Low smoke halogen-free environment-protection fire-retardation type sheet molding compound and preparation method thereof

A sheet molding compound, flame-retardant technology, applied in the direction of coating, etc., can solve the problems of high smoke generation and strong corrosion, the comprehensive mechanical properties of sheet molding compound and the decline of surface quality, secondary hazards, etc., to achieve excellent Mechanical properties, solving the effect of high combustion smoke density and reducing combustion smoke density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

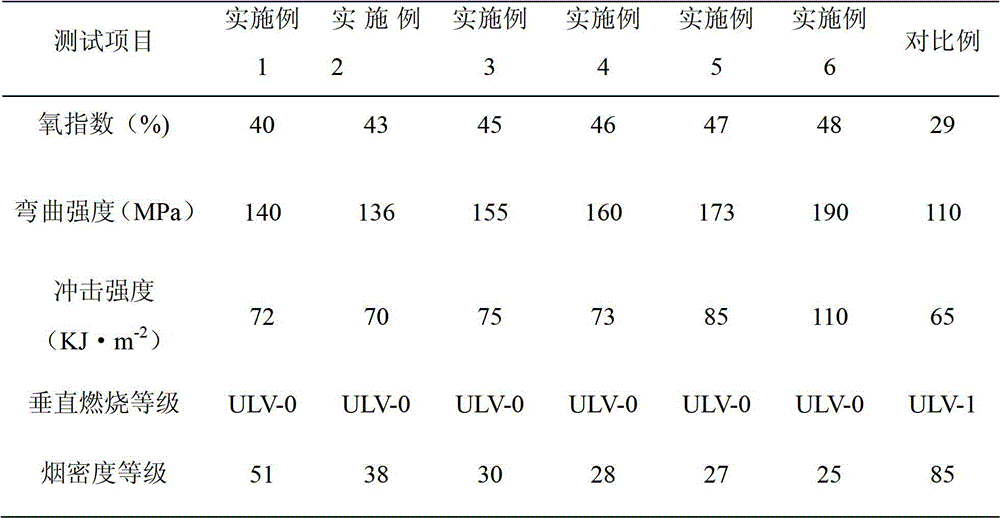

Examples

Embodiment 1

[0026] Embodiment 1: The sheet molding compound of the present invention, its components are selected in parts by mass, 60 parts of unsaturated polyester resin, 40 parts of polystyrene slurry, 1.5 parts of initiator, 3 parts of thickener, polymerization inhibitor 0.03 parts, 8 parts of release agent, 60 parts of filler, 80 parts of aluminum hydroxide, 5 parts of silicone synergist, 3 parts of smoke suppressant, 15 parts of novolac resin, 50 parts of glass fiber, 10 parts of basalt fiber, first Grind the unsaturated polyester resin and novolak resin in a three-roll mill, and disperse the novolac resin uniformly in the resin; then grind the resin, smoke suppressant, silicone synergist, initiator, polymerization inhibitor Add the agent and release agent into the batching kettle and stir at 400 rpm for 5 minutes; add filler calcium carbonate and aluminum hydroxide to the batching kettle and stir vigorously at 800 rpm for 15 minutes; finally add the thickener and stir evenly ; The ...

Embodiment 2

[0027] Embodiment 2: The sheet molding compound of the present invention, its component by mass parts, selects 60 parts of unsaturated polyester resin, 40 parts of polystyrene slurry, 1.5 parts of initiator, 3 parts of thickener, polymerization inhibitor 0.04 parts, 9 parts of mold release agent, 60 parts of filler, 100 parts of aluminum hydroxide, 5 parts of silicone synergist, 4 parts of smoke suppressant, 20 parts of novolac resin, 50 parts of glass fiber, and 10 parts of basalt fiber. Grind the unsaturated polyester resin and novolak resin in a three-roll mill, and disperse the novolac resin uniformly in the resin; then grind the resin, smoke suppressant, silicone synergist, initiator, polymerization inhibitor Add the agent and release agent into the batching kettle and stir at 400 rpm for 5 minutes; add filler calcium carbonate and aluminum hydroxide to the batching kettle and stir vigorously at 800 rpm for 15 minutes; finally add the thickener and stir evenly ; The prepa...

Embodiment 3

[0028] Embodiment 3: The sheet molding compound of the present invention, its component by mass parts, selects 60 parts of unsaturated polyester resins, 40 parts of polystyrene slurry, 1.5 parts of initiators, 3 parts of thickeners, polymerization inhibitors 0.06 parts, 9 parts of release agent, 60 parts of filler, 100 parts of aluminum hydroxide, 8 parts of silicone synergist, 5 parts of smoke suppressant, 20 parts of novolac resin, 60 parts of glass fiber, 20 parts of basalt fiber, first Grind the unsaturated polyester resin and novolak resin in a three-roll mill, and disperse the novolac resin uniformly in the resin; then grind the resin, smoke suppressant, silicone synergist, initiator, polymerization inhibitor Add the agent and release agent into the batching kettle and stir at 400 rpm for 5 minutes; add filler calcium carbonate and aluminum hydroxide to the batching kettle and stir vigorously at 800 rpm for 15 minutes; finally add the thickener and stir evenly ; The prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com