Glass microsphere and glass fiber composite reinforced corrugated pipe and production method thereof

A technology of composite reinforcement and glass microbeads, which is applied in the direction of building components, slender components, etc., can solve the problems of affecting the practical value of bellows, low impact of falling weight, and poor compression resistance, and achieve high practical value and tensile strength. High strength and good pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

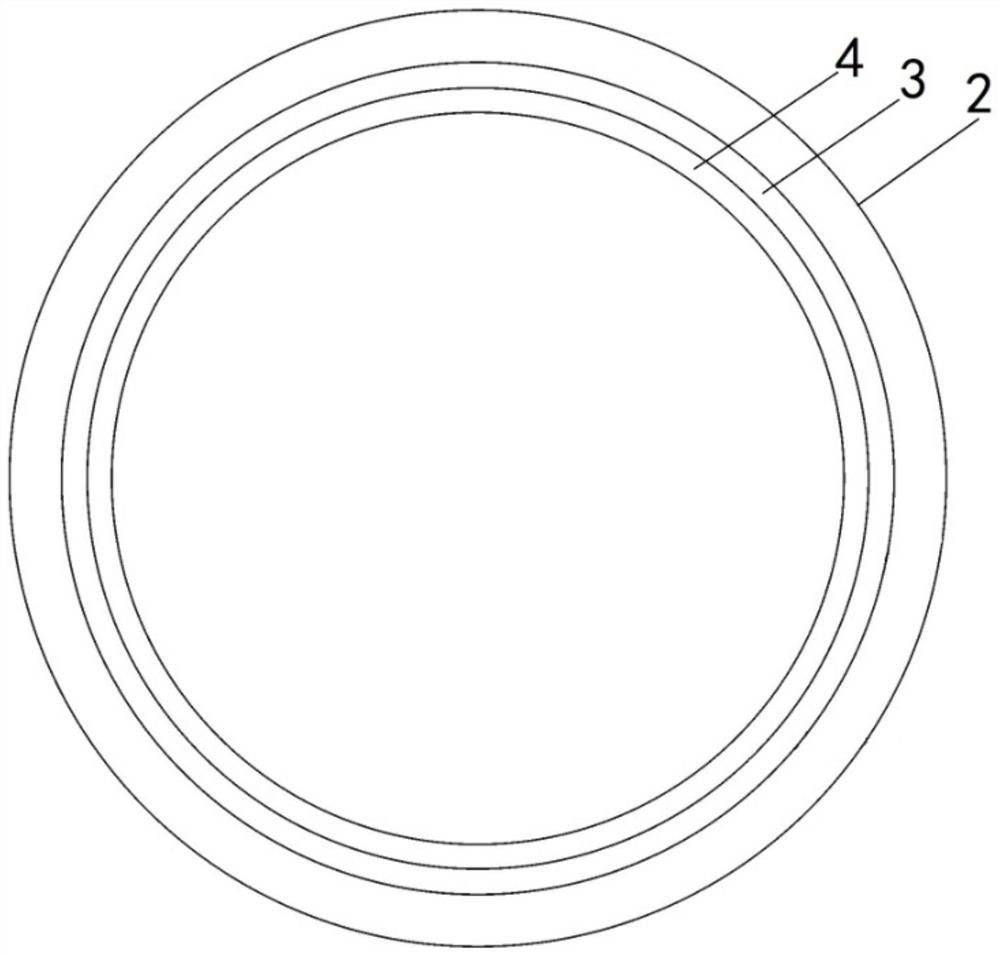

Image

Examples

Embodiment 1

[0044] A method for producing a glass microsphere and glass fiber composite reinforced corrugated pipe, the specific steps are:

[0045] Step 1: Measure the composite reinforcing material components required for the production of the outer wall in proportion, add them to a high-speed mixer and stir for 5 minutes, and after mixing evenly, discharge the materials and add them to the hopper of the outer wall extruder.

[0046] The composite reinforcing material of the outer wall is measured in parts by mass, and its composition is: 20 parts of hollow glass microspheres, 20 parts of chopped glass fibers, 25 parts of calcium carbonate, 50 parts of high crystalline polypropylene, 4 parts of Malay Anhydride grafted polypropylene, 0.5 parts of titanium blue pigment, 0.2 parts of silane coupling agent KH550, 0.8 parts of stearic acid SA1801 lubricant, 0.8 parts of polyethylene wax PE 110 lubricant.

[0047] Step 2: Measure the composite reinforcing material components required for the ...

Embodiment 2

[0059] A method for producing a glass microsphere and glass fiber composite reinforced corrugated pipe, the specific steps are:

[0060] Step 1: Measure the composite reinforcing material components required for the production of the outer wall in proportion, add them to a high-speed mixer and stir for 5 minutes, and after mixing evenly, discharge the materials and add them to the hopper of the outer wall extruder.

[0061] The composite reinforcing material of the outer wall is measured in parts by mass, and its composition is: 40 parts of hollow glass microspheres, 40 parts of chopped glass fibers, 50 parts of calcium carbonate, 100 parts of high crystalline polypropylene, 6 parts of Malay Anhydride grafted polypropylene, 0.8 parts of titanium blue pigment, 1 part of silane coupling agent KH550, 1.5 parts of stearic acid SA1801 lubricant, 1.5 parts of polyethylene wax PE 110 lubricant.

[0062] Step 2: Measure the composite reinforcing material components required for the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com