Artificial wood grain floor and its press-paste technique and equipment

A technology for simulating wood and flooring, which is applied in the crafts, decorative arts, floors and other directions used to produce decorative surface effects. Application, good effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

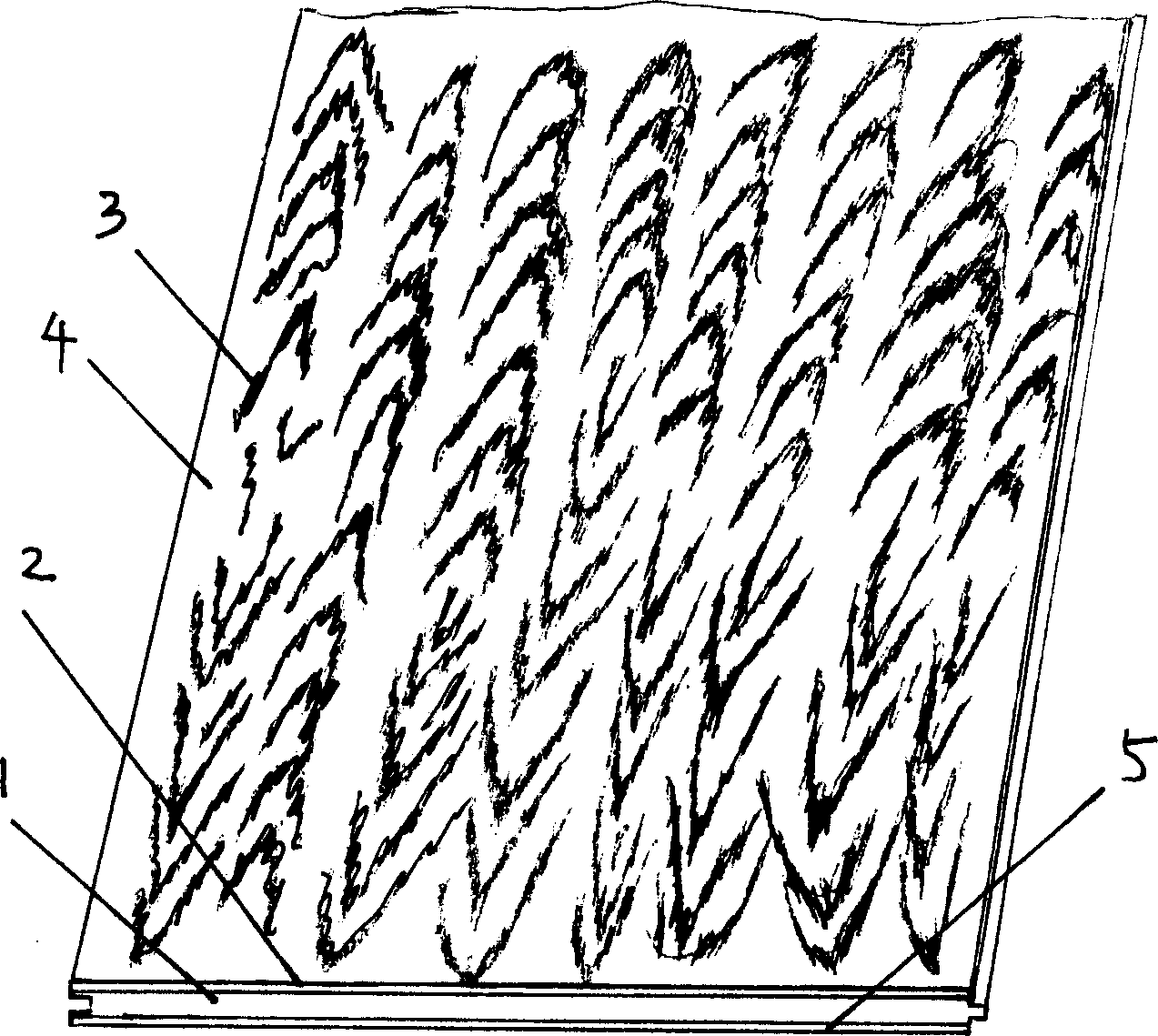

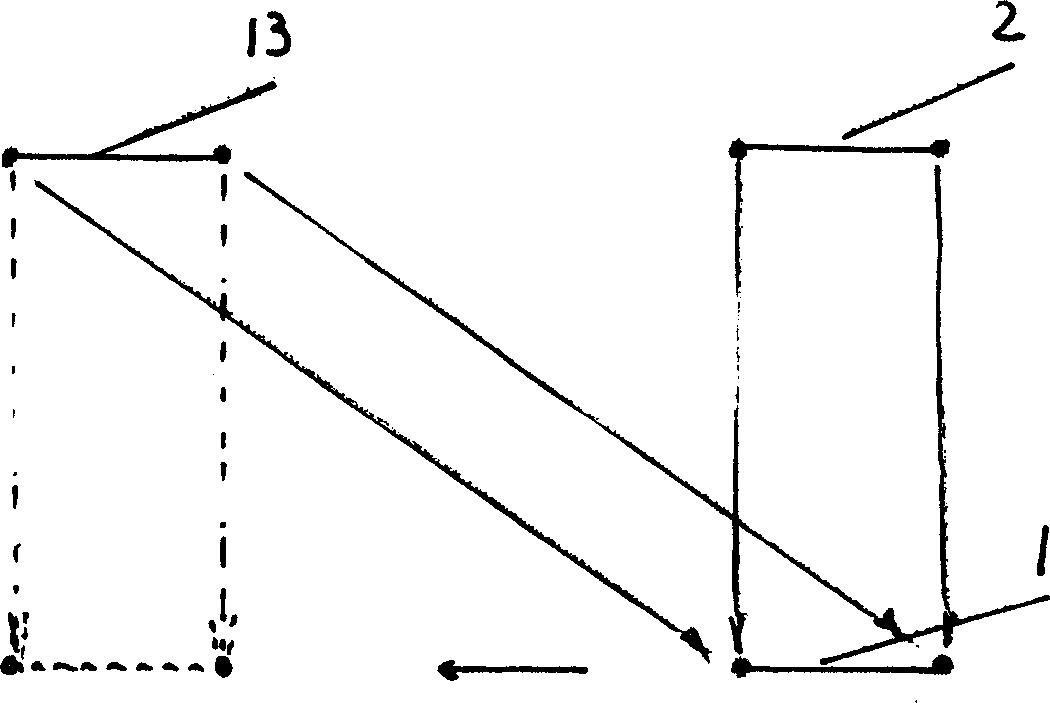

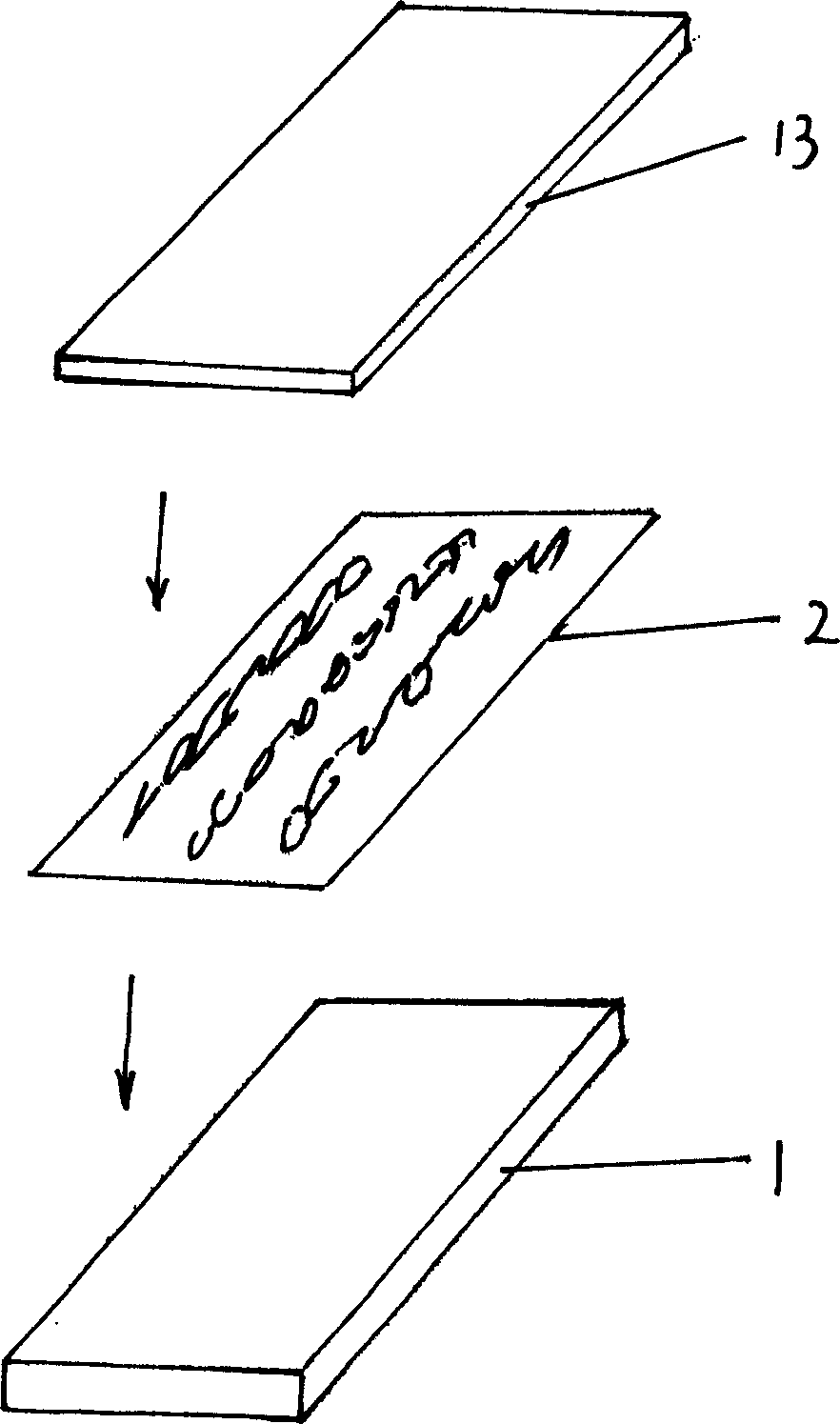

[0018] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the simulated wood-grain floor of the present invention mainly includes a floor substrate 1, which is compounded with a layer of impregnated wood-grain paper 2 printed with a wood-grain pattern on the floor substrate 1, and the impregnated wood-grain paper The surface of 2 is pressed with a concave-convex wood grain figure 3 according to the wood grain figure, which makes the surface of the formed composite floor comparable to the natural wood grain pattern of the wooden floor, and it has a three-dimensional effect. A layer of impregnated wear-resistant paper 4 is compounded on the impregnated wood grain paper. The impregnated wood grain paper 2 described in the utility model and the composite floor base material 1 below are one piece or a composite medium density fiberboard. A layer of impregnated balancing paper 5 is compounded under the floor substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com