Preparation method of high-dispersion nano-zirconia powder

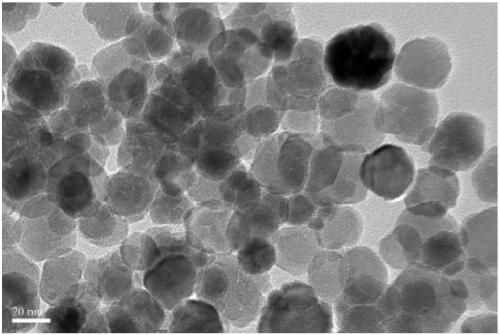

A nano-zirconia and zirconia powder technology, applied in zirconia and other directions, can solve the problems of colloidal precipitates that are difficult to wash, decrease in purity, material cracking, etc., and achieve the effect of narrow particle size distribution, good dispersibility, and improved purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of high-purity and highly dispersed nano-zirconia powder, the method comprising the following steps:

[0030] A. Weigh 131g of ZrOCl2 8H2O and 3.88g of YCl3 6H2O, put them in a container, add deionized water to 1L, so that the concentration of zirconium ions is 0.4mol / L, and stir evenly until the solution is clear;

[0031] B. Weigh 2g of polyethylene glycol 400, and add it to the clear solution prepared in step A, and stir at room temperature;

[0032] C. control the stirring speed in the step B, slowly drop the NaOH solution of 1mol / L in the solution, until the reaction ends when the pH value of the solution is 10;

[0033] D. At normal temperature, the precipitation solution prepared in step C is aged for 24 hours, then added to the ceramic composite membrane separation equipment, and the precipitation agent is cleaned by ultrafiltration with deionized water to remove impurity ions in the filtrate until the use of 0.1 mol / L silver nitrate soluti...

Embodiment 2

[0038] A preparation method of high-purity and highly dispersed nano-zirconia powder, the method comprising the following steps:

[0039] A. Weigh 131g of ZrOCl2 8H2O and place it in a container, add deionized water to 0.5L to configure the zirconium ion concentration at 0.8mol / L, then weigh 1.5g of yttrium oxide and dissolve it in concentrated nitric acid. After stirring and dissolving Add it to the zirconium solution and stir evenly until the solution becomes clear;

[0040] B. Weigh 2g of polyethylene glycol 400, and add it to the clear solution prepared in step A, and stir at room temperature;

[0041] C. control the stirring speed in the step B, slowly add dropwise the ammonia solution of 25% mass percent concentration in the solution, until the pH value of the solution is at 9 o'clock and the reaction ends;

[0042] D. At normal temperature, the precipitation solution prepared in step C is aged for 18 hours, then added to the ceramic composite membrane separation equipm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com