Antibacterial mildew-resistant corrosion-resistant flame-resistant integrated nanometer functional paint, and preparation method and applications thereof

An antibacterial, antifungal, and nano-functional technology, which is applied in the field of protective material preparation, can solve the problems of non-flammability, lower coating efficiency, and breeding of bacteria and mold, and achieve enhanced anti-corrosion performance, significant smoke suppression effect, and enhanced anti-corrosion properties. The effect of flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] In some specific embodiments, the preparation method may include:

[0060] A. Preparation method of epoxy primer:

[0061] (1) Weigh a certain proportion of epoxy resin, titanium dioxide, anti-precipitation agent, dispersant, flame retardant additive, talcum powder, nano-metal oxide and diluent and mix evenly to prepare component A of epoxy primer ;

[0062] (2) Add an epoxy curing agent to component A of the epoxy primer in a certain proportion, stir and mix evenly, and prepare an epoxy primer coating.

[0063] B. Preparation method of polyurethane topcoat:

[0064] (1) Take a certain proportion of acrylic resin, titanium dioxide, anti-precipitation agent, dispersant, leveling agent, nano wear-resistant filler, antibacterial auxiliary agent and diluent and mix uniformly to prepare polyurethane topcoat A component;

[0065] (2) Add an isocyanate curing agent to the polyurethane topcoat A component in a certain proportion, stir and mix evenly, and prepare the polyuret...

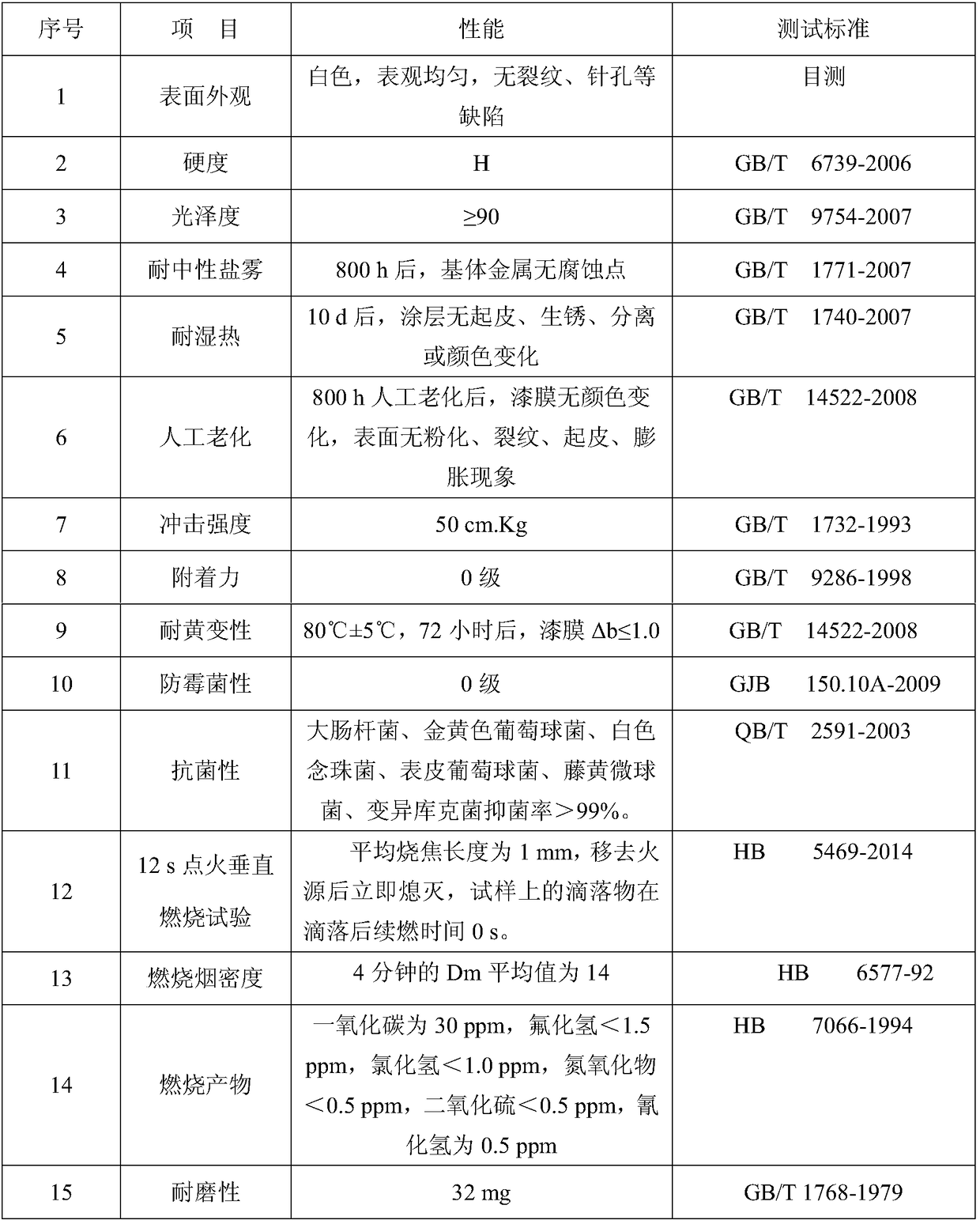

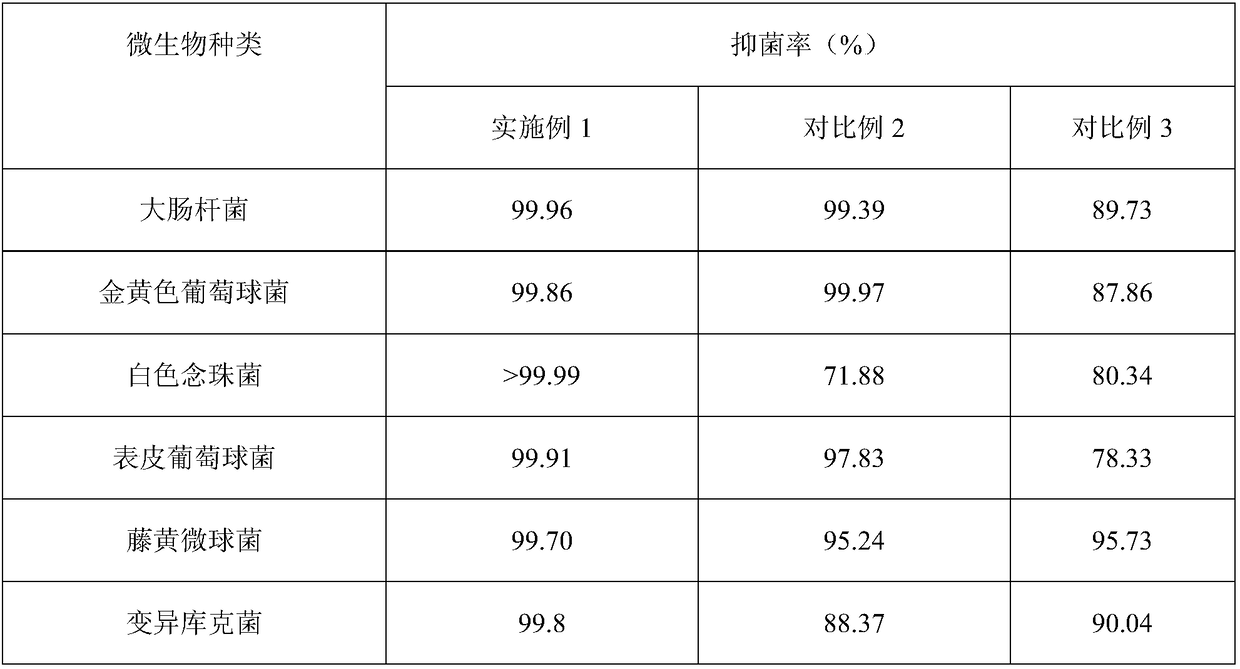

Embodiment 1

[0101] This embodiment provides a method for preparing an antimicrobial, anti-mildew, anti-corrosion, flame-retardant integrated nano-functional coating and coating, which specifically includes the following steps:

[0102] (1) According to mass percentage (if not specified below, it refers to the mass percentage content of each component in the epoxy primer A component), respectively take 30% of E44 epoxy resin, 20% of titanium dioxide, and 0.1% of organic bentonite %, anionic dispersant 0.1%, graphene 1%, intumescent flame retardant 18.8%, talcum powder 10%, nano-alumina 5%, nano-zirconia 5%, and diluent 10% are dispersed and mixed in a high-speed dispersion kettle After uniformity, the A component of the epoxy primer is obtained; the modified amine T31 is used as the B component of the epoxy curing agent;

[0103] (2) by mass percentage (if not specified below, then all refer to the mass percentage content of epoxy primer A, B component in epoxy primer) weigh 80% epoxy prim...

Embodiment 2

[0108] This embodiment provides a method for preparing an antimicrobial, anti-mildew, anti-corrosion, flame-retardant integrated nano-functional coating and coating, which specifically includes the following steps:

[0109] (1) Take 20% of E20 epoxy resin, 5% of titanium dioxide, 0.5% of organic bentonite, 5% of anionic dispersant, 0.1% of graphene, 9.9% of intumescent flame retardant, 10% of talcum powder, and 30% of nanometer metal oxide and 19.5% of diluent are uniformly dispersed and mixed in a high-speed dispersion kettle to prepare component A of epoxy primer; take polyamide as component B of epoxy curing agent;

[0110] (2) weigh 70% epoxy primer A component and 30% epoxy primer B component respectively by mass percentage, disperse and mix in the dispersing kettle, stir evenly, make epoxy primer;

[0111] (3) Take 30% of acrylic acid, 30% of titanium dioxide, 0.5% of organic bentonite anti-precipitation agent, 5% of anionic dispersant, 0.5% of organic silicon leveling a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com