Large wheel diameter skateboard

A large wheel diameter, skateboard technology, applied in the field of entertainment products, can solve the problems of high requirements on the ground, laborious swing, sensitive impact, etc., and achieve the effect of weight reduction, simple twisting mechanism and good visual perception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

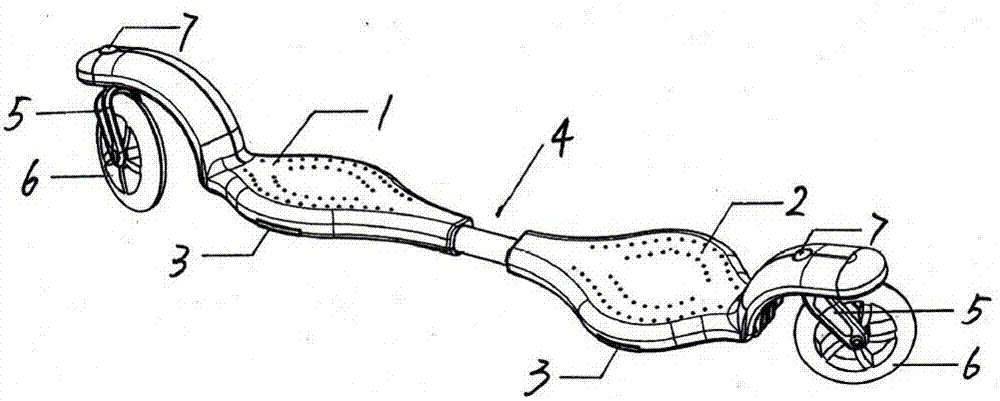

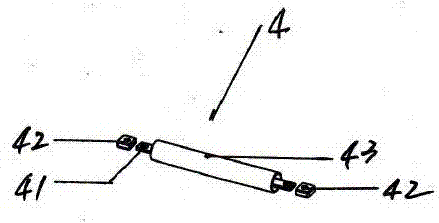

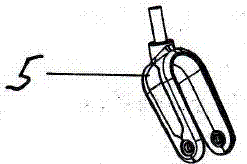

[0015] according to figure 1 , figure 2 and image 3 , the large wheel diameter skateboard includes a front plate frame 1, a rear plate frame 2, an anti-wear bottom strip 3, a wheel fork bearing, a twisting mechanism 4, a plastic wheel fork 5 with inserts, a PU wheel 6 and inserts round cover 7;

[0016] The front plate frame 1 is made of plastic injection molding, the front part of the front plate frame 1 is arc-shaped upward throw, and the front end of the arc-shaped upward throw of the front plate frame 1 has a counterbore on the upper and lower sides , the counterbore holes on the upper and lower sides of the front end of the front frame 1 are all counterbore holes with a diameter of φ26mm, a through hole is connected between the counterbore holes on the upper and lower sides of the front end of the front frame 1, and the front end of the front frame 1 sinks up and down The center connection line of the hole is inclined up and down, the inclination of the center connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com