Glass ceramic, sintered glass ceramic material, glass ceramic complex, glass micropowder, slurry-like mixture, and photocatalyst

A technology of glass ceramics and sintered body, applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of weak photocatalytic activity, no crystal structure, insufficient Sufficient and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

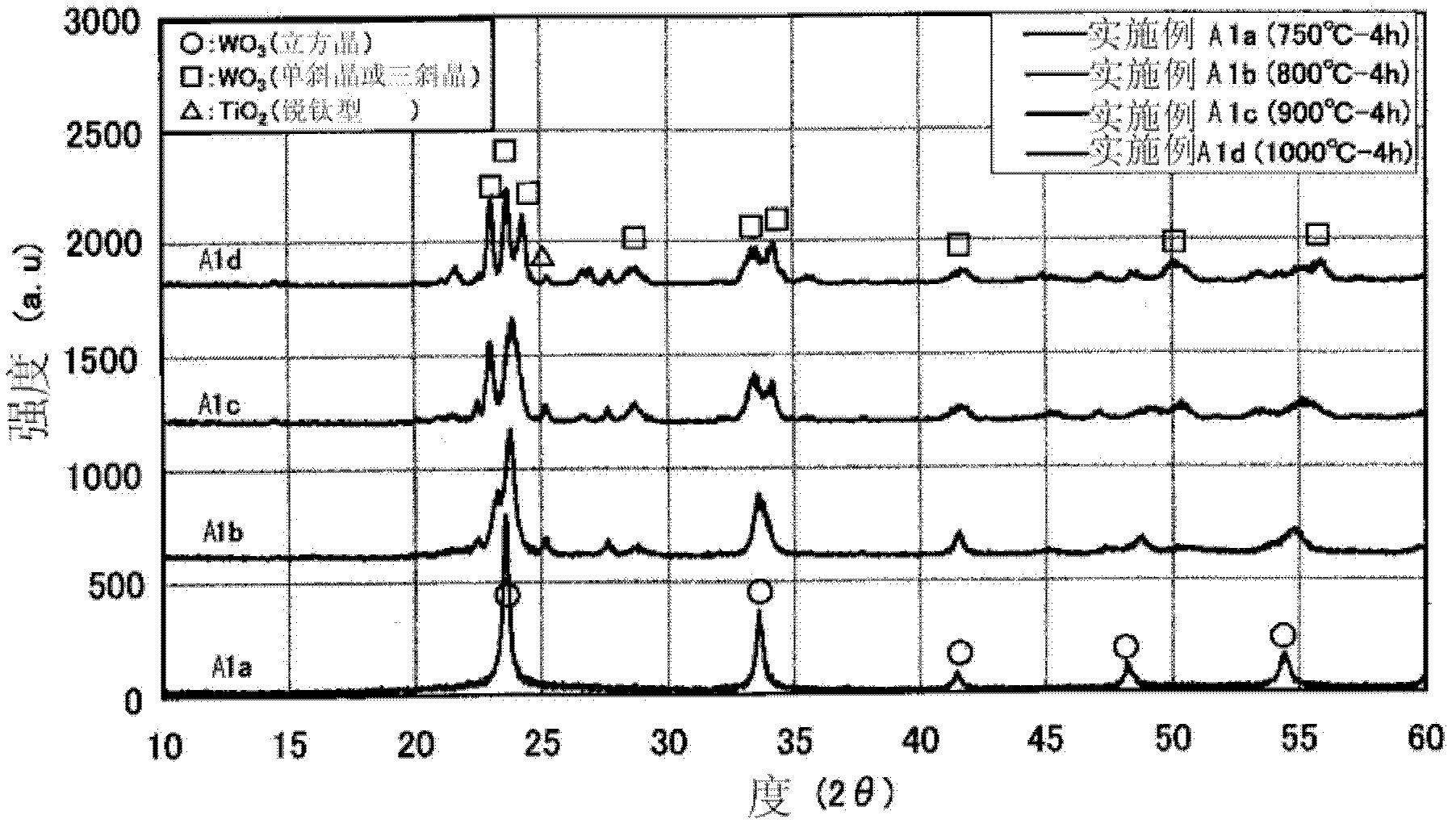

[0071] First Embodiment: Glass Ceramics

[0072] The glass ceramics of this embodiment contain a crystal phase (hereinafter sometimes referred to as "WO") containing tungsten oxide and / or a solid solution thereof. 3 Crystal phase"). Glass ceramics is a material obtained by precipitating a crystal phase in a glass phase by heat-treating glass, and is also called "crystallized glass". Glass ceramics may include not only materials having a glass phase and a crystal phase, but also Also include the material that all glass phases become crystalline phases, that is, the amount of crystallization (crystallinity) in the material is 100% by mass.The glass-ceramic of this embodiment can utilize the control of the crystallization process to control the grain size of the crystal, the precipitation The type and degree of crystallinity.

[0073] [composition]

[0074] Next, the components of the glass ceramics according to the present embodiment will be described. In addition, in this sp...

no. 2 approach

[0216] Second embodiment: glass ceramic sintered body and its manufacturing method

[0217] Next, the glass-ceramics sintered body and its manufacturing method which are 2nd Embodiment of this invention are demonstrated. The glass-ceramic sintered body of the present embodiment is a glass-ceramic sintered body obtained by sintering pulverized glass, and contains at least a crystal phase (WO) containing tungsten oxide and / or a solid solution thereof. 3 crystal phase). That is, the glass ceramics sintered body of this embodiment contains the glass ceramics of 1st Embodiment.

[0218]The manufacturing method of the glass-ceramic sintered body of this embodiment has a vitrification process, a pulverization process, a molding process, and a sintering process as a main process. The details of each step will be described below. In addition, the term "glass-ceramic sintered body" refers to a material obtained by solidifying and sintering a powdery material including glass frit. Th...

no. 3 approach

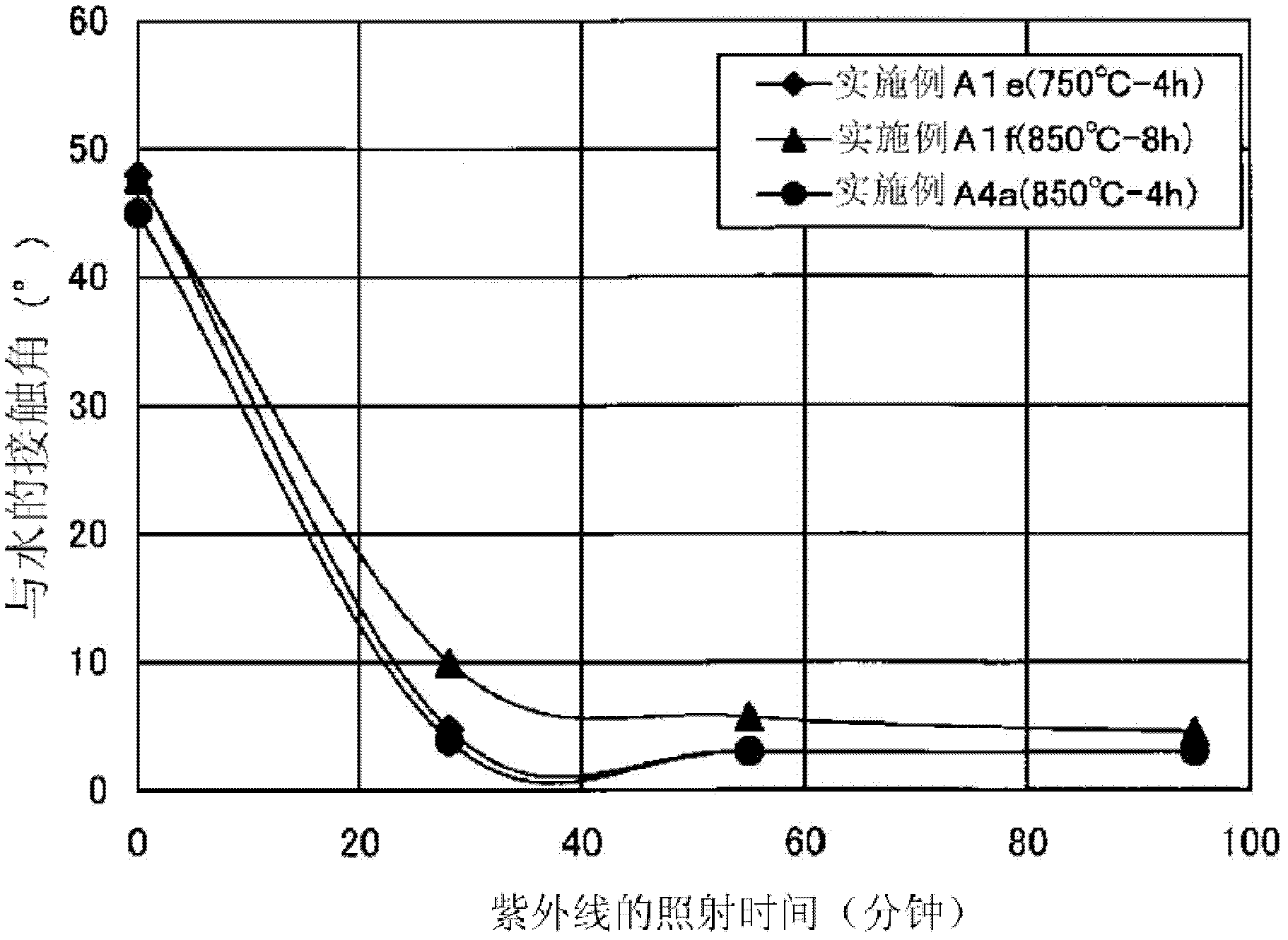

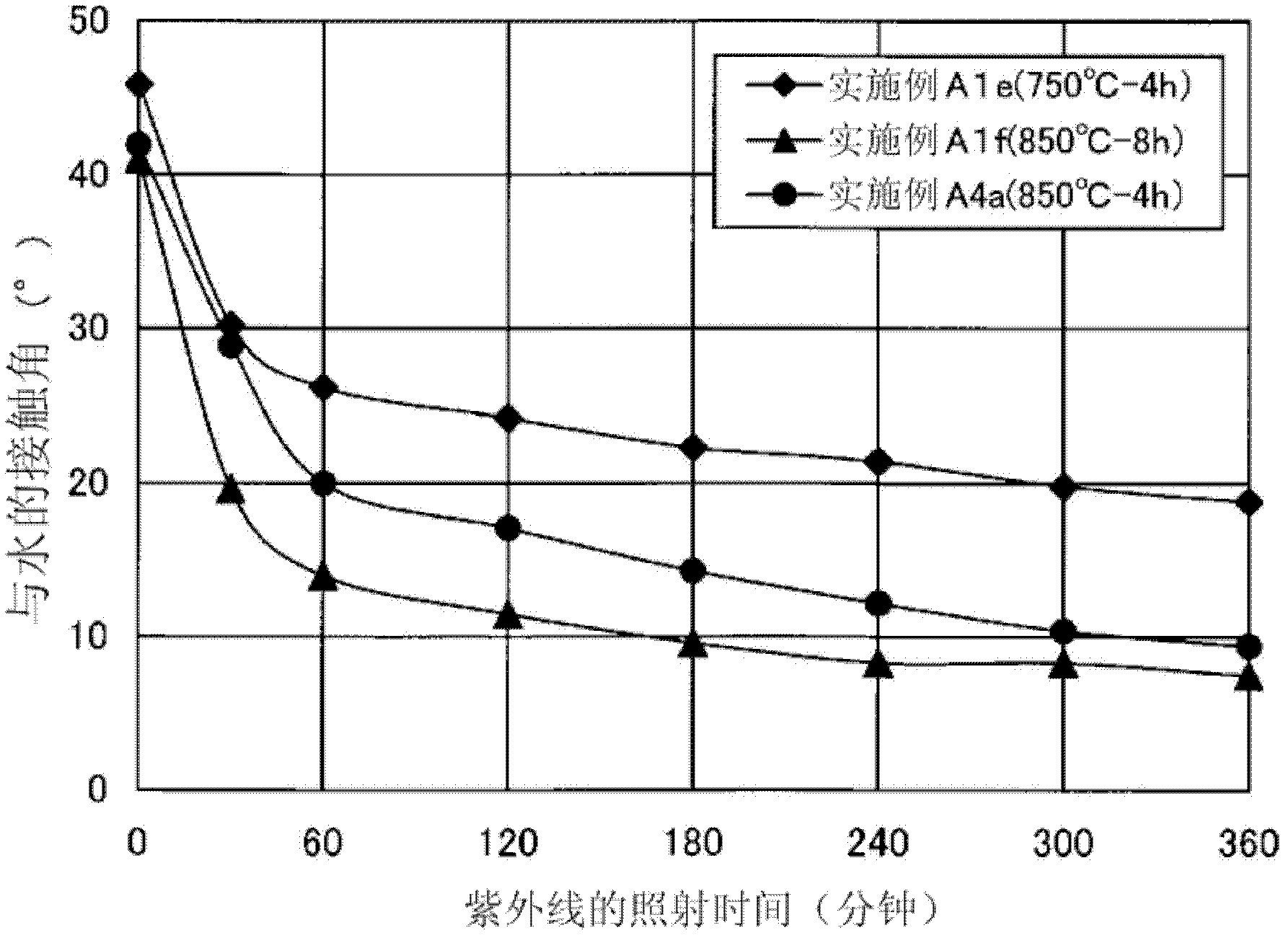

[0297] Third Embodiment: Glass-ceramic composite and its manufacturing method

[0298] Next, a glass-ceramic composite according to a third embodiment of the present embodiment and a method for producing the same will be described. In the present embodiment, the glass-ceramic composite (hereinafter sometimes referred to as "composite") is a material including a glass-ceramic layer obtained by heat-treating glass to form a crystal phase, and a base material. The glass-ceramic layer of the composite contains at least a crystalline phase (WO) comprising tungsten oxide and / or its solid solution 3 crystal phase). That is, the glass-ceramic composite of this embodiment contains the glass-ceramics of 1st Embodiment.

[0299]

[0300] The manufacturing method of the glass-ceramic composite body of this embodiment comprises the steps of firing pulverized glass obtained from the raw material composition on a base material to form 3 The process (firing process) of the glass ceramic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com