Nano Al2O3 and MgO composite ceramic bonded spinel-magnesia fireproof casting material and preparation method thereof

A technology for refractory castables and composite ceramics, applied in the field of refractory materials, can solve the problems of spalling, reduced service life of aluminum-spinel refractory castables, incompatibility, etc., and achieves low production costs, advanced and reasonable processing technology, and economical adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

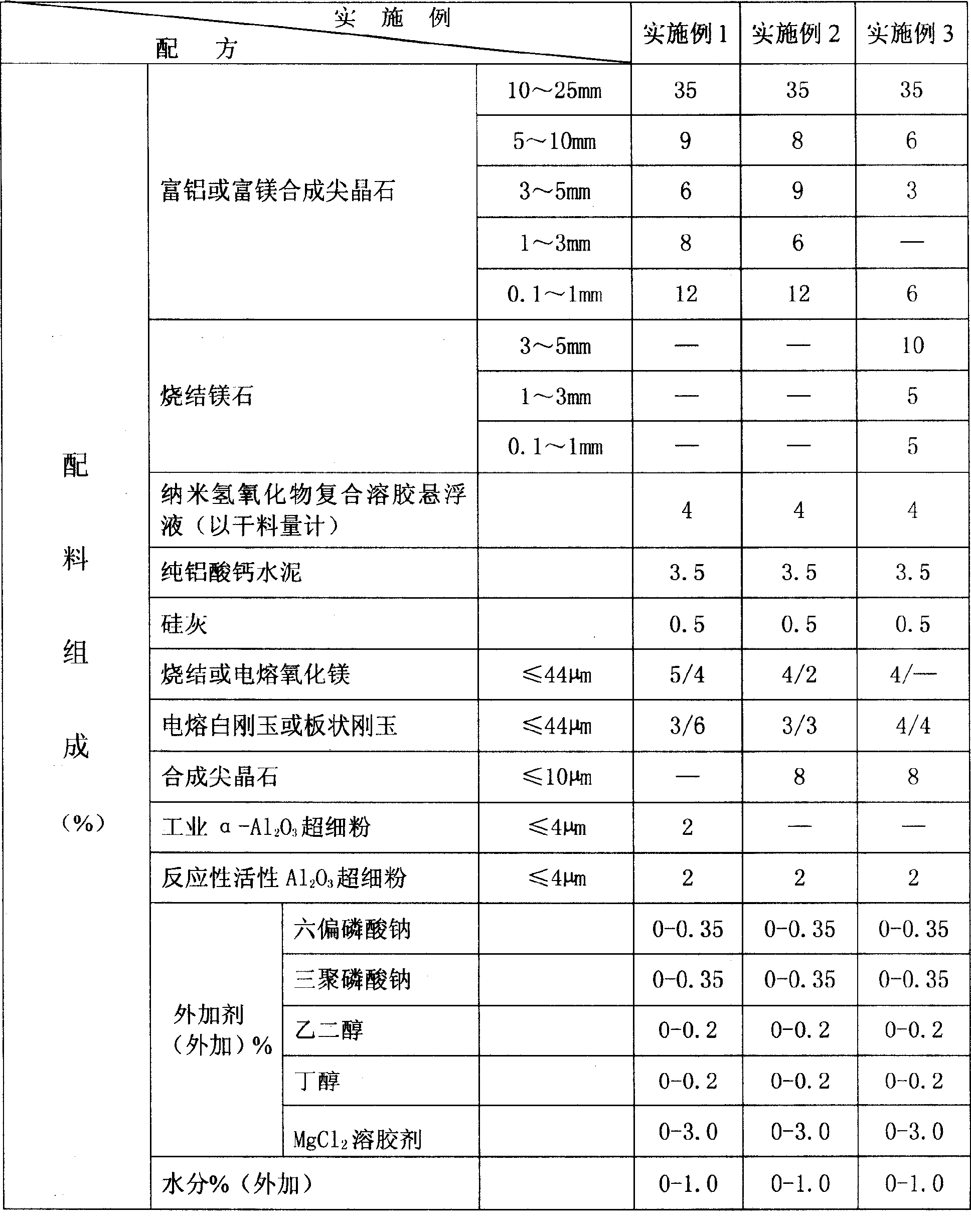

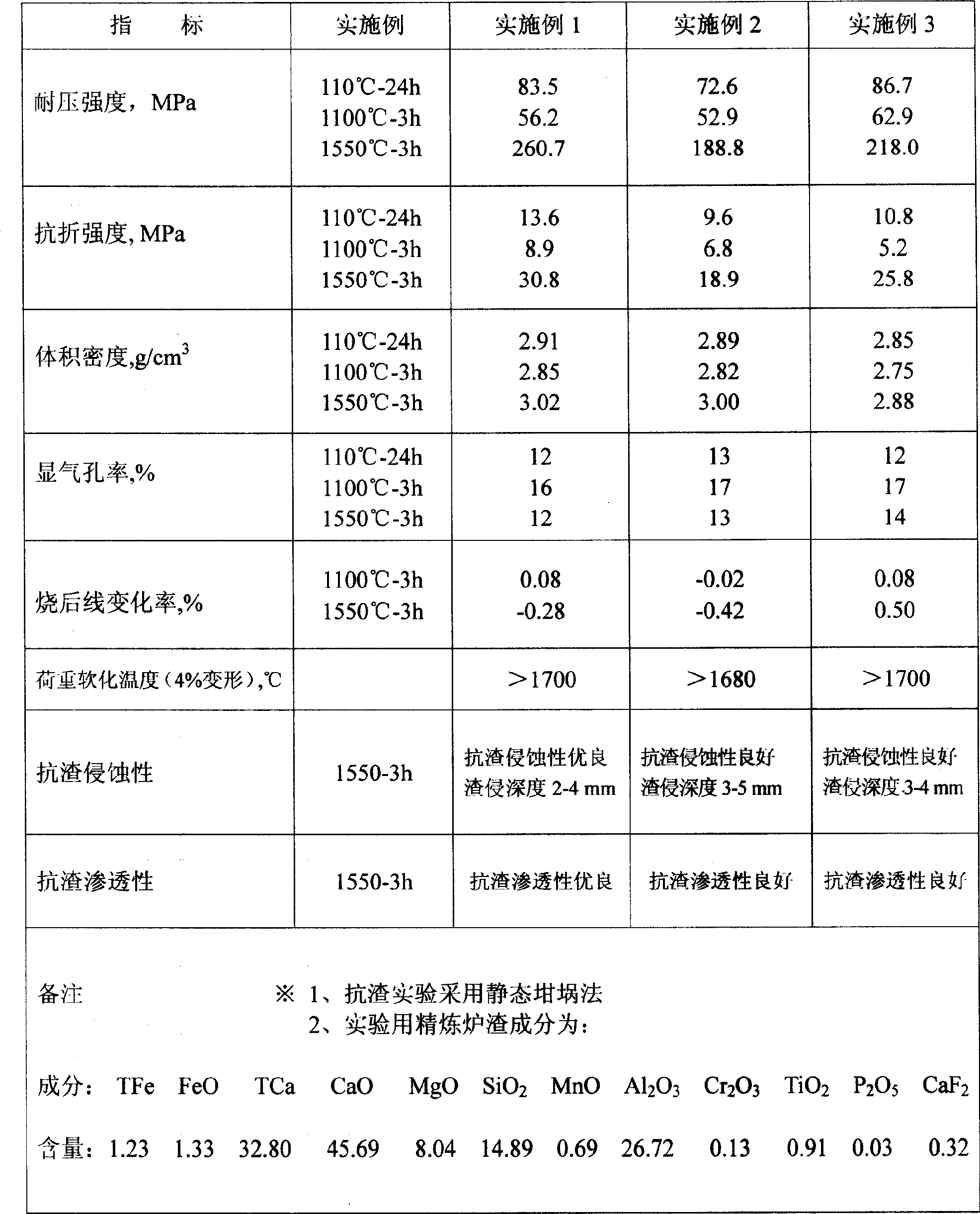

Embodiment 1

[0036] According to the fully synthesized reaction spinel-magnesia refractory castable formula of Example 1 listed in Table 1 according to the present invention, the prepared mixture is added to a forced mixer and mixed for 1-2 minutes, and then the prepared concentration Add 46-49% nano-composite hydroxide sol suspension binder directly into the mixture, then wet mix and stir for 5 minutes, and add 0-1% water according to the water requirement of the mixture to make the present invention Total reaction synthesis of nanocomposite oxide ceramic-bonded spinel-magnesia refractory castables. The main feature of this castable is that the aggregate part of the ingredients is all made of aluminum-rich or magnesium-rich synthetic spinel, and the matrix powder part is all made of magnesia and a small amount of alumina with different characteristics, and the secondary spinel and oxide Magnesium is used as the matrix phase of the nanostructure of the castable, and the difference in parti...

Embodiment 2

[0038] According to the reaction synthesis and pre-synthesis composite spinel-magnesia refractory castable formula listed in Example 2 of Table 1 according to the present invention, the prepared mixture is added to a forced mixer and mixed for 1-2 minutes, and then Add the prepared nano-composite hydroxide sol suspension binder with a concentration of 46-49% directly into the mixture, then wet mix and stir for 5 minutes, and add 0-1% water according to the water demand of the mixture , to make the composite nano-ceramic combined spinel-magnesia refractory castable of the present invention. The main feature of this castable is that the aggregate part is still all made of aluminum-rich or magnesium-rich synthetic spinel, and the matrix powder part is not only made of In addition to the synthesis reaction of magnesium oxide and alumina composite oxide, a certain amount of pre-reaction synthetic spinel is also added, which relatively reduces the content of secondary spinel synthesi...

Embodiment 3

[0040] According to the formula of reaction synthesis and pre-synthesis of spinel-magnesia castable in Example 3 listed in Table 1 according to the present invention, the prepared mixture is added to a forced mixer and mixed for 1-2 minutes, and then the prepared Concentration of 46-49% nano-composite hydroxide sol suspension binder is directly added to the mixture, then wet mixed and stirred for 5 minutes, and 0-1% of water is added according to the water demand of the mixture to make the cost Invented reactive synthesis and pre-synthesis of nano-composite oxide ceramics combined with spinel-magnesia refractory castables. The main feature of this castable is that the aggregate part of the ingredients is in the aluminum-rich spinel aggregate, and a certain amount of magnesia particles of different sizes ≤ 5mm are added; and a matrix similar to that of Example 2 is used in the matrix powder. Powder batching, to further increase the overall MgO content in the castable of the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com