Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

173results about How to "Good smoke suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fire-retardant polyolefin based wood plastic composite material and preparation method thereof

ActiveCN102321374AGood smoke suppression performanceExcellent flame retardancy and mechanical propertiesPolyolefinEnvironmentally friendly

The invention discloses a fire-retardant polyolefin based wood plastic composite material and a preparation method thereof, and relates to a wood plastic composite material and a preparation method thereof, and the composite material and method provided by the invention can be used for solving problems that the existing fire-retardant wood plastic composite material has high heat release efficiency in burning and high smoke production, and can generate CO harmful gas easily. The flame-retardant polyolefin based wood plastic composite material is prepared from wood fiber materials, plastics, acoupling agent, a lubricant, an antioxidant, a nano inorganic fire retardant and a mineral filler. The method comprises the following steps: putting the wood fiber materials, the coupling agent and the lubricant into a high-speed mixing machine for hot mixing; then putting into a cold mixing machine for cold mixing, sending the plastics, the antioxidant, the nano inorganic fire retardant and the mineral filler into the cold mixing machine and then mixing; and then carrying out fusing and extruding for granulation by adopting extruding, injection, hot compressing or mold compression for molding, thus the fire-retardant polyolefin based wood plastic composite material is obtained. The wood plastic composite material provided by the invention has low heat release rate in burning and less smoke production, and is healthy and environmentally-friendly, and can be widely applied to the fields of indoor construction, decoration and furnishing materials and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

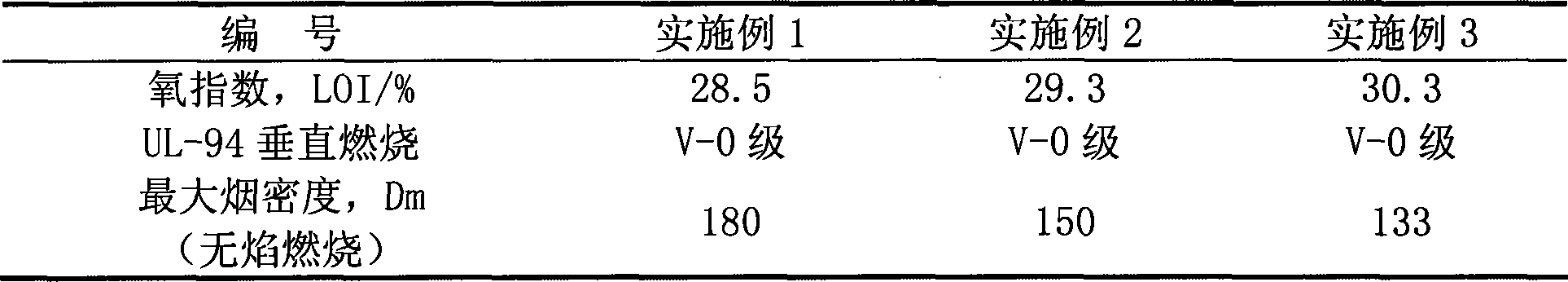

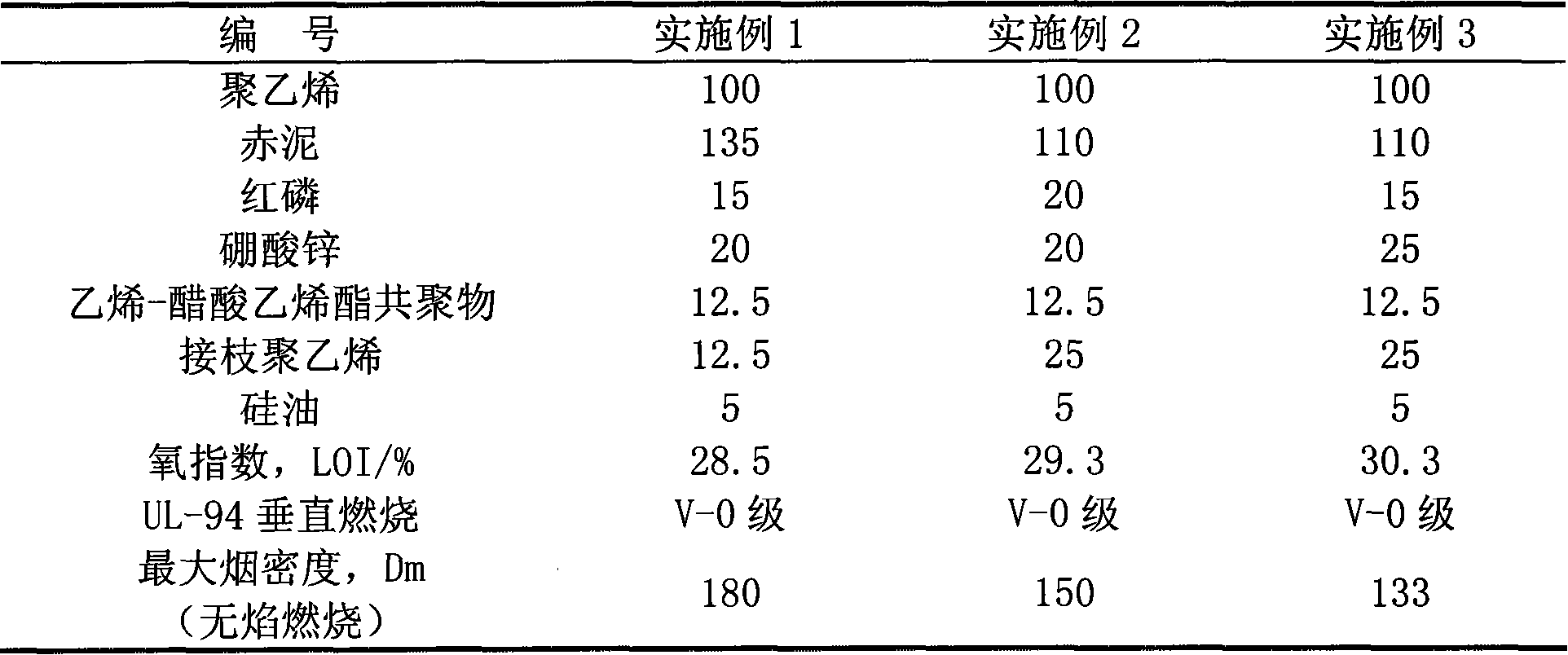

Environmental protection based red mud combination modification synergism fire-retardant polyethylene

InactiveCN101624457AIncrease added valueMeet environmental protection requirementsRed mudCarvacryl acetate

The invention relates to an environmental protection based red mud combination modification synergism fire-retardant polyethylene, and belongs to the technical field of compressive utilization and fire-retardant plastics. The fire-retardant polyethylene is suitable for fire safety protection in important public places in the fields of electric products, building materials and transportation. The fire-retardant polyethylene consists of the following components in percentage by weight: 30 to 35 percent of polyethylene, 34 to 39 percent of red mud, 6 to 13 percent of red phosphorus, 5 to 17 percent of zinc borate, 3 to 8 percent of ethylene-vinyl acetate copolymer, 2 to 7 percent of grafted polyethylene, and 2 to 8 percent of silicone oil. The preparation process comprises the following steps of: grinding and drying the red mud; blending the ground red mud with other raw materials according to the blending ratio; mixing the mixture with polyethylene resin by fully stirring at a high speed; fusing, co-mixing and processing the mixture; and preparing a sample. The processing conditions comprise that: the roll temperature of a double-roller mixing mill is between 140 and 150 DEG C; and the forming temperature of the flat vulcanizing machine sample is between 120 and 130 DEG C, the heating time is between 4 and 8 minutes, and the pressure is between 10 and 20MPa. The fire-retardant system meets the requirements of industrial application on mechanical property, and simultaneously has comprehensive properties such as good fire-retardant effect, low cost, environmental protection and the like; moreover, the application field of the red mud is widened, and the red mud product with high added value is prepared.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

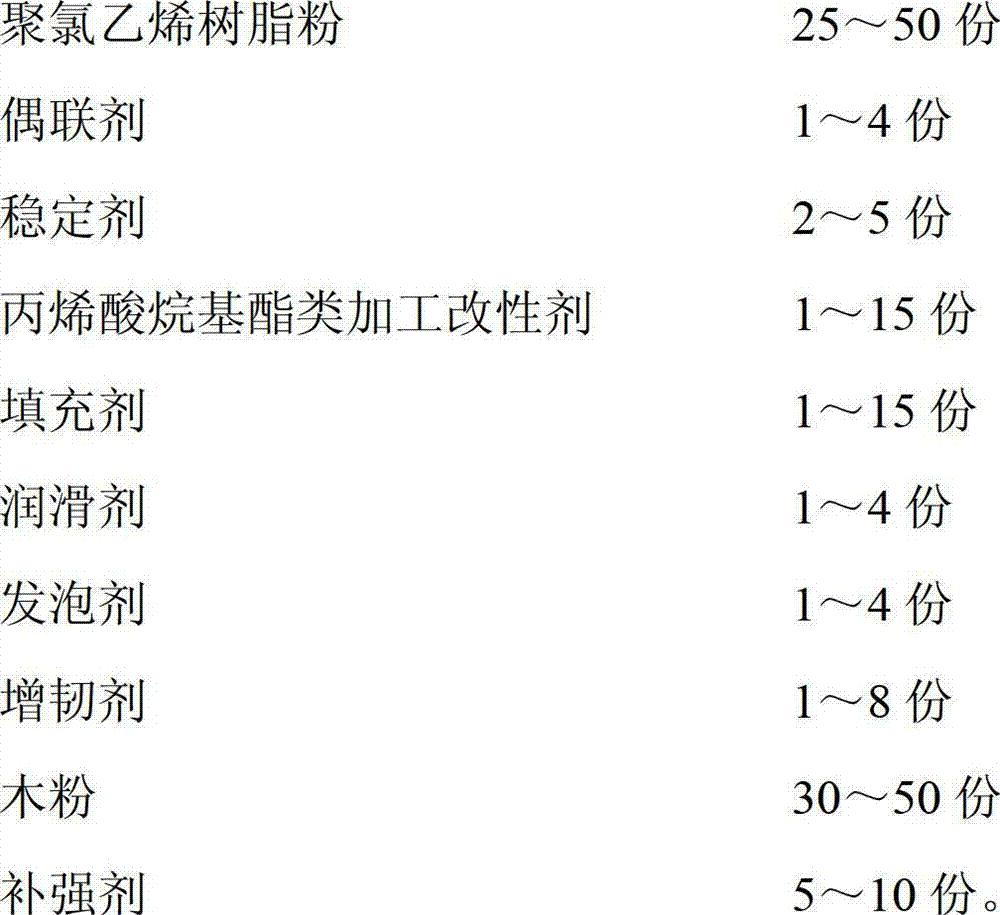

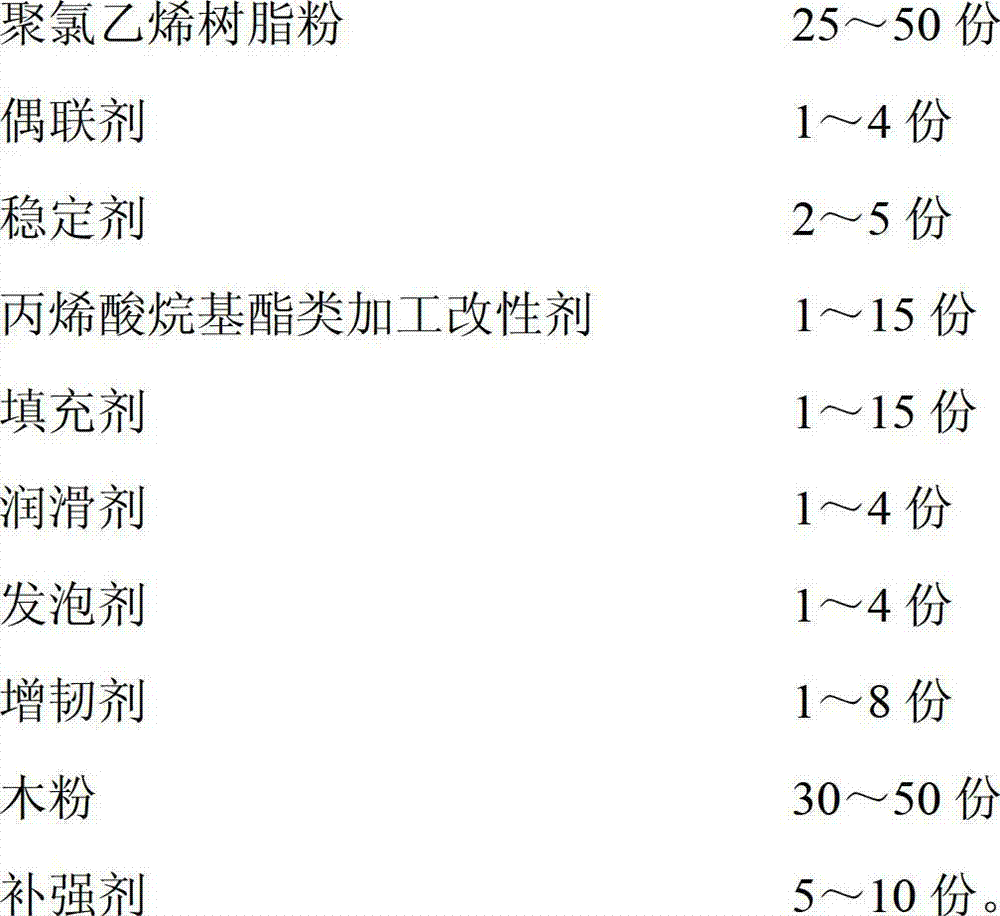

High-hardness wood-plastic building template and preparation method thereof

The invention relates to a high-hardness wood-plastic building template and a preparation method thereof, which belong to the technical field of polyvinyl chloride plates. The 100 parts by weight of high-hardness wood-plastic building template comprises the following raw materials in parts by weight: 20-50 parts of polyvinyl chloride resin powder, 1-4 parts of a coupling agent, 2-5 parts of a stabilizing agent, 1-15 parts of an acrylic alkyl ester processing modifier; 1-15 parts of a filling agent, 1-4 parts of a lubricant, 1-4 parts of a foaming agent, 1-8 parts of a toughening agent, 30-50 parts of wood flour, and 5-10 parts of a reinforcing agent. According to the invention, the plate stacking density is less than or equal to 700 kg / m<3>, so that the building template is good in flame retardancy and smoke suppression, meanwhile, the building template is high in hardness and strong in wood texture; and just like raw woods, the building template also has the properties that the template can be nailed, drilled, planed and adhered and the like, the surface of the template is smooth and fine, and the template is water-proof, corrosion-resistant, fireproof, mould-proof, moth-preventing, and pollution-free.

Owner:SHANDONG BODO PLASTICS CO LTD

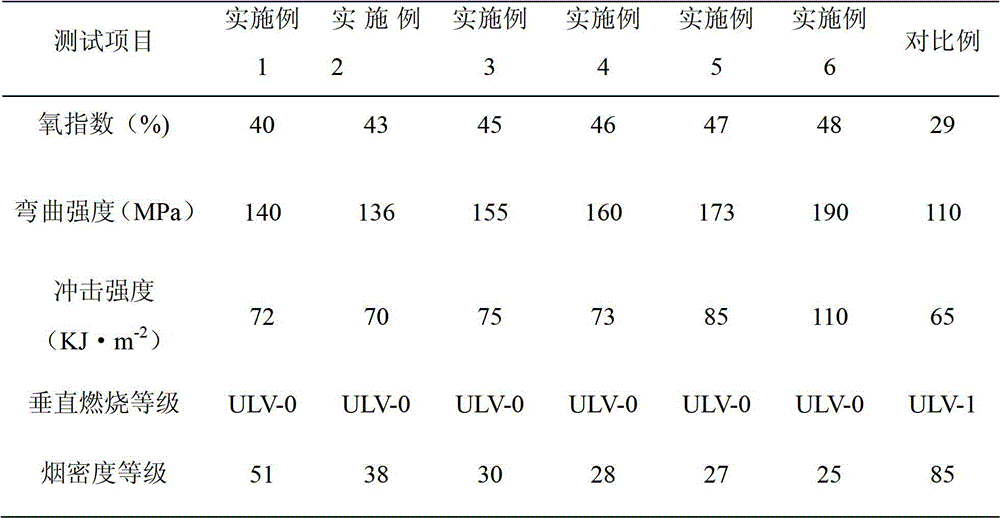

Low smoke halogen-free environment-protection fire-retardation type sheet molding compound and preparation method thereof

InactiveCN102942761AImprove flame retardant performanceReduce combustion smoke densityCoatingsOrganosiliconPhenol formaldehyde resin

The present invention discloses a low smoke halogen-free environment-protection fire-retardation type sheet molding compound, which comprises, by weight, 60-80 parts of an unsaturated polyester resin mixture, 20-60 parts of a thermoplastic high molecule polymer slurry, 1-3 parts of an initiator, 2-4 parts of a thickener, 0.02-0.5 part of a polymerization inhibitor, 5-15 parts of a mold release agent, 90-140 parts of a filler, 80-150 parts of aluminum hydroxide powder, 1-10 parts of an organosilicon synergist, 1-8 parts of a smoke suppressant, 5-25 parts of a liner phenol formaldehyde resin, and 80-200 parts of reinforcing fibers. Compared with the conventional fire retardation agent, the low smoke halogen-free environment-protection fire-retardation type sheet molding compound has the following advantages that: a fire retardation performance of the composite material is increased, smoke density during burning is reduced, excellent mechanical properties of the material is maintained, and disadvantages of large smoke density during burning and low comprehensive mechanical performance of the existing fire-retardation sheet molding compound are solved.

Owner:CHANGZHOU UNIV

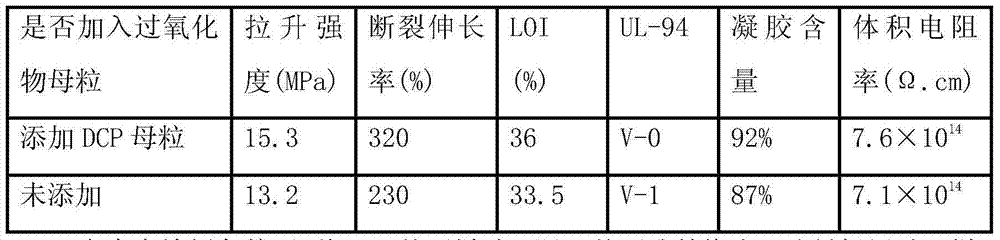

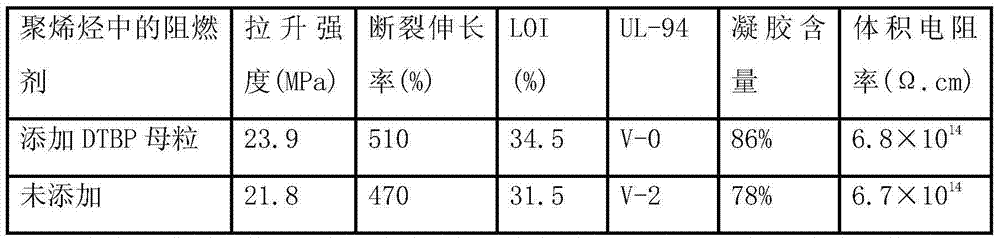

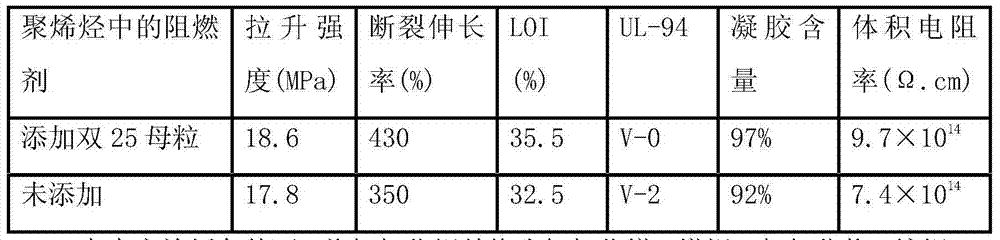

Peroxide pre-crosslinked low smoke zero halogen flame retarding irradiation crosslinking polyolefin composite and preparation method thereof

The invention discloses a peroxide pre-crosslinked low smoke zero halogen flame retarding irradiation crosslinking polyolefin composite and a preparation method thereof. The preparation method comprises steps of adding 0.5-5 parts of antiflaming synergist into 50-70 parts of polyolefin, mixing uniformly, then adding 30-50 parts of fire retardant, 0.5-5 parts of polyfunctional group cross-linking agent and 0.1-1 part of antioxygen, mixing uniformly, then extruding and pelletizing so as to obtain an irradiation crosslinking material, then uniformly mixing 100 parts of irradiation crosslinking material and 1-5 parts of peroxide master batch, extruding and wrapping on the electric lead core of an electric wire, finally, irradiating 60-180KGy dosage with high-power electron beam or cobalt source for crosslinking, wherein the components above are weighed in parts by weight. The low smoke zero halogen flame retarding irradiation crosslinking polyolefin composite prepared through peroxide pre-crosslinking has fast crosslinking speed, high productivity, low energy consumption, and good flame resistance, and also has excellent smoke suppression performance and better mechanical property.

Owner:合肥聚泰安全材料合伙企业(有限合伙)

Xylem filber-polyvinyl chloride composite material and method for producing the same

A wood fiber-polyvinyl chloride composite material and a preparation method thereof, which relate to a composite material and a preparation method thereof. It solves the problem that the wood fiber-polyvinyl chloride composite material has high flammability and produces a large amount of black smoke and toxic gas when burned. The wood fiber-polyvinyl chloride composite material is mainly composed of 100-600 parts of polyvinyl chloride resin, 30-700 parts of wood fiber material, 3-145 parts of intumescent flame retardant, 1-55 parts of copper oxide, 6 ~75 parts of heat stabilizer, 4~60 parts of plasticizer and 4~65 parts of compatibilizer. Preparation method: 1. premixed material; 2. extrusion molding. According to the GB / T8924-2005 standard test of the wood fiber-polyvinyl chloride composite material of the present invention, the oxygen index of the wood fiber-polyvinyl chloride composite material of the present invention is greater than 35%, the ignition time is long, no melting drops occur, and it belongs to the flame retardant grade Material. The preparation method of the wood fiber-polyvinyl chloride composite material of the invention is simple, easy to operate, has low requirements on equipment, and is convenient for popularization and application.

Owner:NORTHEAST FORESTRY UNIVERSITY

Environment-friendly flame-retardant rubber for shoe soles and preparation method thereof

The invention discloses an environment-friendly flame-retardant rubber for shoe soles and a preparation method thereof. The environment-friendly flame-retardant rubber for shoe soles comprises the following components in parts by weight: 55-65 parts of 2# standard rubber, 8-12 parts of styrene-butadiene rubber, 25-35 parts of cis-1,4-polybutadiene rubber, 1-3 parts of sulfur, 2-4 parts of accelerator, 1-3 parts of stearic acid, 4-6 parts of nano zinc oxide, 0.5-0.7 part of releasing agent, 54-66 parts of reinforcing filler, 15-21 parts of softening system, 18-22 parts of red phosphorus, 4-6 parts of nitrogen-based flame retardant MCA (melamine cyanurate) and 18-22 parts of nitrogen-phosphorus flame retardant. In the invention, the natural rubber, styrene-butadiene rubber and cis-1,4-polybutadiene rubber are used as the main materials, the reinforcing filler and softening system are added to ensure the physical properties of the rubber, thereby ensuring the service life of the rubber sole, and the red phosphorus, nitrogen-based flame retardant MCA and nitrogen-phosphorus composite flame retardant NPR (nitrogen and phosphorus retardant) are together used as a flame retardant system, thereby providing excellent flame retardancy for the product. The invention has the advantages of simple method, low cost and favorable use effect.

Owner:JIHUA 3537 SHOE MAKING

Preparation method of magnesium-hydroxide-coated calcium carbonate inorganic composite flame retardant filler

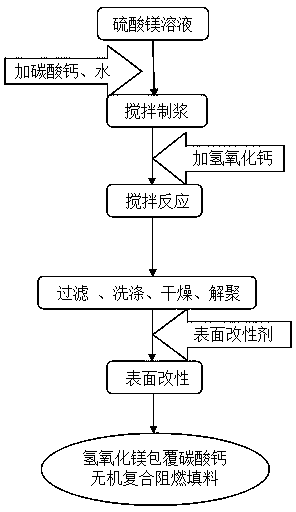

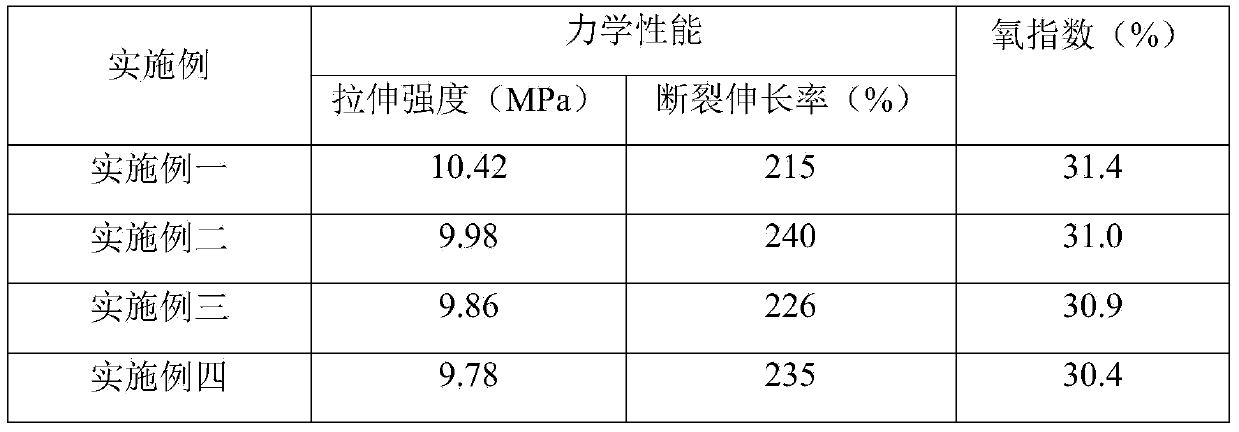

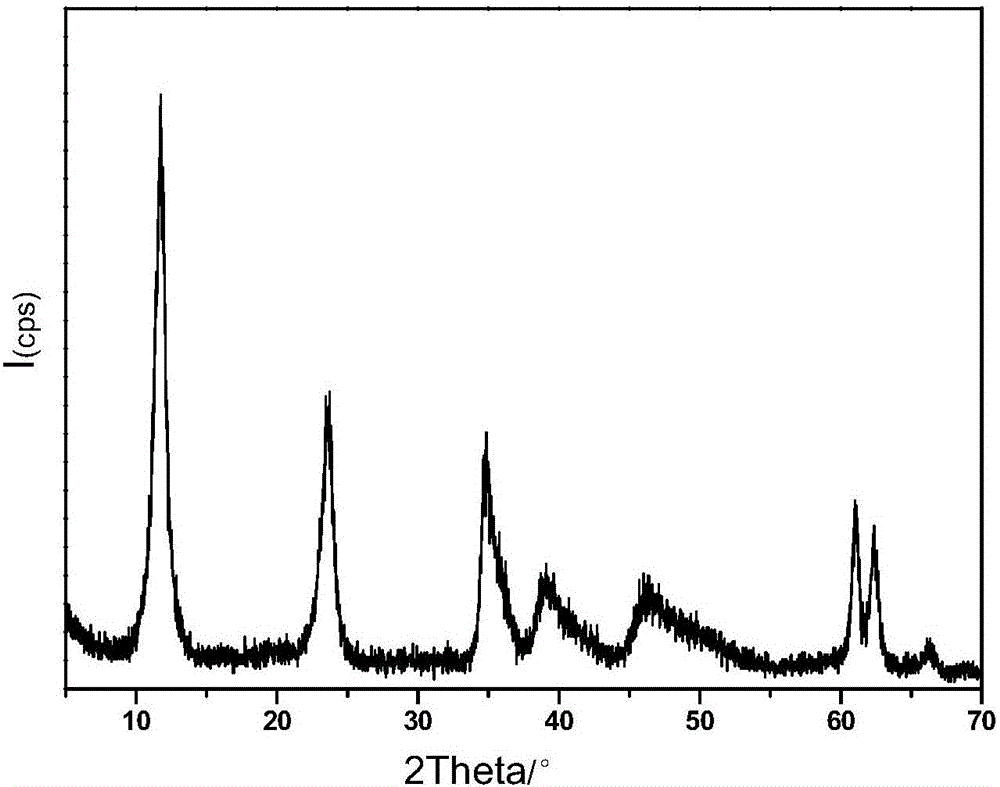

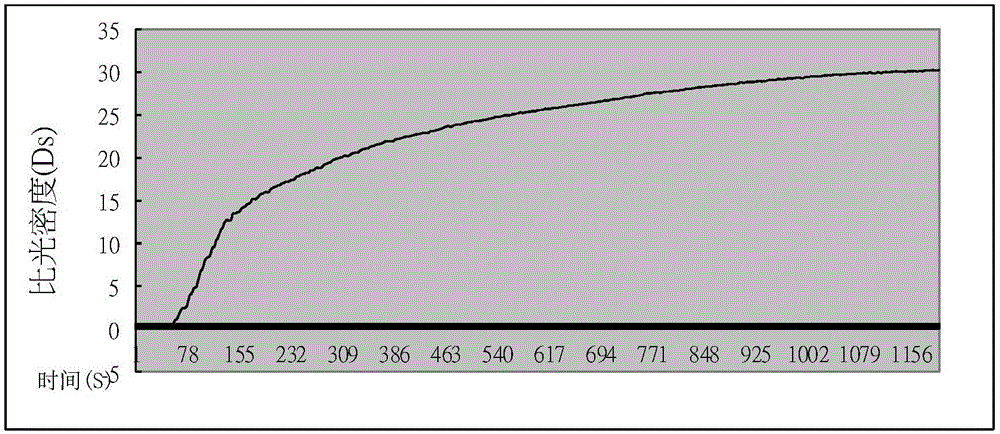

ActiveCN103773082AImprove flame retardant performanceGood smoke suppressionPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsCalcium hydroxideSlurry

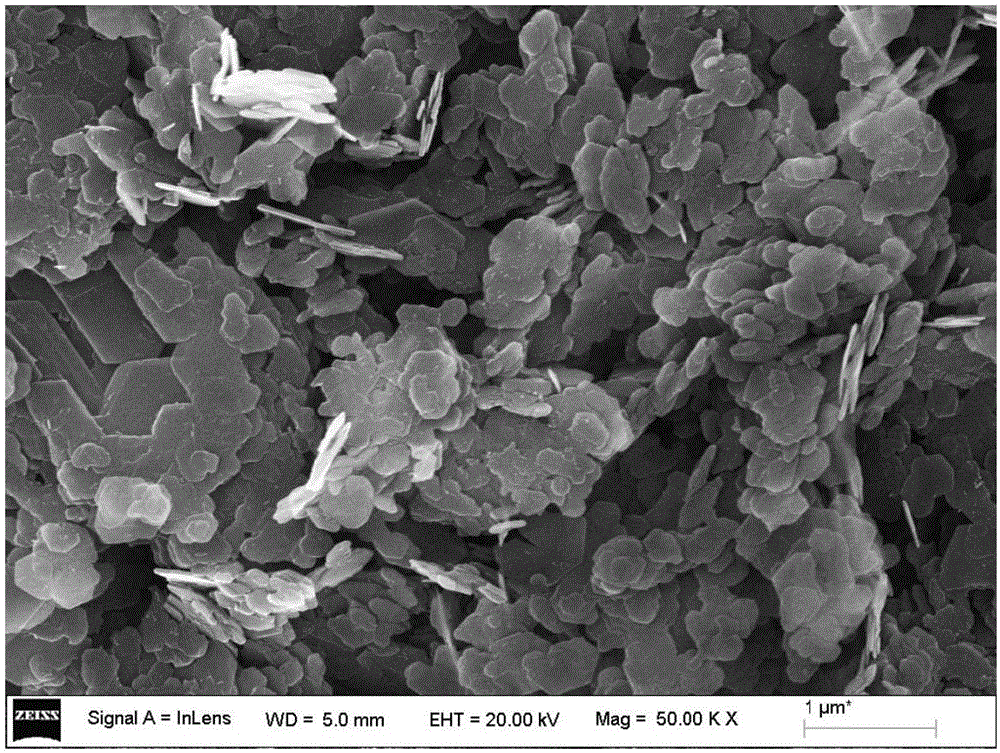

The invention relates to a preparation method of magnesium-hydroxide-coated calcium carbonate inorganic composite flame retardant filler. The preparation method comprises the following steps: adding water to calcium carbonate powder and magnesium sulfate so as to prepare slurry, adding calcium hydroxide to the slurry at a certain temperature, stirring, reacting for a certain time, then filtering, washing, drying, depolymerizing, and carrying out surface modification, thus obtaining the magnesium-hydroxide-coated calcium carbonate inorganic composite flame retardant filler. The inorganic composite flame retardant filler prepared by using the method has the excellent flame retardant property and smoke suppression property of magnesium hydroxide, also has the excellent filling technological property of calcium carbonate and the enhanced mechanical property and auxiliary flame retardant and smoke abatement property of calcium sulphate dehydrate, integrates multiple functions of filling enhancement, flame retardancy, smoke abatement and the like; the production cost of a magnesium hydroxide flame retardant is reduced, the functions of the calcium carbonate filler are added; and the magnesium-hydroxide-coated calcium carbonate inorganic composite flame retardant filler has good application prospect.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Intercalated layered double hydroxide smoke inhibitor and preparation method thereof

The invention discloses an intercalated layered double hydroxide smoke inhibitor and a preparation method thereof. The smoke inhibitor is a layered structural material formed by assembling a laminated sheet consisting of metal cations and interlayer anions, wherein a specific composition general formula of the smoke inhibitor is M<2+>1-xM<3+>x(OH)2(A<n->)n / 2.mH2O. According to the preparation method disclosed by the invention, the intercalated layered double hydroxide smoke inhibitor is prepared by adopting a one-step coprecipitation method or a clean hydrothermal reaction at one step; the preparation method is simple and practical; according to the obtained intercalated layered double hydroxide smoke inhibitor, smoke inhibiting groups such as molybdate anions, an octamolybdate radical, a cuprate radical and a stannate radical are arranged at an interlayer, and smoke inhibiting elements such as iron and copper are introduced into the laminated sheet, so that a good carbon forming effect is realized, the smoke generating amount can be reduced, and the smoke inhibiting effect is synergically enhanced; meanwhile, a layered double hydroxide laminated sheet forms an alkaline porous substance at high temperature; the alkaline porous substance has greater specific surface area and can effectively adsorb smog; the prepared intercalated layered double hydroxide smoke inhibitor is applied to an ordinary rubber-plastic product and a high-temperature rubber-plastic product; the maximum density (Ds, max) at low additive amount (1phr) can be reduced by 87.3 percent; the intercalated layered double hydroxide smoke inhibitor is remarkable in smoke inhibiting effect and is a smoke inhibitor material with excellent performance.

Owner:BEIJING UNIV OF CHEM TECH

Expansive waterborne fireproof and flame-retardant coating for wood material and preparation method of expansive waterborne fireproof and flame-retardant coating

The invention relates to an expansive waterborne fireproof and flame-retardant coating for a wood material and a preparation method of the expansive waterborne fireproof and flame-retardant coating. The coating comprises water and the following components in parts by weight: 200 parts of melamine-modified urea resin emulsion, 110-120 parts of ethylene-vinyl acetate copolymer emulsion, 20-24 partsof boric acid, 36-38 parts of ammonium polyphosphate, 20-24 parts of guanylurea phosphate, 36-40 parts of pentaerythritol, 30-34 parts of melamine, 1.0-1.4 parts of sulfonated carbon, 3.6-4.0 parts ofzinc borate, 2.0-2.4 parts of ammonium octamolybdate, 16-20 parts of coating auxiliaries and 0-44 parts of pigment and filler. When heated, the expansive waterborne fireproof and flame-retardant coating is capable of greatly retarding the combustion of the wood material so as to prevent fire spreading; and the expansive waterborne fireproof and flame-retardant coating has good smoke inhibiting property and is capable of delaying the smoke generation time, reducing the release amount of smoke and the generation of poisonous gases and providing more safety time and space for escape and rescue of personnel under the condition of a fire hazard.

Owner:湘诚新材料科技有限公司

Surface activation modification technology for environment-friendly magnesium hydroxide flame retardant special for insulating materials

InactiveCN102558914AComply with halogen-free environmental protection requirementsLarge specific surface areaPigment treatment with organosilicon compoundsPigment treatment with non-polymer organic compoundsCopperMechanical property

The invention relates to a surface activation modification technology for an environment-friendly magnesium hydroxide flame retardant special for insulating materials. The flame retardant is a modified magnesium hydroxide composite flame retardant, and comprises the following components in part by weight: 80 to 95 parts of magnesium hydroxide, 1 to 10 parts of surface modifier, 0 to 5 parts of dispersing agent and 0 to 25 parts of flame-retardant aid. The environment-friendly magnesium hydroxide flame retardant is mainly applied to the field of the insulating materials, namely the application fields of laminated wood boards, copper-clad plates, insulating sleeves, insulating paper, insulating tape and the like. The environment-friendly magnesium hydroxide flame retardant belongs to a halogen-free environment-friendly product; and the prepared insulating materials have a good flame-retardant effect and an obvious smoke-inhibiting effect, and the mechanical properties and electric properties are improved.

Owner:大连亚泰科技新材料股份有限公司

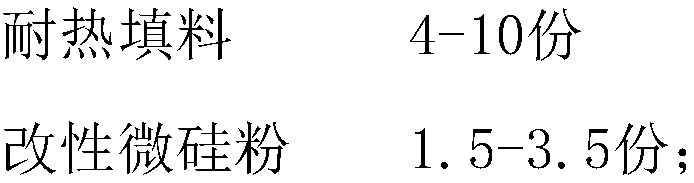

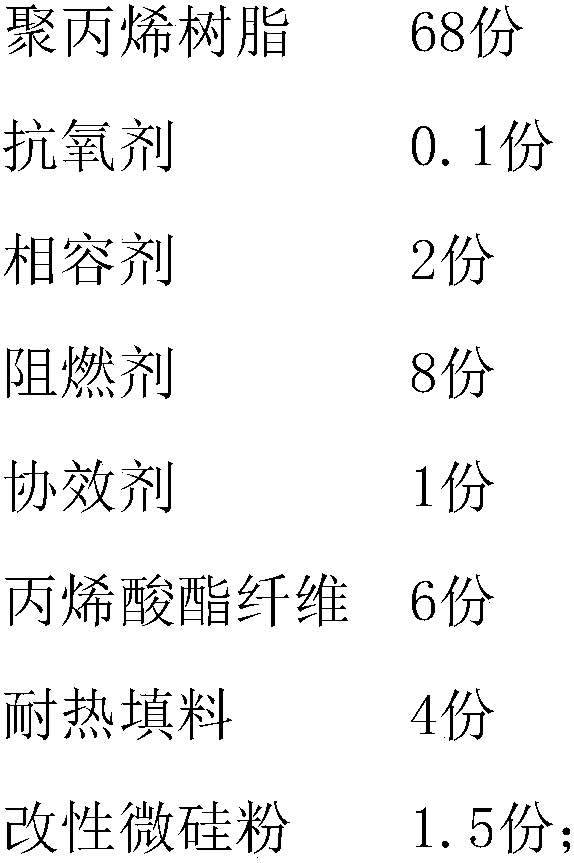

High-flame-retardancy high-heat-resistance MPP pipe and preparation method thereof

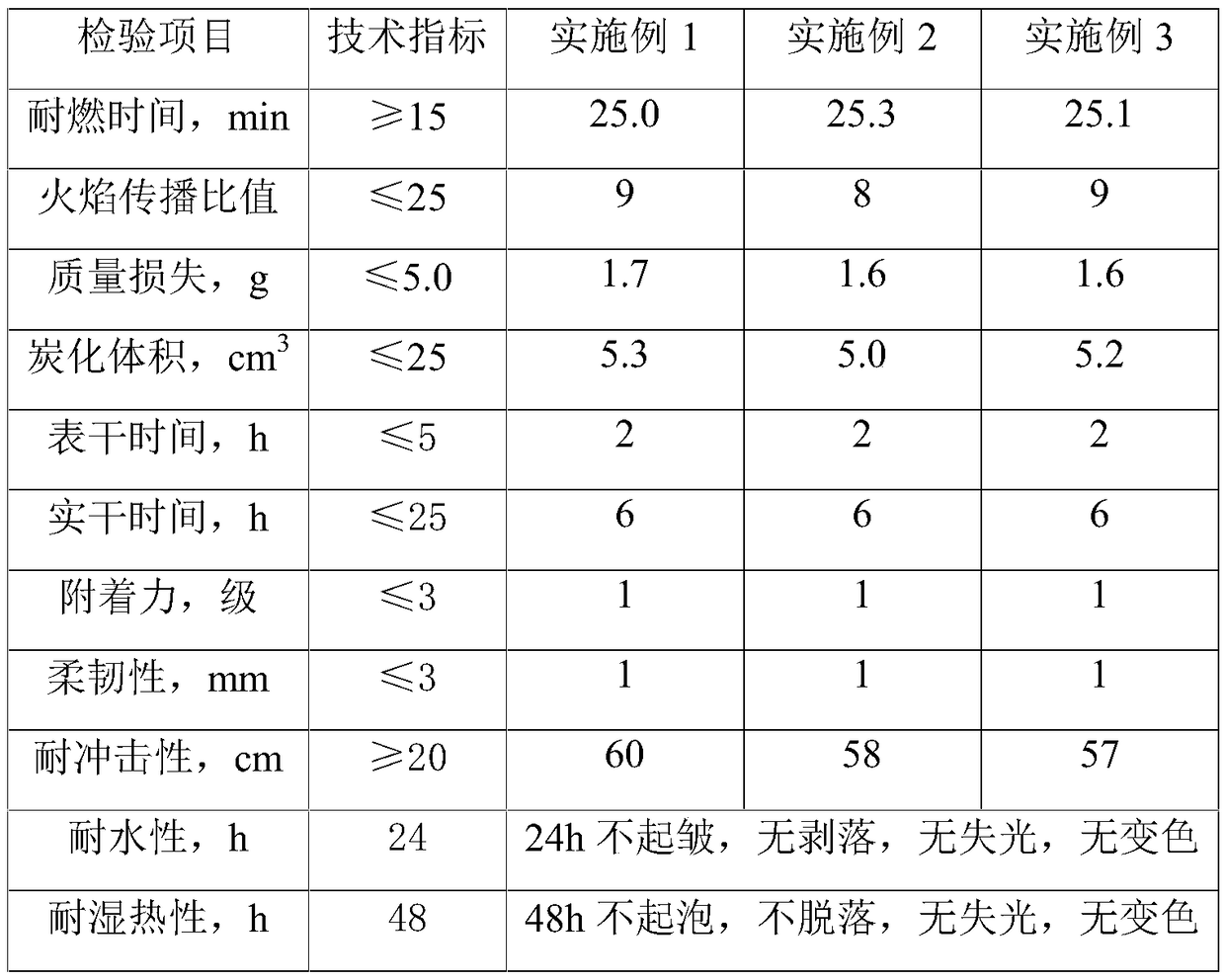

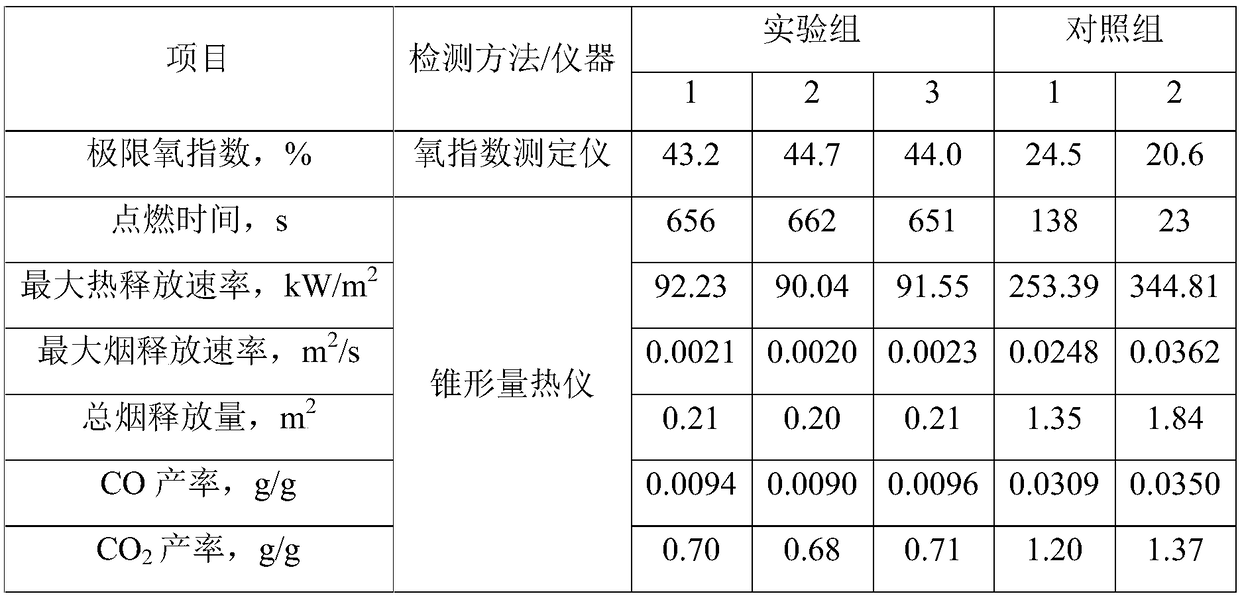

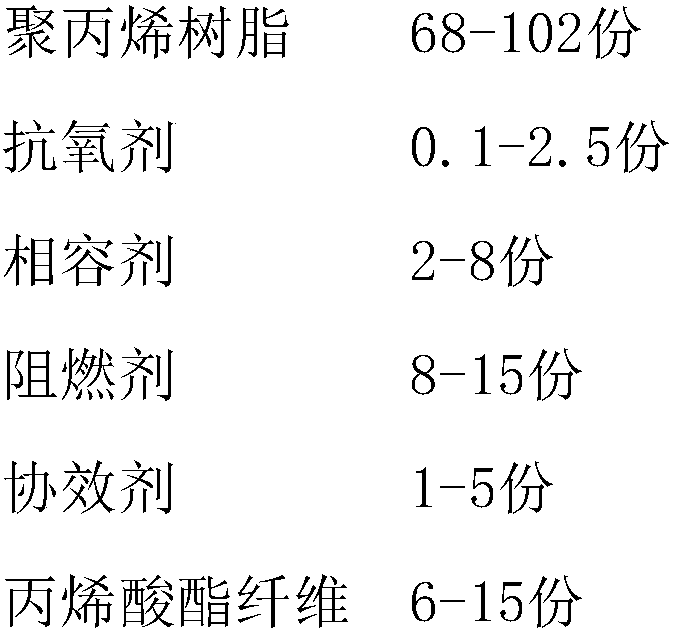

The invention relates to the technical field of high polymer materials, and in particular relates to a high-flame-retardancy high-heat-resistance MPP pipe and a preparation method thereof. The MPP pipe comprises the following raw materials in parts by weight: 68-102 parts of polypropylene resin, 0.1-2.5 parts of an antioxidant, 2-8 parts of a compatilizer, 8-15 parts of a flame retardant, 1-5 parts of a synergistic agent, 6-15 parts of an acrylate fiber, 4-10 parts of a heat-resistant filler and 1-5 parts of modified micro-silicon powder, wherein the heat-resistant filler is the mixture composed of calcium carbonate, lignocelluloses and magnesium silicide according to the weight ratio of 3-12:3-8:1-2. The MPP pipe disclosed by the invention has better flame retardancy, heat resistance, smoke inhibition performance, stability, oxidation aging resistance and the like, the strength is high, and the heat-resistant filler is adopted, the heat resistance and the processing flowing property of the MPP pipe can be effectively improved, the surface glossiness is reduced, the forming performance is good, the processing performance is good, and the use value is high.

Owner:SHENZHEN ANPOWER ELECTRIC

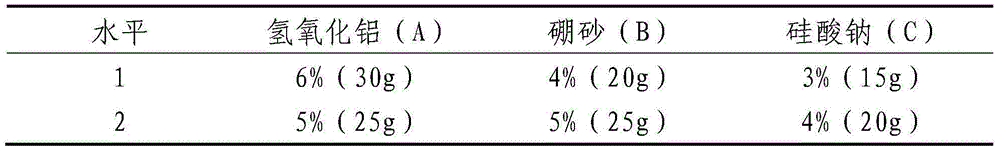

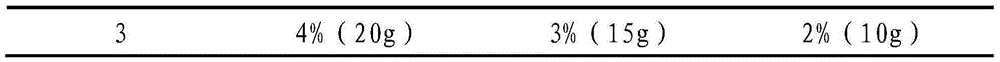

Composite flame retardant and method for preparation of flame retardant fiber board from the same

ActiveCN105131627AGood flame retardant effectGood smoke suppressionDomestic articlesFlat articlesSodium silicateFire retardant

Belonging to the technical field of fireproof material development, the invention specifically relates to a composite flame retardant and a method for preparation of a flame retardant fiber board from the same. The composite flame retardant is composed of aluminum hydroxide, borax and sodium silicate in a mass ratio of 4-6:3-5:2-4. The composite flame retardant provided by the invention has the advantages of good flame retardant effect, low toxicity, good smoke suppression and environmental friendliness, can significantly improve the flame retardant properties of the fiber board, and has cheap price, thus being suitable for industrial production of the flame retardant fiber board.

Owner:GUANGXI UNIV

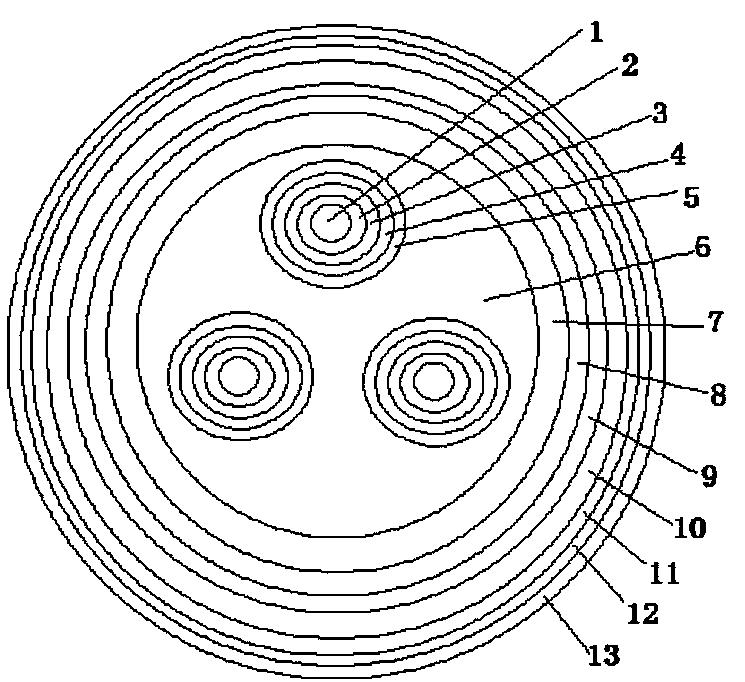

Purple-light cross-linked low-smoke halogen-free high flame-retardant EVA cable and production method thereof

InactiveCN104200906AImprove performanceImprove shielding effectInsulated cablesCable/conductor manufactureLow smoke zero halogenGlass fiber

The invention provides a purple-light cross-linked low-smoke halogen-free high flame-retardant EVA cable which comprises conductors. Each conductor is covered with a shield layer, the shield layer is covered with a purple-light cross-linked insulating layer, the purple-light cross-linked insulating layer is covered with a ceramic silicone rubber layer, and the ceramic silicon rubber layer is covered with an anticorrosive layer. Flame-retardant glass fiber filling ropes are filled among the conductors, the conductors and the flame-retardant glass fiber filling ropes are together covered with a flame-retardant tape, the flame-retardant tape is covered with an internal purple-light cross-linked protective layer, the internal purple-light cross-linked protective layer is provided with an armor layer, the armor layer is covered with an external purple-light cross-linked protective layer, the external purple-light cross-linked protective layer is covered with a waterproof layer, the waterproof layer is covered with an SBS rubber layer, and the SBS rubber layer is coated with an ultraviolet-proof layer. The invention further provides a production method of the cable. The purple-light cross-linked low-smoke halogen-free high flame-retardant EVA cable is provided with multiple flame-retardant layers and the waterproof layer.

Owner:ZHANGQIU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO

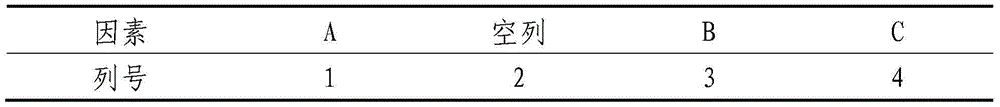

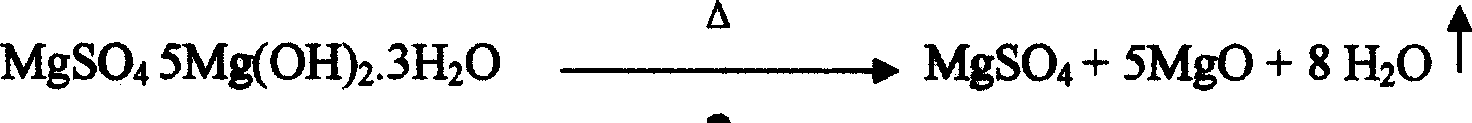

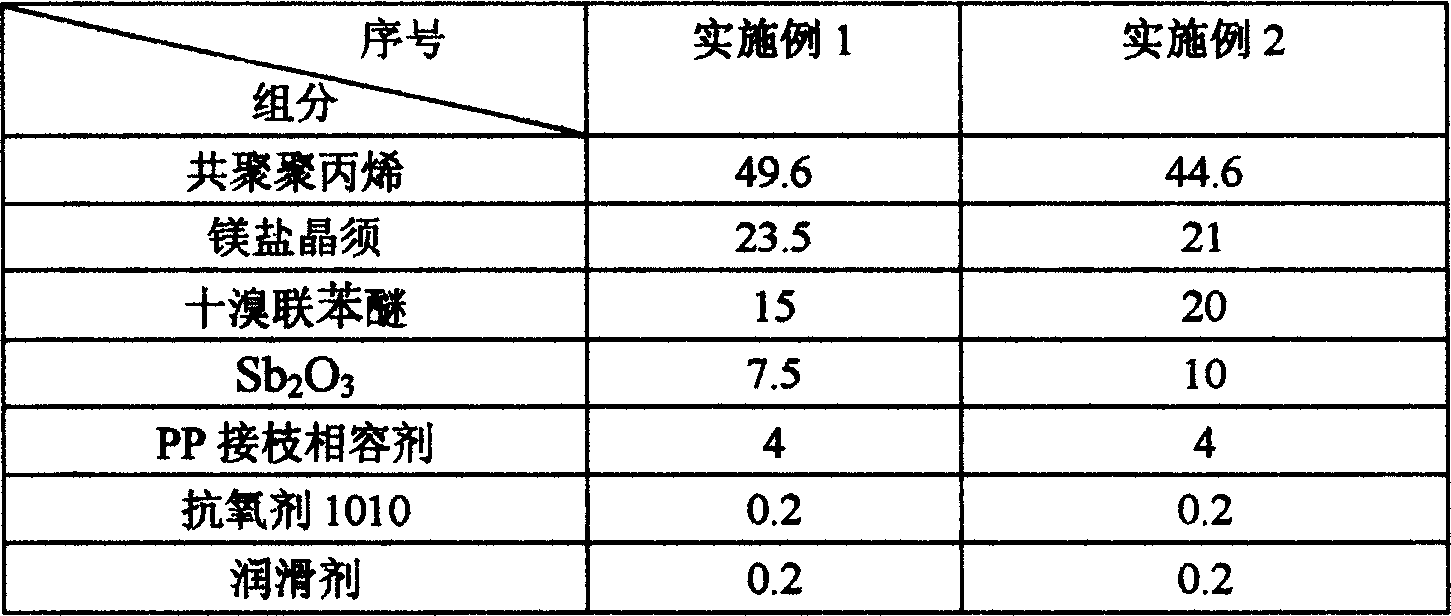

Magnesium solt whisker rein forced fire-resisting polypropylene composition

InactiveCN1536012AImprove flame retardant performanceGood smoke suppressionPolypropylene compositesLow speed

The present invention relates to a magnesium salt whiskers reinforced fire-resisting polypropylene composite. Its composition includes polypropylene, magnesium salt whiskers, fire-retardant and bromobiphenylate, high-effective fire-retarding synergist Sb2O3, PP graft compatilizer, antioxidant and other adjuvant. It is characterized by that the whiskers reinforced fire-retarding smoke-inhibitor is added, and its preparation method includes the following steps: except for magnesium salt whiskers placing all the other components into high-speed mixing machine, high-speed mixing them for 2-3 min, adding magnesium salt whickers, low-speed mixing them for about 1 min, discharging material, extruding by using twin screw extruder and granulating so as to obtain the invented product. Its extruding temp. is 170-240 deg.C, and its screw rod rotating speed is 180-600 rpm. Said invention also provides its application range and field.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

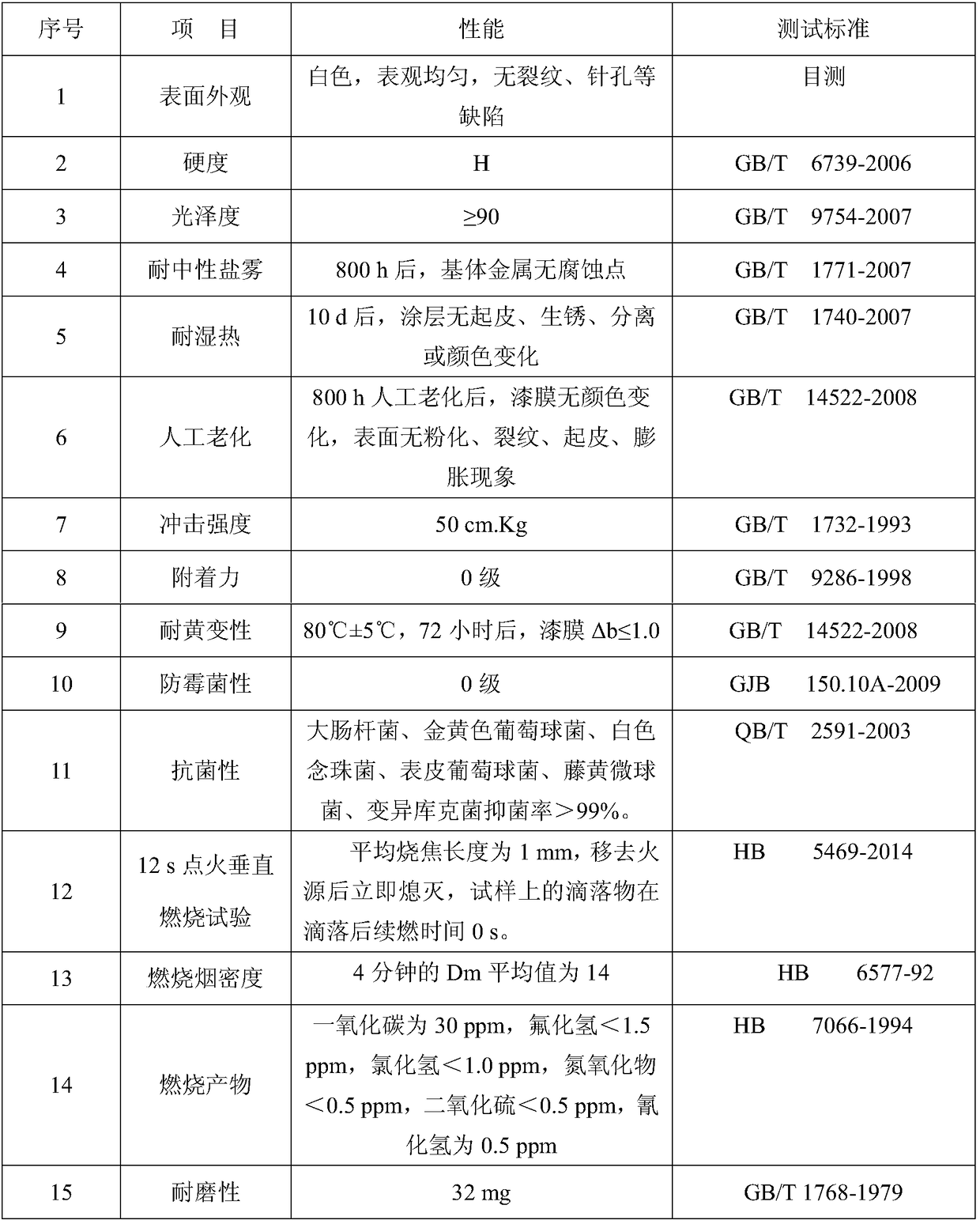

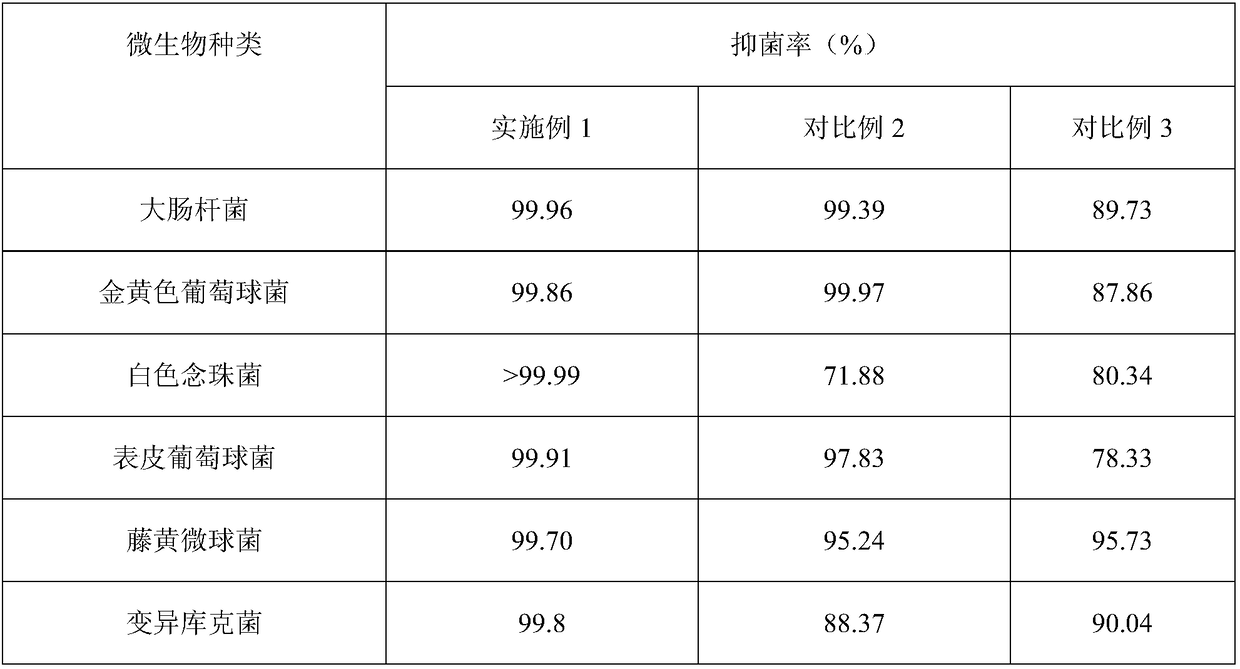

Antibacterial mildew-resistant corrosion-resistant flame-resistant integrated nanometer functional paint, and preparation method and applications thereof

InactiveCN108912945AImprove flame retardant performanceImprove corrosion resistanceFireproof paintsAntifouling/underwater paintsWear resistantAntiseptic solutions

The invention discloses an antibacterial mildew-resistant corrosion-resistant flame-resistant integrated nanometer functional paint, and preparation method and applications thereof. The antibacterialmildew-resistant corrosion-resistant flame-resistant integrated nanometer functional paint is mainly composed of a corrosion-resistant flame-resistant epoxy priming paint and an antibacterial mildew-resistant wear-resistant polyurethane finish paint. According to the preparation method, an intumescent flame retardant and graphene are added into the epoxy priming paint as flame retardation auxiliary agents; the paint flame resistance is improved greatly through the cooperative effect of the nanometer material and the intumescent flame retardant; nanometer silver antiseptic and hyperbranched polyethylene imide quaternary ammonium salt nanometer particles are added into the polyurethane finish paint as antibacterial auxiliary agents, and the paint antibacterial mildew-resistant performance isimproved through the cooperative effect of the nanometer silver antiseptic and the hyperbranched polyethylene imide quaternary ammonium salt nanometer particles. The reasonable combination of the priming paint with the finish paint is capable of improving the paint corrosion resistance further. The antibacterial mildew-resistant corrosion-resistant flame-resistant integrated nanometer functionalpaint possesses the antibacterial performance, the mildew resistance, the flame resistance, the corrosion resistance, and the wear resistance, is wide in application range, is simple in preparation method, is convenient in operation, and is convenient for large scale applications.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Low-smoke fireproofing cable material without halide and its preparation method

InactiveCN1951993AAdd lessHigh flame retardant efficiencyInsulated cablesInsulated conductorsAmmonium polyphosphateSmoke

The invention discloses a low-smoke flame-proof non-halogen cable material and preparing method, which comprises the following steps: blending polyphosphoric ammonia and zinc boride evenly; spraying and cladding the composite material through coupler; adding middle-density polyethylene, copolymer, functional nylon, compatible agent, anti-oxidant and lubricant to stir evenly; transmitting composite material into concurrent twin-screw extruder to fuse; graining after winding to obtain the product.

Owner:YUNNAN CHEM RES INST

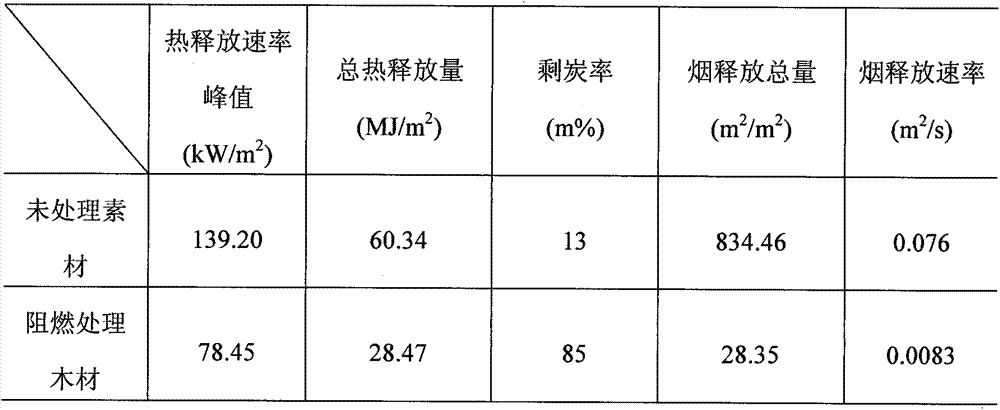

Multifunctional wood inflaming retarding agent and method for preparing smoke suppressing and inflaming retarding pinus sylvestris solid wood by utilizing of multifunctional wood inflaming retarding agent

InactiveCN103158181AEasy to infuseImprove immersion effectWood treatment detailsPressure impregnationSolubilitySolid wood

The invention discloses a multifunctional wood inflaming retarding agent and a method for preparing smoke suppressing and inflaming retarding pinus sylvestris solid wood by utilizing of the multifunctional wood inflaming retarding agent, and relates to the multifunctional wood inflaming retarding agent capable of antiflaming, suppressing smoke and preventing running off and a technique for processing the pinus sylvestris solid wood by utilizing the antiflaming and smoke suppressing properties of the multifunctional wood inflaming retarding agent. To solve the problems that the pinus sylvestris solid wood is rich in grease and can not be immersed easily, the flame retardation property of an existing wood inflaming retarding agent is single, and antiflaming components are easy to run off, the wood inflaming retarding agent comprises, by weight, 22-56 parts of phosphoric acid amidinourea, 15-25 parts of boric acid, 24-56 parts of water-solubility ammonium polyphosphate, 1-5 parts of ammonium molybdate and 20-45 parts of silica sol. The preparation method of the inflaming retarding and smoke suppressing pinus sylvestris solid wood comprises the following steps. Firstly, the microwave process is carried out on the dried pinus sylvestris solid wood. Secondly, the pinus sylvestris solid wood is placed in inflaming retarding liquid to be pressurized and immersed in a vacuum mode. The dried inflaming retarding and smoke suppressing pinus sylvestris solid wood has a good smoke suppressing property, the smoke suppressing effect and anti-running-off property are obvious.

Owner:NORTHEAST FORESTRY UNIVERSITY

High heat-resistant anti-aging CPVC power cable protection tube and preparation method thereof

The invention discloses a high heat-resistant anti-aging CPVC power cable protection tube. The tube comprises the following raw materials, in parts by weight: 450-550 parts of CPVC, 200-300 parts of PVC, 150-200 parts of calcium powder, 30-50 parts of a toughening agent, 3-15 parts of nitrile rubber, 20-30 parts of a stabilizer, 10-20 parts of a flame retardant, 1-5 parts of stearic acid, and 12-18 parts of paraffin. The high heat-resistance anti-aging CPVC power cable protection tube provided by the invention has a temperature resistant to heat deformation of 98 DEG C or more, has excellent high-temperature resistance, and can adapt to high-temperature harsh environments; the flame retardant performance reaches a FV-0 level; the tube has the characteristics of good flexibility, uneasy breakage and aging, long service life, no radiation pollution and a light weight; and in addition, a preparation method provided by the invention is simple and controllable, and the production is easy tooperate.

Owner:东莞市庆隆塑胶有限公司

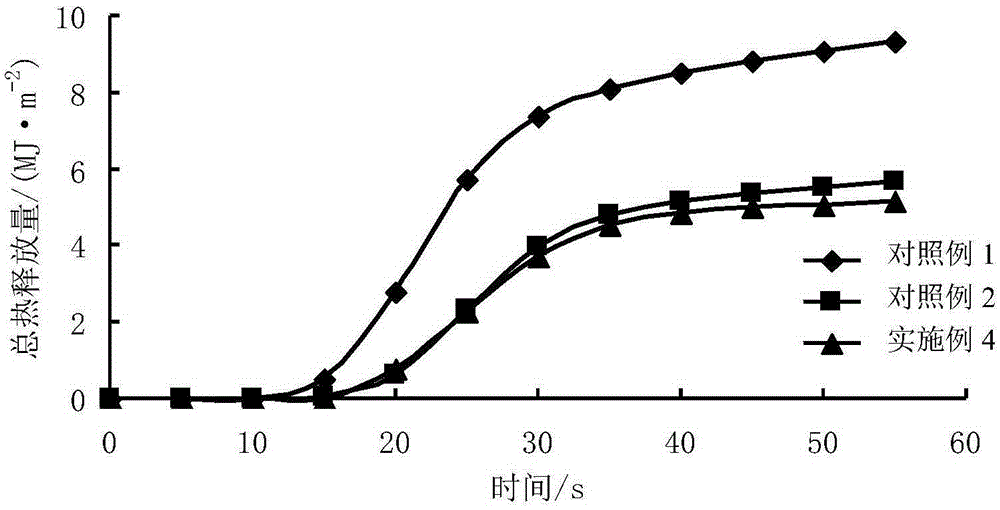

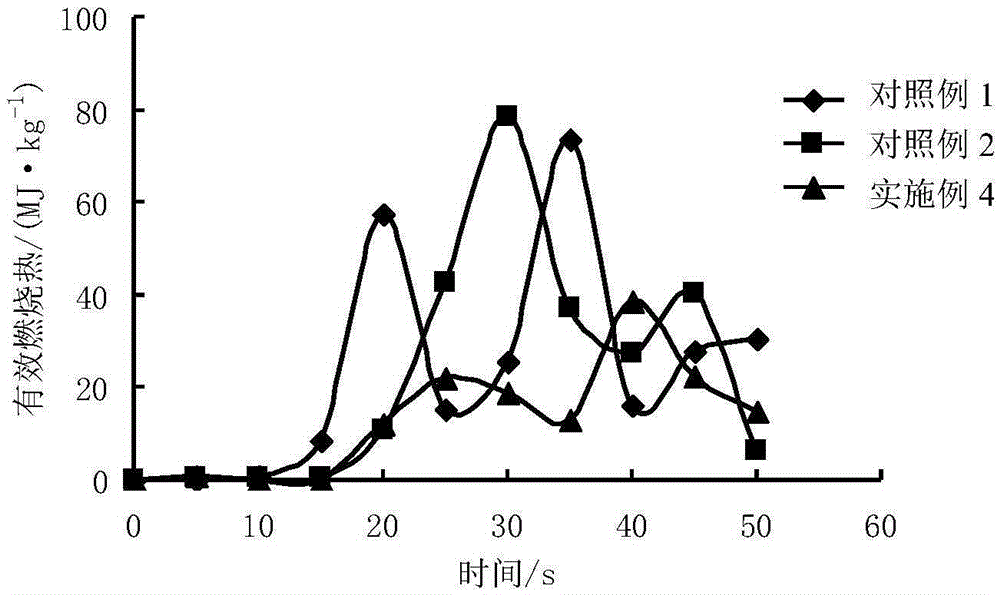

Flame-retardant wallpaper and preparation method thereof

ActiveCN105297551AImprove flame retardant performanceTotal calories lowSpecial paperLaminationToxic gasFire risk

The invention discloses flame-retardant wallpaper as an indoor wall decoration material and a preparation method thereof. The preparation method for the flame-retardant wallpaper includes the following steps: after being immersed in a flame retardant solvent, a decorative veneer and a wallpaper substrate (backing paper) are ultrasonically immersed, so that a flame-retardant decorative veneer and a flame-retardant substrate are obtained; the flame-retardant decorative veneer is attached onto the surface of the flame-retardant substrate. The flame-retardant property of the wallpaper is good, the potential fire risk is low when the material burns, and the flame-retarding effect is remarkable; the smoke suppression effect is obvious, the amount of CO released from smoke is obviously reduced, toxic CO gas can be partially turned into non-toxic gas, and the wallpaper has a good effect of suppressing CO released at fire scenes. Moreover, since the adopted materials are natural materials, the wallpaper is safe to use.

Owner:沈阳领拓科技有限公司

Environment-friendly smoke-suppression-type non-cured rubber-asphalt waterproof coating material and preparation method thereof

InactiveCN104789127AReduce asphalt fumeGood creepConjugated diene hydrocarbon coatingsBituminous coatingsRubberized asphaltPolymer chemistry

The invention relates to an environment-friendly smoke-suppression-type non-cured rubber-asphalt waterproof coating material and a preparation method thereof. An environment-friendly waterproof material with a smoke suppression effect is achieved through adding smoke suppressants of certain fractions based on a non-cured rubber-asphalt waterproof coating material. The waterproof coating material contains the ingredients in percentage by weight: 35-45% of modified asphalt, 25-35% of dispersant, 5-12% of tackifier, 0.5-1.5% of physical smoke suppressant, 3-5% of polymer smoke suppressant and 20-30% of heavy calcium carbonate. The waterproof coating material has good creep property and bond strength and is outstandingly characterized by having smoke suppression characteristic. According to the waterproof coating material, a large volume of harmful smoke generated during the high-temperature melting of the non-cured rubber-asphalt waterproof coating material can be effectively suppressed. The waterproof coating material disclosed by the invention has the characteristics of never curing, low-temperature resistance, no high-temperature flow, good waterproof performance, environmental friendliness, smoke suppression and the like, and can be extensively applied to waterproof projects of various building structures.

Owner:TANGSHAN DESHENG WATERPROOF

Protection method for outdoor willow furniture product

ActiveCN106221446AImprove adhesionEnhanced weather resistance and stabilityFireproof paintsAntifouling/underwater paintsCorrosion preventionPre treatment

The invention discloses a protection method for an outdoor willow furniture product. The protection method comprises the following steps: (1) preparation of a protection paint; (2) pretreatment of a willow product; (3) protection treatment. The protection paint in the protection method has an excellent use characteristic, the adsorbability of the protection paint and the willow product is further improved through a reasonable spraying method, and the protection paint on the surface of the willow product does not fall off or degrade even under the weather with bad environmental change. According to the outdoor willow furniture product treated by the method, the characteristics of inflaming retarding, smoke inhibition, corrosion prevention, mould prevention, insect prevention, antisepsis and loss resistance are well strengthened, the surface of the outdoor willow furniture product is smooth and has no wrinkle, the bending strength is improved by 20-30%, the compressive strength is improved by 15-20%, and the protection method has a high use value.

Owner:ANHUI XINDA HOME FURNISHING CO LTD

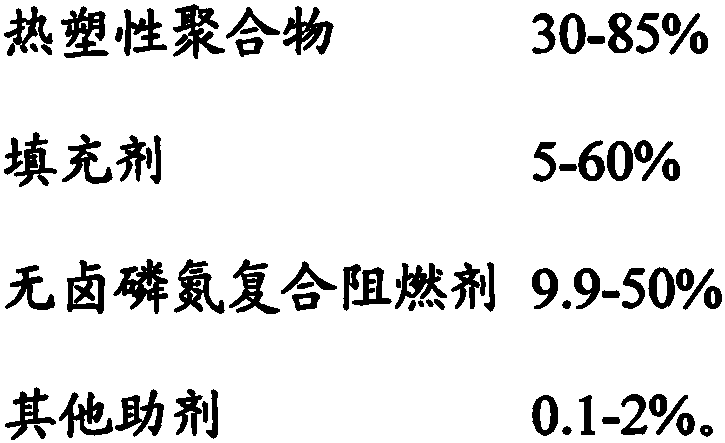

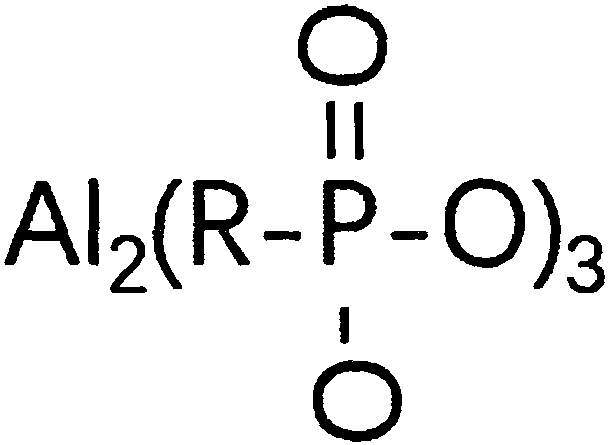

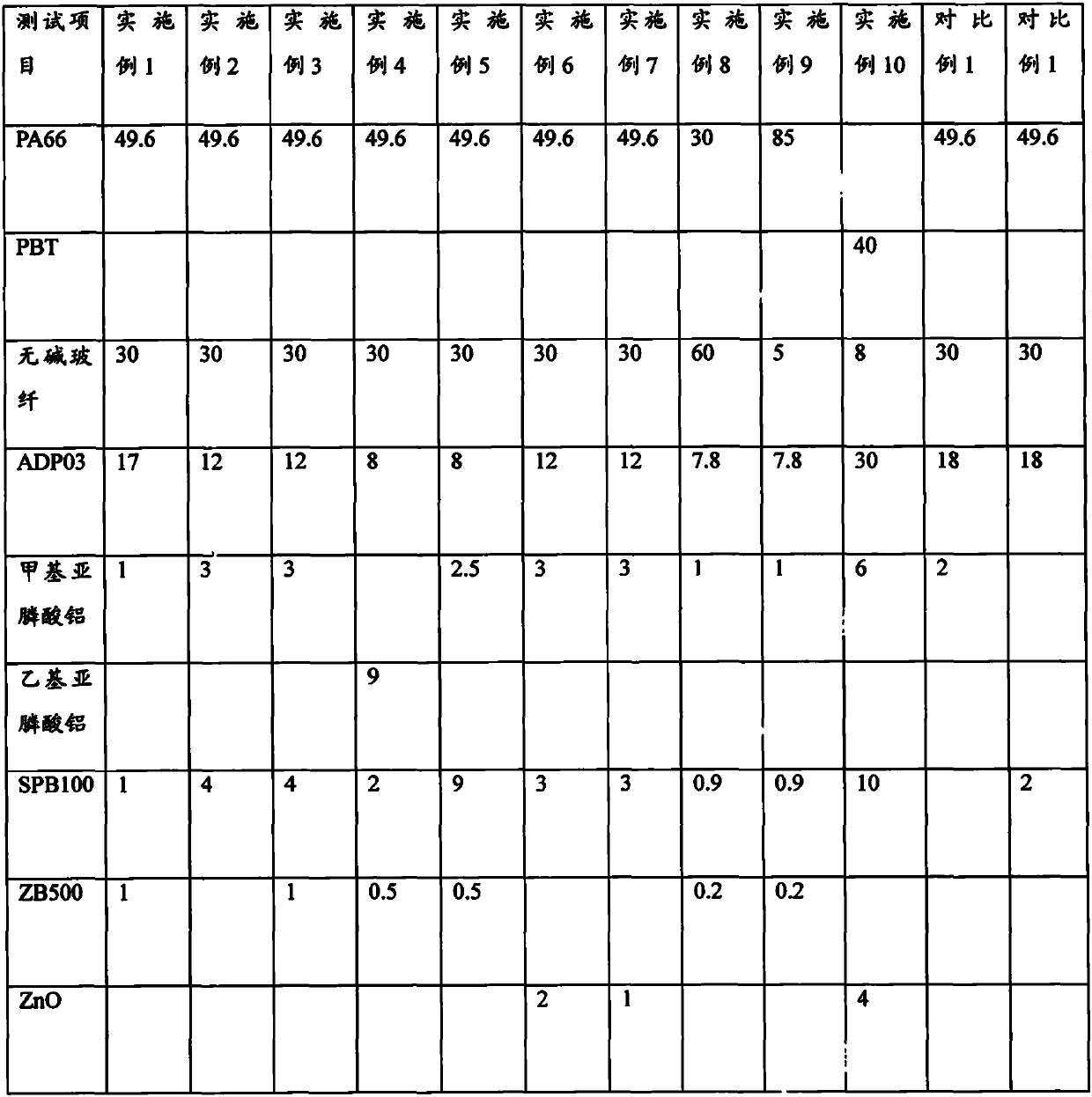

Halogen-free phosphorus-nitrogen composite flame retardant and halogen-free flame-retardant plastic polymer containing composite flame retardant

PendingCN109721768AGood environment friendlyImprove flame retardant performanceGlass fiberEngineering plastic

The invention discloses a halogen-free phosphorus-nitrogen composite flame retardant. The composite flame retardant is prepared from the following components in parts by weight: 40-89.5 parts of aluminum diethylphosphinate, 5-45 parts of organic aluminum phosphite, 5-45 parts of phosphonitrile and 0.5-10 parts of a heat stabilizer, wherein the organic aluminum phosphite is methyl or ethyl substituted aluminum phosphite, and the heat stabilizer is a zinc salt compound and / or cerium oxide. The invention aims to provide the halogen-free phosphorus-nitrogen composite flame retardant with high glowing filament performance and high flame retardancy. The flame retardant can be applied to non-filled or filled thermoplastic polymers, especially has excellent flame retardancy to glass fiber reinforced engineering plastic, and can be used to prepare parts or products in the field of electronic equipment.

Owner:广州市寅源新材料股份有限公司

Preparation method of moisture-proof and flame-retardant plywood

ActiveCN110341262AImprove clearanceImprove retentionFireproof paintsAntifouling/underwater paintsHardnessFire prevention

The invention discloses a preparation method of a moisture-proof and flame-retardant plywood. The method includes: drying a set of veneers or a set of sliced veneers, then coating adjacent veneers orsliced veneers with an adhesive to prepare a slab, conducting cold pressing and hot pressing on the slab, and then performing shearing, edge sawing, surface finishing, sanding and polishing, and thenspraying primer and top coat. The product has bonding strength of 50-70MPa and a mould inhibition rate of 78.4-83.6%, accords with the GB50222 "fire prevention code for interior decoration design of buildings", meets the requirements of B1-C flame retardant grade, the inner flame tip height in 20s is 17-84mm, and the paint film hardness is 2-4H.

Owner:NANJING FORESTRY UNIV

High-smoke suppression and high-oxygen index phenolic aldehyde fire-proof heat-preserving board and preparation method thereof

The invention relates to a high-smoke suppression and high-oxygen index phenolic aldehyde fire-proof heat-preserving board and a preparation method thereof and belongs to the technical field of a building fire-proof material. The high-smoke suppression and high-oxygen index phenolic aldehyde fire-proof heat-preserving board comprises the following components in parts by mass: 100 parts of phenolic resin, 10 to 20 parts of expansive fire retardant, 5 to 10 parts of liquid fire retardant, 5 to 8 parts of coal ash, 1 to 2 parts of tiny silicon powder, 1 to 2 parts of magnesium hydroxide, 5 to 7 parts of foaming agent, 5 to 7 parts of foam stabilizer and 20 to 30 parts of curing agent. The preparation method of the high-smoke suppression and high-oxygen index phenolic aldehyde fire-proof heat-preserving board comprises the following steps of 1) preparing a mixed slurry, i.e. (1) optionally selecting a formula, (2) mixing the phenolic resin and the liquid fire retardant, (3) mixing the expansive fire retardant, the hollow coal ash, the magnesium hydroxide and the tiny silicon powder, and adding the mixture into the mixed liquid, (4) adding the foaming agent and the foam stabilizer, and uniformly stirring the materials, and (5) adding the curing agent, stirring the materials, and filling the mixture into a die; and 2) molding and curing to obtain the fire-proof heat-preserving board. The fire-proof heat-preserving board has the advantages of convenience in construction, good fire resistance, low water absorption per volume, capability of meeting the requirements of high smoke suppression and high oxygen index of inner and outer wall heat-preserving boards, and the like.

Owner:TIANJIN CHENGJIAN UNIV

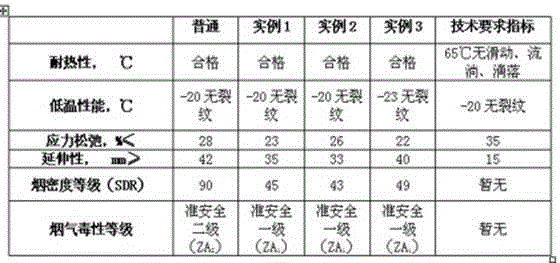

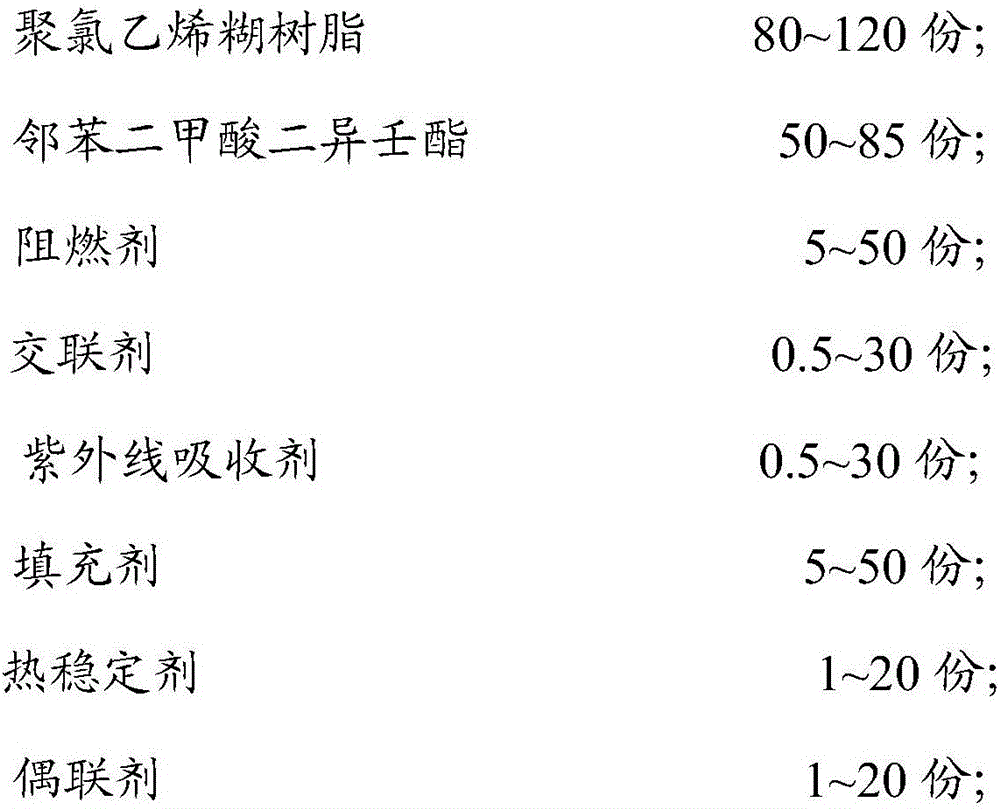

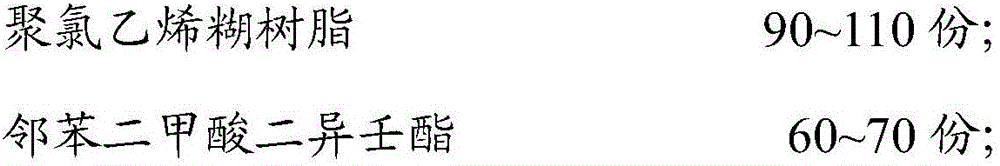

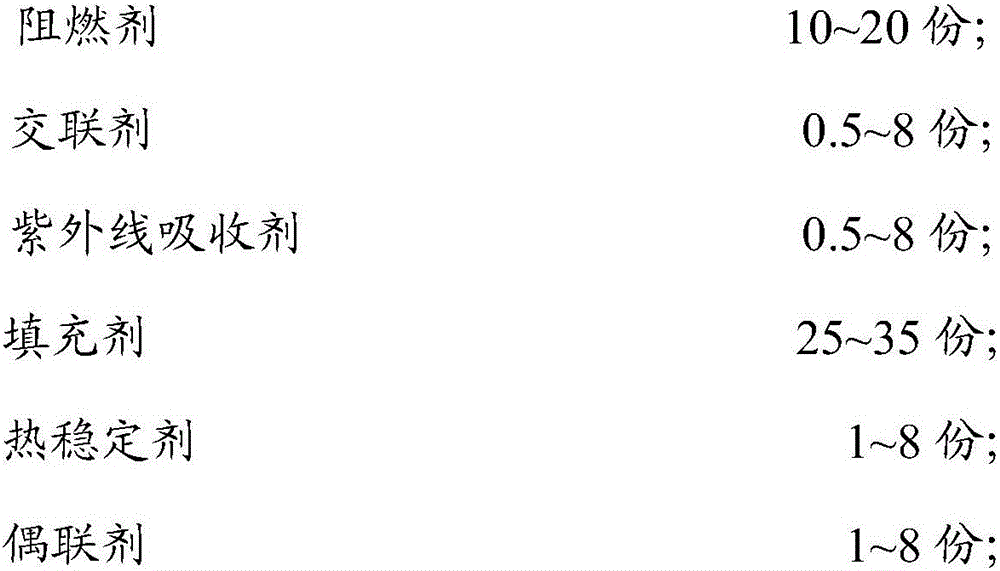

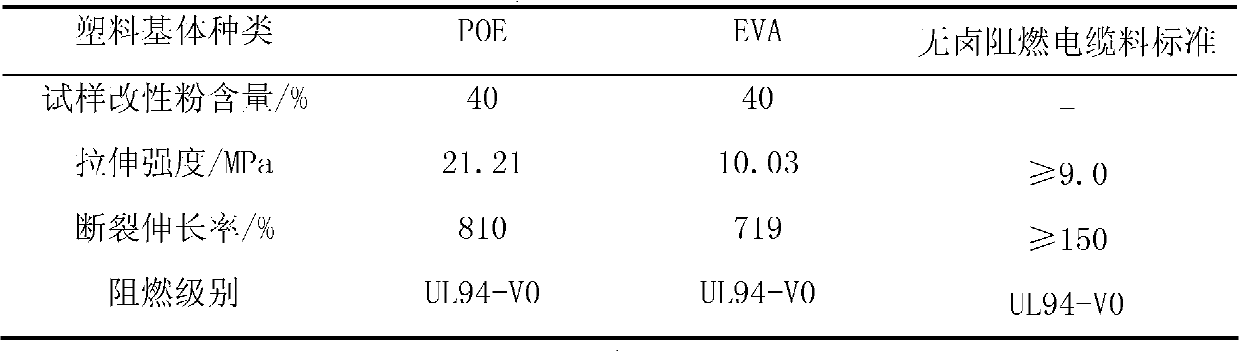

Flame-retarding and smoke-suppressing polyvinyl chloride membrane structure material

The invention relates to a flame-retarding and smoke-suppressing polyvinyl chloride membrane structure material.The material is prepared from, by mass, 80-120 parts of polyvinyl chloride paste resin, 50-85 parts of diisononyl phthalate, 5-50 parts of fire retardant, 0.5-30 parts of a cross-linking agent, 0.5-30 parts of ultraviolet light absorber, 5-50 parts of filler, 1-20 parts of heat stabilizer and 1-20 parts of a coupling agent, wherein the fire retardant is zinc stannate-molybdenum trioxide or zinc stannate-ammonium molybdate.According to the flame-retarding and smoke-suppressing polyvinyl chloride membrane structure material, an efficient flame-retarding and smoke-suppressing agent is added to polyvinyl chloride, so that flame retardation performance, heat resistance and smoke suppression performance of the material are improved.

Owner:ZHEJIANG UNIFULL IND FIBER

Fireproof emulsion paint

InactiveCN105062264AGood weather resistanceImprove water resistanceFireproof paintsAnti-corrosive paintsPhosphateKetone

The invention discloses fireproof emulsion paint. The fireproof emulsion paint comprises acrylic acid emulsion, polyurethane emulsion, epoxy resin, a fire retardant, expanded perlite, titanium dioxide, nanometer silica sol, silicon powder, nanometer titanium dioxide, zinc trifluoroacetylacetonate, dodecafluoroheptyl methacrylate, a film forming auxiliary agent, sorbitan monopalmitate, lauric acid, an antifoaming agent, hydroxyethyl cellulose, methyl ethyl ketone, N-phenyl-N'-cyclohexyl p-phenylenediamine, potassium citrate, dimethyldiallylammonium chloride and water. The fire retardant comprises dimethyl phosphite, methylvinyldichlorosilane, 3-aminopropyltriethoxysilane, 5-ethyl-5-butyl-2-chloro-1,3,2-dioxaphosphorinane, potassium tripolyphosphate, cetyl pyridinium bromide, decabromodiphenyl ethane, aluminum dihydrogen phosphate, calcium borate, melamine and cyanuric acid. The fireproof emulsion paint has excellent flame resistance, good fire retardancy, good adhesion to a base material and good decorative effects.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

Method for preparing nitrogen-phosphorus-magnesium compound fire retardant

InactiveCN101792674AImprove performancePrevent peelingFireproof paintsFire retardantOrganic inorganic

The invention belongs to the technical field of organic-inorganic compound fire retardants and relates to preparation technology of a nitrogen-phosphorus-magnesium compound fire retardant. The invention is characterized by taking a micron magnesium-based compound as the raw material, activating the surface of the compound in the presence of a surface activating assistant, then adding a phosphorus-containing compound and a nitrogen-containing compound with fire retardant effects according to certain sequence and formula ratio, mixing the mixture uniformly and reacting the mixture completely, then carrying out filtering and drying to obtain the nitrogen-phosphorus-magnesium compound fire retardant product. The nitrogen, the phosphorus and the magnesium in the prepared compound fire retardant can generate synergic fire retardant effect and effectively reduce the filling volume of the compound fire retardant while ensuring good smoke suppression effect. No waste is discharged in the whole preparation process and the reaction flow is simple and easy to control. The method shows obvious competitive advantage and profit space in such aspects as manufacture cost, product performance, environment-friendly property, etc.

Owner:DALIAN UNIV OF TECH

Low-smoke halogen-free flame-retardant B1-grade polyolefin cable sheath material and preparation method thereof

PendingCN111117054AImprove compatibilityImprove flame retardant effect and mechanical propertiesPlastic/resin/waxes insulatorsMaleic anhydridePolyolefin

Owner:ANHUI MENTOR CABLE GROUP

Composite flame retardant

InactiveCN103554917AImprove flame retardant performanceImprove mechanical propertiesZinc borateBoric acid

The invention discloses a composite flame retardant which is used as a flame retardant product and can be directly used as an additive to be added into ingredients of a product with a flame retardant requirement. The composite flame retardant comprises the following components in parts by weight: 5-30 parts of polydimethylsiloxane, 5-30 parts of silicate ester resin, 2-12 parts of stearate, 10-40 parts of zinc borate, 5-20 parts of calcium carbonate, 20-40 parts of aluminum hydroxide, 20-40 parts of magnesium hydroxide, 5-15 parts of talcum powder and 10-20 parts of sodium silicate. The composite flame retardant is easy to obtain raw materials, simple in preparation process, excellent in flame retardance, free of poisonous gas, good in smoke suppression, low in consumption and capable of meeting the general flame retardant requirement and also improving the mechanical property and compatibility of a substrate to a certain extent.

Owner:SHANDONG JIQING CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com