A gel infiltration ceramic modification method for special-shaped parts of c/c composite materials

A technology for composite materials and special-shaped parts, which is applied in the field of ceramic matrix composite material preparation, can solve the problems of deteriorating mechanical properties, cumbersome process, easy to fall off, etc., and achieves the effects of low process cost, simple process operation and small volume shrinkage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

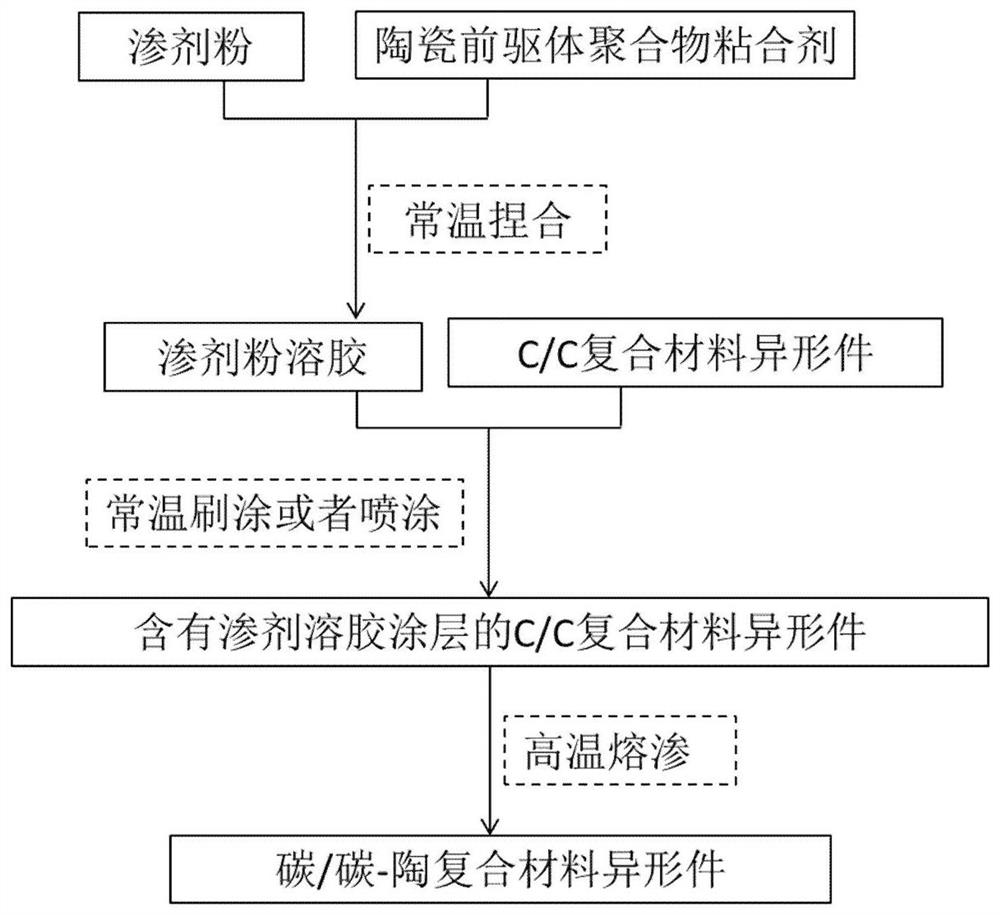

[0048] A kind of gel infiltration ceramization modification method of C / C composite special-shaped parts of the present invention, the technological process is as follows figure 1 shown, including the following steps:

[0049] (1) Take 15 g of silicon powder with a particle size of 10 μm and 5 g of polycarbosilane, mix them uniformly and knead them for 10 min;

[0050] (2) The cutting density is 1.35g / cm 3 10g of special-shaped C / C composite material, put it in ethanol and ultrasonically clean it for 5 minutes to remove surface impurities and dry it;

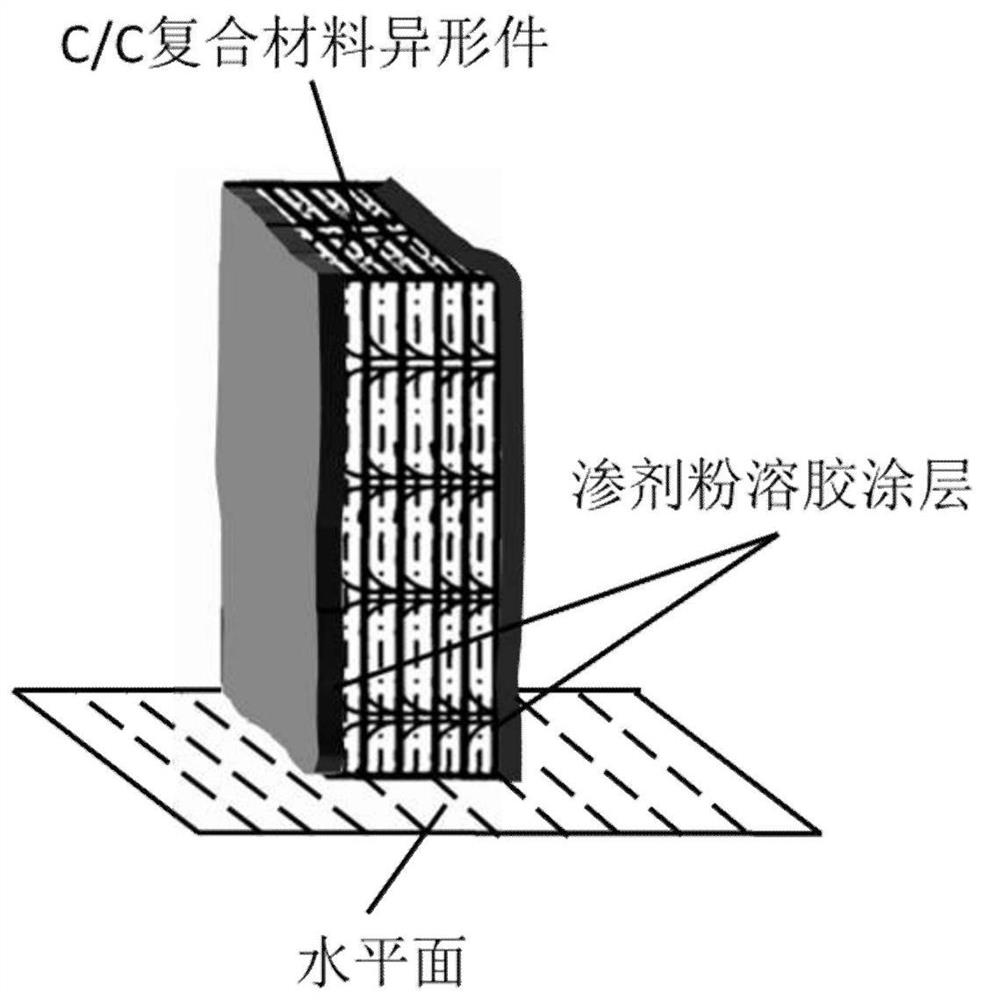

[0051] (3) Brush the prepared silica powder sol onto the surface of the C / C composite special-shaped part with a curved structure (the coating is perpendicular to the horizontal plane), and the coating thickness is 3mm, as shown figure 2 shown;

[0052] (4) Place the special-shaped C / C composite material containing silica powder sol in a carbon tube sintering furnace, evacuate the carbon tube sintering furnace to 5 Pa, heat ...

Embodiment 2

[0057] A kind of gel infiltration ceramization modification method of C / C composite special-shaped parts of the present invention, the technological process is as follows figure 1 shown, including the following steps:

[0058] (1) Take 20 g of silicon-zirconium alloy powder with a particle size of 10 μm (the atomic ratio of silicon to zirconium is 90:10) and 7 g of polycarbosilane, mix them uniformly and knead them for 10 minutes;

[0059] (2) The cutting density is 1.40g / cm 3 15g of special-shaped C / C composite material, put it in ethanol and ultrasonically clean it for 5 minutes to remove surface impurities and dry it;

[0060] (3) Brush the prepared silicon-zirconium alloy powder sol onto the surface of the C / C composite special-shaped part with an arc structure (the coating is perpendicular to the horizontal plane), and the coating thickness is 3 mm, as shown figure 2 shown;

[0061] (4) Place the C / C composite special-shaped part containing silicon-zirconium alloy pow...

Embodiment 3

[0066] A method for infiltration and ceramization modification of C / C composite special-shaped parts of the present invention, the process flow is as follows figure 1 shown, including the following steps:

[0067] (1) Take 15g of silicon powder with a particle size of 10μm and 5g of polycarbaziborosilane, mix them uniformly and knead them for 10min;

[0068] (2) The cutting density is 1.4g / cm 3 10g of special-shaped C / C composite material, put it in ethanol and ultrasonically clean it for 5 minutes to remove surface impurities and dry it;

[0069] (3) Brush the prepared silica powder sol onto the surface of the C / C composite special-shaped part (with a curved structure and the coating is perpendicular to the horizontal plane), the coating thickness is 3mm, as shown figure 2 shown;

[0070] (4) Place the special-shaped C / C composite material containing silica powder sol in a carbon tube sintering furnace, evacuate the carbon tube sintering furnace to 5 Pa, heat the sinterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com