Microwave dielectric ceramic material as well as preparation method and application thereof

A microwave dielectric ceramic and modified technology, applied in the field of new materials and microwave communication, can solve the problems of high cost, tight spectrum resources, high energy consumption, etc., and achieve cheap and easy-to-obtain raw materials, good microwave dielectric properties, and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

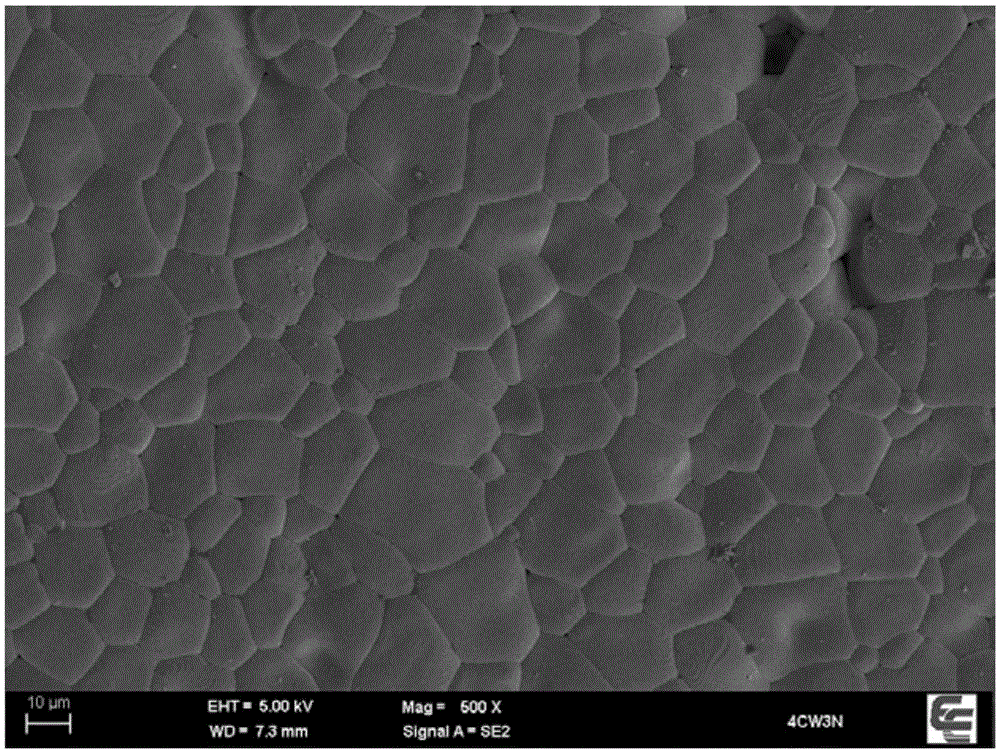

Image

Examples

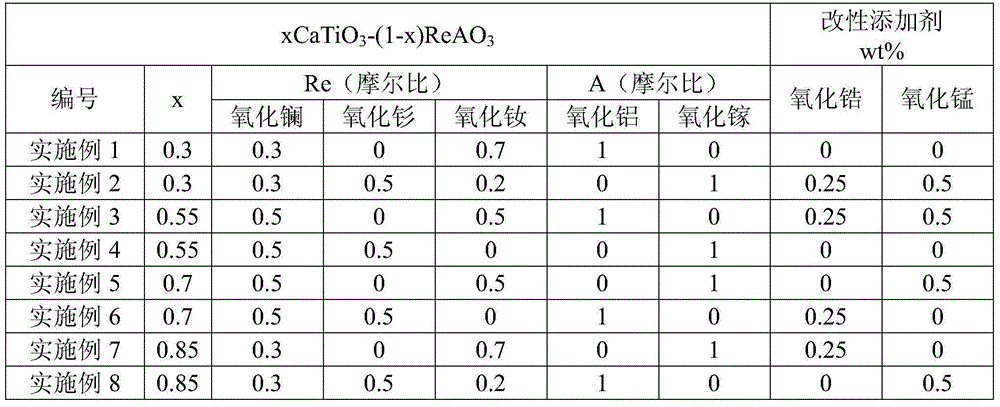

Embodiment 1

[0039] (1) According to the main crystal phase structure formula: xCaTiO 3 -(1-x)ReAO 3 Stoichiometric ratio Calcium carbonate 2.91kg, titanium dioxide 2.32kg, lanthanum oxide 3.32kg, samarium oxide 0kg, neodymium oxide 7.99kg, aluminum oxide 3.46kg, gallium oxide 0kg are mixed to obtain the first mixture; the first mixture, Deionized water and zirconia balls are mixed with a sand mill for 1 hour at a mass ratio of 1:2:0.5 to make them evenly mixed;

[0040] (2) The material is discharged, spray-dried at 220°C in a spray drying tower, then pre-fired at a temperature of 1250°C for 5 hours, the heating rate is 3°C / min, and cooled with the furnace to obtain the first pre-fired material;

[0041] (3) Get the pulverized first calcined material 16kg, modified additive zirconia 0g and manganese oxide 0g, mix to obtain the first calcined mixed material; mix the first calcined mixed material, deionized water and zirconia The balls are sanded with a sand mill for 1 hour at a mass rati...

Embodiment 2

[0045] (1) According to the main crystal phase structure formula: xCaTiO 3 -(1-x)ReAO 3 Stoichiometric ratio Weigh 2.52kg of calcium carbonate, 2.01kg of titanium dioxide, 2.87kg of lanthanum oxide, 5.12kg of samarium oxide, 1.98kg of neodymium oxide, 0kg of aluminum oxide, and 5.5kg of gallium oxide, and mix them to obtain the second mixture; 1. Deionized water and zirconia balls are sanded with a sand mill for 1 hour to make the mixture uniform with a mass ratio of 1:2:0.5;

[0046] (2) The material is discharged, spray-dried at 220°C in a spray drying tower, then pre-fired at a temperature of 1250°C for 5 hours, and the heating rate is 3°C / min, and cooled with the furnace to obtain the second pre-fired material;

[0047] (3) Get the pulverized second calcined material 16kg, modified additive zirconia 40g and manganese oxide 80g, mix to obtain the second pre-calcined mixture; mix the second calcined mixed material, deionized water and zirconia The balls are sanded with a s...

Embodiment 3

[0051] (1) According to the main crystal phase structure formula: xCaTiO 3 -(1-x)ReAO 3 The stoichiometric ratio takes by weighing calcium carbonate 5.61kg, titanium dioxide 4.47kg, lanthanum oxide 3.73kg, samarium oxide 0kg, neodymium oxide 3.85kg, aluminum oxide 2.34kg, gallium oxide 0kg, mixes and obtains the 3rd mixture; The 3rd mixture, Deionized water and zirconia balls are mixed with a sand mill for 1 hour at a mass ratio of 1:2:0.5 to make them evenly mixed;

[0052] (2) The material is discharged, spray-dried at 220°C in a spray drying tower, then pre-fired at a temperature of 1250°C for 5 hours, the heating rate is 3°C / min, and cooled with the furnace to obtain the third pre-fired material;

[0053] (3) Get the third calcined material 16kg after pulverization, modified additive zirconia 40g and manganese oxide 80g, mix to obtain the third calcined mixed material; mix the third calcined mixed material, deionized water and zirconia The balls are sanded with a sand mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Quality factor | aaaaa | aaaaa |

| Frequency temperature coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com