Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Good visual appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Health-care flax powder and production method thereof

ActiveCN103652867APerfect nutritional ingredientsGreat tasteFood ingredient functionsFood preparationSudden deathCrowds

The invention belongs to the technical field of food with a health-care function, and provides health-care flax powder and a production method thereof in order to solve the problems of nutritious substance absence in the flax powder, unstable product quality, shortening of product storage time due to high oxidation probability, and the like. The health-care flax powder is formed by combing 30%-50% of the flax powder taken as a basic material, 50%-70% of an auxiliary material, and a compound anti-oxidant made of tea polyphenol accounting for 0.01%-0.1% of the flax powder, L-ascorbyl palmitate accounting for 0.01%-0.1% of the flax powder and vitamin E accounting for 0.005%-0.08% of the flax powder, wherein the auxiliary material adopts one or a mixture mixed in a optional proportion by following: rice, wheat powder, oat and minor grain crops. The health-care flax powder is food which is convenient to make beverage, is abundant in nutrition, safe and convenient, is suitable for being eaten by all-age-group crowds, has unique physiological efficacy on a human body, and has the functions of morbidity and sudden death rate reduction for cardiovascular disease, brain development promotion, vision protection, anti-aging and the like; and the compound anti-oxidant prolongs the shelf life of the food, and enhances the nutritional value simultaneously.

Owner:SHANXI BAOSHAN DINGSHENG TECH

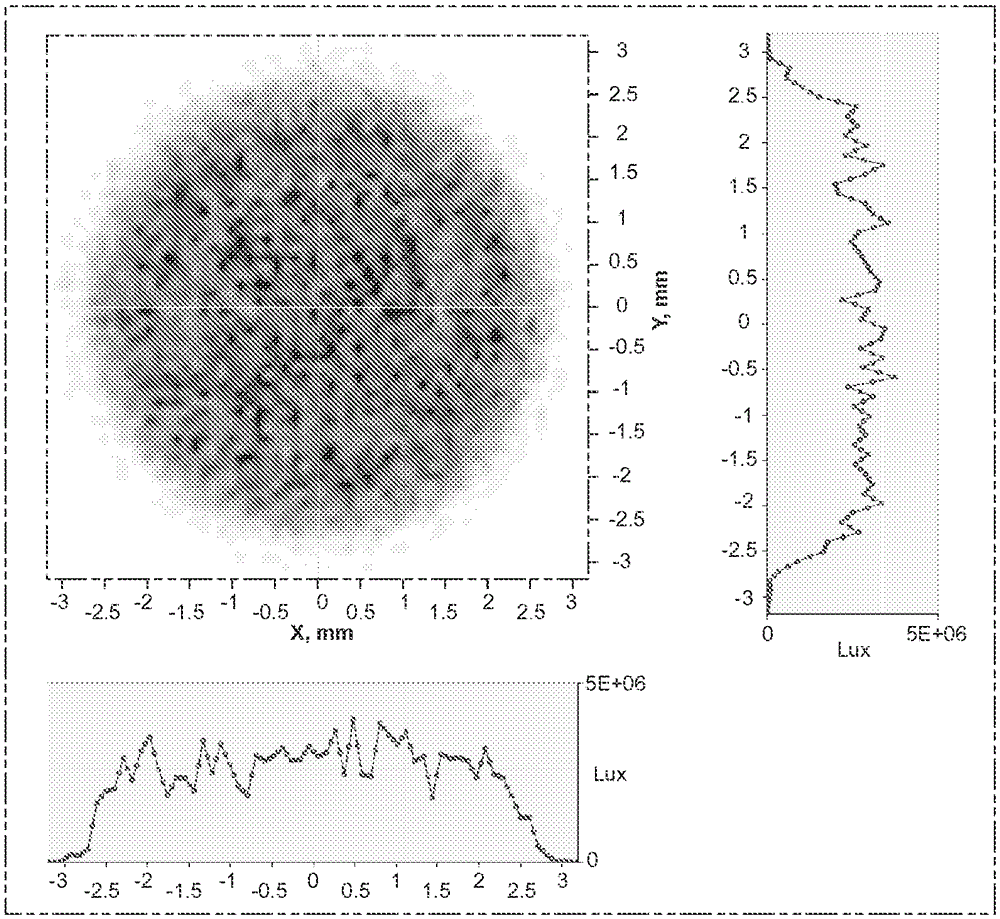

Solar energy flow measurement instrument for trough light condenser

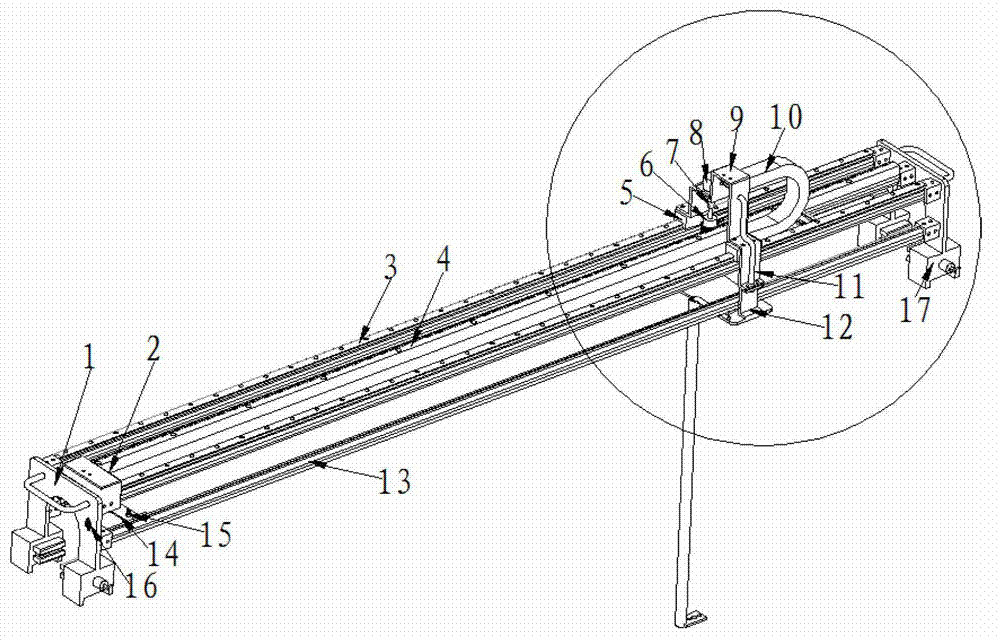

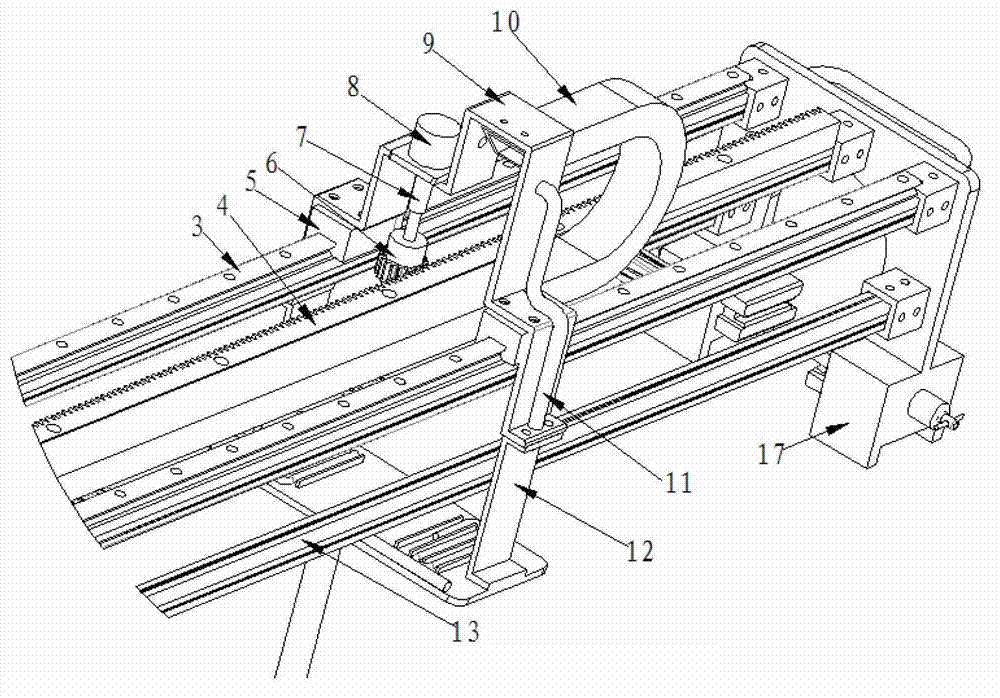

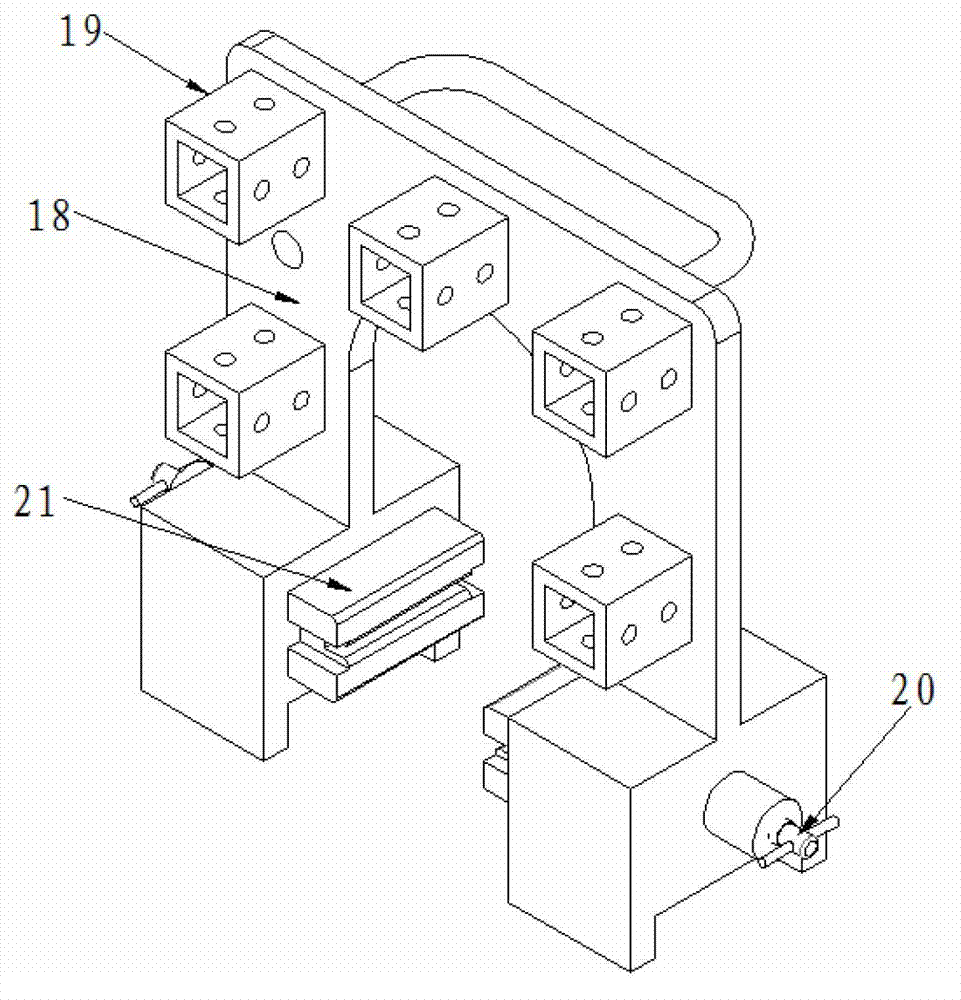

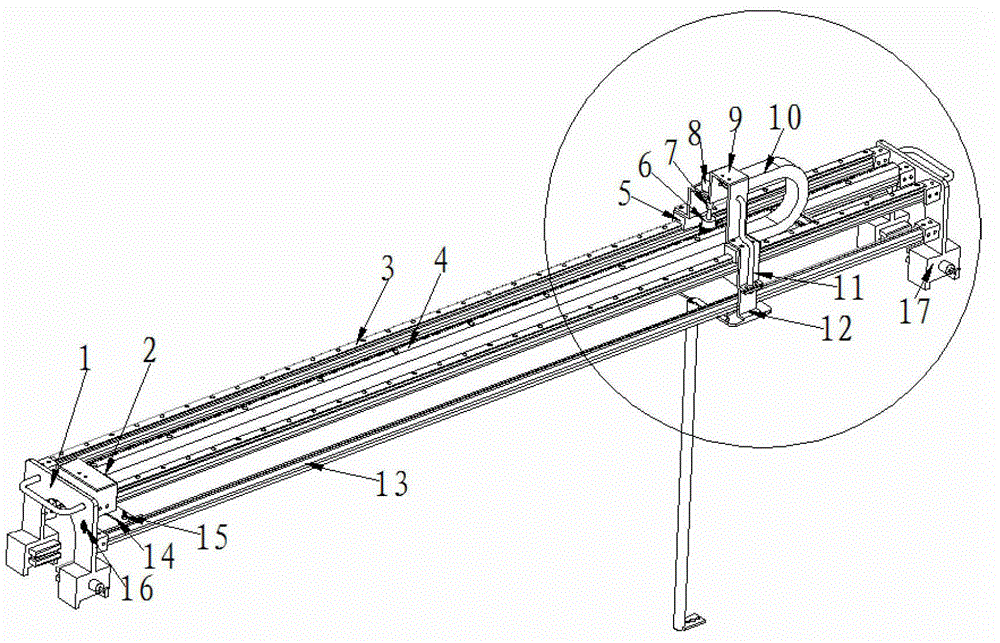

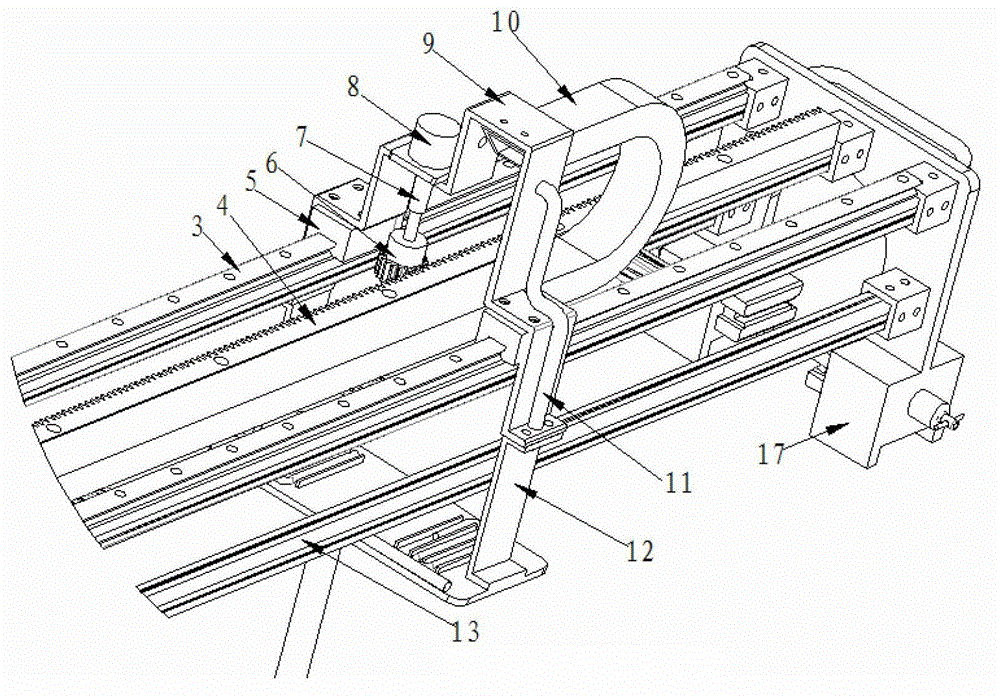

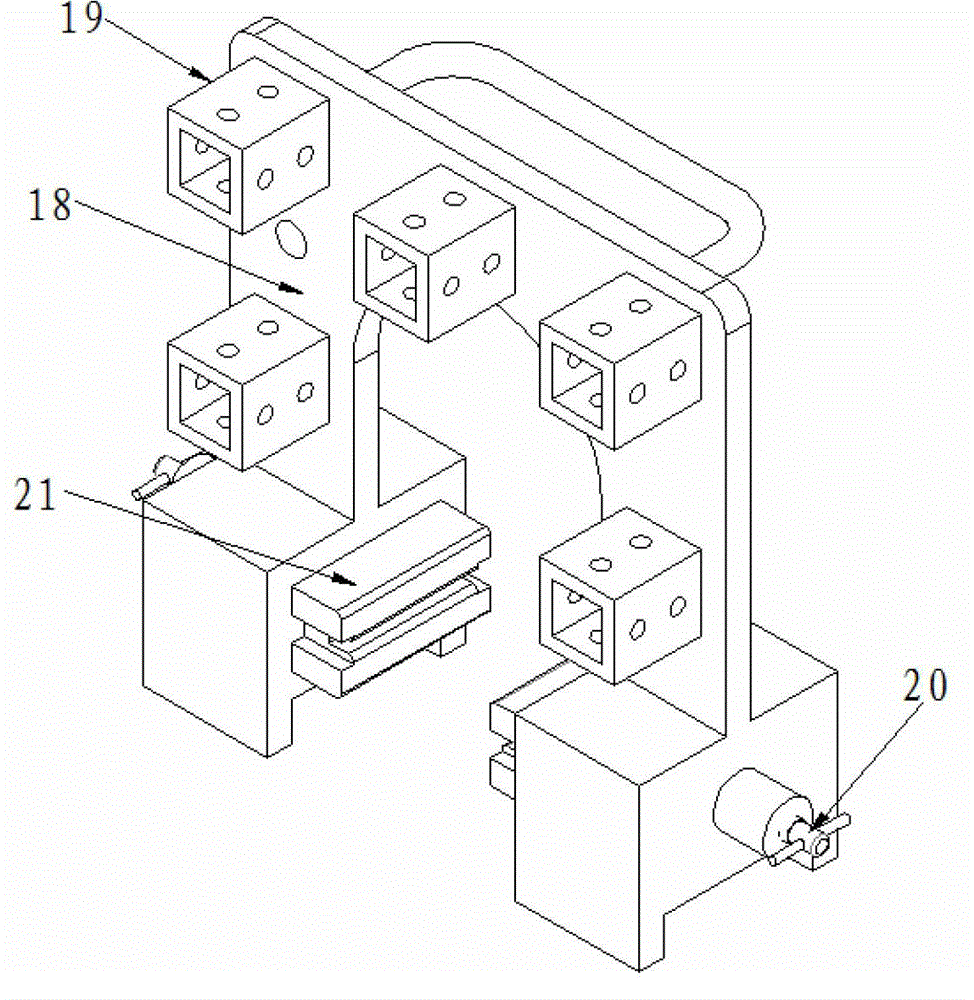

InactiveCN103206792ACompact structureImprove transmission efficiencySolar heating energySolar heat devicesGear wheelCoupling

A solar energy flow measurement instrument for a trough light condenser comprises a main body part, a supporting part and a transmission part, wherein the main body part consists of a lambert target, energy flow bases and two energy flow meters; the supporting part consists of a first end seat, an aviation plug, a drag chain fitting seat, five aluminum profiles, a cable drag chain and a second end seat; and the transmission part consists of two sliding rails, two sliders, a gear stand, a gear, a rack, a stepping motor, a coupler and a spool. The stepping motor (8) is connected with the gear (6) by the coupler (7), and the gear (6) is driven by the stepping motor (8) to do reciprocating movement on the rack (4). The slider (5), the coupler (7), the stepping motor (8), the gear stand (9), the cable drag chain (10), the spool (11) and the lambert target (12) which are combined as a whole do the reciprocating movement on the sliding rails (3) by the lambert target (12) and the cable drag chain (10) which are connected with the gear stand (9) through the driving of the gear (6).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

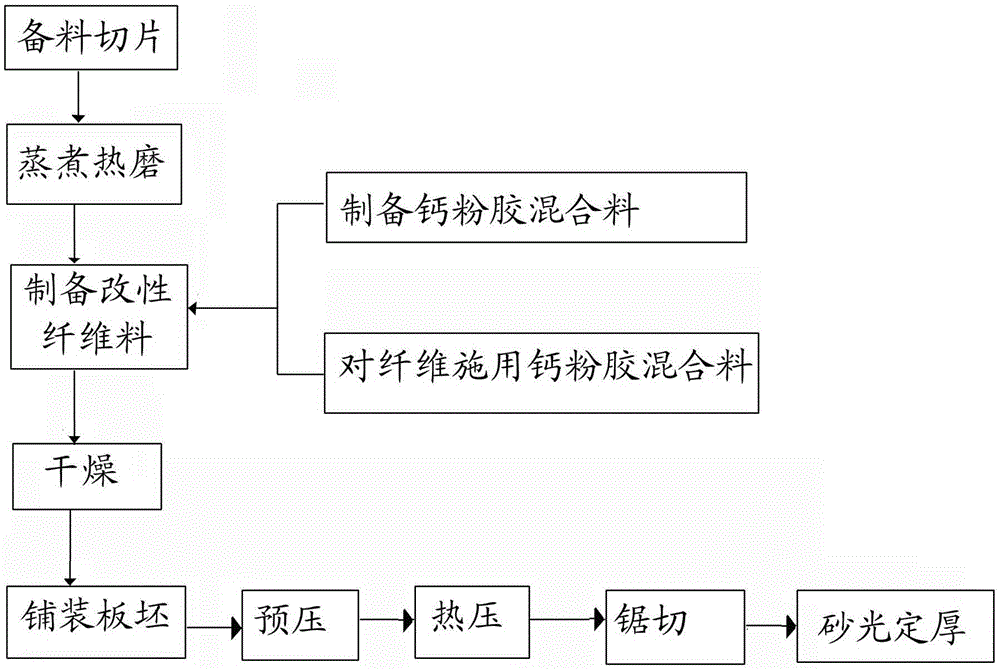

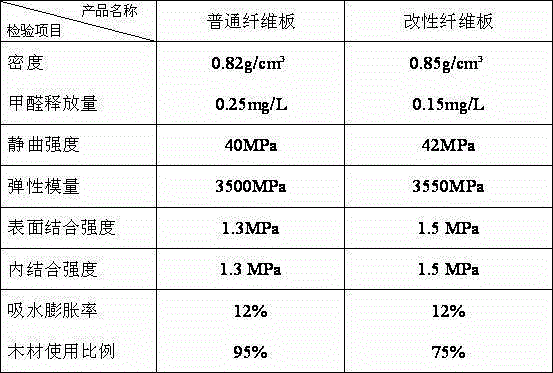

Modified fiber board production process

The invention relates to a modified fiber board production process. The modified fiber board production process includes steps of chipping, digesting, hot grinding, preparation of modified fibers, drying, preparation of blank materials, cold pressing, hot pressing, saw cutting, sanding, thickness determination and the like. In the step of preparation of modified fibers, calcium powder is added into fibers and used for replacing part of wood fibers, the calcium powder is mixed with glue prior to being mixed with the fibers during filling so as to enable clearances of the fibers to be filled by mixture of the calcium powder and the glue, and accordingly physical and chemical performances of fiber boards are improved, and improvement of board density, reduction of wood consumption and improvement of elasticity modulus indexes and static bending strength of the boards are achieved while reduction of fiber board production cost and effective saving of wood resources are realized. Wood consumption is reduced by about 20% as compared with that of common fiber boards, and the modified fiber boards produced according to the process have the advantages of high strength, high nail holding ability, excellent bending resistance and high stability and flame retardance.

Owner:湖北益嘉林业发展有限公司

Blueberry fruity sauce and preparation method thereof

InactiveCN110771841AExtended shelf lifeImprove stabilityFood preservationFood ingredient as taste affecting agentBiotechnologyThickening

The invention relates to the technical field of food processing, in particular to blueberry fruity sauce. The blueberry fruity sauce comprises the following components in percentages by weight: 25% to30% of white granulated sugar, 10% to 15% of apple juice, 3% to 4% of blueberry pulp, 1% to 2% of a compound thickener, 0.16% to 0.18% of an acidity regulator, 0.03% to 0.04% of a colorant and the balance of water. According to the blueberry fruity sauce provided by the invention, the blueberry fruity sauce prepared by adding a special thickening stabilizer and the acidity regulator has the advantages of long shelf life, good stability, delicious sour-sweet ratio and rich taste. The problem that the color of the blueberry sauce cannot be well controlled after the blueberry fruity sauce and flavor fermented milk in the market are filled is solved, so that the type of products has good visual appearance.

Owner:上海赢创食品发展有限公司

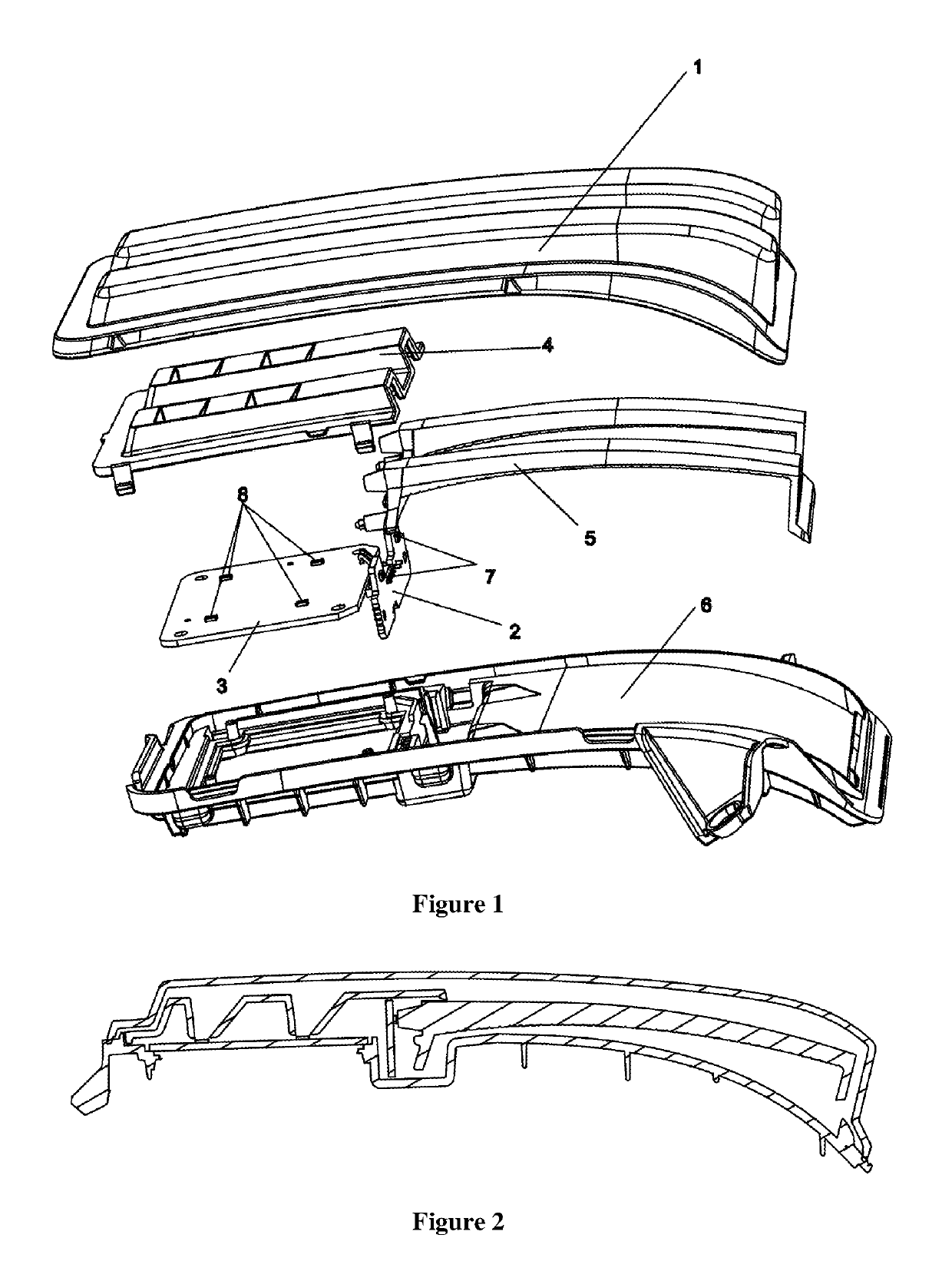

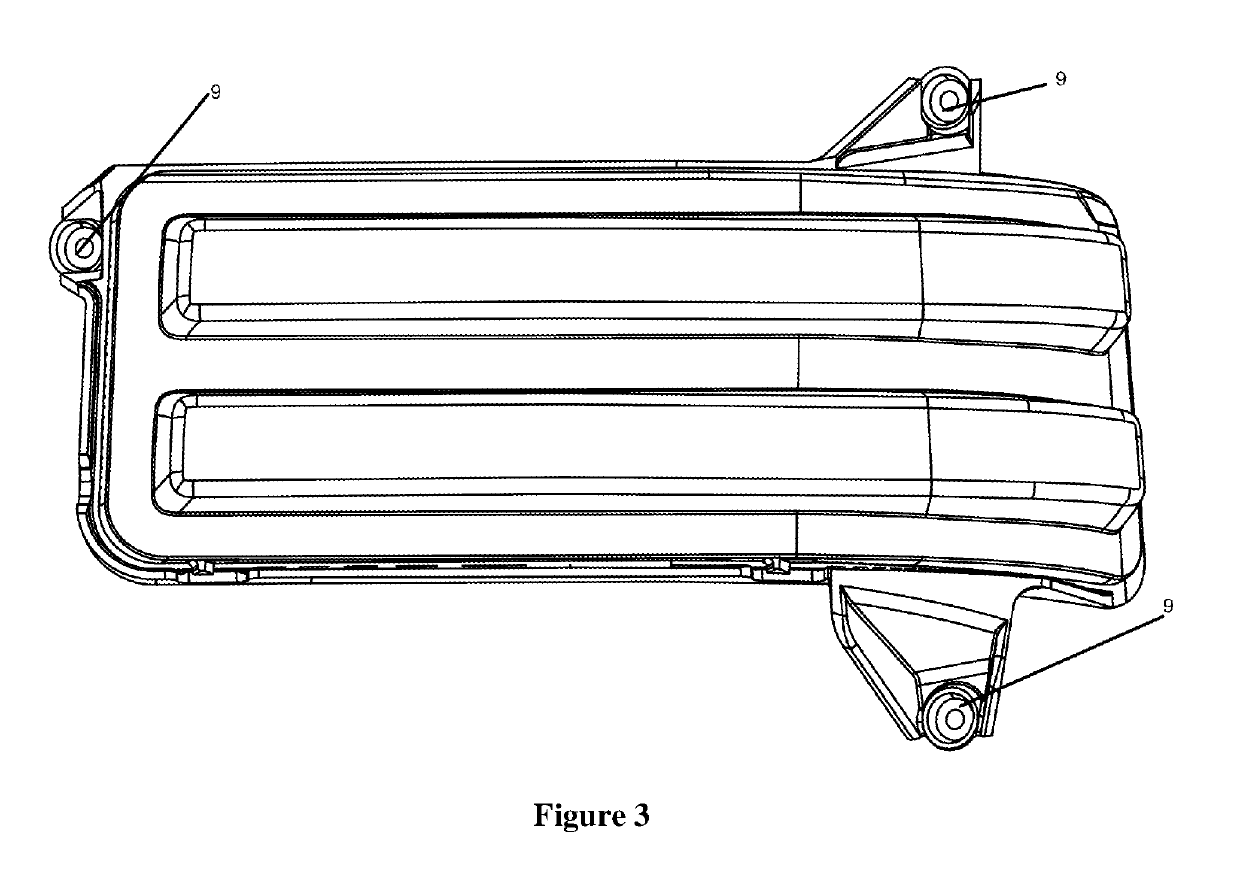

Vehicle lamp integrating a turn signal light, a side marker light and a headlight

InactiveUS20190338907A1Ingenious designSimple structureVehicle headlampsLighting and heating apparatusSignal lightOptoelectronics

The invention relates to a vehicle lamp which integrates the turn signal light, the side marker light and the headlight comprising: a headlight circuit board, a second circuit board, a reflector panel, a transparent light guide, a mask and a housing, said headlight circuit board is provided with a headlight light source facing said reflector panel, said second circuit board is provided with a second light source facing said transparent light guide, and said transparent light guide is provided with optical stripes for refracting or reflecting said second light source, and said second circuit board and said headlight circuit board are disposed between said reflector panel and said housing, said reflector panel and said transparent light guides are all connected to said mask. The vehicle lamp which integrates the turn signal light, the side marker light and the headlight of the invention has beautiful appearance, light weight and suitable for large-scale promotion and application.

Owner:MAGNA MIRRORS (TAICANG) AUTOMOTIVE TECHNOLOGY CO LTD

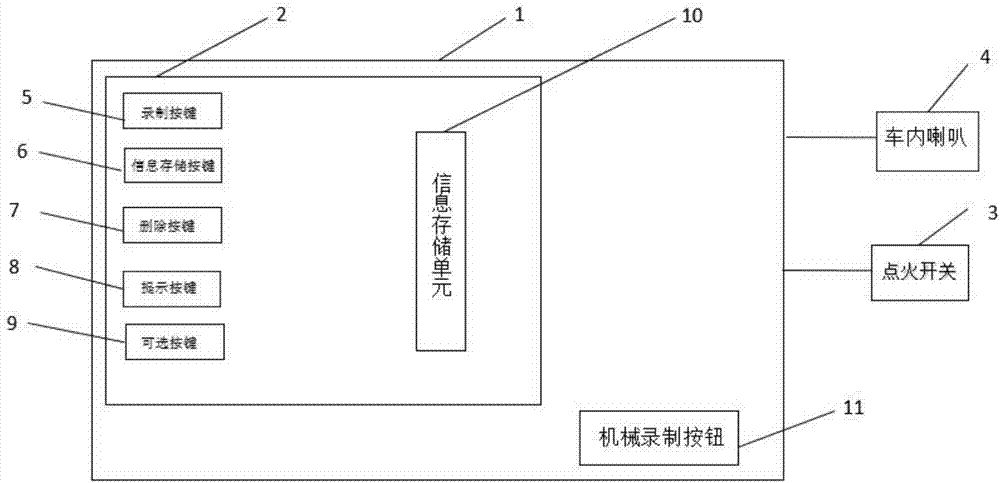

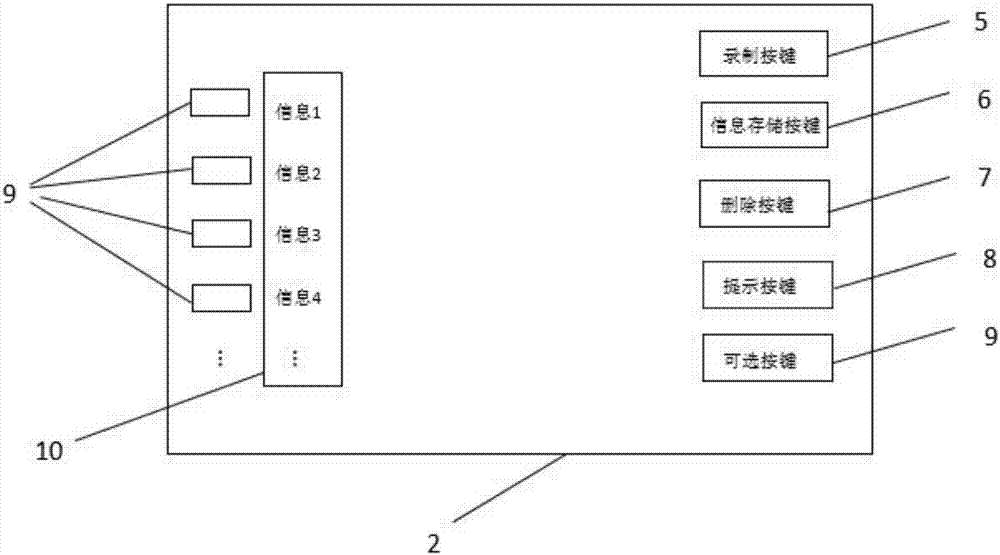

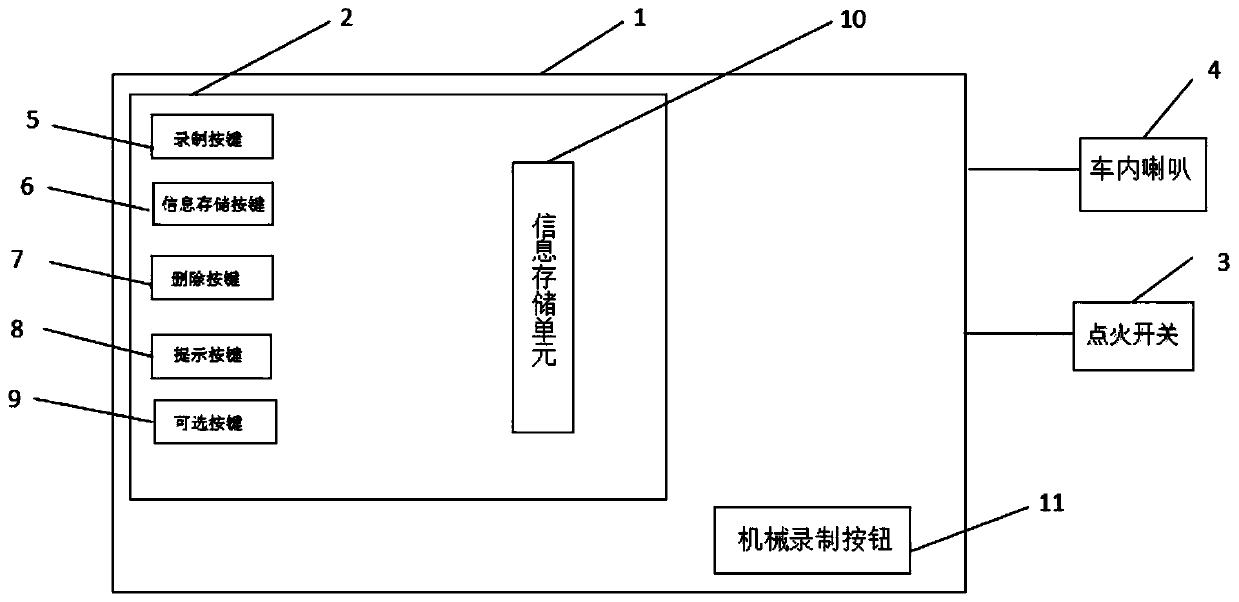

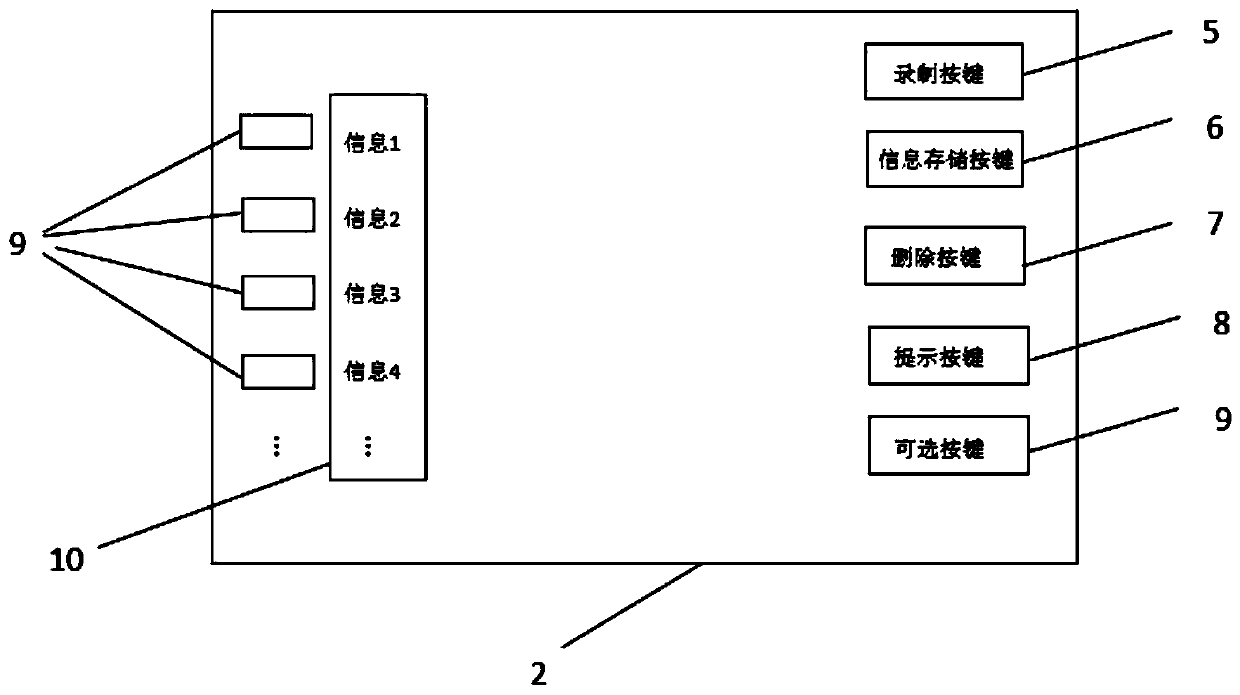

Sound system for vehicles

ActiveCN106921909AImprove experienceWith dustproofSignal processingTransducer circuitsKey pressingComputer hardware

The invention provides a sound system for vehicles. The sound system is used for recording, playing and / or displaying recorded information, and comprises a touch display screen with multiple touch keys; the multiple touch keys include a recording key and an information storage key; the recording key is used for recording voice information by responding to the click operation of a user; the information storage key is used for storing at least one voice information according to a time sequence; the information storage key is operable; therefore, after the user performs the click operation, the voice information is played; and / or, the voice information is converted into character information to display; the sound system further comprises an additional mechanical recording button for recording the voice information by responding to the user operation; and, when any one of the recording key and the mechanical recording button is operated, recording of the voice information can be started. By means of the sound system provided by the invention, information is conveniently recorded in a driving process; furthermore, the information integrity can be repeated after a driver gets off; and in addition, the sound system is timely and rapid when a great and important event needs to be recorded.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

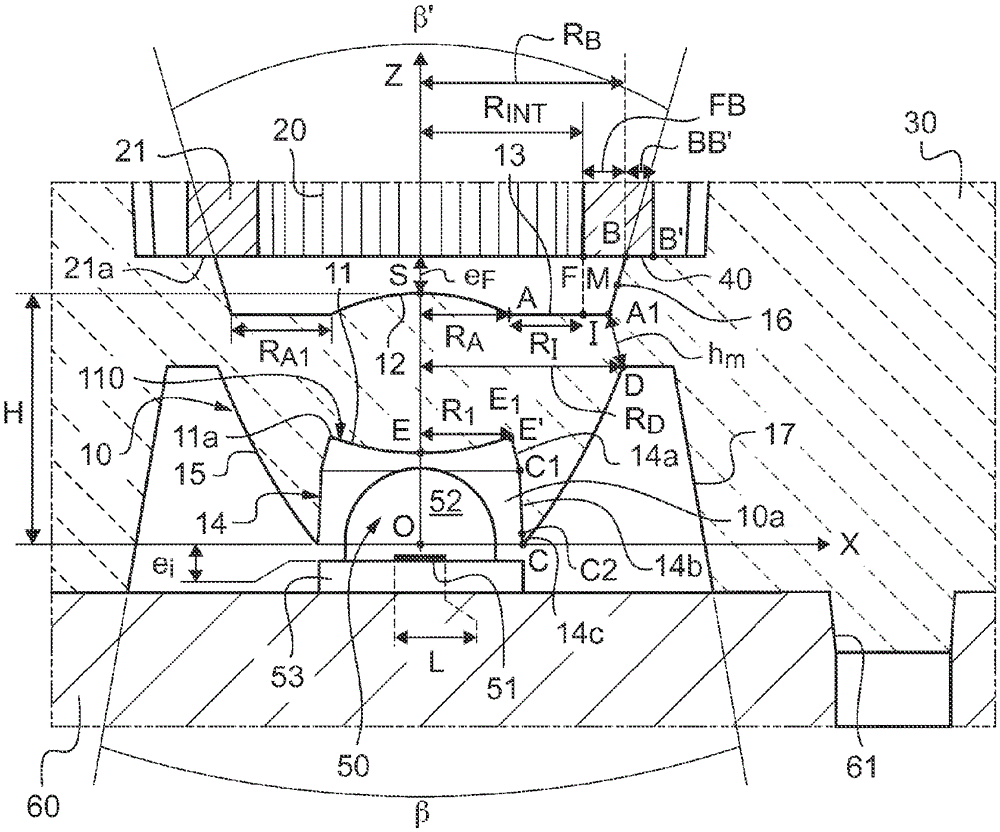

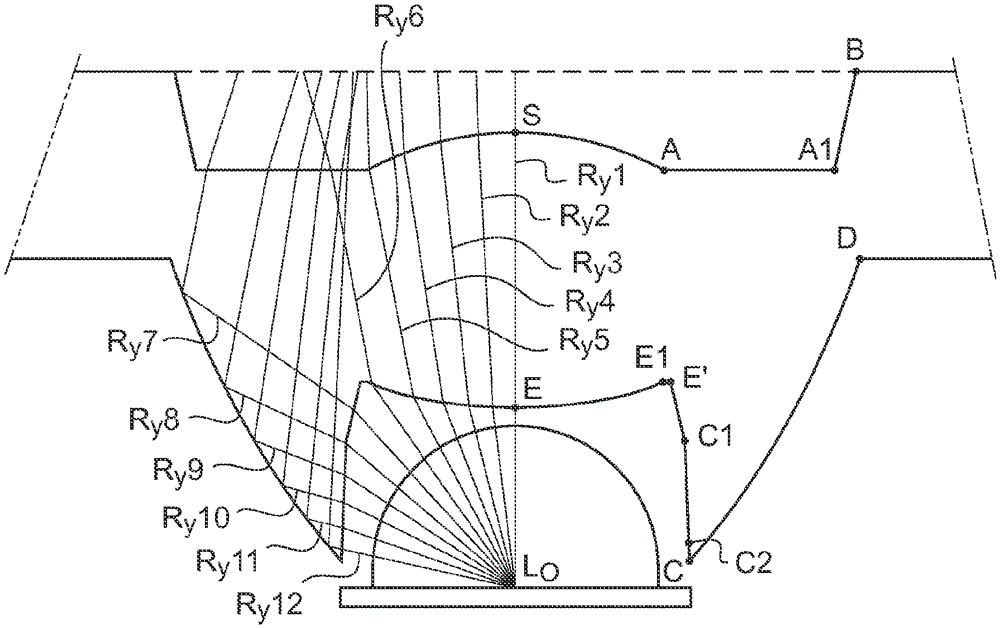

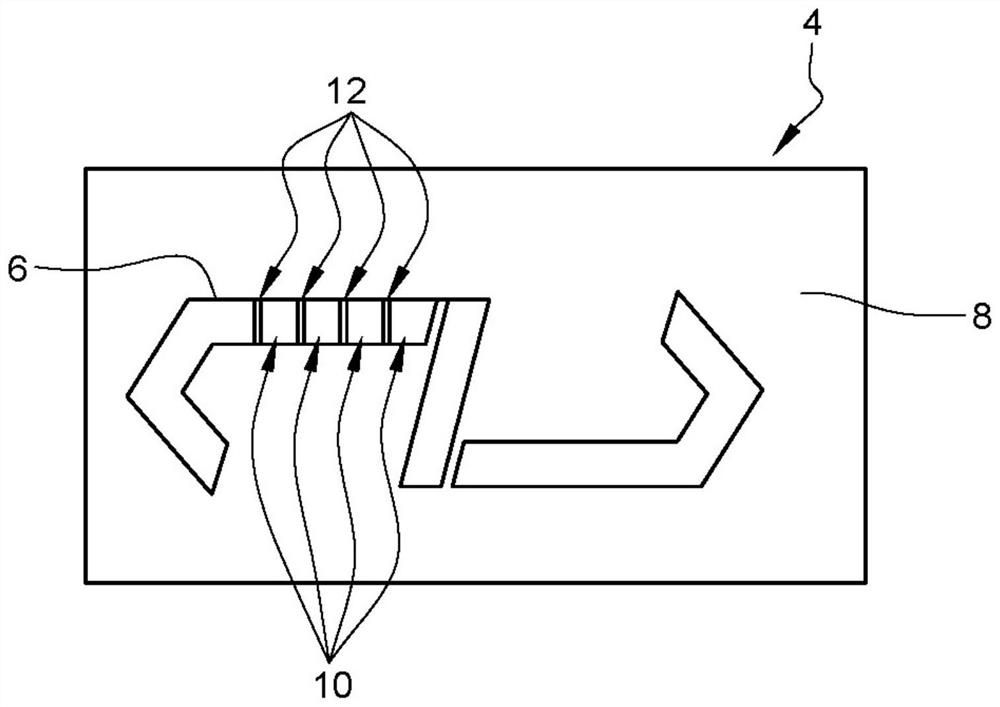

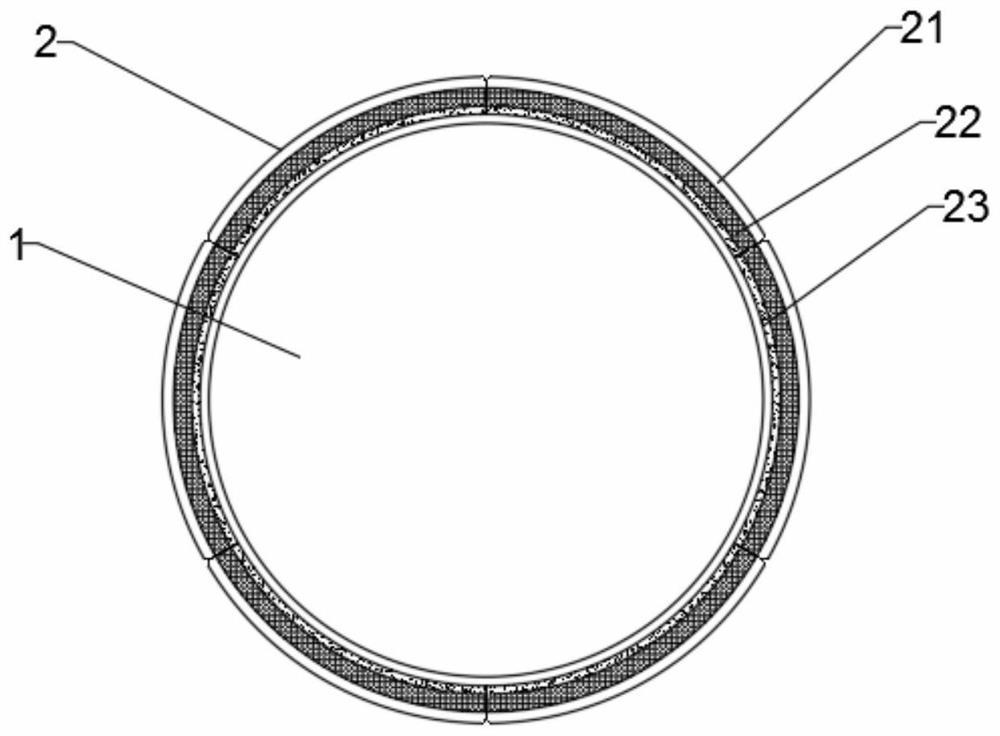

Optomechanical system for injecting light, optical coupler of said system, and illuminating device with said system

InactiveCN105659026AGood visual appearanceHigh power applicationsFibre light guidesCoupling light guidesOptical couplingOptical coupler

The invention relates to a system (1000) for injecting light, comprising: an optical coupler (1) having: a lens (10) having a convex entrance face (11) of radial extent R, a convex central exit face (12) and a peripheral exit face (13); a cavity (10a), containing the entrance face (11) and with an entrance lateral surface (14); and a peripheral reflective surface (15), encircling the lens and the cavity, extending beyond the entrance face (11); an optical collector (20), with an entrance, a collecting surface (20a) facing the central exit face, and a numerical aperture NA smaller than 1, the collector (20) comprising a jacket (21) having an end surface (21a); and a member (30) for aligning the optical collector (20), the optical coupler and the aligning member being integrally formed or being indirectly or directly fastened together, the central distance eF on the axis Oz between the collecting surface and the central exit face (12) being nonzero and smaller than 5 mm, and the system comprising a stop (40) for the end surface (21a). The invention also relates to the illuminating device with this system.

Owner:SAINT GOBAIN ADFORS +1

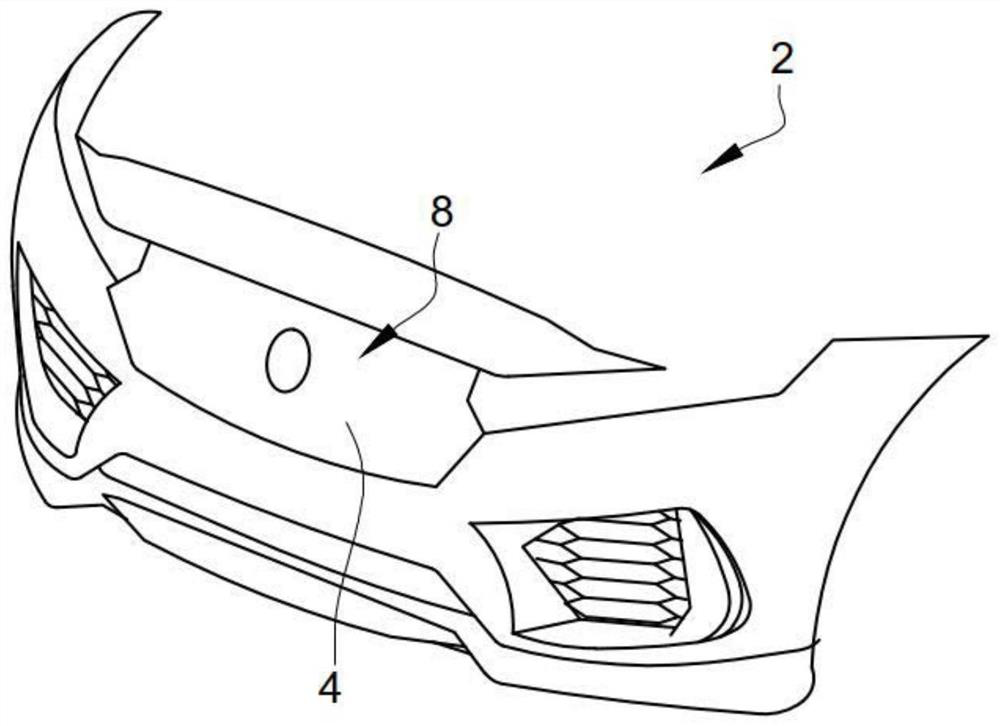

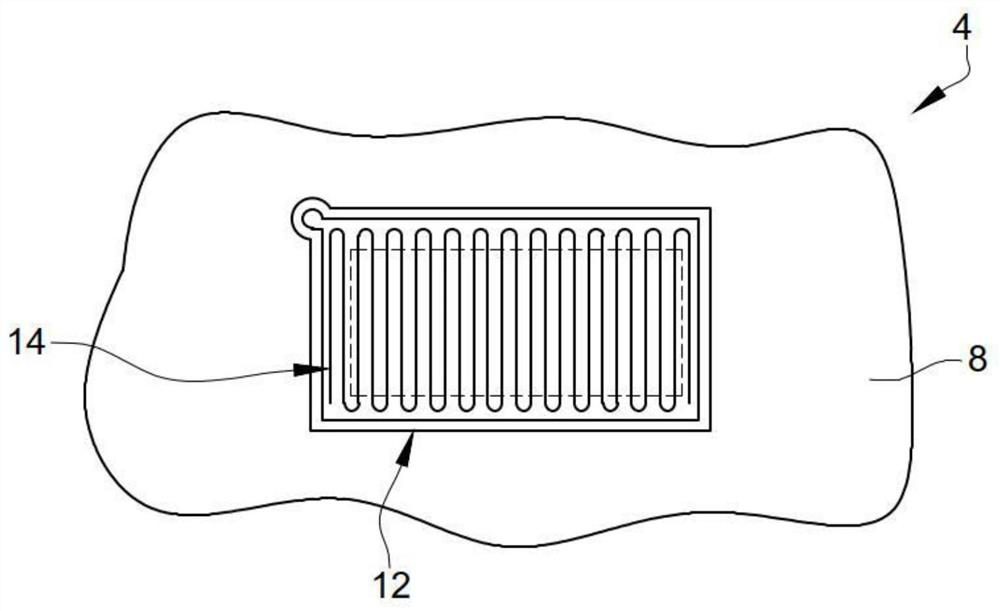

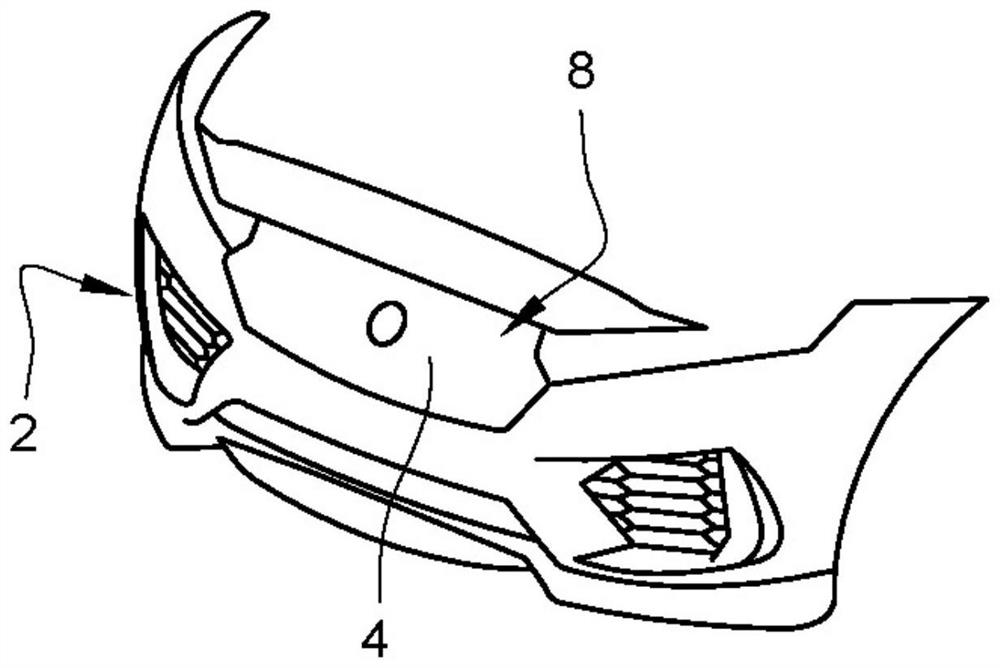

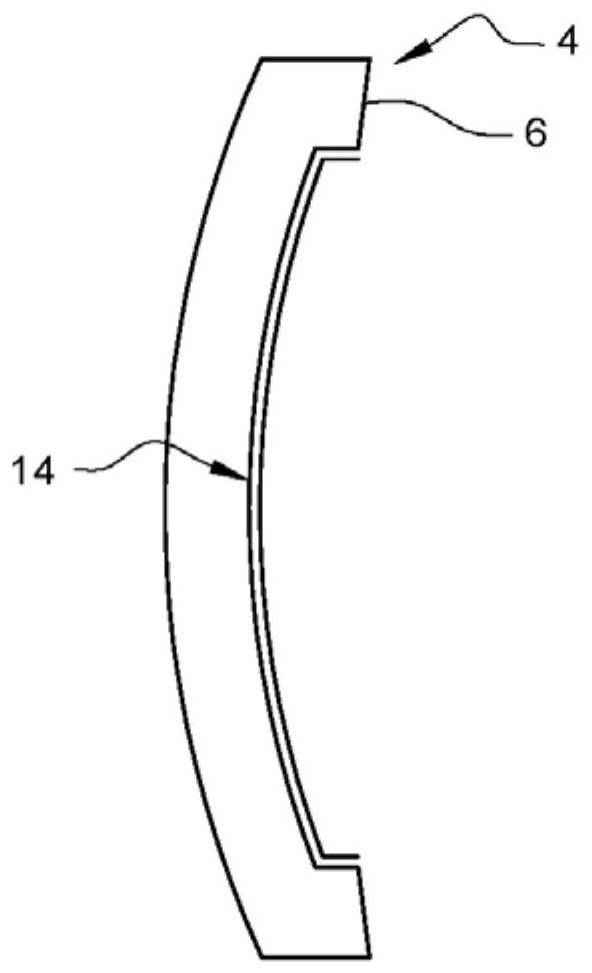

Radome for motor vehicle

PendingCN113030864AGood visual appearanceSolve the problem of disseminationOhmic-resistance heatingVehicle componentsEngineeringMechanical engineering

The invention relates to a radome (4) for a motor vehicle, comprising: a main body (8) comprising at least one first region (5) which is transparent to waves emitted by at least one wave-emitting member (6) and at least partially transparent to visible light, a textile support (12) fixed to the main body (8) and covering the first region (5), the portion of the fabric support (12) covering the first area is transparent to the waves emitted by the wave emitting member, the fabric support (12) comprises, on its face in contact with the body (8), an optical fiber (10) woven on the fabric support (12) and arranged to diffuse visible light through the first area, and a deicer (14) of the radome (4) woven on the fabric support (12).

Owner:CO PLASTIC OMNIUM S

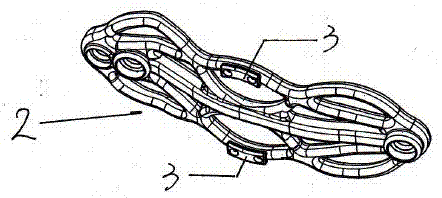

Large wheel diameter skateboard

ActiveCN105498191BLow ground clearanceLower center of gravitySkate-boardsRoller skatesEngineeringWheel sizing

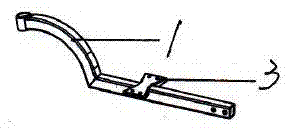

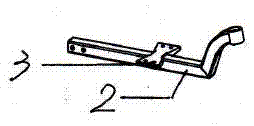

A large-wheel-diameter slide plate comprises a front plate frame, a rear plate frame, anti-abrasion bottom bars, wheel fork bearings, a twisting mechanism, plastic wheel forks with inserts, PU wheels and insert round covers. The bottoms of the two edges of the front plate frame and the rear plate frame are connected with the anti-abrasion bottom bars. The wheel fork bearings are embedded in vertical counter bores in the front end of the front plate frame and in the rear end of the rear plate frame. The twisting mechanism is composed of a leaf spring set, a plastic sleeve, a round pipe and a hexagon socket screw. The twisting mechanism is connected between the front plate frame and the rear plate frame. Each plastic wheel fork with the insert comprises the wheel fork insert and a plastic wheel fork body. The plastic wheels with the inserts are connected to the front end of the front plate frame and the rear end of the rear plate frame and are screwed through flat-base bolts of the insert round covers. The PU wheels are connected with the plastic wheel forks with the inserts through pair-locking bolts.

Owner:山东中聚电器有限公司

A sound system for a vehicle

ActiveCN106921909BImprove experienceWith dustproofSignal processingTransducer circuitsKey pressingEngineering

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

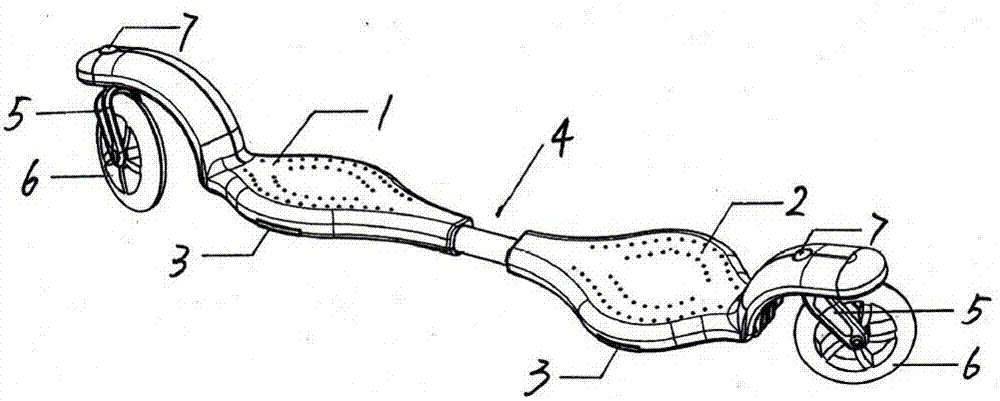

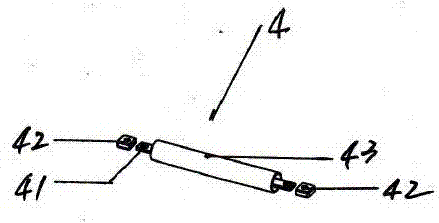

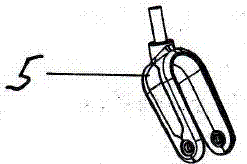

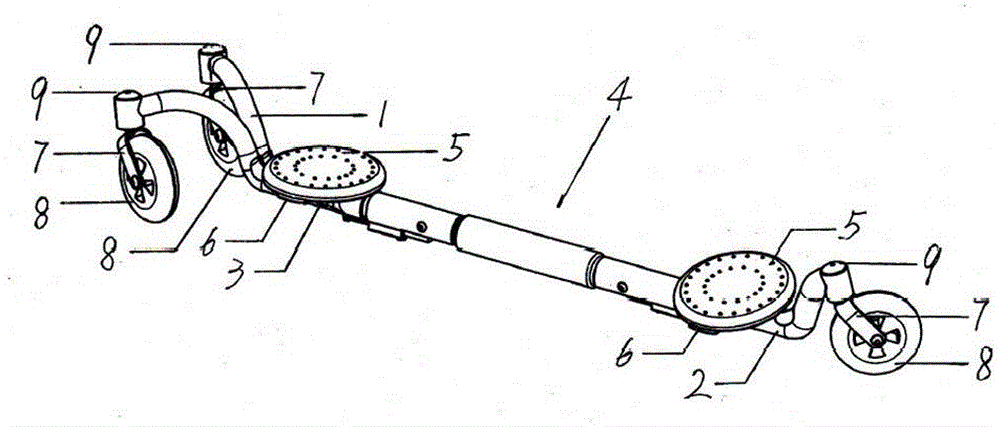

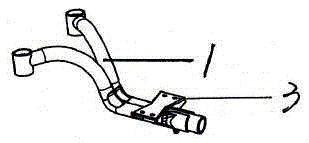

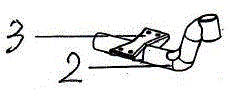

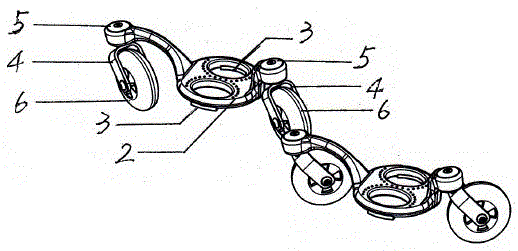

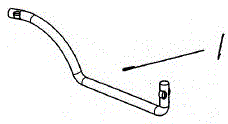

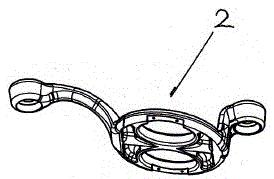

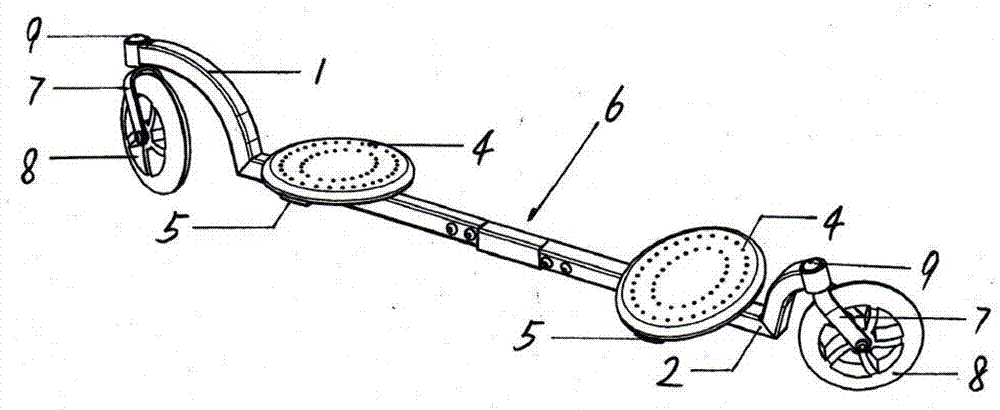

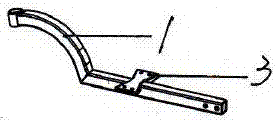

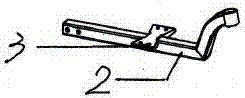

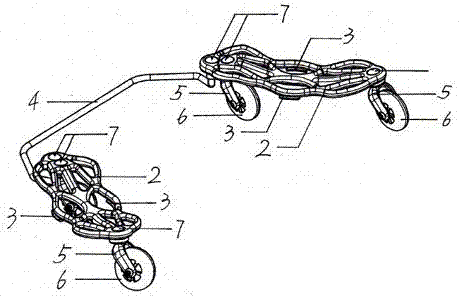

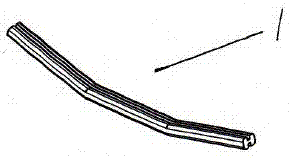

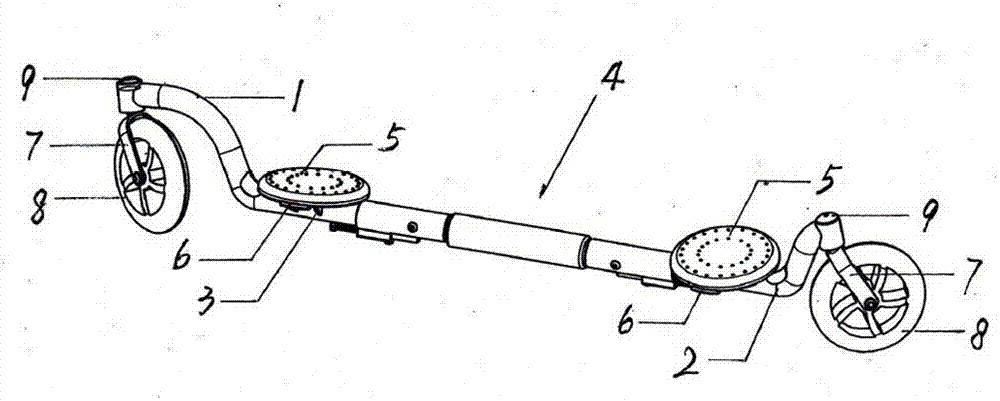

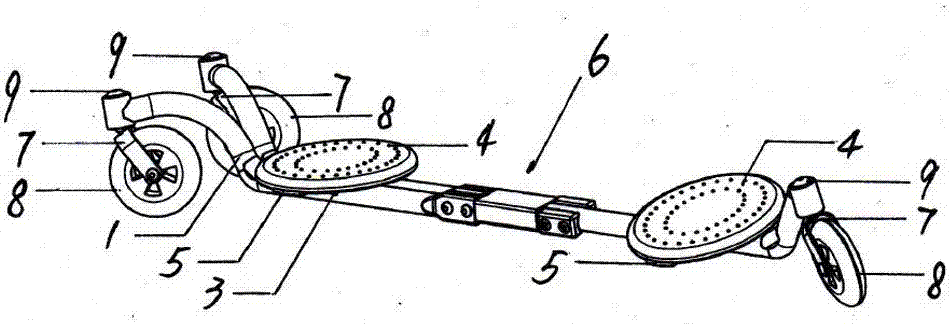

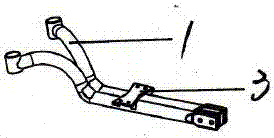

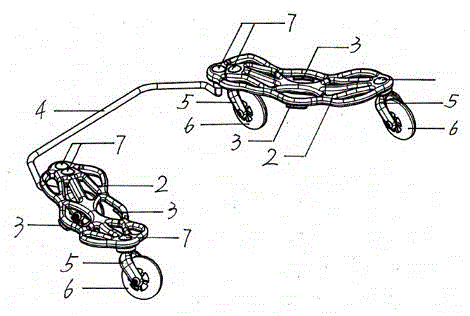

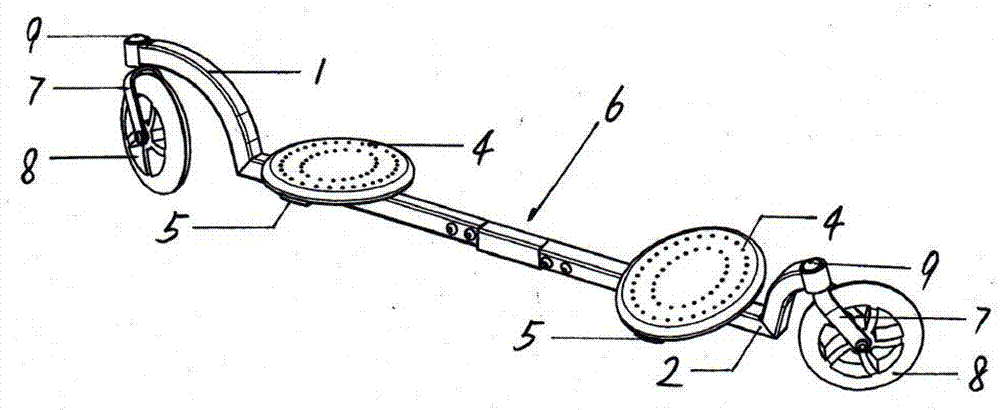

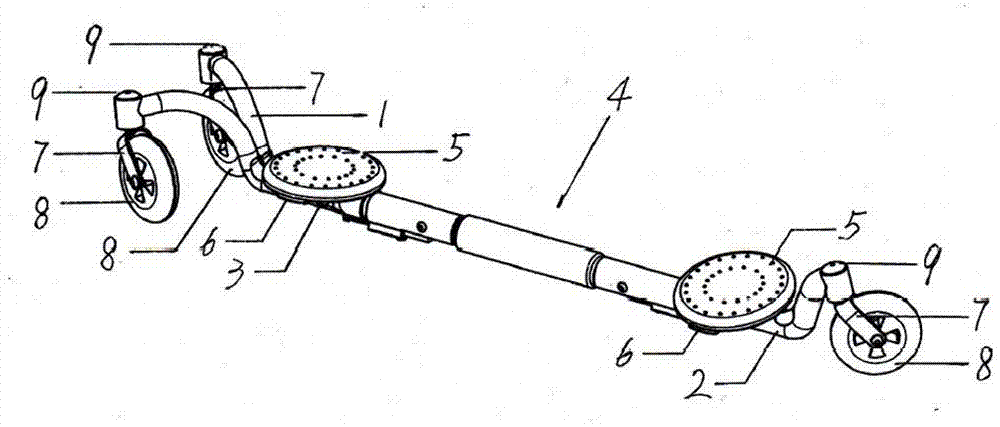

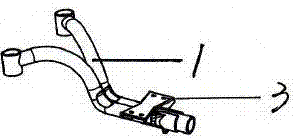

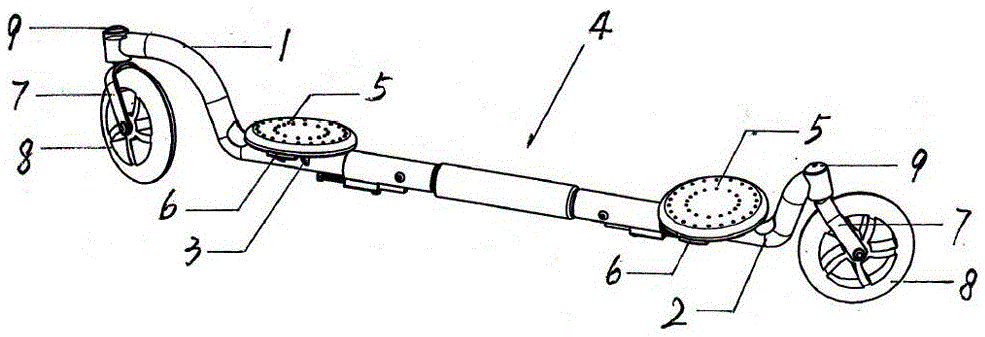

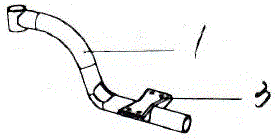

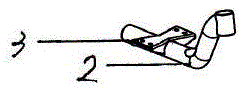

Large-wheel-diameter swinging, twisting and folding type three-wheel skateboard

ActiveCN105457257ALower center of gravityLow ground clearanceSkate-boardsRoller skatesRotating drumWheel sizing

A large-wheel-diameter swinging, twisting and folding type three-wheel skateboard comprises a double front frame, a back frame, pedal connecting parts, a swinging, twisting and folding mechanism, pedals, abrasionproof bottom strips, wheel fork bearings, wheel forks with shafts, PU wheels and circular insert covers. The double front frame is formed by welding two bent pipes, a back circular pipe and two rotating drums; the back frame is formed by welding a back bent pipe and a rotating drum; the pedal connecting parts are welded to the double front frame and the back frame; the swinging, twisting and folding mechanism is formed by connecting locking bushes, lock pin locating rings, nylon linings, a swinging and twisting structure, lock pins, springs and stepped bolts, and the two ends of the swinging, twisting and folding mechanism are connected with the double front frame and the back frame; the pedals are connected with the pedal connecting parts and the abrasionproof bottom strips; the wheel fork bearings are inlaid into the rotating drums; the wheel forks with the shafts are connected with the wheel fork bearings and the PU wheels; the circular insert covers are connected to the tops of screwed drums of locking bolts of the wheel forks with the shafts in a screwed mode.

Owner:徐州博创建设发展集团有限公司

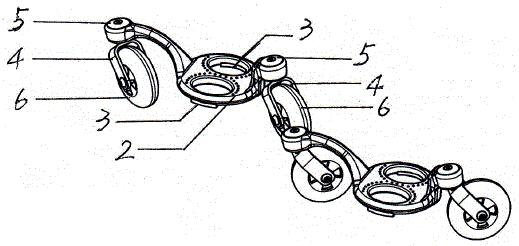

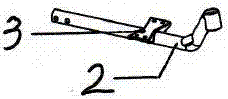

Front and rear bar-shaped swing-foot roller skates

Owner:TAICANG CHEZHONGBAO LEISURE ARTICLES +1

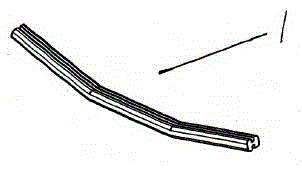

Large wheel diameter swing twist skateboard

ActiveCN105435441BLow ground clearanceLower center of gravitySkate-boardsRoller skatesBeam tubeSlide plate

Provided is a large-wheel-diameter swinging and twisting type sliding plate. The large-wheel-diameter swinging and twisting type sliding plate comprises a front frame, a rear frame, pedal connecting pieces, pedals, anti-abrasion bottom rods, wheel-fork bearings, a swinging and twisting mechanism, wheel forks with shafts, PU wheels and insert circular caps. The front frame is formed by welding a front arc tube, a front beam tube and a rotating drum, the rear frame is formed by welding a rear arc tube, a rear beam tube and a rotating drum, the pedal connecting pieces are welded to the front beam tube and the rear beam tube respectively, the pedals are connected with the pedal connecting pieces, the anti-abrasion bottom rods are connected with the front frame and the rear frame respectively, the wheel-fork bearings are inlaid in the upper end and the lower end of the rotating drum respectively, the swinging and twisting mechanism is composed of spring steel, a polyurethane locating sleeve and a plastic lining piece and connected to the rear end of the front beam tube and the front end of the rear beam tube, each wheel fork with the shaft is formed by welding a metal wheel fork and a screw cylinder of a counterlocked bolt, the PU wheels are connected with the wheel forks with the shafts respectively, the wheel forks with the shafts are connected with the wheel fork bearings, and a flat bolt of each insert circular cap is connected in the screw cylinder of the corresponding counterlocked bolt in a screwed mode.

Owner:临沂高新人才教育发展集团有限公司

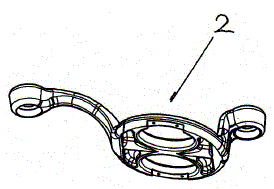

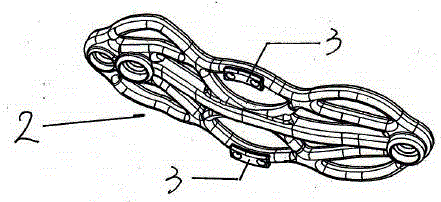

Lattice Panel Frog Skateboard

The invention relates to breaststroke skateboards with latticed panels. The breaststroke skateboards comprise aluminum inserts, the latticed panels, abrasion-proof bottom strips, front bearings, upper bearings, lower bearings, a connecting rod, four plastic wheel forks with inserts, PU wheels and upper round covers, wherein the aluminum inserts are formed into the latticed panels through injection molding, symmetrical geometric grids and strip-shaped channels are formed in the latticed panels, a vertical counter bore is formed in each of the front and the back of the front end of the top surface of each latticed panel, a vertical counter bore is formed in the rear end of each latticed panel, through holes are connected with the vertical counter bores, the abrasion-proof bottom strips are connected to two sides of the middles of the latticed panels, the bearings are embedded into the vertical counter bores, the connecting rod passes through inner holes of the bearings in the front vertical counters in the front ends of the two latticed panels from bottom to top, and are screwed down and positioned by the insert round cover, the PU wheels are connected with the plastic wheel forks with the inserts, the four plastic wheel forks with the inserts pass through inner holes of the bearings embedded into the rear vertical counter bores of the front ends of the two latticed panels and inner holes of bearings in the vertical counter bores in the rear end of the latticed panels, and are screwed down and positioned by the other insert round cover.

Owner:山东润蒙应急救援装备有限公司

Front-and-rear-rod-shaped foot swing type roller skates

The invention discloses a pair of front-and-rear-rod-shaped foot swing type roller skates. Each roller skate comprises a round steel embedded part, a front-and-rear-rod-shaped panel, wear-proof bottom strips, lower bearings, upper bearings, wheel forks provided with shafts, upper round covers and PU (polyurethane) wheels, wherein the round steel embedded part is injected into the front-and-rear-rod-shaped panel; the front-and-rear-rod-shaped panel is rod-shaped at the front part, match-head-shaped at the front end, elliptical and cylindrical at the rear part, cylindrical at the rear end and disk-shaped in the middle; a counter bore is formed in each of the upper and lower sides of the front end and the rear end of the front-and-rear-rod-shaped panel; the upper and lower counter bores are connected with through holes; the upper counter bores of the front-and-rear-rod-shaped panel are connected with shallow counter bores; two elliptic holes are formed in the disk-shaped bottom surface of the front-and-rear-rod-shaped panel; the bottom surfaces on two sides in the middle of the front-and-rear-rod-shaped panel are connected with the wear-proof bottom strips; the upper and lower bearings are embedded into the upper and lower counter bores; the shafts of the wheel forks provided with the shafts are connected with the upper and lower bearings; the wheel forks provided with the shafts are connected with the PU wheels; the upper round covers are connected to the tops of the shafts of the wheel forks provided with the shafts and positioned in the shallow counter bores. Two front-and-rear-rod-shaped foot swing type roller skates are matched in a front-rear manner and paired for use.

Owner:TAICANG CHEZHONGBAO LEISURE ARTICLES +1

Large wheel diameter swing twist folding skateboard

ActiveCN105536235BLow ground clearanceLower center of gravitySkate-boardsRoller skatesWear resistantEngineering

A swing twisting folding skateboard with a large wheel diameter comprises a front frame, a rear frame, pedal connecting pieces, a swing twisting folding mechanism, pedals, wear-resistant bottom strips, wheel fork bearings, wheel forks with shafts, PU wheels and insert round covers, wherein the front frame is formed by welding a bend pipe and a drum, the rear frame is formed by welding a rear bent pipe and a drum, the pedal connecting pieces are welded on the front frame and the rear frame, the swing twisting mechanism is formed by connecting a lock picking bush, a lockpin locating ring, a nylon lining piece, a swing twisting structure, a lockpin, a spring and a step bolt, the two ends of the swing twisting mechanism are connected with the front frame and the rear frame, the pedals are connected with the pedal connecting pieces and the wear-resistant bottom strips, the wheel fork bearing are inserted into the drums, the wheel forks with the shafts are connected with the wheel fork bearings and the PU wheels, and the insert piece round cover is connected to the top part of a screw cylinder of pair lock bolts of the wheel forks with the shafts in a screwing manner.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Radome for motor vehicle comprising a decorative pattern

PendingCN113036423AGood visual appearanceSolve the problem of wave propagation being disturbedRadiating element housingsMotorized vehicleMechanical engineering

The invention relates to a radome (4) for a motor vehicle, comprising a main body (8) comprising at least one zone transparent to the waves emitted by the wave-emitting element and intended to be traversed by said waves, the zone comprising a face (14) comprising an alternation of first parts (10) covered by at least one layer of paint and second parts (12) not covered by the layer of paint, the first and second parts (10, 12) forming at least one decorative pattern (6) and being arranged in such a way as to make the decorative pattern (6) transparent to the waves emitted by the wave-emitting element.

Owner:CO PLASTIC OMNIUM

Large wheel diameter swing and twist three-wheel skateboard

ActiveCN105498192BLow ground clearanceLower center of gravitySkate-boardsRoller skatesEngineeringSpring steel

A large-wheel-diameter oscillating and twisting type three-wheel slide plate comprises double front frames, a rear frame, pedal connection pieces, pedals, anti-abrasion bottom bars, wheel fork bearings, an oscillating and twisting mechanism, wheel forks with shafts, PU wheels and insert round covers. The double front frames are formed by welding two bent pipes and two rotating drums. The rear frame is formed by welding a rear bent pipe and a rotating drum. The pedal connection pieces are welded to the double front frames and the rear frame. The pedals are connected with the pedal connection pieces. The anti-abrasion bottom bars are connected with the pedals. The wheel fork bearings are embedded in the upper ends and the lower ends of the rotating drums. The oscillating and twisting mechanism is composed of spring steel, a polyurethane positioning sleeve, a plastic lining and a plastic sleeve. Each wheel fork with the shaft is formed by welding a metal wheel fork and a screw tube of a pair-locking bolt, the wheel forks with the shafts are connected to the wheel fork bearings, the PU wheels are connected with the wheel forks with the shafts, and flat-base bolts of the insert round covers are screwed into threaded holes of the screw tubes of the pair-locking bolts of the wheel forks with the shafts.

Owner:临沂高新人才教育发展集团有限公司

Breaststroke skateboards with latticed panels

ActiveCN104958893ALightweight appearanceVarious shapesSkiingSkate-boardsEngineeringMechanical engineering

The invention relates to breaststroke skateboards with latticed panels. The breaststroke skateboards comprise aluminum inserts, the latticed panels, abrasion-proof bottom strips, front bearings, upper bearings, lower bearings, a connecting rod, four plastic wheel forks with inserts, PU wheels and upper round covers, wherein the aluminum inserts are formed into the latticed panels through injection molding, symmetrical geometric grids and strip-shaped channels are formed in the latticed panels, a vertical counter bore is formed in each of the front and the back of the front end of the top surface of each latticed panel, a vertical counter bore is formed in the rear end of each latticed panel, through holes are connected with the vertical counter bores, the abrasion-proof bottom strips are connected to two sides of the middles of the latticed panels, the bearings are embedded into the vertical counter bores, the connecting rod passes through inner holes of the bearings in the front vertical counters in the front ends of the two latticed panels from bottom to top, and are screwed down and positioned by the insert round cover, the PU wheels are connected with the plastic wheel forks with the inserts, the four plastic wheel forks with the inserts pass through inner holes of the bearings embedded into the rear vertical counter bores of the front ends of the two latticed panels and inner holes of bearings in the vertical counter bores in the rear end of the latticed panels, and are screwed down and positioned by the other insert round cover.

Owner:山东润蒙应急救援装备有限公司

A kind of health-care flax powder and its production method

ActiveCN103652867BPerfect nutritional ingredientsGreat tasteFood ingredient functionsFood preparationBrain developmentSudden death

The invention belongs to the technical field of food with a health-care function, and provides health-care flax powder and a production method thereof in order to solve the problems of nutritious substance absence in the flax powder, unstable product quality, shortening of product storage time due to high oxidation probability, and the like. The health-care flax powder is formed by combing 30%-50% of the flax powder taken as a basic material, 50%-70% of an auxiliary material, and a compound anti-oxidant made of tea polyphenol accounting for 0.01%-0.1% of the flax powder, L-ascorbyl palmitate accounting for 0.01%-0.1% of the flax powder and vitamin E accounting for 0.005%-0.08% of the flax powder, wherein the auxiliary material adopts one or a mixture mixed in a optional proportion by following: rice, wheat powder, oat and minor grain crops. The health-care flax powder is food which is convenient to make beverage, is abundant in nutrition, safe and convenient, is suitable for being eaten by all-age-group crowds, has unique physiological efficacy on a human body, and has the functions of morbidity and sudden death rate reduction for cardiovascular disease, brain development promotion, vision protection, anti-aging and the like; and the compound anti-oxidant prolongs the shelf life of the food, and enhances the nutritional value simultaneously.

Owner:SHANXI BAOSHAN DINGSHENG TECH

Solar energy flow measurement instrument for trough light condenser

InactiveCN103206792BReduce weightImprove corrosion resistanceSolar heating energySolar heat devicesGear wheelCoupling

A solar energy flow measurement instrument for a trough light condenser comprises a main body part, a supporting part and a transmission part, wherein the main body part consists of a lambert target, energy flow bases and two energy flow meters; the supporting part consists of a first end seat, an aviation plug, a drag chain fitting seat, five aluminum profiles, a cable drag chain and a second end seat; and the transmission part consists of two sliding rails, two sliders, a gear stand, a gear, a rack, a stepping motor, a coupler and a spool. The stepping motor (8) is connected with the gear (6) by the coupler (7), and the gear (6) is driven by the stepping motor (8) to do reciprocating movement on the rack (4). The slider (5), the coupler (7), the stepping motor (8), the gear stand (9), the cable drag chain (10), the spool (11) and the lambert target (12) which are combined as a whole do the reciprocating movement on the sliding rails (3) by the lambert target (12) and the cable drag chain (10) which are connected with the gear stand (9) through the driving of the gear (6).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Large-wheel-diameter swinging and twisting type sliding plate

ActiveCN105435441ALow ground clearanceLower center of gravitySkate-boardsRoller skatesEngineeringSlide plate

Provided is a large-wheel-diameter swinging and twisting type sliding plate. The large-wheel-diameter swinging and twisting type sliding plate comprises a front frame, a rear frame, pedal connecting pieces, pedals, anti-abrasion bottom rods, wheel-fork bearings, a swinging and twisting mechanism, wheel forks with shafts, PU wheels and insert circular caps. The front frame is formed by welding a front arc tube, a front beam tube and a rotating drum, the rear frame is formed by welding a rear arc tube, a rear beam tube and a rotating drum, the pedal connecting pieces are welded to the front beam tube and the rear beam tube respectively, the pedals are connected with the pedal connecting pieces, the anti-abrasion bottom rods are connected with the front frame and the rear frame respectively, the wheel-fork bearings are inlaid in the upper end and the lower end of the rotating drum respectively, the swinging and twisting mechanism is composed of spring steel, a polyurethane locating sleeve and a plastic lining piece and connected to the rear end of the front beam tube and the front end of the rear beam tube, each wheel fork with the shaft is formed by welding a metal wheel fork and a screw cylinder of a counterlocked bolt, the PU wheels are connected with the wheel forks with the shafts respectively, the wheel forks with the shafts are connected with the wheel fork bearings, and a flat bolt of each insert circular cap is connected in the screw cylinder of the corresponding counterlocked bolt in a screwed mode.

Owner:临沂高新人才教育发展集团有限公司

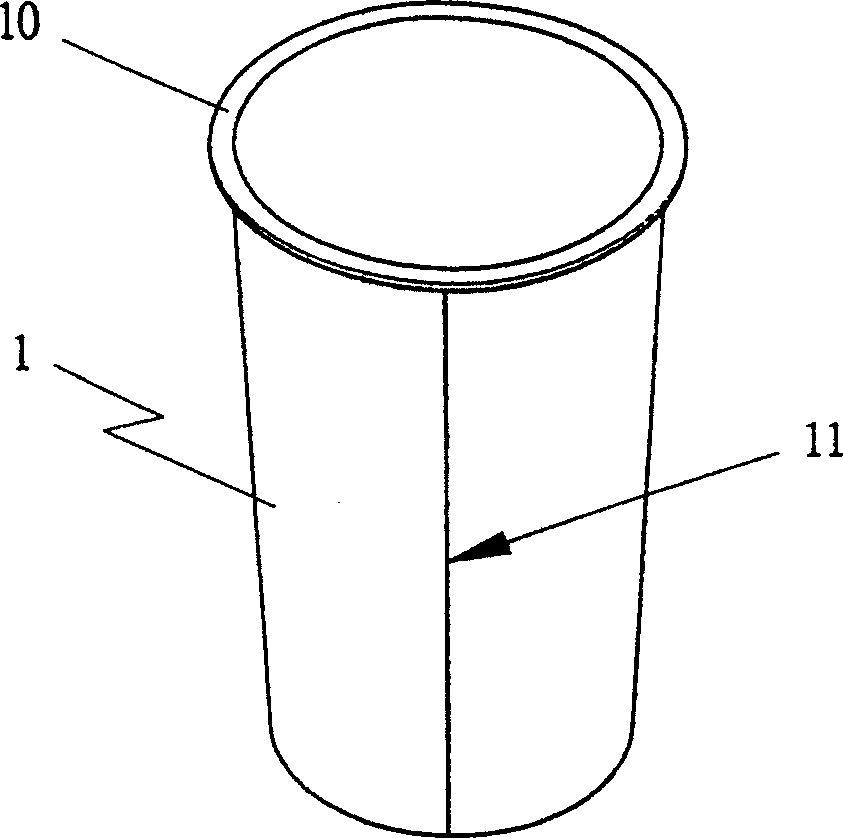

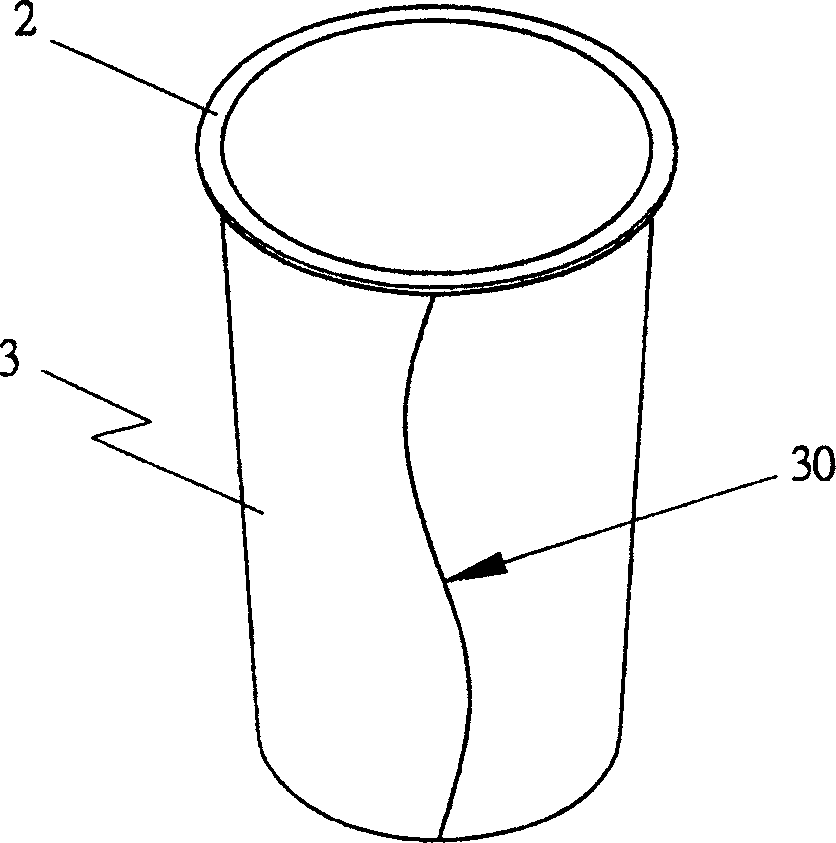

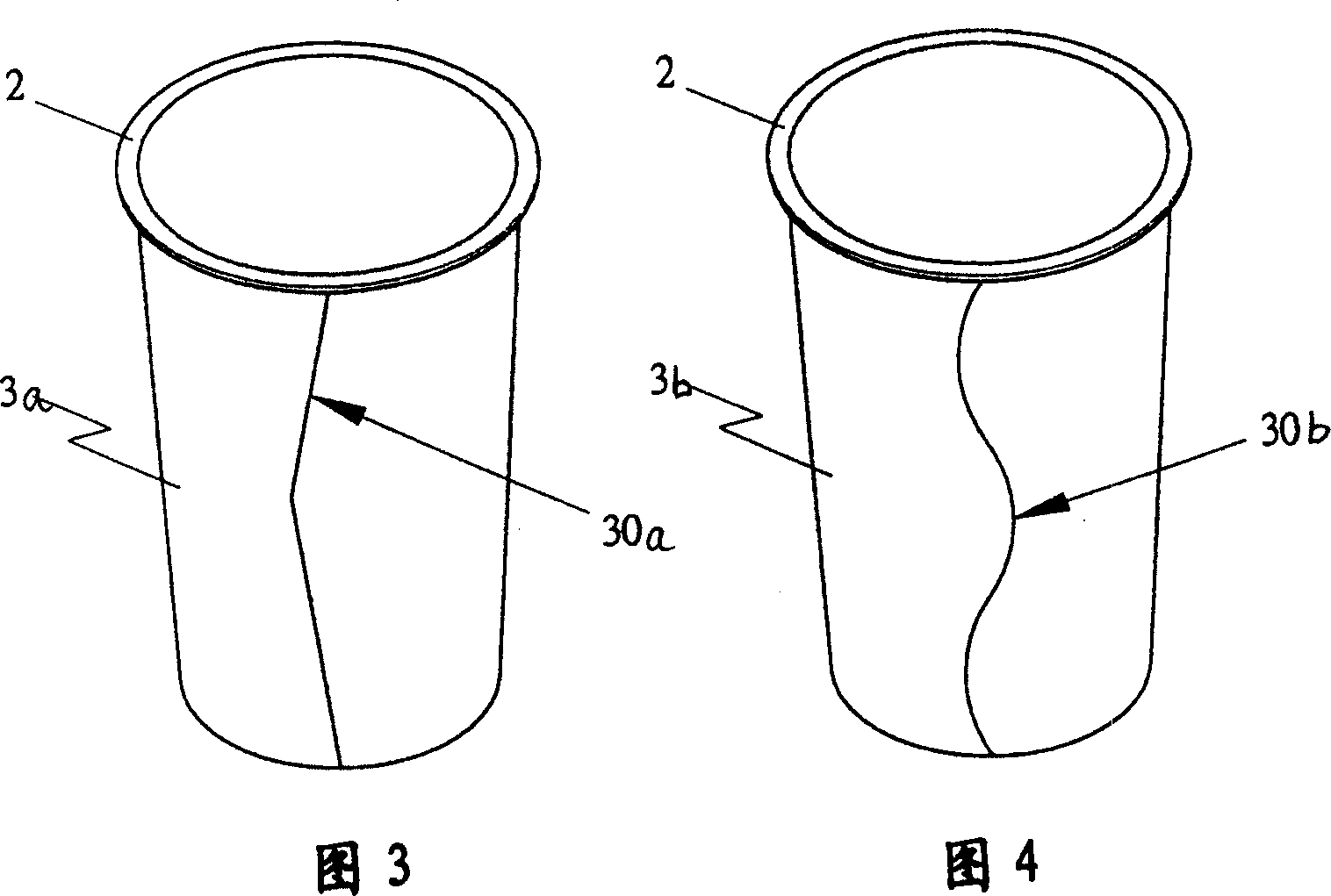

In-mould formed labelled container by utilizing coild label with veiwing window

InactiveCN1257092CEasy to watchBuy with confidenceLinings/internal coatingsRigid containersEngineeringVisual appearance

The utility model relates to a container which is labeled by in-mold molding with a window label. In order to provide a container with good visual aesthetics, effectively attracting consumers’ desire to purchase, and strong labeling and binding force, the present invention is proposed. It is made by a molding method of labeling inside the label, and it at least includes a plastic container body and a plastic container body. The surface of the container body is pre-printed with the required text / pattern label; the label is a roll label; the forming method of the label in-mold labeling is the forming method of the roll label in-mold labeling, and the roll label is provided with a convenient viewing content and decorative effect windows.

Owner:SUPREME TECHNIC PACKAGE

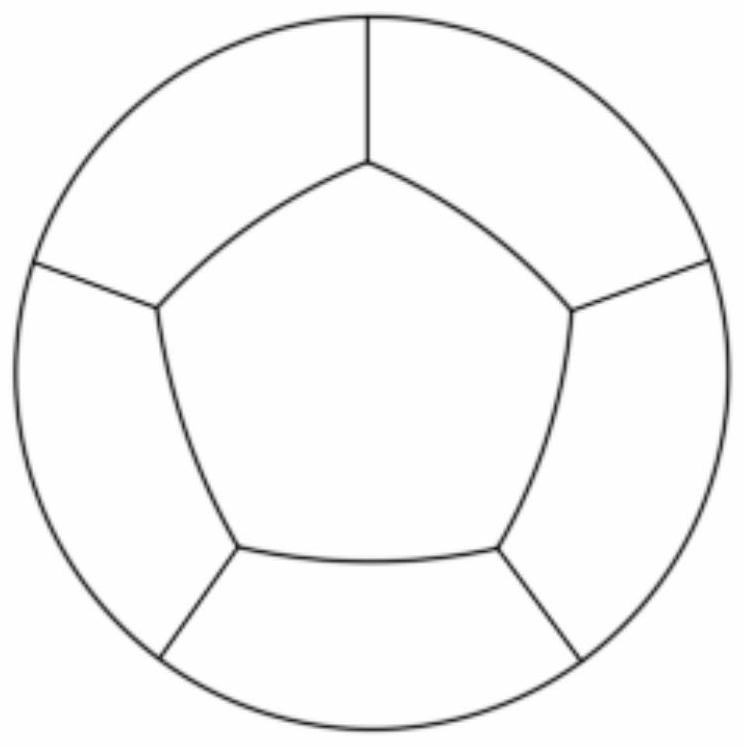

A preparation method of imitating hand-made machine-sewn ball and the prepared imitation hand-made machine-sewn ball

ActiveCN112190889BStrong sewing effectGood visual appearanceWork-feeding meansHollow non-inflatable ballsCosmetic appearanceMaterials science

Owner:XIAMEN PULSA SPORTING GOODS CO LTD

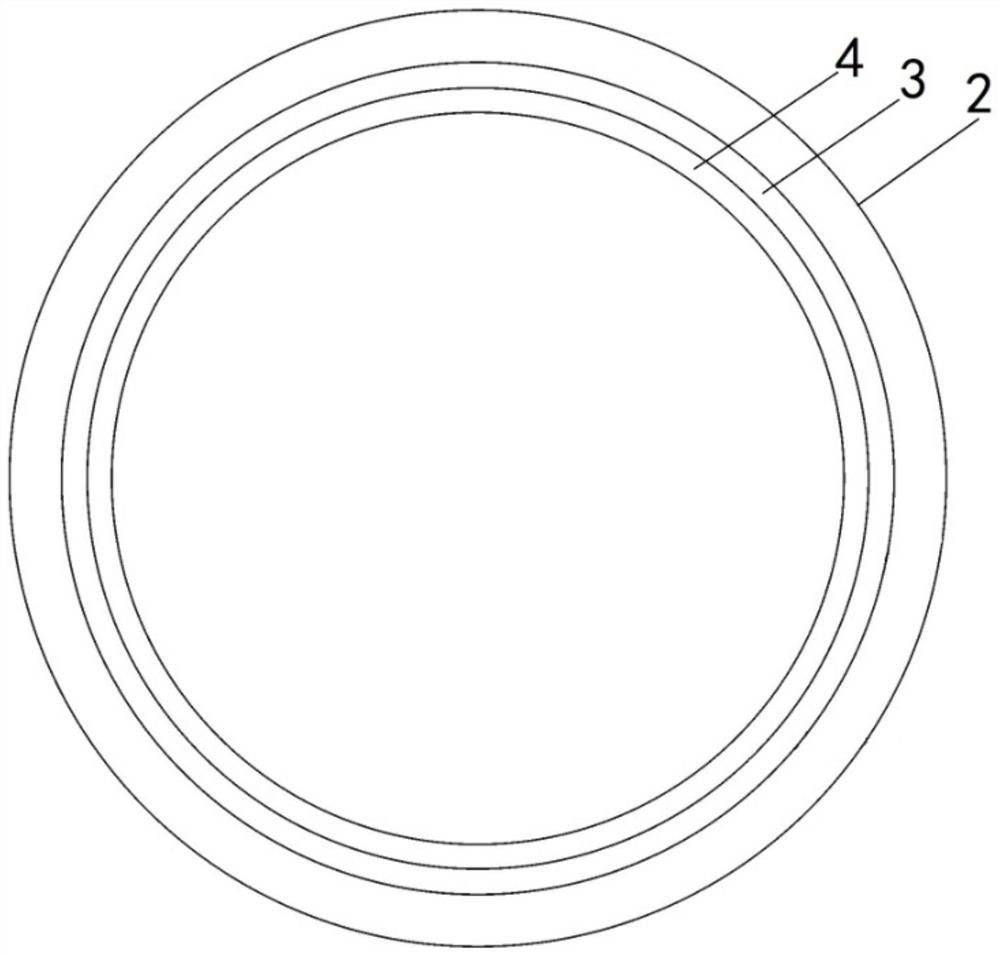

Glass microsphere and glass fiber composite reinforced corrugated pipe and production method thereof

PendingCN113418129ASimple moldingGood visual appearanceElongated constructional elementsThermal insulationSmooth surface

The invention discloses a glass microsphere and glass fiber composite reinforced corrugated pipe and a production method of the glass microsphere and glass fiber composite reinforced corrugated pipe. A pipe body comprises an inner wall and an outer wall. The outer wall comprises wave crest sections and wave trough sections, wherein the wave crest sections and the wave trough sections are regularly spaced in sequence. The inner wall is formed by a smooth pipe body layer. A composite reinforced material of the outer wall contains glass microspheres and glass fibers. The production method of the glass microsphere and glass fiber composite reinforced corrugated pipe comprises the steps that the hollow glass microspheres and the chopped glass fibers are added into the composite reinforced material of the outer wall, and the color of the inner wall and the color of the outer wall are distinguished. The superfine glass microspheres in the corrugated pipe contain gas, are of a hollow structure, have the advantages of low heat conductivity coefficient, light weight, smooth surface and the like, and can be used for preparing pipes with good thermal insulation and mechanical properties. The glass fibers in the corrugated pipe have the advantages of high tensile strength, good heat resistance, heat insulation, sound insulation, flame retardance, acid and alkali resistance, excellent insulativity and the like, and can be used for preparing the heat-resistant, acid-resistant, alkali-resistant and high-strength pipes.

Owner:河南金铨塑业有限公司

Large wheel diameter swing twist folding three-wheel skateboard

ActiveCN105457257BLower center of gravityLow ground clearanceSkate-boardsRoller skatesEngineeringMechanical engineering

A large-wheel-diameter swinging, twisting and folding type three-wheel skateboard comprises a double front frame, a back frame, pedal connecting parts, a swinging, twisting and folding mechanism, pedals, abrasionproof bottom strips, wheel fork bearings, wheel forks with shafts, PU wheels and circular insert covers. The double front frame is formed by welding two bent pipes, a back circular pipe and two rotating drums; the back frame is formed by welding a back bent pipe and a rotating drum; the pedal connecting parts are welded to the double front frame and the back frame; the swinging, twisting and folding mechanism is formed by connecting locking bushes, lock pin locating rings, nylon linings, a swinging and twisting structure, lock pins, springs and stepped bolts, and the two ends of the swinging, twisting and folding mechanism are connected with the double front frame and the back frame; the pedals are connected with the pedal connecting parts and the abrasionproof bottom strips; the wheel fork bearings are inlaid into the rotating drums; the wheel forks with the shafts are connected with the wheel fork bearings and the PU wheels; the circular insert covers are connected to the tops of screwed drums of locking bolts of the wheel forks with the shafts in a screwed mode.

Owner:徐州博创建设发展集团有限公司

A production process of modified fiber board

ActiveCN104175382BGood nail gripStrong nail gripDomestic articlesFlat articlesFiberDensity reduction

The invention relates to a production process of modified fiberboard, which includes: chipping, cooking and grinding, preparation of modified fiber material, drying, preparation of blank material, cold pressing, hot pressing, sawing, sanding and thickness determination, etc. step, wherein, in the preparation step of the modified fiber material, calcium powder is applied to the fiber material, and calcium powder is used to replace part of the wood fiber. When filling, the calcium powder is first mixed with glue, and then mixed with the fiber material , so that the gaps between fibers are filled with a mixture of calcium powder and glue, thereby improving the physical and chemical properties of the fiber board, achieving the purpose of increasing the density of the board, reducing wood consumption, improving the static bending strength and elastic modulus of the board, and The practical effect of reducing the production cost of fiberboard and effectively saving wood resources. Compared with ordinary fiberboard, it can save about 20% of wood, and the modified fiberboard produced has the advantages of high strength, strong nail holding force, good bending resistance, strong stability and flame retardancy.

Owner:湖北益嘉林业发展有限公司

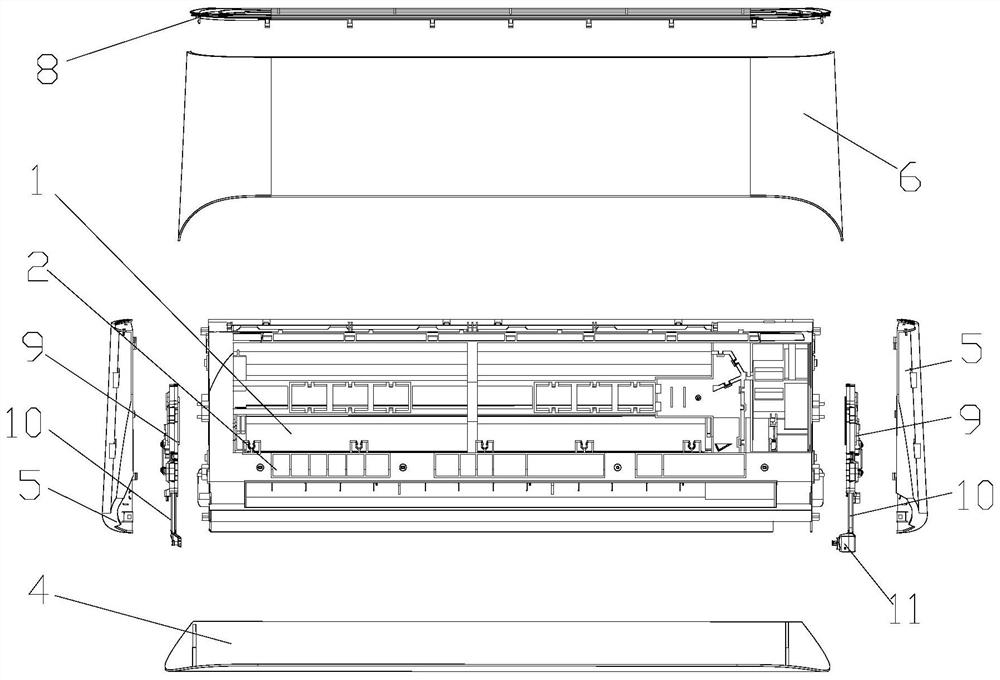

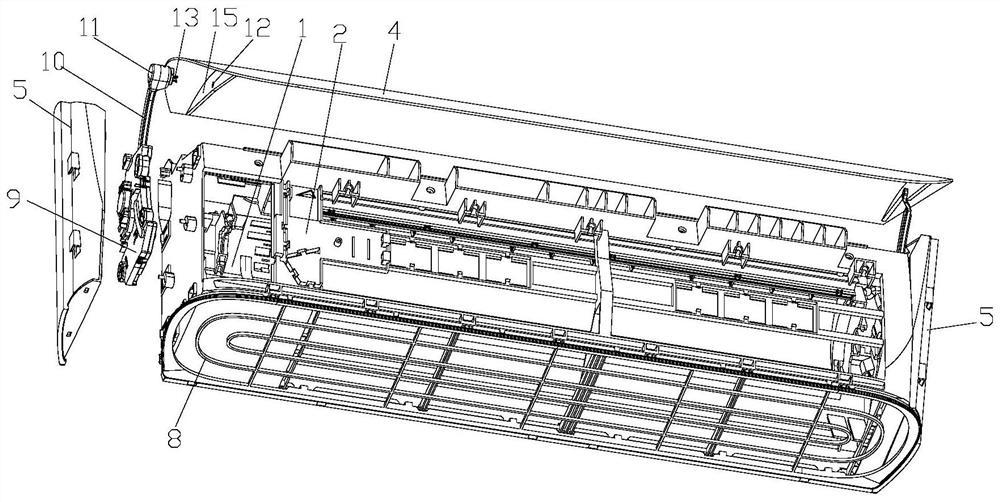

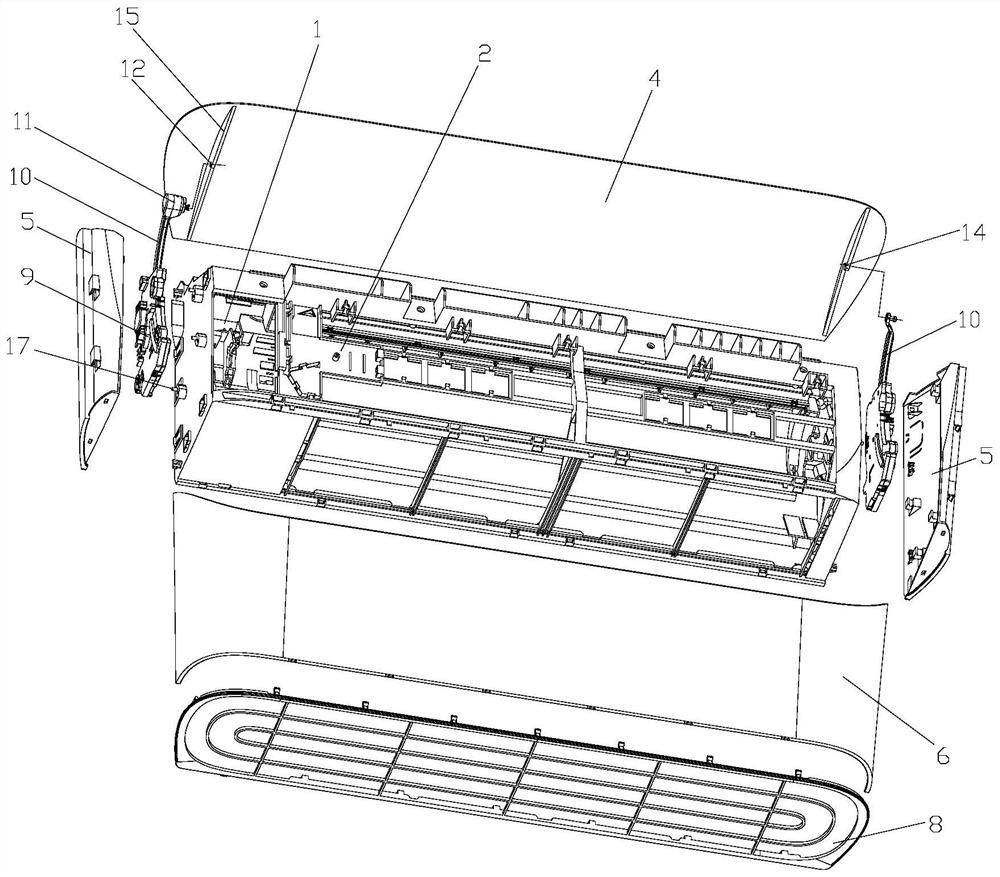

Wall-mounted machine

PendingCN112361458AGood visual appearanceLarge-scale diversionLighting and heating apparatusHeating and ventilation casings/coversPhysicsEngineering

The invention provides a wall-mounted machine. The wall-mounted machine comprises a bottom shell (1), a panel body (2) and an appearance shell, wherein the panel body (2) is installed on the bottom shell (1). The wall-mounted machine further comprises an air outlet (3), the appearance shell covers the bottom shell (1) and the panel body (2), the appearance shell comprises an air outlet panel (4) covering the whole appearance area of the front side of the air outlet (3), and the air outlet panel (4) can move relative to the air outlet (3) so as to guide airflow at the air outlet (3). Accordingto the wall-mounted machine, the wall-mounted machine has a good overall visual effect, meanwhile, large-range flow guide of the air outlet airflow can be achieved, the flow direction of the air outlet airflow is accurately organized, and the comfort of a user is effectively improved.

Owner:GREE ELECTRIC APPLIANCES INC

Swing twisting folding skateboard with large wheel diameter

ActiveCN105536235ALow ground clearanceLower center of gravitySkate-boardsRoller skatesWear resistantSlide plate

A swing twisting folding skateboard with a large wheel diameter comprises a front frame, a rear frame, pedal connecting pieces, a swing twisting folding mechanism, pedals, wear-resistant bottom strips, wheel fork bearings, wheel forks with shafts, PU wheels and insert round covers, wherein the front frame is formed by welding a bend pipe and a drum, the rear frame is formed by welding a rear bent pipe and a drum, the pedal connecting pieces are welded on the front frame and the rear frame, the swing twisting mechanism is formed by connecting a lock picking bush, a lockpin locating ring, a nylon lining piece, a swing twisting structure, a lockpin, a spring and a step bolt, the two ends of the swing twisting mechanism are connected with the front frame and the rear frame, the pedals are connected with the pedal connecting pieces and the wear-resistant bottom strips, the wheel fork bearing are inserted into the drums, the wheel forks with the shafts are connected with the wheel fork bearings and the PU wheels, and the insert piece round cover is connected to the top part of a screw cylinder of pair lock bolts of the wheel forks with the shafts in a screwing manner.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

Fire-retardant polyolefin based wood plastic composite material and preparation method thereof

Owner:NORTHEAST FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com