the molar ratio Li 2 CO 3 :MgO:TiO 2 = 1:1:3 Weigh the material, mix the prepared material with absolute alcohol as the medium, ball mill and mix for 24 h, dry and sieve, and then synthesize Li at 900 °C for 4 h 2 MgTi 3 o 8 main powder.

[0030] 2) Preparation of LMB glass powder: with Li 2 CO 3 (purity ≥ 97.5%), (MgCO 3 ) 4 Mg(OH) 2 ·5HO 2 and H 3 BO 3 (purity ≥ 99%) as raw material, according to aLi 2 O+ bMgO +cB 2 o 3 Carry out batching, wherein a=30%, b=10%, c=60% by mole percentage. Keep the batch material at 950°C for 1 hour, then pour it into cold water to form glass slag, and get D through ball milling 50 =5μm LMB g...

Embodiment 3

[0033] A method for preparing a low-temperature co-fired lithium-magnesium-titanium microwave dielectric ceramic material, in which LMB glass powder is added to the composition.

[0034] 1) Synthesis of Li 2 MgTi 3 o 8 : Li 2 CO 3 (purity ≥ 97.5%), (MgCO 3 ) 4 Mg(OH) 2 ·5HO 2 and TiO 2 (purity ≥ 99%) as raw material, according to the molar ratio Li 2 CO 3 :MgO:TiO 2 = 1:1:3 Weigh the material, mix the prepared material with absolute alcohol as the medium, ball mill and mix for 24 h, dry and sieve, and then synthesize Li at 900 °C for 4 h 2 MgTi 3 o 8 main powder.

[0035] 2) Preparation of LMB glass powder: with Li 2 CO 3 (purity ≥ 97.5%), (MgCO 3 ) 4 Mg(OH) 2 ·5HO 2 and H 3 BO 3 (purity ≥ 99%) as raw material, according to aLi 2 O+ bMgO +cB 2 o 3 Carry out batching, wherein a=30%, b=10%, c=60% by mole percentage. Keep the batch material at 950°C for 1 hour, then pour it into cold water to form glass slag, and get D through ball milling 50 =5μm LMB g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com