Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about How to "Strong wood feeling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

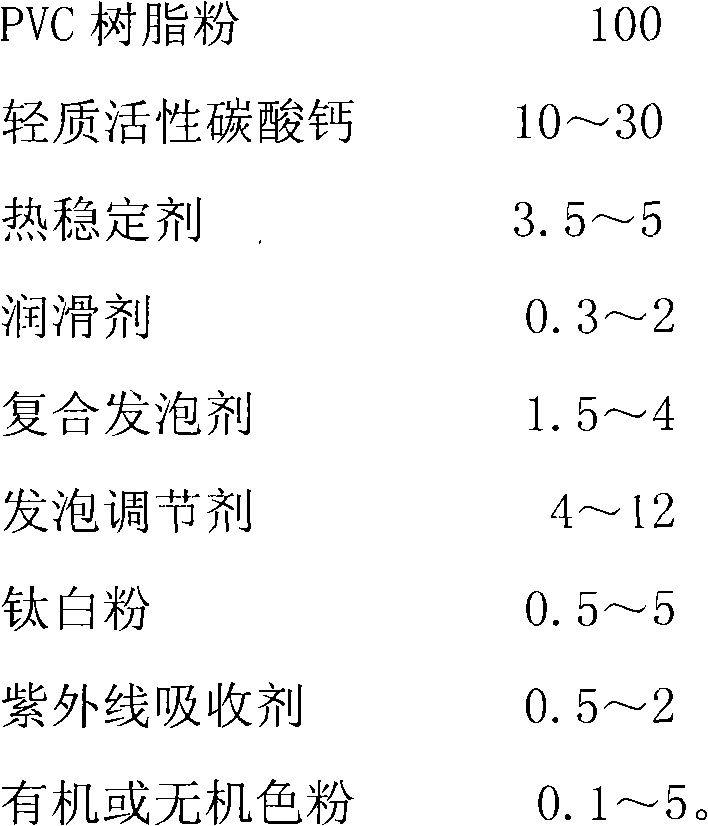

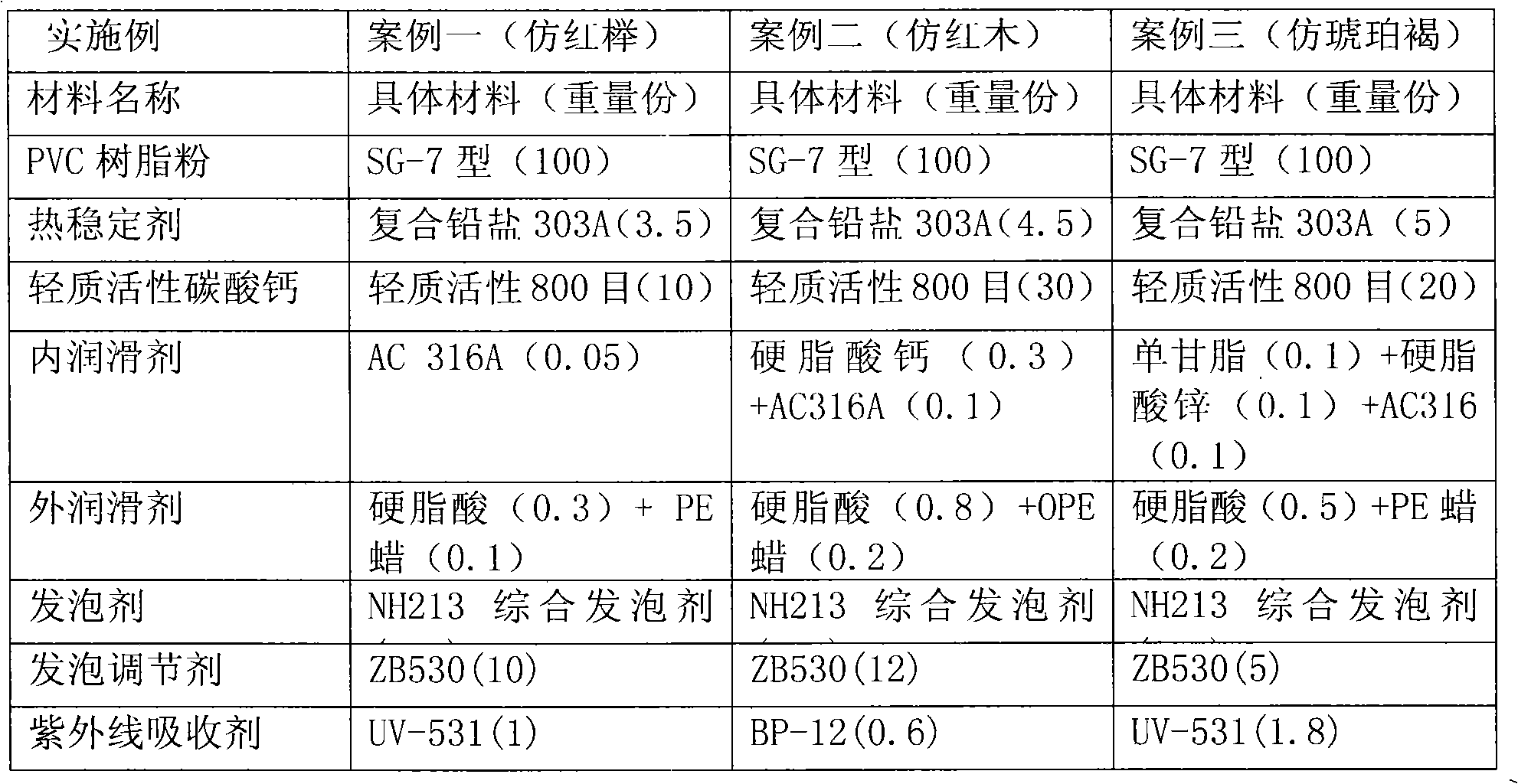

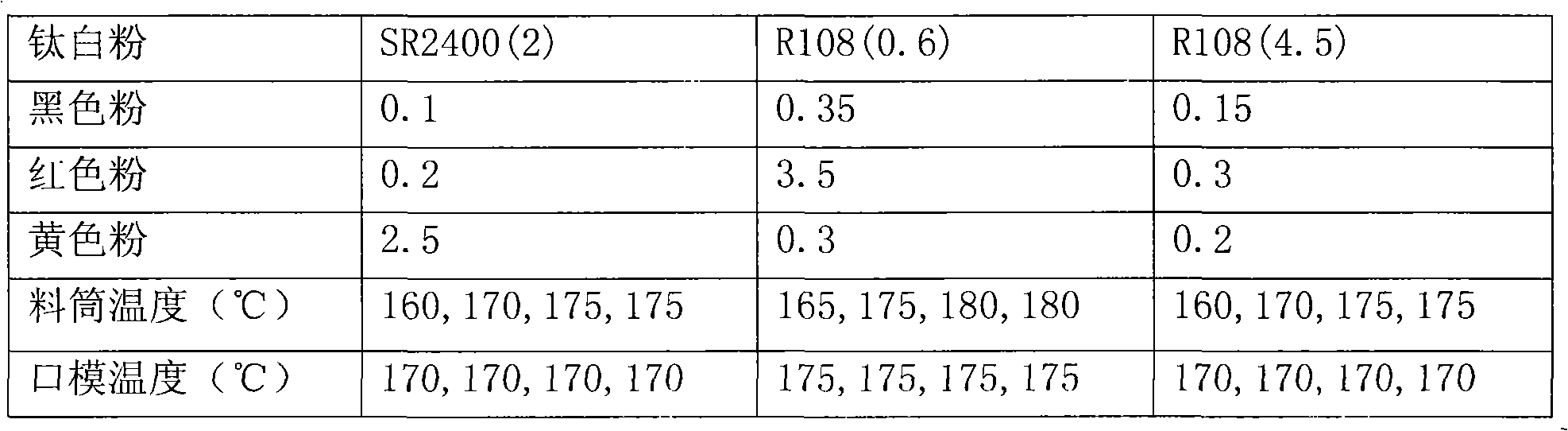

PVC high-weatherability imitation-wood crust foaming material

The invention provides a high-weatherability imitation-wood crust foaming material with high hardness, good toughness, high weatherability and low cost. According to the invention, titanium pigment and an ultraviolet absorbent are added to a common forming material. High weatherability and high thermal stability of rutile type titanium dioxide are utilized; and excellent thermal stability, chemical stability and light stability of the ultraviolet absorbent are utilized. The two materials are adopted in combination in the foaming material, such that the thermolability of the PVC material is effectively reduced, and the weatherability of the foaming material is improved. Organic or inorganic toners are adopted, such that an imitation-wood effect can be achieved through the blending of the toners. With the technical scheme provided by the invention, the appearance of the material is improved; and the use of wood powder is avoided, such that use of wood is reduced. Therefore, the material is beneficial for environmental protection. With the material provided by the invention, the risks during the production and the application processes are reduced.

Owner:ANHUI GUANGDE JINPENG NEW MATERIAL MFG

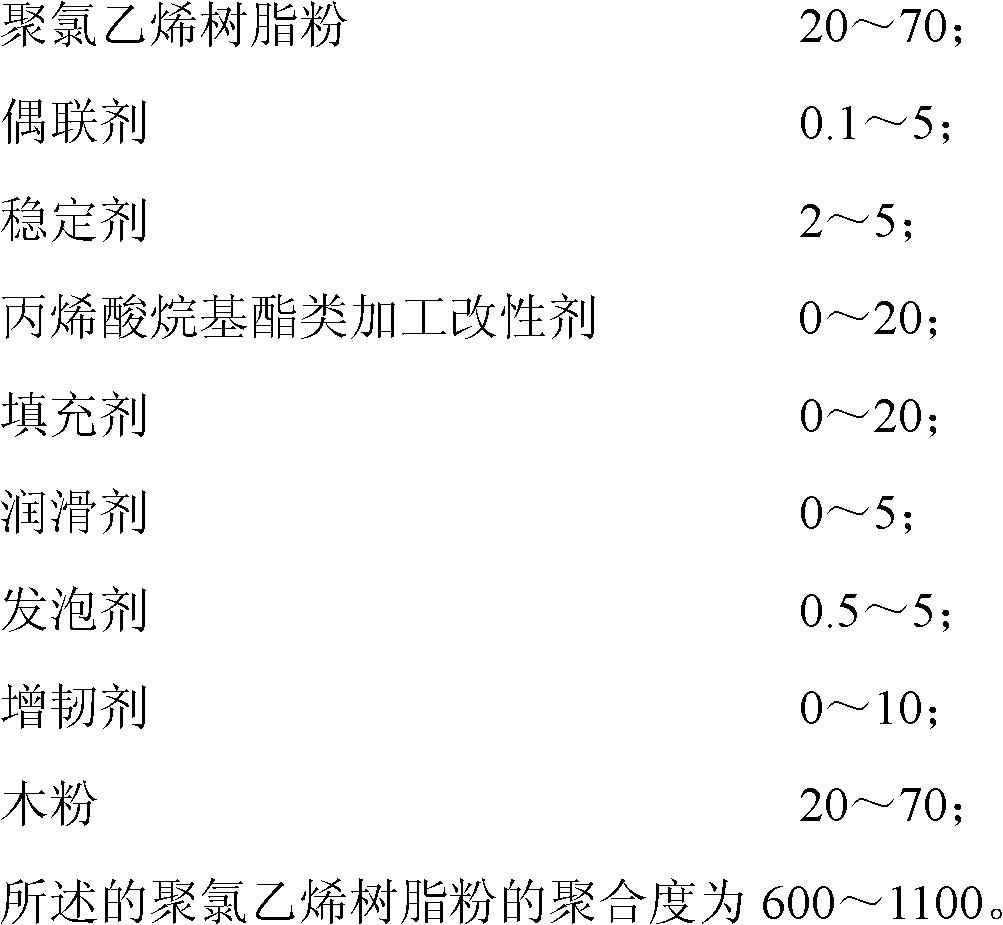

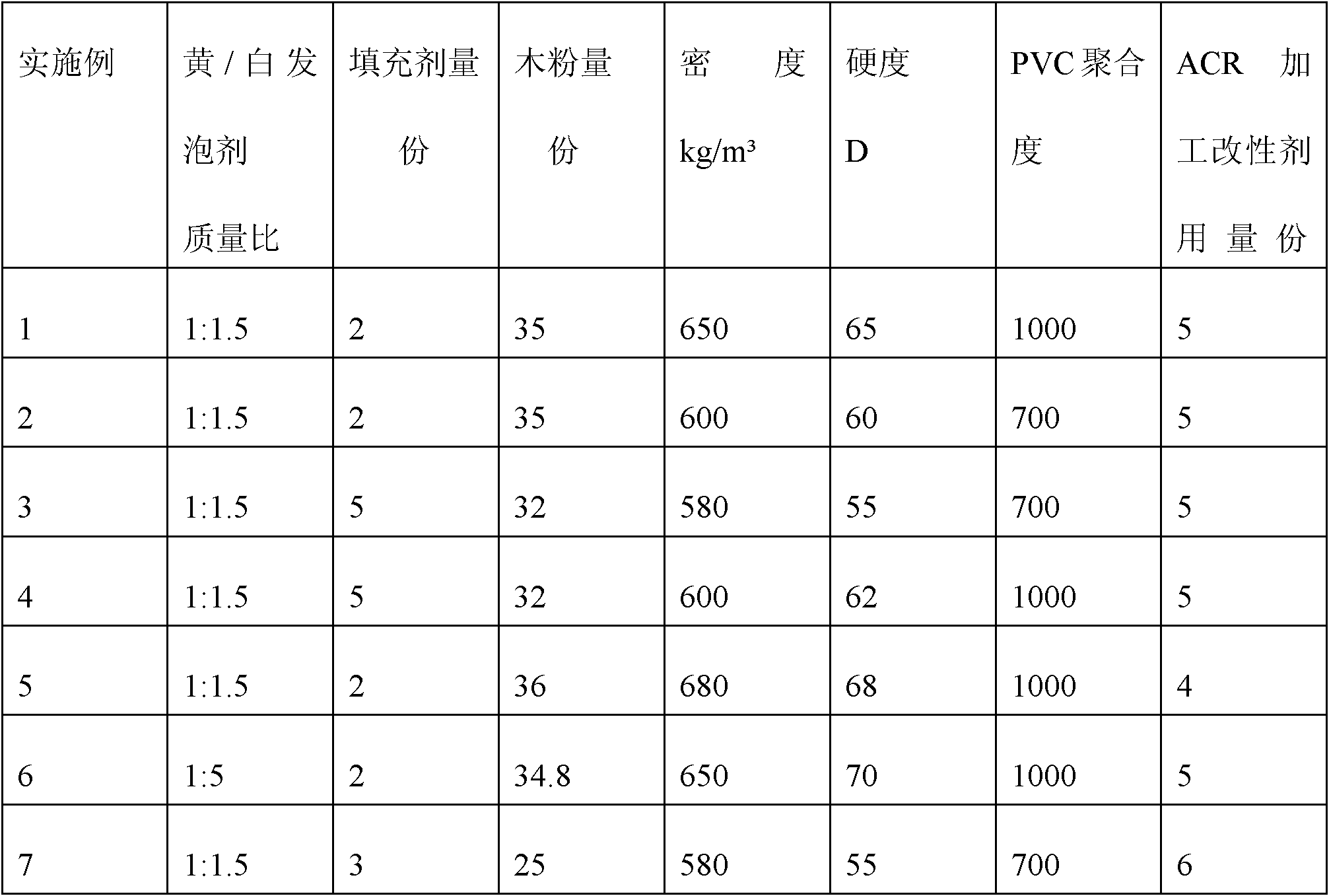

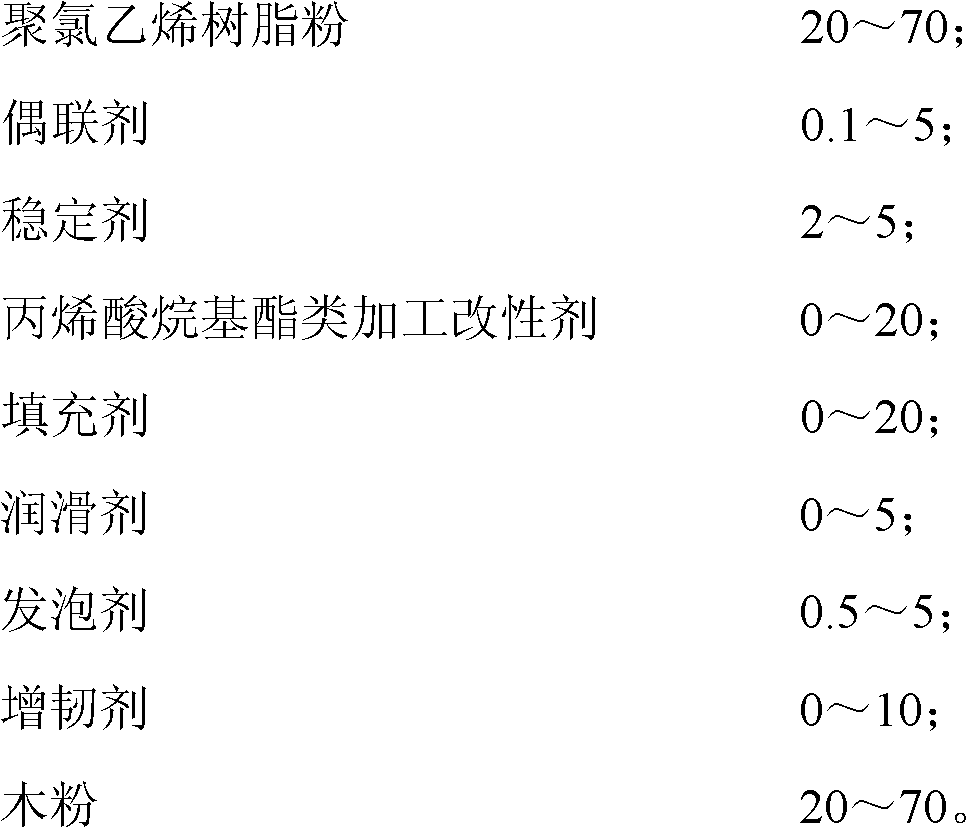

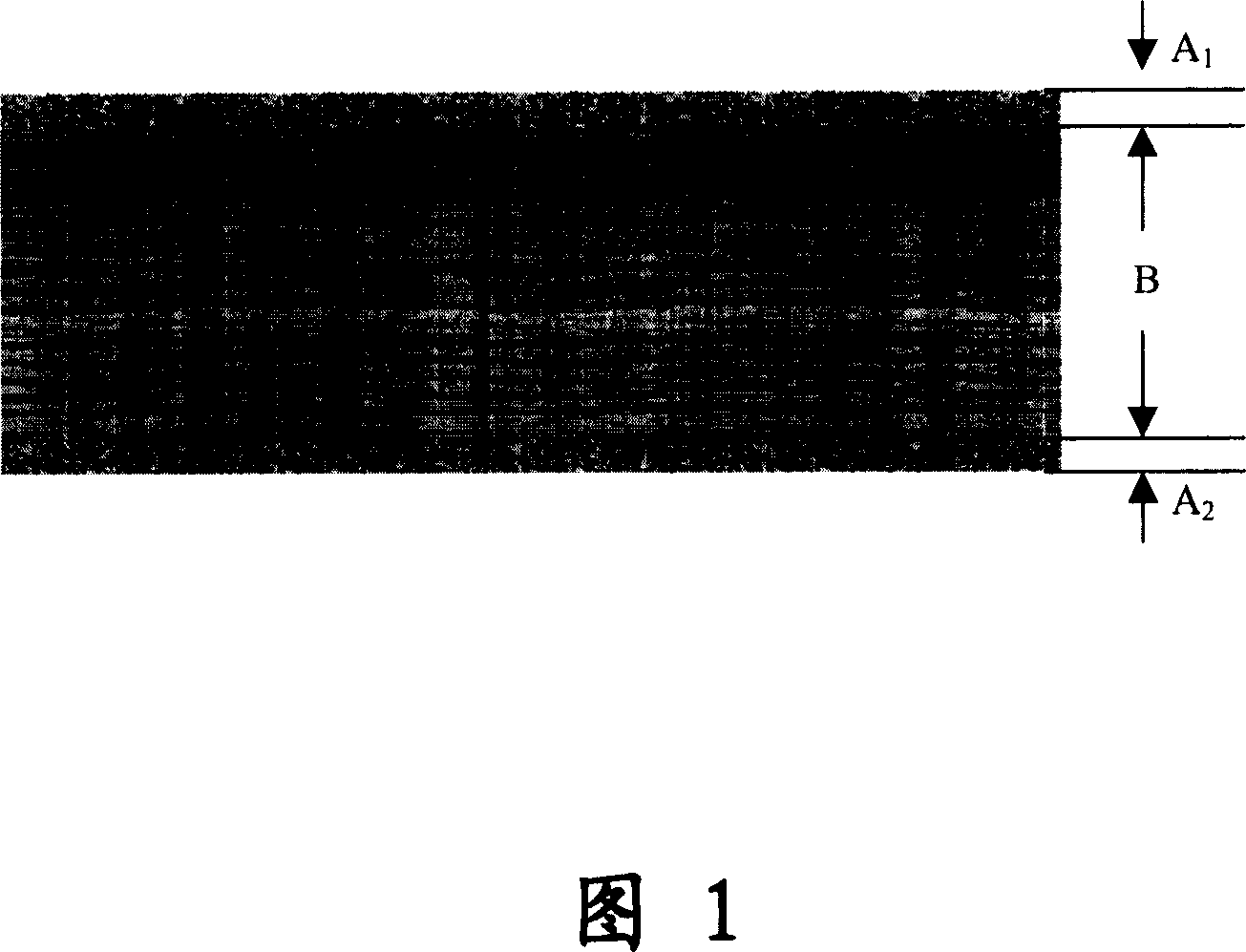

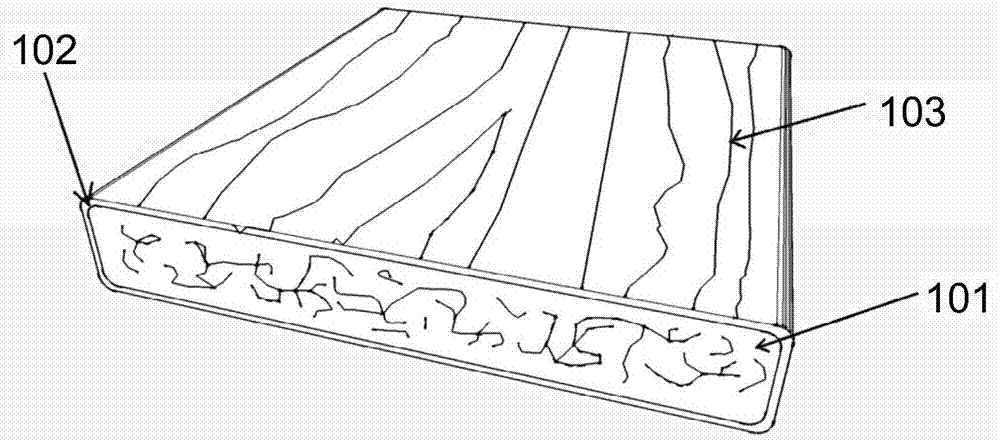

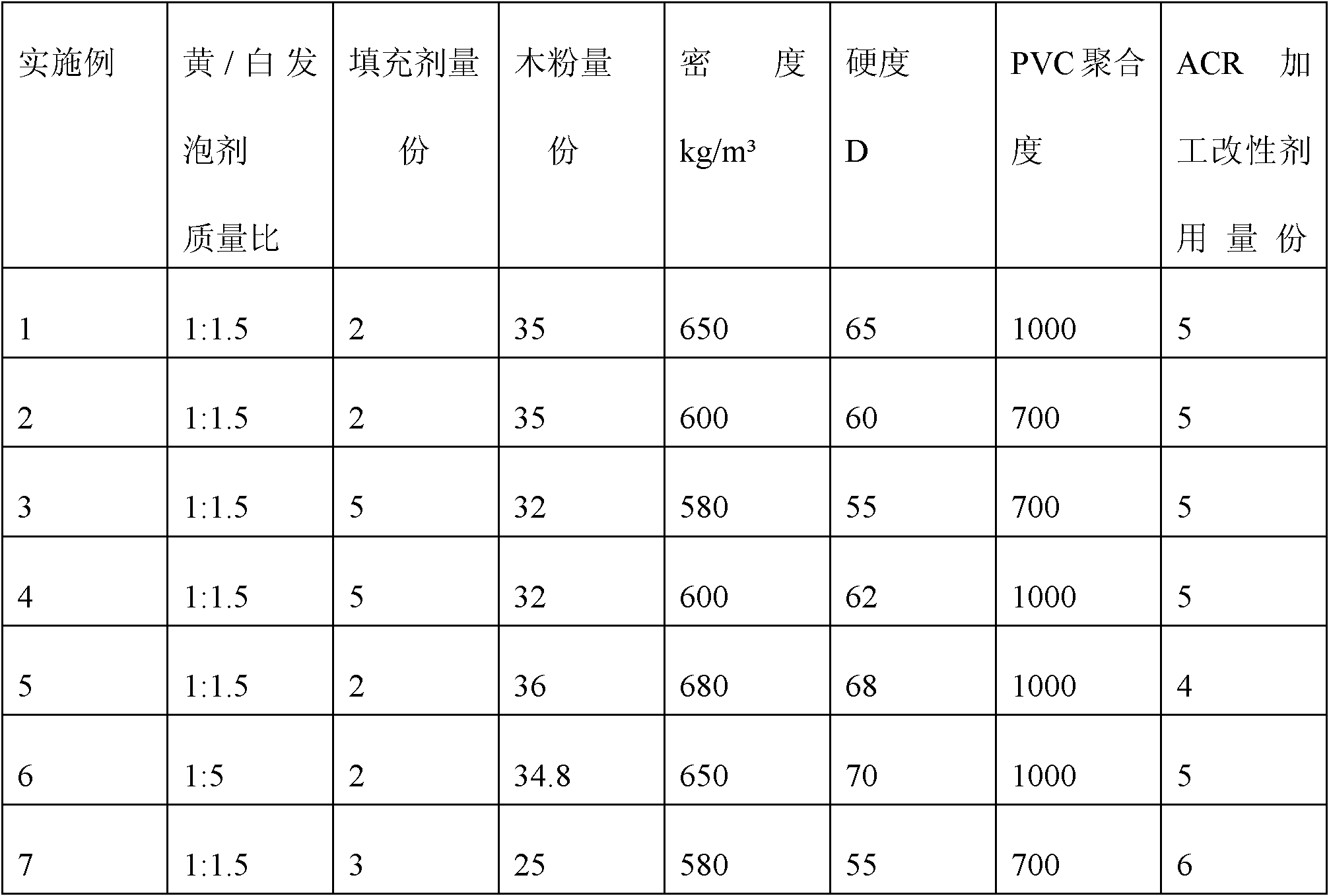

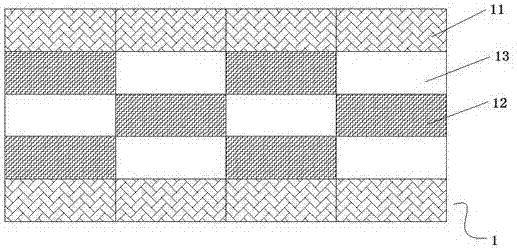

Polyvinyl chloride (PVC) wood-plastic board and preparation method thereof

ActiveCN102492242AImprove flame retardant performanceHigh smoke suppression effectPolyvinyl chlorideToughening

The invention relates to a polyvinyl chloride (PVC) wood-plastic board and a preparation method thereof, belonging to the technical field of PVC boards. The PVC wood-plastic board is composed of the following raw materials in parts by weight: 20-70 parts of PVC resin powder, 0.1-5 parts of coupling agent, 2-5 parts of stabilizer, 0-20 parts of alkyl acrylate processing modifying agent, 0-20 parts of filling agent, 0-5 parts of lubricant, 0.5-5 parts of foaming agent, 0-10 parts of toughening agent and 20-70 parts of wood flour, wherein the total weight parts of the raw materials are 100 parts. The PVC wood-plastic board has the bulk density being not more than 700kg / m<3>, and has good flame resistance and smoke suppression property, high hardness and strong wood feeling; and the same as log, the PVC wood-plastic board has the properties of being nailed, drilled, planed, stuck and the like, is smooth and fine in surface, is waterproof, corrosion-resistant, fireproof and mildewproof, is not eaten by worms and is pollution-free.

Owner:SHANDONG BODO PLASTICS CO LTD

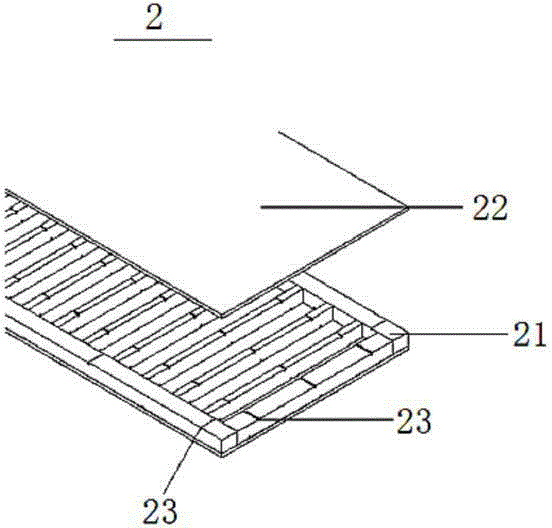

Novel floor and manufacturing method thereof

The present invention is one new type of floor board and its production process. The floor board is produced with calcite powder or limestone powder, granular waste PVC plastic, PVC resin and dibutyl ester or dioctyl ester in certain weight proportion, and through drying in a drying apparatus for 5-7 min, adding paraffin, stearic acid and other assistants in certain amount into the drying apparatus and drying for other 10-15 min, pelletizing in a pelletizer, extruding into hollow or solid floor board base in a floor board forming machine, cooling, cutting, blocking hole, tenoning, polishing, dedusting, and adhering floor film. The floor board has clear patterns, and is waterproof, fireproof and environment friendly.

Owner:吕富

Plastic wood composite material and preparation method

The invention relates to a plastic wood composite material which comprises the following raw materials in parts by weight: 15-30 parts of waste plastics, 70-85 parts of waste physical fibers, 1-5 parts of lubricant, 1-2 parts of tackifier, 2-5 parts of compatibilizer, 1-3 parts of anti-aging agent and 5-10 parts of flame retardant. The compositions are treated by procedures of mixing, stirring, extruding and pressure molding to obtain a finished product. In the invention, the waste plastics and the waste physical fibers are composited to form an advantageous plastic wood composite material which can be recycled by 100 percent, and has the advantages of low cost, good surface finish and good comprehensive properties such as the mechanical property, the heat resistance, the weatherability and the like.

Owner:常熟通江机械有限公司

Preparation method of anesthesia stem and plastic composite material

ActiveCN101081934AReduce extrusion resistanceImprove mobilityPlastic compoundingWood-plastic composite

The present invention discloses preparation process of composite material of hemp stalk and plastic. The composite material is prepared through mixing hemp stalk powder and mineral powder to obtain composite hemp stalk powder, extruding and pelletizing to obtain composite hemp stalk pellet, mixing with plastic, and pelletizing or extruding into product. The composite material is environment friendly, reusable and low in cost.

Owner:凌彩百川(新兴)科技有限公司

Wood flour putty and preparation process thereof

InactiveCN1962769AImprove mildew resistanceImprove water resistanceFilling pastesPolymer scienceEmulsion

The invention discloses wood powder putty and preparing method, which comprises the following parts: 100% white emulsion, 15-40% wood powder, 1-3% anti-fungus agent, 1-3% curing agent, wherein the fineness of wood powder is 300-1000 order. The putty possesses excellent painting effect, which is superior to calcium carbonate putty. The invention also provides wooden wares and manufacturing method with the wood powder putty.

Owner:山东堡珍家居板材有限公司

Lignin/microcrystalline cellulose complex, reinforced polylactic acid 3D printing material and preparation method thereof

ActiveCN109054323AGood compatibilityGood thermoplasticityAdditive manufacturing apparatusPlasticizerMicrocrystalline cellulose

In order to overcome the defects and shortcomings of poor compatibility between cellulose and a polymer matrix, frequent hole blocking in printing, difficulty in printing of lignin / polymer 3D printingmaterial and the like, common cellulose is subjected to acidolysis by using an inorganic acid solution; then the cellulose is modified by a silane coupling agent and lignin in an alcohol solution, toobtain the lignin / microcrystalline cellulose compound. The compound serving as a reinforcing material and PLA serving as a base material are blended with an inorganic nano material, a toughening agent, a plasticizer and the like, and the reinforced polylactic acid 3D printing material with good mechanical property and 3D printing property is prepared by melt extrusion blending and wiredrawing moulding. The mechanical property of the 3D printing material provided by the invention is better than that of common polylactic acid printing materials; according to a test by an FDM type 3D printer, the 3D printing material is completely applicable to the FDM rapid prototyping technology, and the printed product has high glossiness and wood-texture appearance and can be applied to the printing of furniture, toys, artwork, model design and the like.

Owner:SOUTH CHINA AGRI UNIV +1

Wood-grain-imitated co-extruded plastic-wood profile and preparation method thereof

ActiveCN104723635AImprove anti-corrosion performanceImprove aging resistanceSynthetic resin layered productsSurface layerAging resistance

The invention provides a wood-grain-imitated co-extruded plastic-wood profile. The wood-grain-imitated co-extruded plastic-wood profile comprises a surface layer and a base material, wherein the adding amounts of plastic and a functional aid in the surface layer are more than the adding amounts of the plastic and the functional aid in the base material, so that the cost is favorable to be reduced; the surface layer is subjected to color adjustment by virtue of a main color and a secondary color (a third color can be increased according to requirements), so that the effects of the color shade and the layer variability of the surface layer can be well achieved. The invention further provides a preparation method of the wood-grain-imitated co-extruded plastic-wood profile. The preparation method comprises the processes of granulation, synchronous extrusion and surface treatment. According to the preparation method, surface layer particles including main color particles and secondary color particles are respectively granulated and are uniformly mixed for co-extruding the surface layer, and the surface layer is subjected to surface treatment in a 'hot plate and cold roller' manner. The co-extruded plastic-wood profile prepared by virtue of the preparation method is low in cost, excellent in water resistance, corrosion resistance and aging resistance and durable, further has the grains, color gradation and texture of imitated and natural wood, so that the user experience is improved.

Owner:湖南格林美资源利用有限公司 +2

Wood-plastic foam rise, steel tube combined pipes and formula thereof

InactiveCN101082387AImprove flame retardant performanceImprove waterproof performanceElongated constructional elementsFiberFoaming agent

The invention disclose a kind of wood plastic foaming, steel pipe combination and its formula which make up with PVC, wood flour or plant fiber, composite stabilizer, chlorinated (CPE), acrylic acid anti granule (ACR-401), AC foaming agent, foaming regulator and titanium dioxide. It uses combination structure of wood plastic foaming pipe and steel pipe. The invention can passive crack tip and effective prevent the expansion of crack by uniform distribution good microporous structure which foaming from pipe. The product can do the surface treatment on wood flour make it can be infiltration by PVC resin, greatly improve the compactness of production, can process factory production. The invention has low manufacturing cost, convenient installation, and strong flame retardant, strong waterproofness, and corrosion resistance, strong wood sense, non-toxic and harmless. The product is fidelity and prettiness, accord with long-term notional policy of saving type society construction, realize instead steel by plastic to save resource.

Owner:上海奔奔木塑新材料有限公司

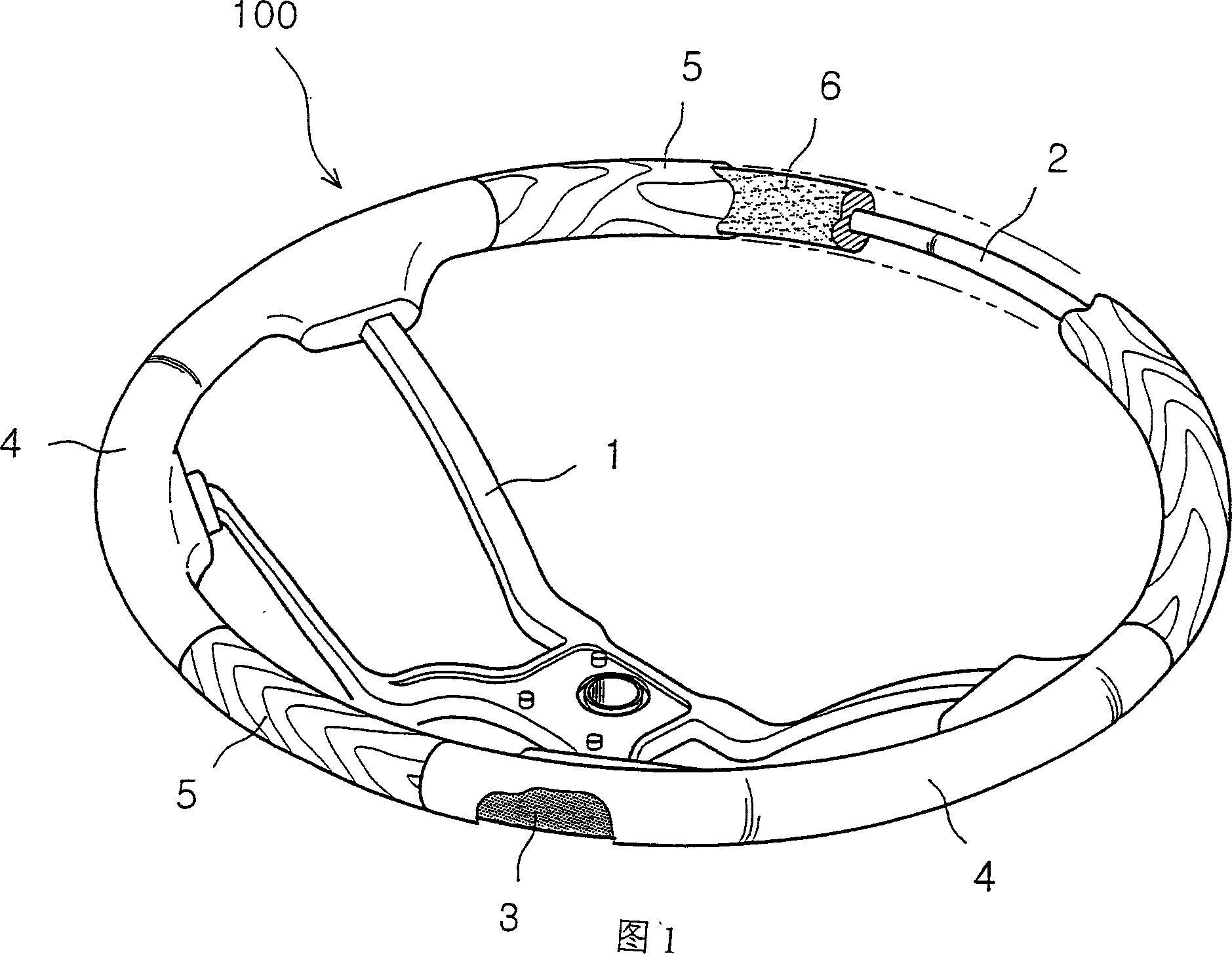

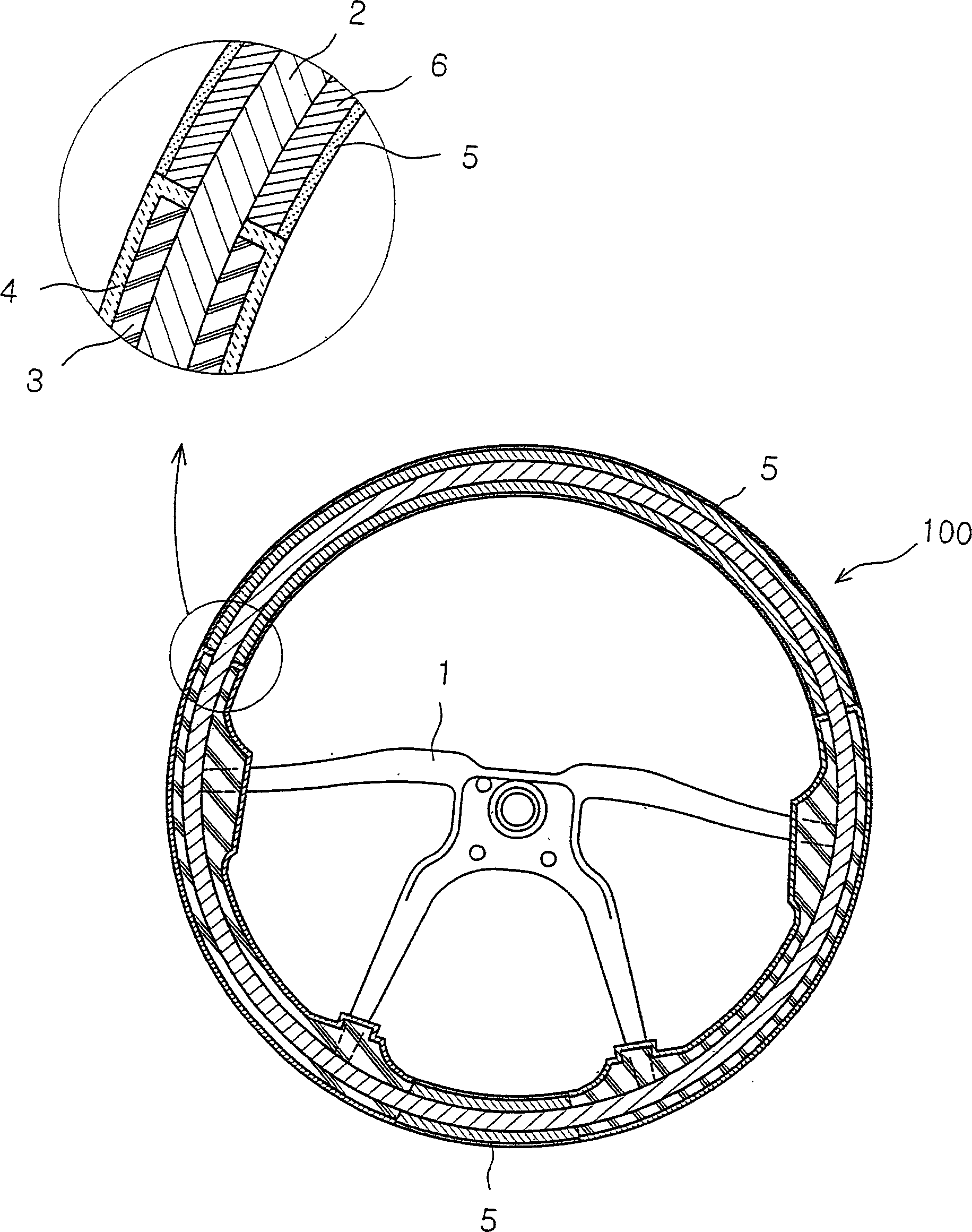

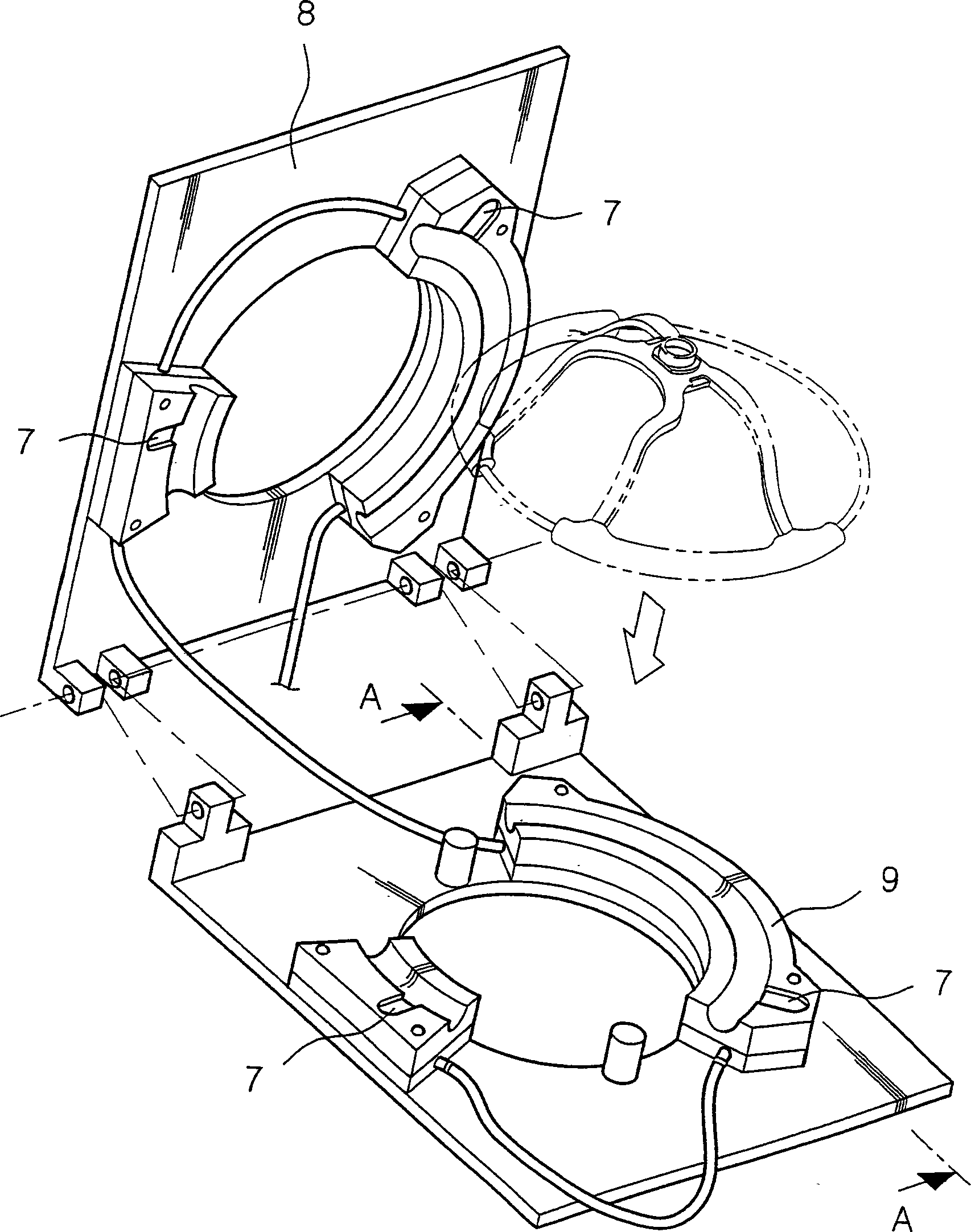

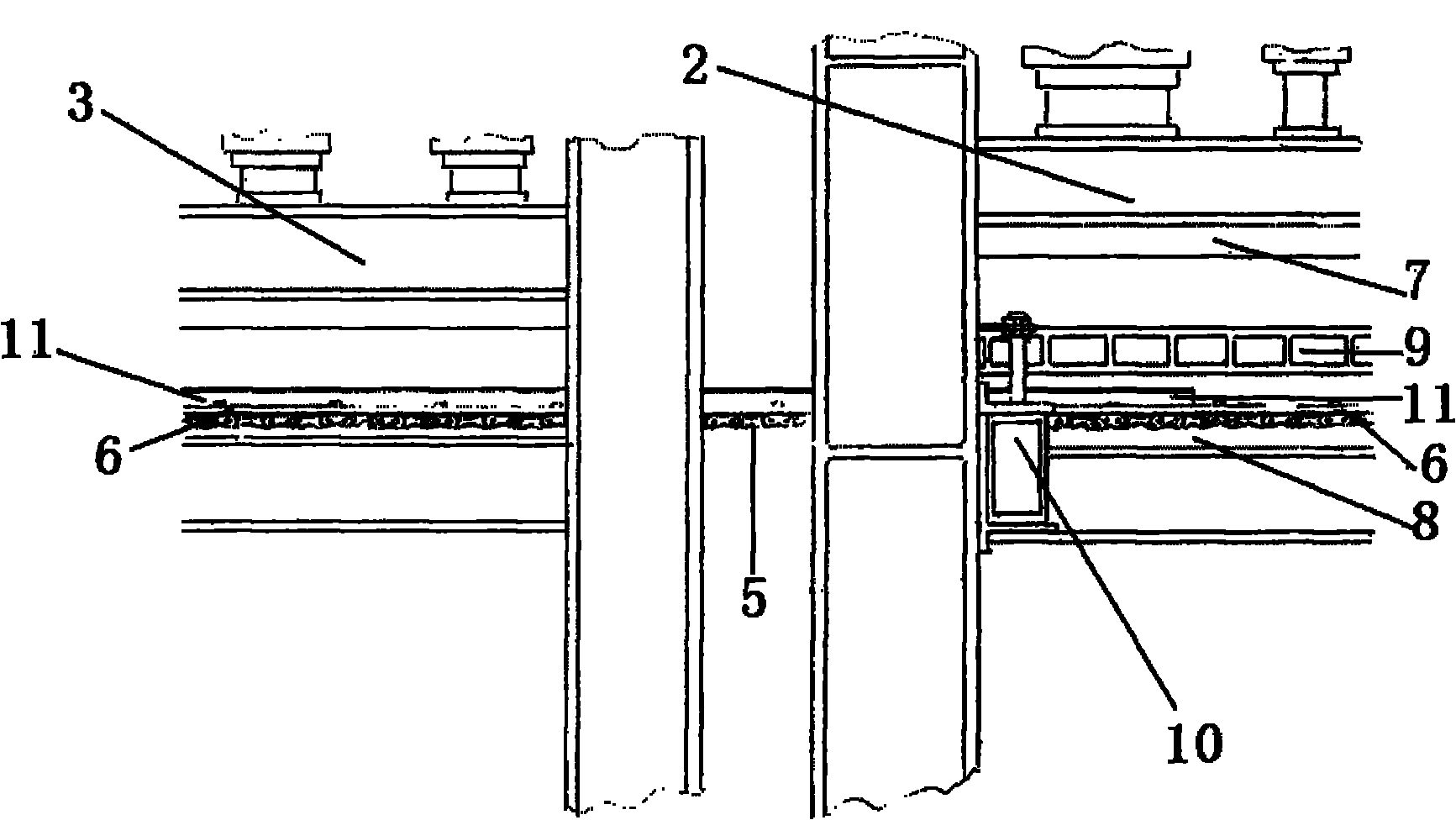

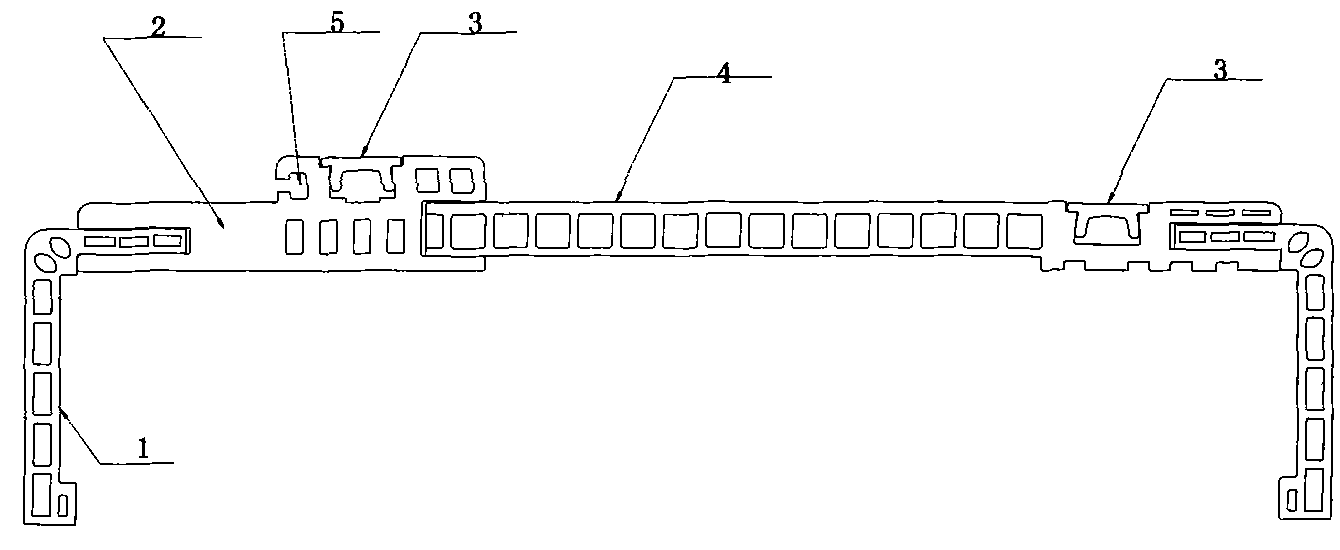

Wood grain steering wheel for car and its making method

The invention discloses a steering wheel for automobiles partially molded from a wood-grain film and a manufacturing method thereof. In particular, it relates to a steering wheel for automobiles which is partly integrally molded with non-foamed polyurethane resin and molded with a wood-grained film, thereby having a good woody feel, and a wood-grained film molded with non-foamed polyurethane resin. The resin part is molded to improve the adhesion of the film to the manufacturing method of the steering wheel of the car. The manufacturing method of the automobile steering wheel includes 1. mixing raw materials; 2. installing the steering wheel between the upper and lower metal molds and connecting the upper and lower metal molds to prepare for non-foaming molding; 3. injecting the mixed raw materials to make non-foaming polyurethane resin molding And take out the product; 4, remove the burr (burr) on the product and clean it; 5, dry and grind the surface to remove the pores; 6, fill the surface pores and re-dry and grind the surface to remove the pores and other six processes.

Owner:李基何 +1

Biodegradable coffee-grounds vine-imitating material

The invention discloses a biodegradable coffee-grounds vine-imitating material. The biodegradable coffee-grounds vine-imitating material is prepared from the following raw materials in parts by weight: 40-50 parts of polylactic acid, 5-15 parts of polyadipate / butylene terephthalate, 20-40 parts of modified coffee grounds, 5-15 parts of nucleator, 0.5-1 part of crystallization accelerant, 2-5 partsof compatibilizer, 0.1-5 parts of melt strength strengthener, 0.5-2 parts of lubricant, 0.1-0.6 part of anti-aging agent, 0.1-0.6 part of antioxidant and 0.1-0.6 part of anti-ultraviolet agent. According to the biodegradable coffee-grounds vine-imitating material, the vine-imitating material is prepared by adopting the coffee grounds, so that a large amount of waste residues generated by a coffeeindustry are put into effective use, meanwhile, odors of original plastic imitated vines are effectively improved, and the woody sense of the vine-imitating material is enhanced; and the traditionalpolyethylene and polyvinyl chloride are replaced with a biodegradable material, i.e., the polylactic acid, so that the generation of environmental pollution is reduced, and protection of ecological environments is facilitated.

Owner:ZUNYI MEDICAL UNIVERSITY

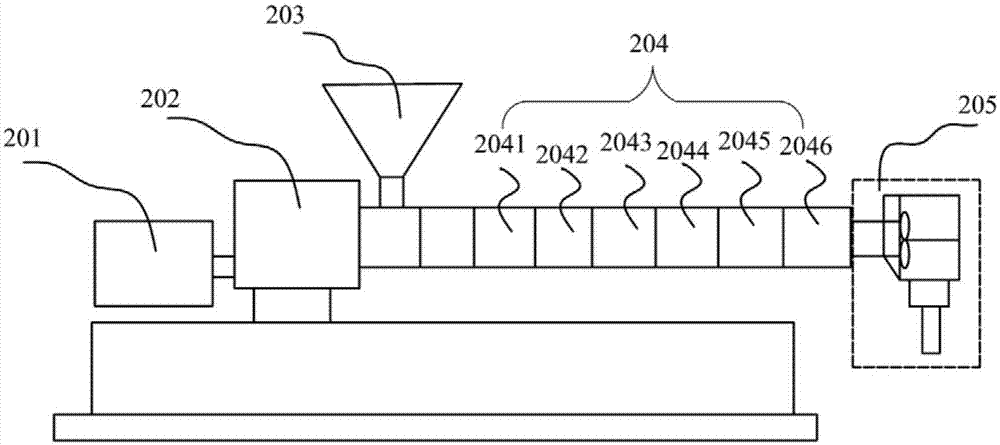

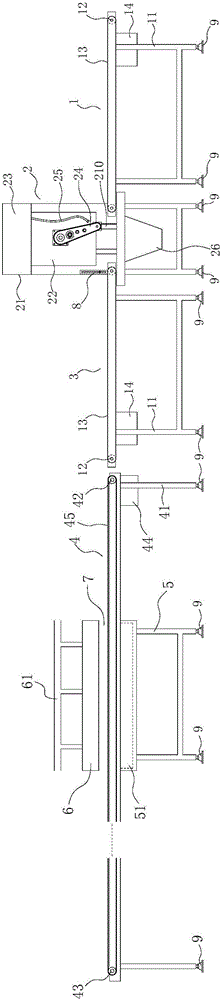

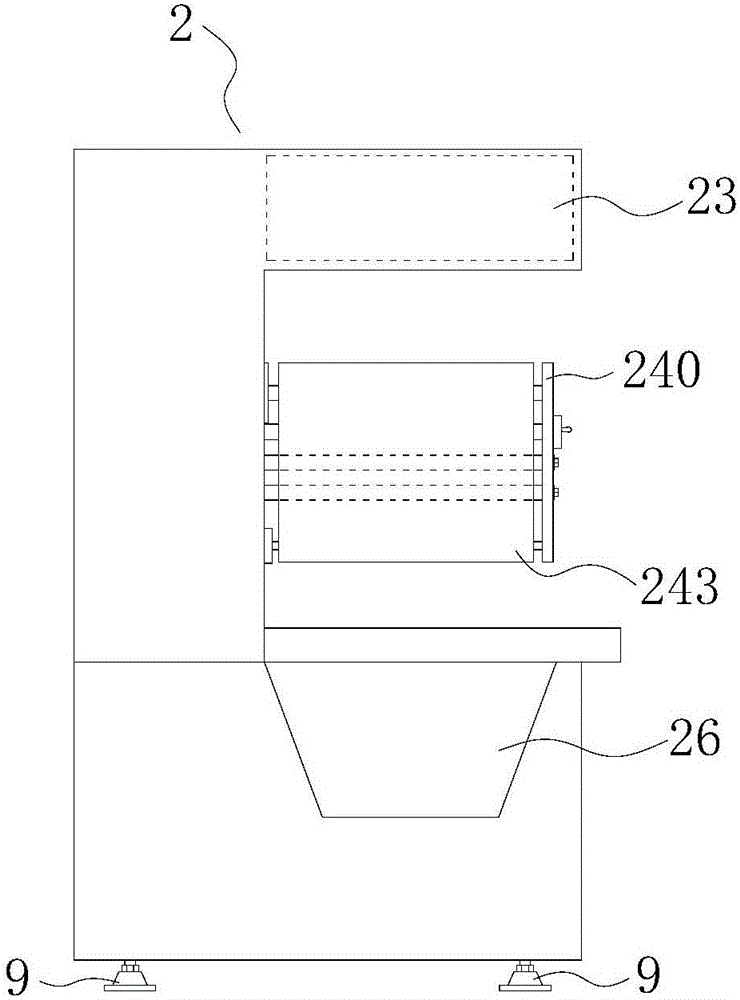

Wood-plastic mould pressing production line

ActiveCN101879741ASave energyImprove efficiencyWood working apparatusFlat articlesProduction lineTransfer system

The invention discloses a wood-plastic mould pressing production line, comprising a feeder, a hot-press forming device, two refrigeration shaping devices and a transfer system, wherein the hot-press forming device is provided with an upper heating plate and a lower heating plate; a liftable single mould frame is arranged between the two heating plates; the two refrigeration shaping devices are respectively arranged at the two sides of the hot-press forming device and are connected by the transfer system; and the transfer system comprises a conveying chain and two supporting plates installed on the conveying chain, one supporting chain is arranged between the lower heating plate of the hot-press forming device and the single mould frame, and the other supporting plate is arranged on one of the two refrigeration shaping devices. The wood-plastic mould pressing production line in the invention adopts single heat and double cold configuration so as to enable hot-press forming and refrigeration shaping to operate simultaneously; and in addition, the mould of the single mould frame only takes part in the hot-press forming and drops out of the refrigeration shaping, and heating is never required after primary preheating. Therefore, the wood-plastic mould pressing production line can be applied in producing wood-plastic plates with high xylon content, saves energy, improves efficiency, lowers production cost and equipment cost and has strong product xylon texture.

Owner:广西福园剑麻股份有限公司 +1

Plastic-wood composite panel

InactiveCN105218977AImprove impact resistanceHigh tensile strengthChemical recyclingGlass fiberFoaming agent

The invention discloses a plastic-wood composite panel. The plastic-wood composite panel comprises the following raw materials in parts by weight: 65-80 parts of polyvinyl chloride resin, 30-42 parts of wood powder, 8-15 parts of a silicon fire retardant, 5-7 parts of a plasticizer, 2-4 parts of a foaming agent, 8-12 parts of glass fiber, 1-3 parts of a lubricating agent and 2-4 parts of a stabilizer. Compared with traditional plastic-wood composite panels, the scheme has the advantages that the plastic-wood composite panel has relatively high tenacity, rigidity and elasticity and good fireproof performance, is applicable to high temperature and humidity areas, is firm and durable and is long in service life, and the shock resistance and the tensile strength of the panel are improved; furthermore, the plastic-wood composite panel has the advantages of environmental friendliness, no pollution, strong wood texture, smooth and fine surface, no granular sensation and the like.

Owner:SHANGHAI CHANGLI INFORMATION TECH CO LTD

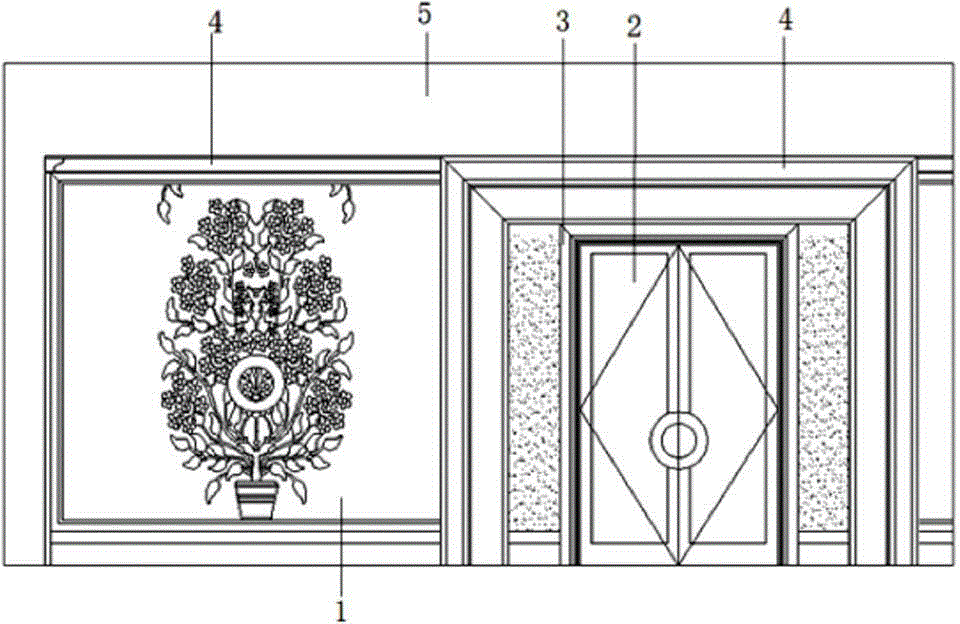

Ecological wood plastic suit door pocket

InactiveCN102011531AAvoid deformationImprove flame retardant performanceWindow/door framesSealing arrangementsGreen environmentPolymer resin

The invention discloses a door pocket, especially an ecological wood plastic suit door pocket, comprising a decorative line, a door stop and an adjusting plate. The ecological wood plastic suit door pocket is special in that: the decorative line, the door stop and the adjusting plate are manufactured by mixing wood super-thin silts with a polymer resin, and then molding. The ecological wood plastic suit door pocket has the advantages of having characteristics of the wood material and the plastic; the produced product has true wood imitation effect; the glue is not used in raw material and producing process to bond so as not to generate harmful substances such as formaldehyde, benzene, ammonia and trichloroethylene, and the like. The ecological wood plastic suit door pocket is a green environment-friendly material for replacing the traditional wood.

Owner:山东避风港门业有限公司

High-strength wood-plastic composite floor

The invention discloses a high-strength wood-plastic composite floor comprising the following components in parts by weight: 100 parts of PVC (Polyvinyl Chloride) resin, 50-75 parts of a PP (Propene Polymer) return material, 120-150 parts of wood flour, 18-32 parts of talcum powder, 12-16 parts of kieselguhr, 2-6 parts of an anti-ageing agent, 20-30 parts of microlite, 3.6-4.5 parts of a plasticizer, 1-3 parts of a heat stabilizer, 0.7-1.5 parts of a lubricating agent, 1-4 parts of an antioxidant and 1-5 parts of an antibacterial agent. The composite floor disclosed by the invention is high in strength, strong in wood texture, smooth in surface, free of formaldehyde, free of water absorption, mildew-proof, antibacterial, and free of deformation or warping, and can be widely applied indoors and outdoors.

Owner:孙宝林

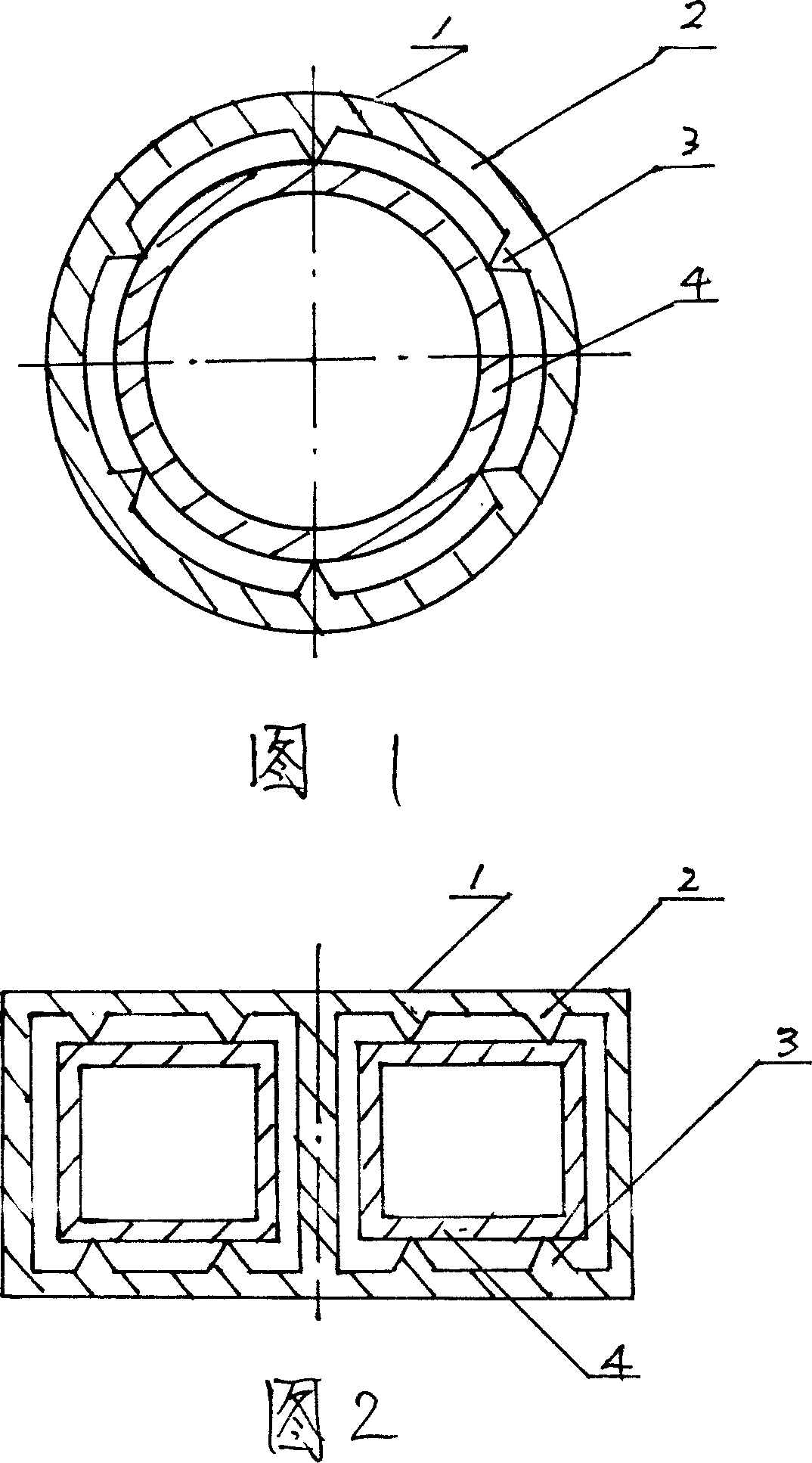

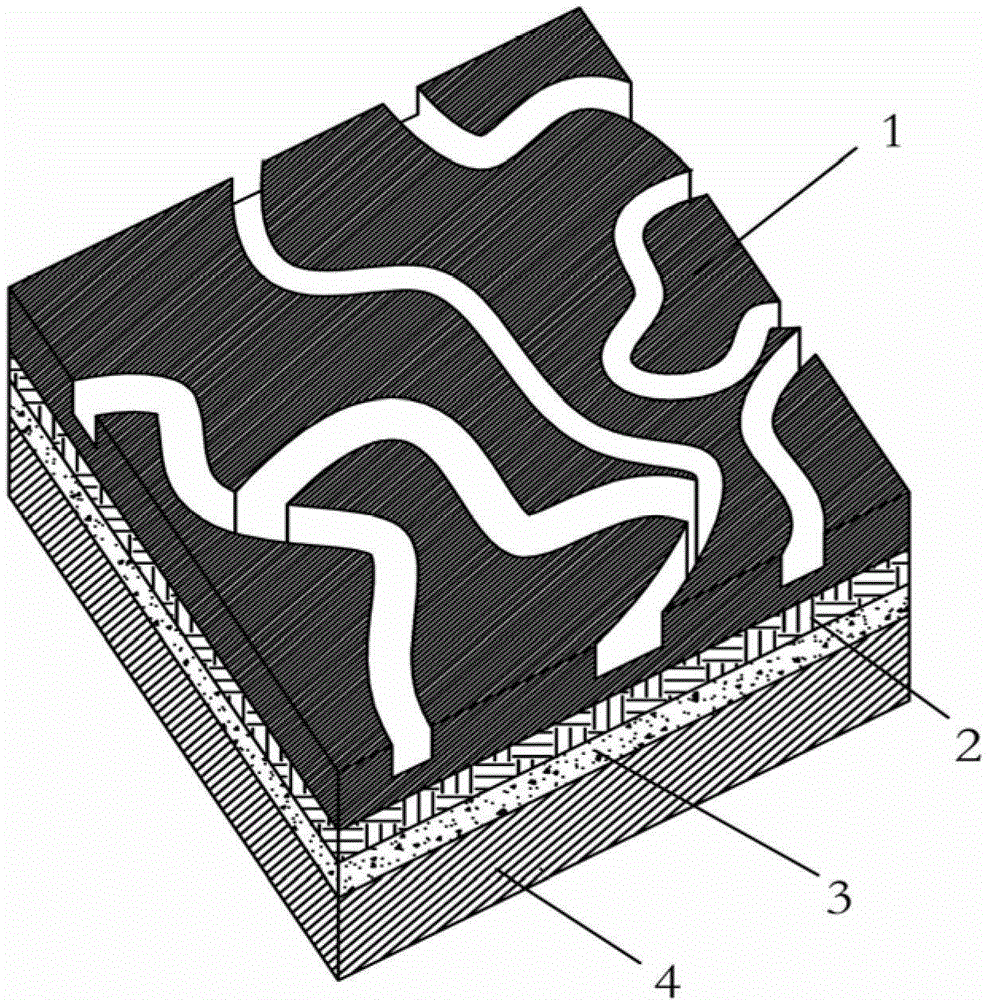

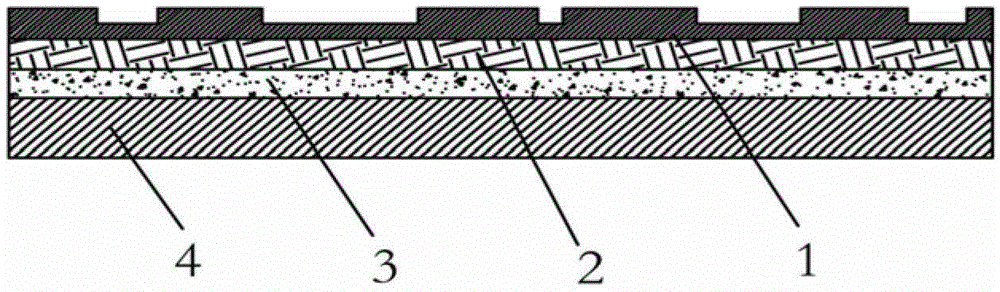

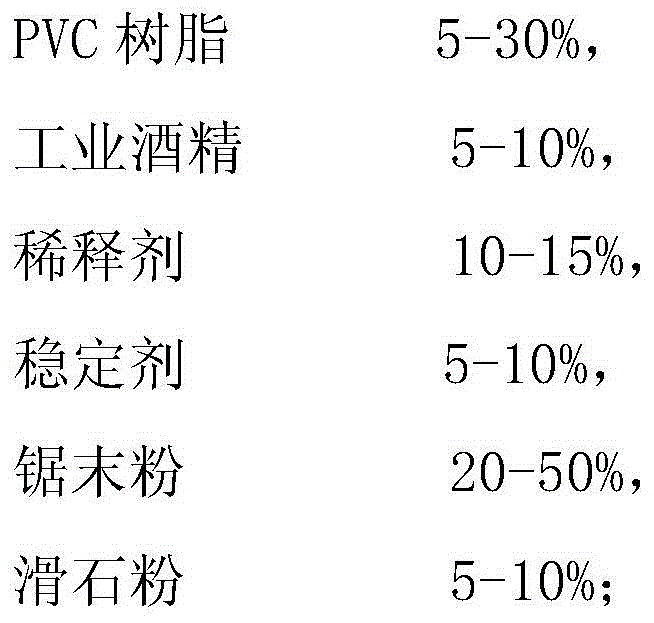

Embossed plate and its forming process

ActiveCN103306449BImprove plasticityEasy to shapeCovering/liningsSynthetic resin layered productsGlass fiberWood plank

The invention discloses a high-intensity complex fireproof anaglyph board and the manufacturing method thereof. The anaglyph board comprises an anaglyph layer (1), a bonding layer (2), a fireproof layer (3) and a baseplate (4), wherein the anaglyph layer comprises the following ingredients in weight percentage: PVC resin 5-30, industrial alcohol 5-10, thinner 10-15, stabilizer 5-10, saw dust 20-50, and talcum powder 5-10; the bonding layer (2) is glass fiber fabric; the fireproof layer (3) is thermosetting resin impregnated paper high pressure laminate or chlorine oxygen magnesium fireproof board; and the baseplate (4) is wood board or gypsum board. The anaglyph board provided by the invention has a good plasticity and convenience in formation, and is free from deformation or cracking under natural condition, so that the over-all structure of the product is hard and firm, and the product appearance has a better stereo perception; the manufacturing process is simple, is free from the 'three pollutions'; and the anaglyph board has the functions of fire prevention, moisture prevention and corrosion prevention.

Owner:JIANGSU JIFU NEW MATERIAL

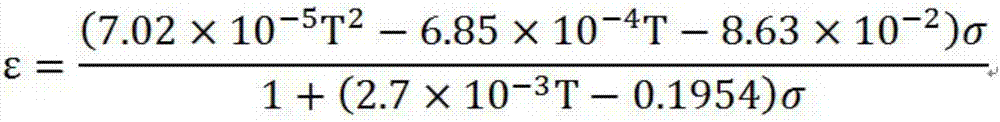

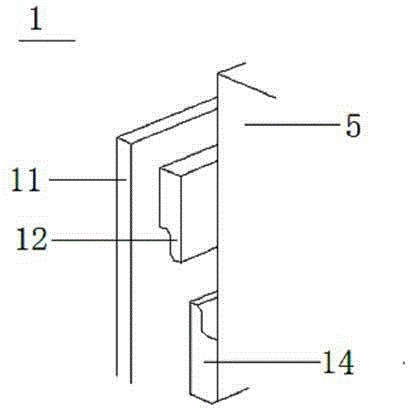

Wood fiber reinforced polyvinyl chloride imitation solid-wood cabinet door panel and manufacturing method thereof

The invention provides a wood fiber reinforced polyvinyl chloride imitation solid-wood cabinet door panel and a manufacturing method thereof. The method comprises the following steps: spraying atomized phosphoric acid to wood fibers while stirring to obtain phosphorylated wood fibers; in sequence spraying a silane coupling agent and melamine resin to the phosphorylated wood fibers and light calcium carbonate respectively while stirring, and drying to obtain the wood fibers and the light calcium carbonate which are both coated by melamine resin; mixing wood fibers coated by PVC resin, foaming agents, calcium-zinc stabilizers, chlorinated paraffin, dioctyl phthalate, stearic acid, and the melamine resin and the melamine resin coated light calcium carbonate to obtain a mixture; (5) successively carrying out kneading and extrusion, open-milling tabletting, film lamination on the upper side and lower side, mould pressing of embossed patterns, cooling shaping, cutting and trimming and periphery closing on the mixture. The cabinet door panel manufactured by the method is good in flame retardance and fire proofing, and high in content of the wood fibers and mechanical strength.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Highly-weatherable allochroic synthetic wood plastic section bar and preparation technology thereof

InactiveCN103289276AStrong wood feelingSimple production processSynthetic resin layered productsEngineeringInorganic pigments

The invention discloses a highly-weatherable allochroic synthetic wood plastic section bar. The raw material of the plastic section bar is obtained through extruding mixed resin particles and an inorganic pigment, and the mixed resin particles are composed of ASA resin particles and ABS resin particles. The disadvantages of the prior art are overcome in the invention, the weatherable allochroic synthetic wood plastic section bar has a bright color and pattern for a long term, can be widely used in floors, window frames, furniture and guardrails, and has the advantages of strong wood sensation, synthetic wood texture appearance, and simple production technology.

Owner:ANHUI MEILUO BUILDING MATERIALS

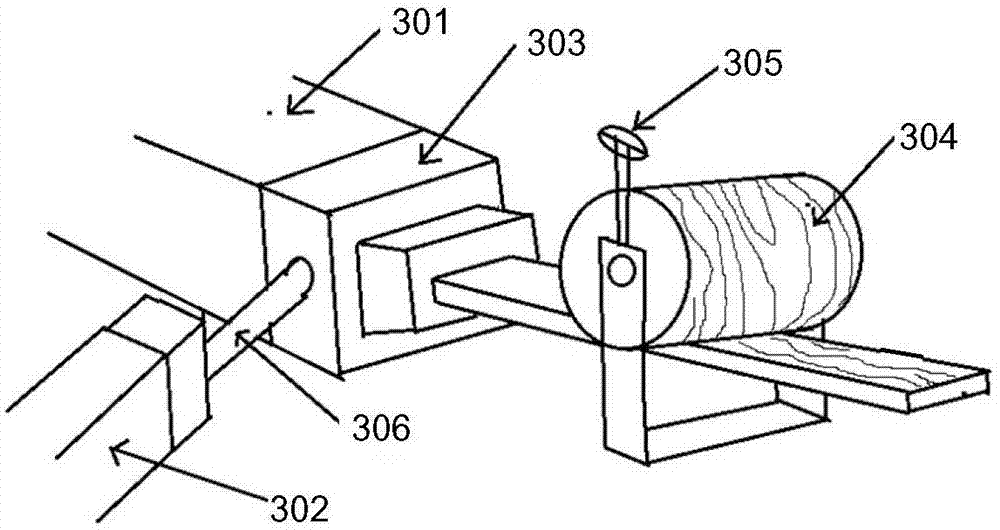

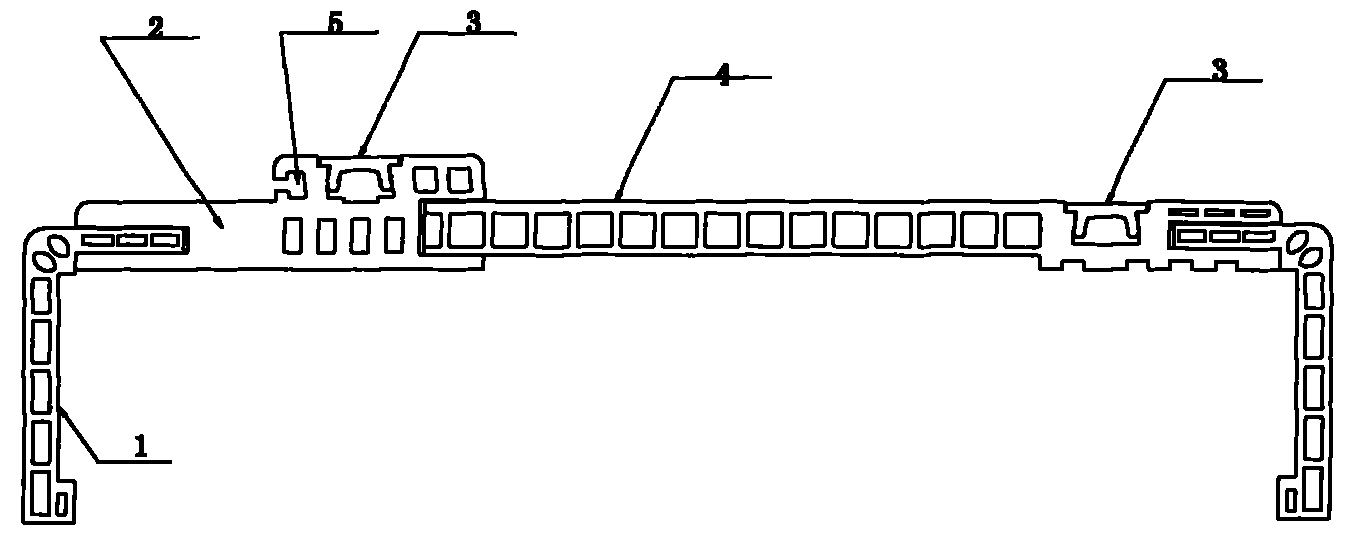

Profile surface hand-feel wood grain generating device

ActiveCN106000806AImprove woodinessStrong wood feelingPretreated surfacesCoatingsAgricultural engineeringUltimate tensile strength

The invention discloses a profile surface hand-feel wood grain generating device. The profile surface hand-feel wood grain generating device comprises a profile input mechanism, an imitation wood grain rolling mechanism, a profile output mechanism, a high-temperature curing and transmitting mechanism, a material collection frame and a heating device, wherein one end of the imitation wood grain rolling mechanism is connected to the profile input mechanism; the other end of the imitation wood grain rolling mechanism is connected to the profile output mechanism; the other end of the profile output mechanism is connected to the high-temperature curing and transmitting mechanism; the material collection frame is arranged at the lower end of the middle part of the high-temperature curing and transmitting mechanism; the heating device is arranged at the upper part of the high-temperature curing and transmitting mechanism; the imitation wood grain rolling mechanism comprises a machine body, a feeding device, a powder storage box, a rolling device, a powder spraying hose pipe and a powder collection hopper. The profile surface hand-feel wood grain generating device is reasonable in structure, low in labor intensity, high in production efficiency and strong in profile surface wooden feeling.

Owner:浙江富丽华铝业有限公司

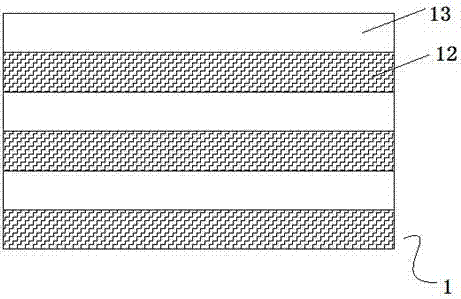

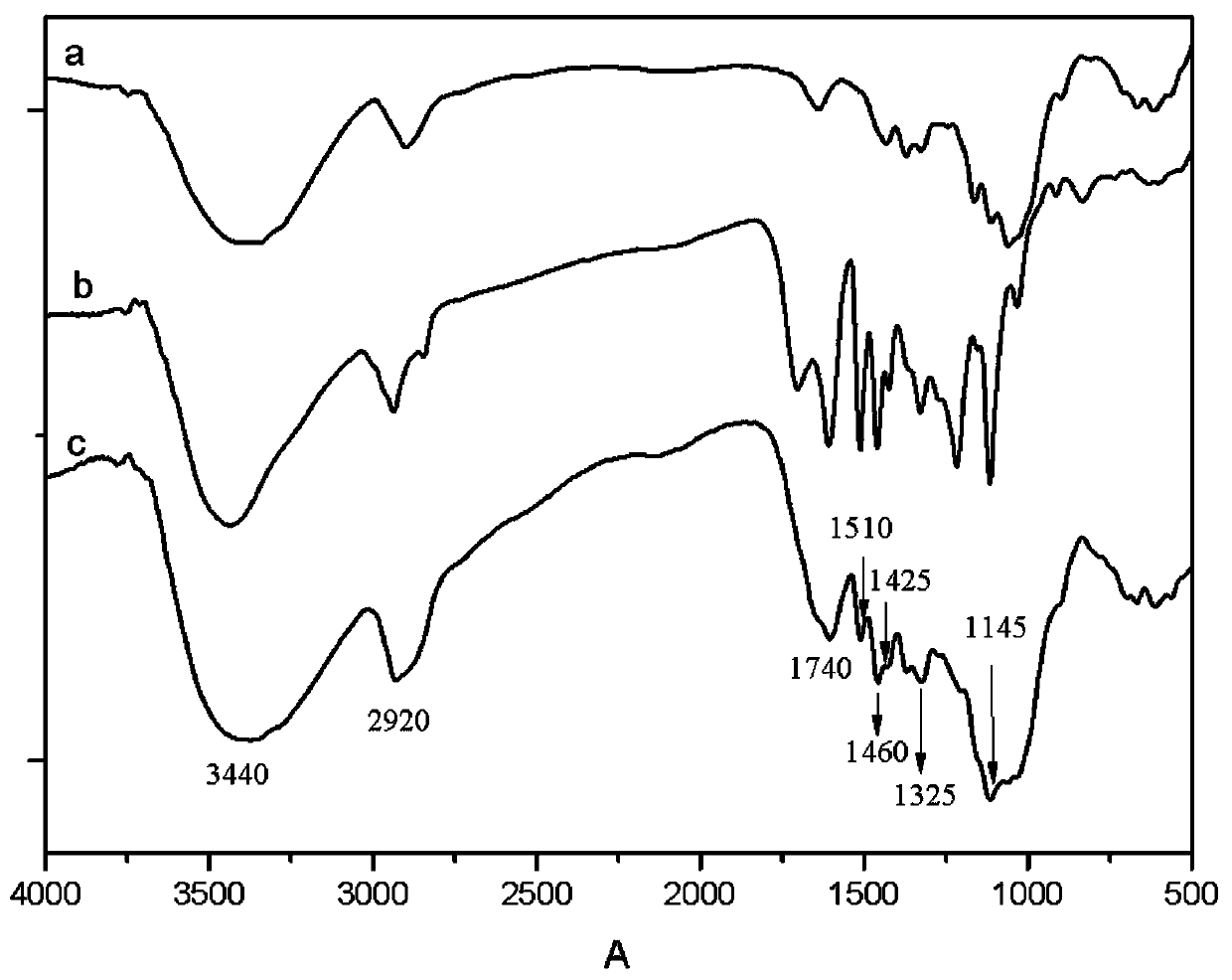

An outdoor weather-proof engineering material based on fast-growing grass and a preparing method thereof

ActiveCN107471771AGood compatibilityStrong wood feelingSynthetic resin layered productsLaminationLayered structureHigh-density polyethylene

An outdoor weather-proof engineering material based on fast-growing grass is disclosed. The engineering material has an alternant layered structure. The layered structure includes 3 layers or above, and includes odd-number layers and even-number layers. The odd-number layers are pennisetum alopecuroides (L.) Spreng. The even-number layers include polylactic acid wood wool and wood composite particles. The polylactic acid wood wool includes 20-30% by weight of wheat straw powder and 70-80% by weight of polylactic acid. The wood composite particles include 50-55% of high density polyethylene (PE), 35-40% of wheat straw powder, 3-10% of stearic acid and 2-5% of an ethylene-vinylacetate copolymer (EVA). The invention also discloses a preparing method of the outdoor weather-proof engineering material based on fast-growing grass. The objective of the invention is to provide the outdoor wood engineering material having high weatherability, high apparent hardness, good static bending intensity and good processing / etching properties and the preparing method thereof, aiming at defects of present artificial panels and preparing processes thereof.

Owner:吴仪

Integrated production process of fixedly-assembled furniture

InactiveCN103061461AIncreased speed of on-site installationReduce some inevitable defects of on-site assemblyCovering/liningsWindow/door framesIndustrial engineeringManufacturing engineering

An integrated production process of fixedly-assembled furniture includes first conducting accurate measurement of upper thread and elevation line according to onsite basic level, recording size on the wall face to serve as an accordance for review and onsite assembly and transmitting drawing size resources to a factory to place an order and produce the furniture after a design party, a decoration party and an owner party confirm. Various wall face veneer panels, doors, door pockets, wire frames and furniture are produced in the factory according to the drawing and are transmitted to the construction site for assembly. The process can reduce onsite construction, is less in pollution and capable of saving cost due to unified production in the factory, shortens erection time, and is stable in quality. The integral style is coordinated in unified mode.

Owner:SHANGHAI TAIYI ENTERPRISE

Polyvinyl chloride (PVC) wood-plastic board and preparation method thereof

ActiveCN102492242BImprove flame retardant performanceHigh smoke suppression effectPolyvinyl chlorideToughening

The invention relates to a polyvinyl chloride (PVC) wood-plastic board and a preparation method thereof, belonging to the technical field of PVC boards. The PVC wood-plastic board is composed of the following raw materials in parts by weight: 20-70 parts of PVC resin powder, 0.1-5 parts of coupling agent, 2-5 parts of stabilizer, 0-20 parts of alkyl acrylate processing modifying agent, 0-20 parts of filling agent, 0-5 parts of lubricant, 0.5-5 parts of foaming agent, 0-10 parts of toughening agent and 20-70 parts of wood flour, wherein the total weight parts of the raw materials are 100 parts. The PVC wood-plastic board has the bulk density being not more than 700kg / m<3>, and has good flame resistance and smoke suppression property, high hardness and strong wood feeling; and the same as log, the PVC wood-plastic board has the properties of being nailed, drilled, planed, stuck and the like, is smooth and fine in surface, is waterproof, corrosion-resistant, fireproof and mildewproof, is not eaten by worms and is pollution-free.

Owner:SHANDONG BODO PLASTICS CO LTD

Abrasion-resistant integrated composite decorative timber-recombined material

InactiveCN107283592AStrong wood feelingHigh densityWood treatment detailsPressure impregnationUltimate tensile strengthBoard structure

The invention provides an abrasion-resistant integrated composite decorative timber-recombined material which comprises at least one board structure unit body and is characterized in that each board structure unit body consists of timber edgings laminated and arranged sequentially and alternatively. The timber edgings include the first timber edgings, the second timber edgings and the third timber edgings. A produced abrasion-resistant integrated composite decorative timber-recombined material product is strong in woodiness, high in density and strength and good in decorating performance.

Owner:龙门县品汐竹木制品有限公司

Outdoor high-weather-resistance polycarbonate plastic-wood composite board for building purposes

InactiveCN105924924AImprove toughnessImprove rigidityChemical recyclingPolycarbonate plasticWeather resistance

The invention discloses an outdoor high-weather-resistance polycarbonate plastic-wood composite board for building purposes. The outdoor high-weather-resistance polycarbonate plastic-wood composite board is prepared from the following components in parts by weight: 80-90 parts of polycarbonate, 60-70 parts of locust tree wood flour, 10-15 parts of EVA, 3-5 parts of titanium dioxide, 3-7 parts of triallylisocyanurate, 5-10 parts of nilox resin, 2-3 parts of TOTD, 2-3 parts of ethylene thiourea, 3-9 parts of epoxidized soybean oil, 6-15 parts of calcium stearate, 6-15 parts of dibasic lead phosphate, 2-4 parts of sodium pyrophosphate and 8-12 parts of 4,4'-thiobis(6-tertiary-butyl-3-methylphenol). The outdoor high-weather-resistance polycarbonate plastic-wood composite board provided by the invention is good in tenacity, rigidity and elasticity, firm, durable and long in service life, and can resist various severe climates outdoors; moreover, the board has the advantages of environmental protection, no pollution, high wood texture, smooth and fine surface, no granular sensation and the like.

Owner:ZHEJIANG QIAO XING CONSTR GRP HUZHOU INTELLIGENT SCI & TECH

Fibre-reinforced U-PVC foam material and its preparing process

The invention relates to a fiber-reinforced U-PVC foaming material and a preparation method thereof, which comprises 60-85% of PVC, 5-20% of flax, 2-10% of non-toxic composite stabilizer, 2-6% of foaming agent and lubricant 2-6%, fully mixed and reacted, then extruded at 100-200°C, cooled and shaped, and then surface treated to obtain the finished product. Compared with the prior art, the present invention has the advantages of light specific gravity, high strength, strong woody feeling, wear resistance, non-toxic and tasteless, non-oily, easy to clean, and aging resistance.

Owner:水浩 +1

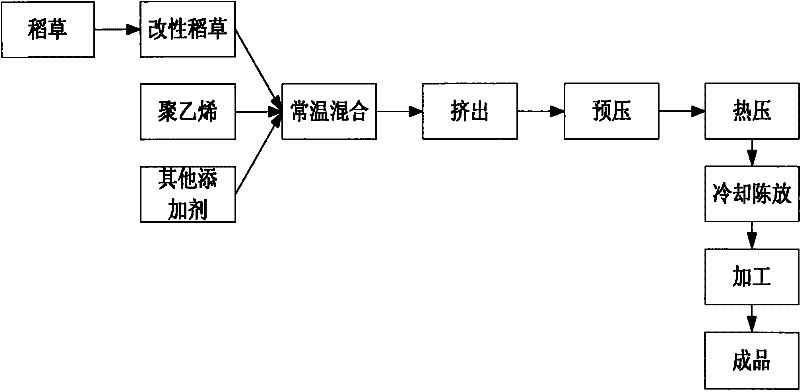

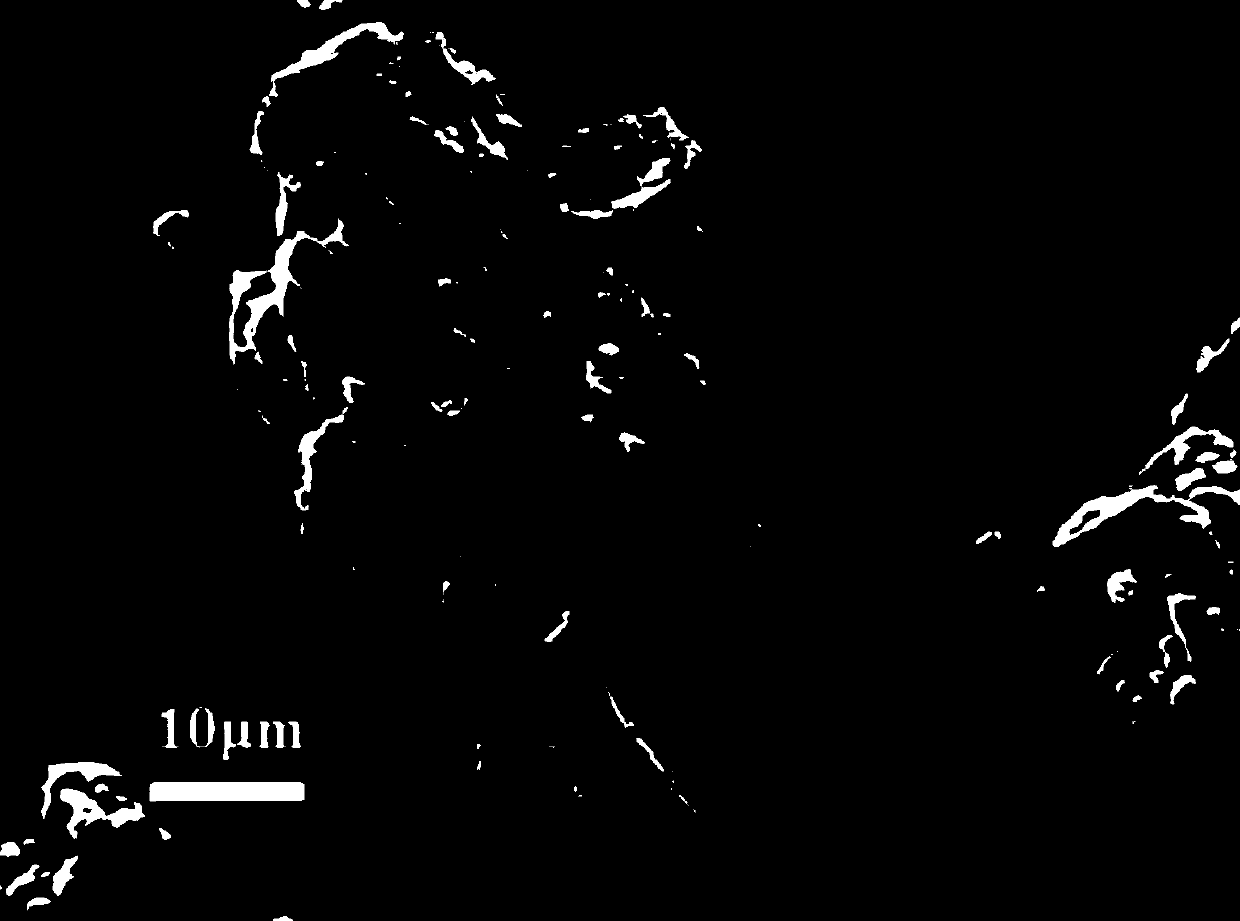

A kind of modified straw/polyethylene composite material and preparation method thereof

The invention relates to a modified rice straw / polyethylene composite material. The components and their mass-to-number ratios are: 60-70 parts of modified rice straw, 25-30 parts of polyethylene, 3.5-5 parts of adhesive, and 1 part of solubilizer. ~ 2 parts, lubricant 2.5 ~ 4 parts. The preparation method is to firstly modify the common rice straw; then add the modified rice straw and other components according to the ratio of parts by weight to a mixer with a stirring speed of 400-500r / min, stir evenly, extrude and granulate; The particles are pre-pressed in a pre-pressing machine, then put into a hot-pressing machine for hot-pressing, cooling, and cutting; finally, the finished product is finished by surface roughening and shaping. The product obtained by the invention is easy to process, does not contain formaldehyde, has strong wood feeling, high surface hardness, strong wear resistance and environmental protection, and has the performance of being similar to wood but superior to wood.

Owner:常熟市慧丰塑料制品有限公司

A wood-plastic composite material board with cross-linked microporous structure and preparation method thereof

Owner:扬州润友复合材料有限公司

Lignin/microcrystalline cellulose composite, reinforced polylactic acid 3D printing material and preparation method thereof

ActiveCN109054323BStrong wood feelingGood compatibilityAdditive manufacturing apparatusRapid prototypingMelt extrusion

In order to overcome the defects and shortcomings of poor compatibility between cellulose and a polymer matrix, frequent hole blocking in printing, difficulty in printing of lignin / polymer 3D printingmaterial and the like, common cellulose is subjected to acidolysis by using an inorganic acid solution; then the cellulose is modified by a silane coupling agent and lignin in an alcohol solution, toobtain the lignin / microcrystalline cellulose compound. The compound serving as a reinforcing material and PLA serving as a base material are blended with an inorganic nano material, a toughening agent, a plasticizer and the like, and the reinforced polylactic acid 3D printing material with good mechanical property and 3D printing property is prepared by melt extrusion blending and wiredrawing moulding. The mechanical property of the 3D printing material provided by the invention is better than that of common polylactic acid printing materials; according to a test by an FDM type 3D printer, the 3D printing material is completely applicable to the FDM rapid prototyping technology, and the printed product has high glossiness and wood-texture appearance and can be applied to the printing of furniture, toys, artwork, model design and the like.

Owner:SOUTH CHINA AGRI UNIV +1

High-hardness wood-plastic building template and preparation method thereof

ActiveCN102964740BImprove flame retardant performanceHigh smoke suppression effectPolyvinyl chlorideVolumetric Mass Density

The invention relates to a high-hardness wood-plastic building template and a preparation method thereof, which belong to the technical field of polyvinyl chloride plates. The 100 parts by weight of high-hardness wood-plastic building template comprises the following raw materials in parts by weight: 20-50 parts of polyvinyl chloride resin powder, 1-4 parts of a coupling agent, 2-5 parts of a stabilizing agent, 1-15 parts of an acrylic alkyl ester processing modifier; 1-15 parts of a filling agent, 1-4 parts of a lubricant, 1-4 parts of a foaming agent, 1-8 parts of a toughening agent, 30-50 parts of wood flour, and 5-10 parts of a reinforcing agent. According to the invention, the plate stacking density is less than or equal to 700 kg / m<3>, so that the building template is good in flame retardancy and smoke suppression, meanwhile, the building template is high in hardness and strong in wood texture; and just like raw woods, the building template also has the properties that the template can be nailed, drilled, planed and adhered and the like, the surface of the template is smooth and fine, and the template is water-proof, corrosion-resistant, fireproof, mould-proof, moth-preventing, and pollution-free.

Owner:SHANDONG BODO PLASTICS CO LTD

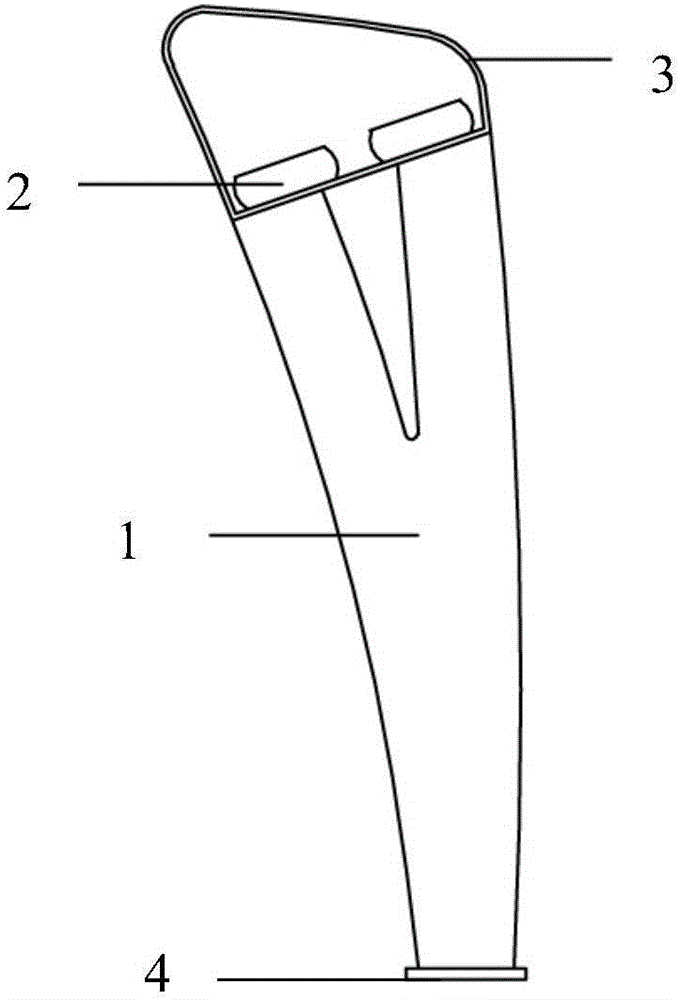

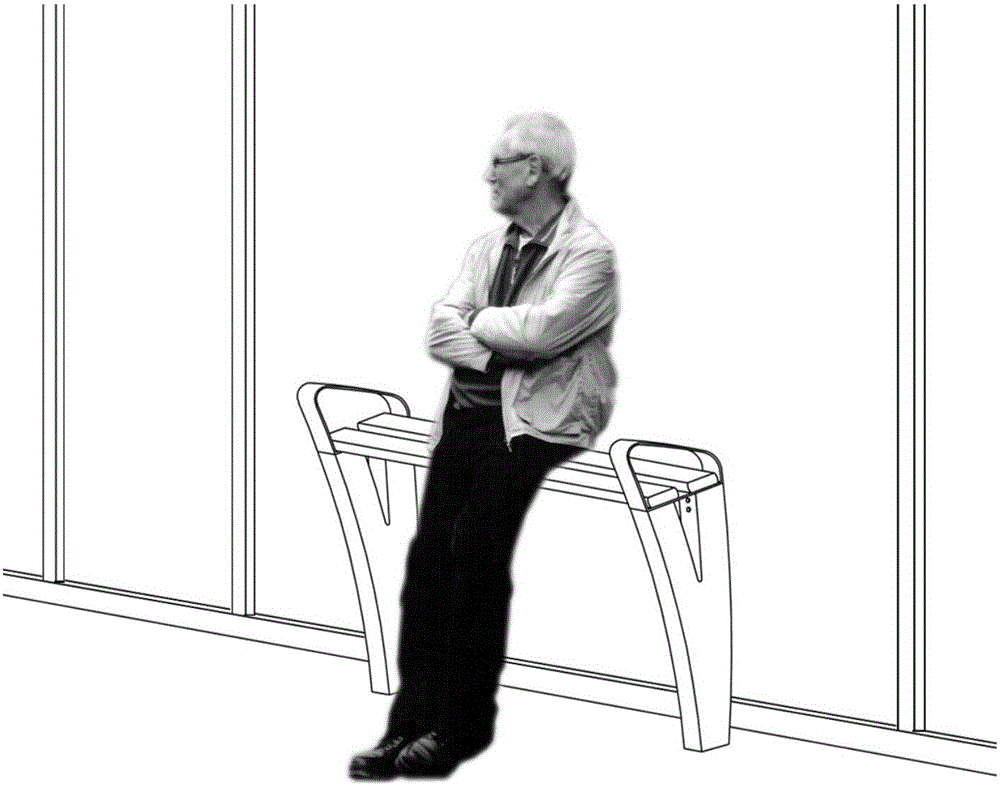

Cant arm-chair

Owner:ZHUODA NEW MATERIALS TECH GRP WEIHAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com