A preparation method of imitating hand-made machine-sewn ball and the prepared imitation hand-made machine-sewn ball

A machine-sewn ball, hand-like technology, which is applied to balls, sewing equipment, cloth feeding mechanisms, etc., can solve the problems of poor appearance quality and low stitching strength of machine-sewn balls, and is not easy to wear, not easy to leak, and has a visual appearance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

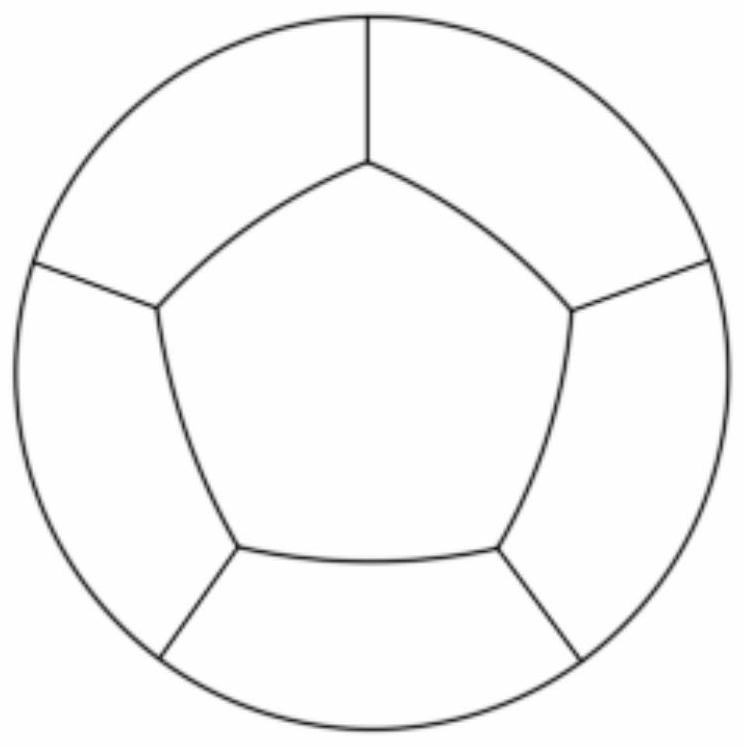

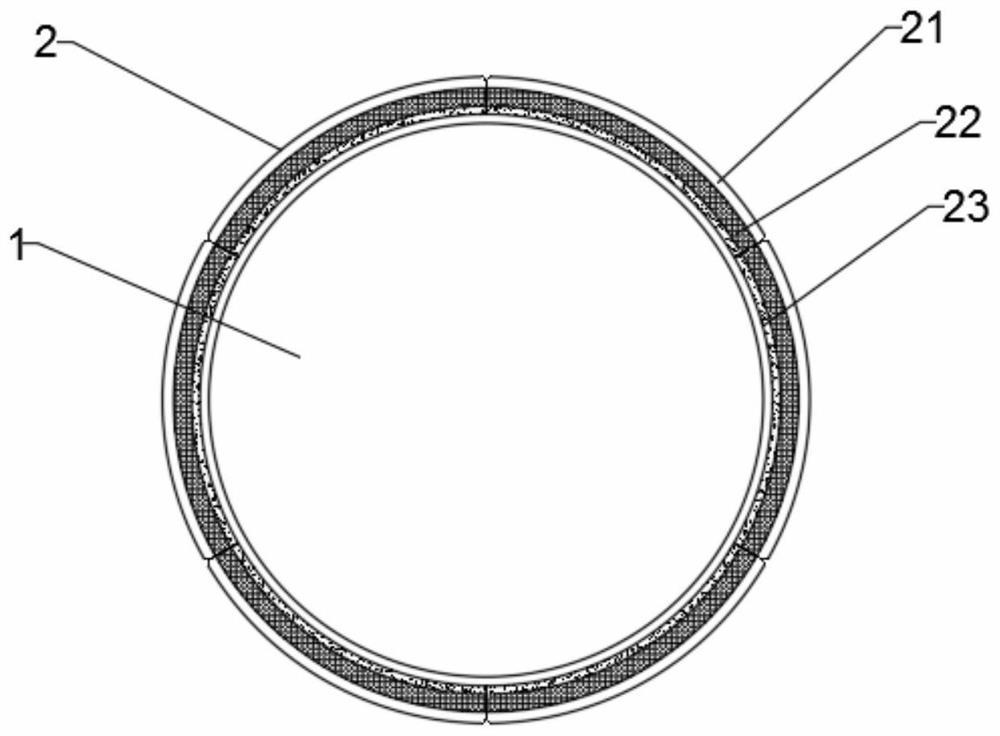

[0032] see Figure 1-4 , the present embodiment provides a ball imitating manual machine stitching, including a ball skin 2 and a bladder 1, the ball skin 2 includes a plurality of sheet-shaped monomers 24, and the sheet-shaped monomers 24 are provided with surfaces from the outside to the inside. Material layer 21, buffer layer 22 and base layer 23, the adjacent sheet-shaped monomers 24 are sewed together, and the periphery of the outer surface of the sheet-shaped monomer 24 is provided with a sewing edge 25, and the sewing edge 25 is Alternate concavo-convex grooves 251 and protrusions 252 are provided, and the grooves 251 and protrusions 252 are inlaid with each other on the seams 25 of adjacent sheet-shaped monomers 24 .

[0033] The shape of the sheet-shaped monomer 24 can be pentagonal, hexagonal, curved, fan-shaped, plum-shaped, straight, drum-shaped, S-shaped or circular. In this embodiment, the sheet-shaped monomer 24 The shape is a regular pentagon, the protrusion 2...

Embodiment 2

[0044] Compared with Embodiment 1, the difference of this embodiment is that the angle α between the two sides of the groove is 30°, the depth of the groove is 1 mm, the number of sewing stitches on the sewing edge is 6 stitches / inch, and the thickness of the sewing thread is 2400D, the tension N of the bottom thread in the sewing machine is 4kgf during sewing, and the temperature is 70°C during hot pressing and shaping. Two sheet-shaped monomers are sewn by the above sewing method and then tested for tensile strength.

Embodiment 3

[0046] Compared with Embodiment 1, the difference of this embodiment is that the angle α between the two sides of the groove is 40°, the depth of the groove is 2 mm, the number of sewing stitches on the sewing side is 7 stitches / inch, and the thickness of the sewing thread is 2700D, the tensile force of the bottom thread in the sewing machine is 5kgf when sewing, and the temperature is 80°C when hot-pressing and shaping. Two sheet-shaped monomers are sewn by the above sewing method and then tested for tensile strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile load | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com