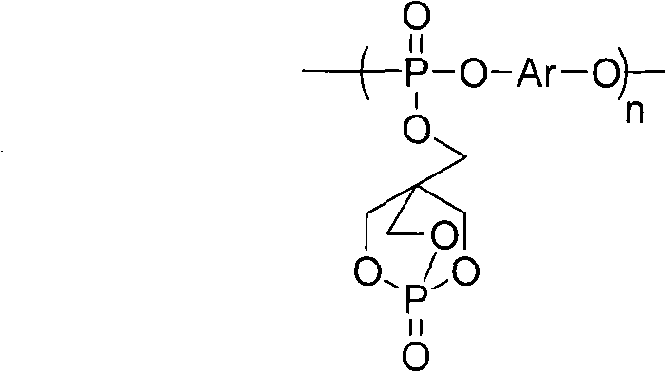

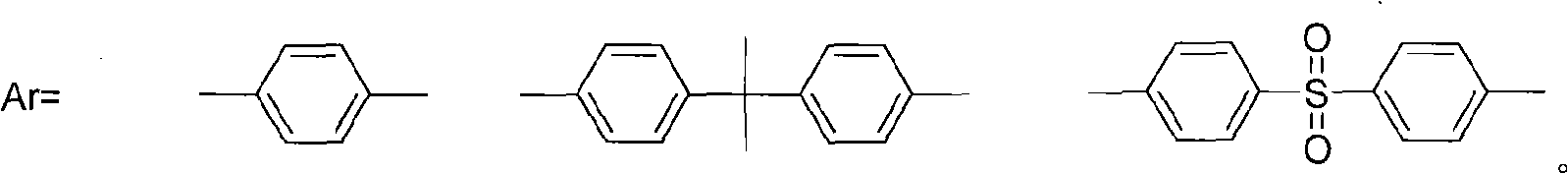

Preparation of polyphosphate flame retardant having dicyclic phosphoric acid ester structure

A technology of bicyclic phosphate and polyphosphate, which is applied in the fields of chemical instruments and methods, organic chemistry, and compounds of Group 5/15 elements of the periodic table, etc., which can solve the problem of material performance degradation, difficult and durable flame retardancy, and thermal stability Low-level problems, to achieve the effect of good char formation, narrow decomposition range, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Step 1: Add 4.5g (0.025mol) of PEPA, 2.3ml (0.025mol) of phosphorus oxychloride and 20ml of dichloromethane into a three-necked flask equipped with a constant pressure dropping funnel, a stirrer and a thermometer. Stir and slowly add 2.51 g (0.025 mol) triethylamine dropwise, and continue to react for 4 hours after the dropwise addition is completed. After the reaction is completed, the salt is removed by filtration to obtain the reaction intermediate. The intermediate was directly used in the next step of synthesis without further isolation.

[0022] Step 2: Add the intermediate mother liquor and bisphenol S (BPS) 6.25g (0.025mol) into a multi-necked flask equipped with a stirrer, a distillation device and a nitrogen inlet and outlet, heat and stir under a nitrogen flow, and evaporate the solvent, and then Gradually raise the temperature by 25°C / hour, and control the reaction at different temperatures for a certain period of time, until the final reaction temperature ...

Embodiment 2

[0025] Step 1: Add 4.5g (0.025mol) of PEPA, 2.98ml (0.033mol) of phosphorus oxychloride and 20ml of dichloromethane into a three-necked flask equipped with a constant pressure dropping funnel, a stirrer and a thermometer. Stir and slowly add 2.51 g (0.025 mol) triethylamine dropwise, and continue to react for 4 hours after the dropwise addition is completed. After the reaction is completed, the salt is removed by filtration to obtain the reaction intermediate. The intermediate was directly used in the next step of synthesis without further isolation.

[0026] Step 2: Add 9.07g (0.036mol) of the intermediate mother liquor and bisphenol S (BPS) into a multi-necked flask equipped with a stirrer, a distillation device and a nitrogen inlet and outlet, heat and stir under a nitrogen flow, and evaporate the solvent, and then Gradually raise the temperature by 25°C / hour, and control the reaction at different temperatures for a certain period of time, until the final reaction temperat...

Embodiment 3

[0029] Step 1: Add 4.5g (0.025mol) of PEPA, 2.3ml (0.025mol) of phosphorus oxychloride and 20ml of dichloromethane into a three-necked flask equipped with a constant pressure dropping funnel, a stirrer and a thermometer. Stir and slowly add 2.51 g (0.025 mol) of triethylamine dropwise, and continue to react for 1 hour after the dropwise addition is completed. After the reaction is completed, the salt is removed by filtration to obtain the reaction intermediate. The intermediate was directly used in the next step of synthesis without further isolation.

[0030] Step 2: Add the intermediate mother liquor and bisphenol S (BPS) 6.25g (0.025mol) into a multi-necked flask equipped with a stirrer, a distillation device and a nitrogen inlet and outlet, heat and stir under a nitrogen flow, and evaporate the solvent, and then Gradually raise the temperature by 25°C / hour, and control the reaction at different temperatures for a certain period of time, until the final reaction temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com