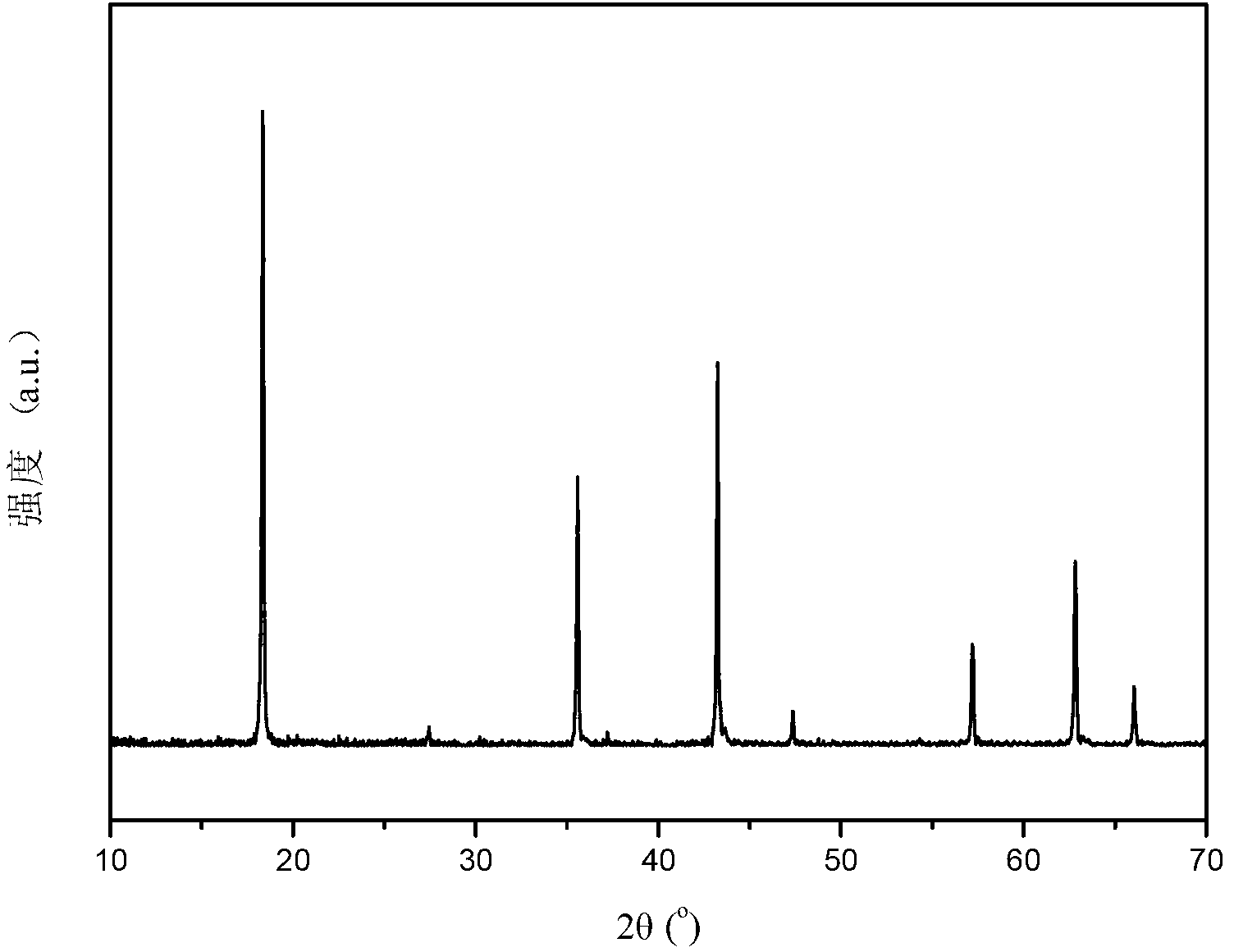

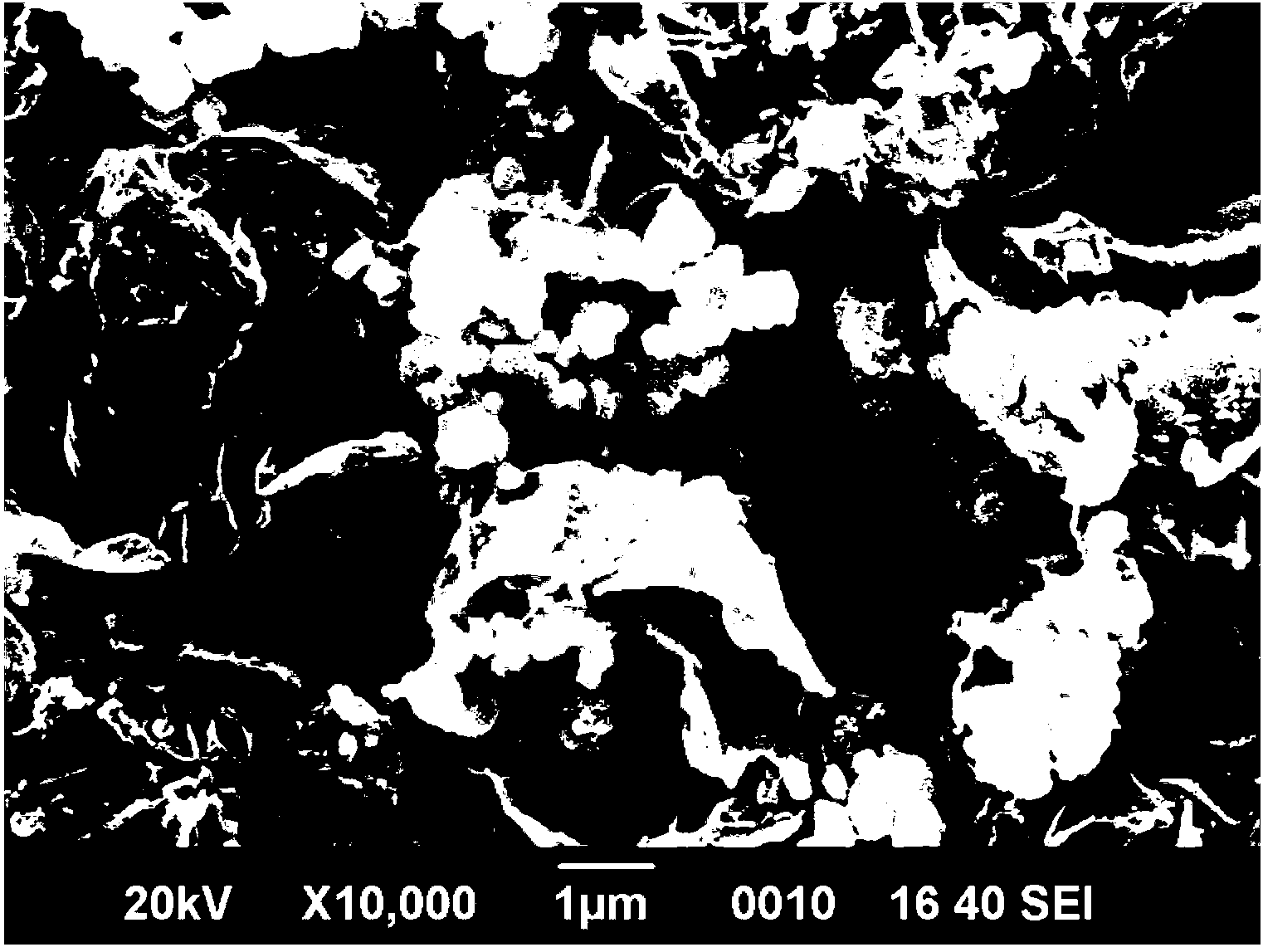

Li4Ti5O12/ grapheme composite electrode material and preparation method thereof

A graphene composite and electrode material technology, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, battery electrodes, etc., to achieve the effects of inhibiting agglomeration, excellent battery capacity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1) Carbon coating of titanium dioxide

[0046] Weigh 0.3454g glucose and 1.3699gTiO by mass ratio 1:4 2 Nano-powder, first dissolve glucose in 50ml (water: ethanol = 1:5) mixture of water and ethanol, add TiO 2 Add the nanometer powder into the glucose solution, stir vigorously for 2 hours, at 110 o C in a forced air oven to dry. Dry the product at 600 o Calcined in C nitrogen atmosphere for 5h to obtain black carbon-coated TiO 2 Nano powder.

[0047] 2) Preparation of graphene

[0048] Mix 2.004g of natural flake graphite and 2.0064g of sodium nitrate, add 110ml of concentrated sulfuric acid solution, stir in an ice-water bath for 15 minutes, then slowly add 12.0728g of potassium permanganate into the solution, react in an ice-water bath for 0.5h, and then After continuous stirring for 48 hours, add 184ml of deionized water, 40ml of hydrogen peroxide (30%wt) for 20 minutes, and centrifuge. The isolated product was washed with a mixed solution of sulfuric acid an...

Embodiment 2

[0055] Repeat Example 1, the difference is that the carbon source in step 1) is sucrose, according to sucrose and TiO 2 The mass ratio of nano-powder is 1:4 and 0.3454g sucrose is weighed. In step 3), 0.0672g graphene is weighed according to the proportion of graphene accounting for 5%wt of the total composite material, and cyclohexane is used as a dispersant, and the planetary ball mill is used for 5h , the speed is 300 rpm. The first reversible capacity of the material in this example is 183 mAh / g at 0.2C, and the capacity after 100 cycles at 1C rate is 169 mAh / g.

Embodiment 3

[0057] Repeat Example 1, the difference is that the carbon source in step 1) is sucrose, according to sucrose and TiO 2 The mass ratio of nanopowder is 1:4 and 0.3454g sucrose is weighed. In step 3), 0.1418g graphene is weighed according to the proportion of graphene accounting for 10%wt of the total composite material, and cyclohexane is used as a dispersant, and planetary ball milling is carried out for 5h , the speed is 300 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com