Preparation method for hollow porous carbon composite material

A technology of composite materials and porous carbon, applied in nanotechnology for materials and surface science, electrical components, battery electrodes, etc., can solve problems such as limited applications, unsuitable for fast charging and discharging, limited capacity, etc., and achieve modification methods The effect of simplicity, environmental friendliness and convenient preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh 7.5mmol of nickel acetate tetrahydrate and 15mmol of dimethylglyoxime, grind them separately in an agate mortar at room temperature, and then mix and grind them evenly. The mixture was transferred into a burning boat, which was then pushed into a tube furnace under N 2 Atmosphere, at 5°C min -1 The heating rate was increased to 60°C and kept at this temperature for 5h. Then at 3°C min -1 The heating rate was increased to 650°C and kept at this temperature for 4h. After cooling down to room temperature with the furnace, a hollow porous nitrogen-doped carbon composite material uniformly inlaid with high-content Ni nanoparticles is obtained. This sample is denoted as H-NiN-CNetwork.

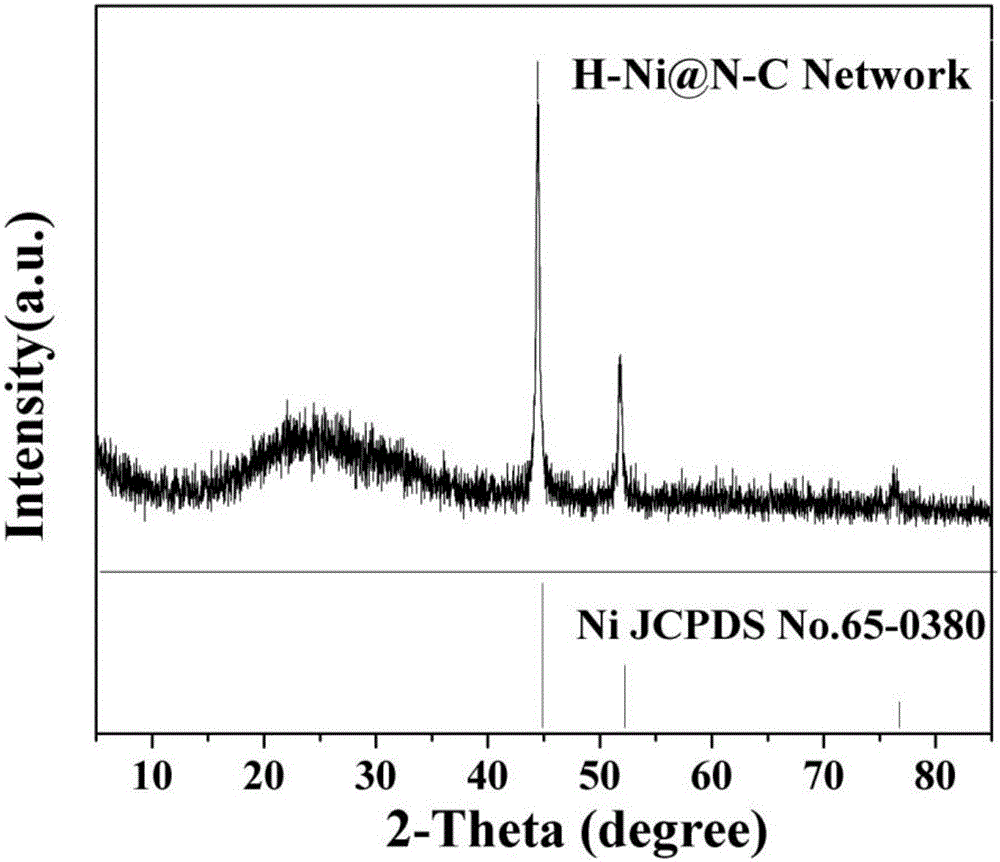

[0040] figure 1 It is the H-NiN-CNetwork X-ray diffraction pattern synthesized in this embodiment. The results show that the H-NiN-CNetwork material contains metal Ni (JCPDSNo.65-0380), and the size of Ni nanoparticles is about 20nm (calculated using the Scherrer formula, which i...

Embodiment 2

[0046] Ultrasonic dispersion of 0.3g of H-NiN-CNetwork obtained in Example 1 in 20mL, 1molL -1 hydrochloric acid solution, and then transferred to a 40mL reactor, at 80 ° C, kept for 10h. After natural cooling to room temperature, a hollow porous nitrogen-doped carbon composite material uniformly inlaid with low-content Ni nanoparticles was obtained, and the sample was denoted as L-NiN-CNetwork.

[0047] Figure 5 It is the X-ray diffraction pattern of the L-NiN-CNetwork synthesized in this example. The results show that the L-NiN-CNetwork material still contains metal Ni, but the particle size of Ni is smaller than that before acid etching, which is 8nm (calculated by Scherrer's formula, and this result is consistent with Figure 7-d The results measured in the transmission electron microscope images are consistent).

[0048] Image 6 It is the thermal analysis curve measured in the air atmosphere of the L-NiN-CNetwork synthesized in this embodiment. The results show tha...

Embodiment 3

[0054] Weigh 12.5mmol of zinc acetate dihydrate and 25mmol of dimethylglyoxime, grind them uniformly in an agate mortar at room temperature, then mix and grind them uniformly. The mixture was transferred into a burning boat, and then the burning boat was pushed into a tube furnace, under an Ar atmosphere, at 5 °C min -1 The heating rate was raised to 50°C and kept at this temperature for 7h. Then at 5°C min -1 The heating rate was raised to 500°C and kept at this temperature for 7h. After cooling down to room temperature with the furnace, a hollow porous carbon composite material evenly embedded with ZnO nanoparticles is obtained.

[0055] Similar to Examples 1 and 2, acid etching modification and characterization were carried out on the prepared hollow porous carbon composite material uniformly embedded with ZnO nanoparticles, and the conclusions obtained were basically similar to those of Examples 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com