Ceramic reinforced metal matrix abrasion-resisting compound material and preparation method

A composite material and metal-based technology, which is applied in the field of ceramic-reinforced metal-based wear-resistant composite materials and its preparation, can solve problems such as difficult penetration and complicated process, and achieve the effects of ensuring wear resistance, simple process, and impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

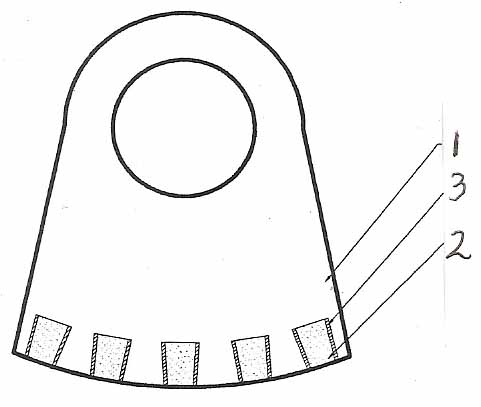

[0039] Example 1: Crusher Hammer

[0040] (1) With the hammer head of the crusher as the main body 1, a plurality of blind holes are set on the surface of the main body;

[0041] (2) Put the sintered ceramic rod 2 into the hole of the hammer head, there is a gap between the ceramic rod and the body, and the gap is filled with suitable self-fluxing alloy powder 3; among them, in the self-fluxing alloy powder, there is no The amount of water and ethanol added is 1% to 4% of the powder mass; then the hammer head is placed as a whole at 80°C to 100°C to dry.

[0042] (3) Put the dried crusher hammer head into a vacuum furnace for sintering at a temperature of 1000°C to 1150°C and a vacuum degree of 0.1Pa. The self-fluxing alloy powder will melt and form a firm metallurgical bond with the crusher hammer head matrix. Combination, metallurgical bonding with cermet rods also occurs. If the ceramic rods are oxide ceramics, nitride ceramics, and carbide ceramics, the ceramic rods are d...

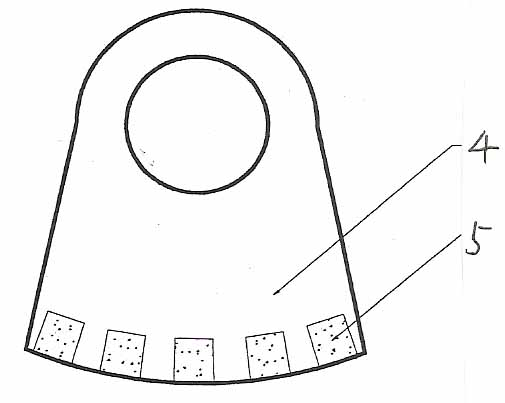

Embodiment 2

[0045] Step (2) is changed to: mix self-fluxing alloy powder and ceramic particles with absolute ethanol to form a mixture, and fill it in the hole of the hammer head. In the mixture, the ratio of ceramic particles to self-fluxing alloy powder 5 is 1:0.6~1.2, the amount of absolute ethanol added is 2%~6% of the mass of self-fluxing alloy powder.

[0046]After sintering in step (3), the self-fluxing alloy in the mixed particles melts and forms a firm metallurgical bond with the crusher hammer base 4, and the ceramic particles are also firmly wrapped by the self-fluxing alloy.

[0047] All the other are with embodiment 1.

Embodiment 3

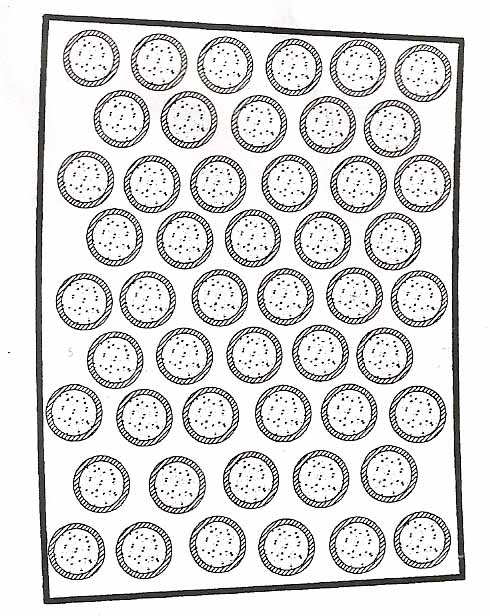

[0048] Embodiment 3: Grinding roller of coal mill

[0049] (1) With the coal mill roller liner as the main body, multiple blind holes are set on the surface of the main body;

[0050] (2) Put the sintered ceramic rod into the hole of the grinding roller liner of the coal mill, there is a gap between the ceramic rod and the body, and the gap is filled with suitable self-fluxing alloy powder; among them, the self-fluxing alloy powder In the process, the amount of absolute ethanol added is 1% to 4% of the powder mass; then the whole lining board is placed at 80°C to 100°C to dry.

[0051] (3) Put the dried coal mill roller liner as a whole into a vacuum furnace for sintering at a temperature of 1000°C to 1150°C and a vacuum of 0.1Pa, and the self-fluxing alloy powder will melt and bond with the coal mill roller lining The plate matrix produces a firm metallurgical bond, and also produces a metallurgical bond with the cermet rod. If the ceramic rod is an oxide ceramic, nitride ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com