Polylactic acid/starch expansion flame-resistant composite material, and preparation method thereof

A technology of intumescent flame retardant and composite materials, which is applied in the field of polylactic acid/starch intumescent flame retardant composite materials and its preparation, can solve the problems of poor compatibility between starch and matrix plastics, failure to meet application requirements, poor thermal stability of starch, etc. , to achieve the effect of promoting char formation ability, high phosphorus content and high phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

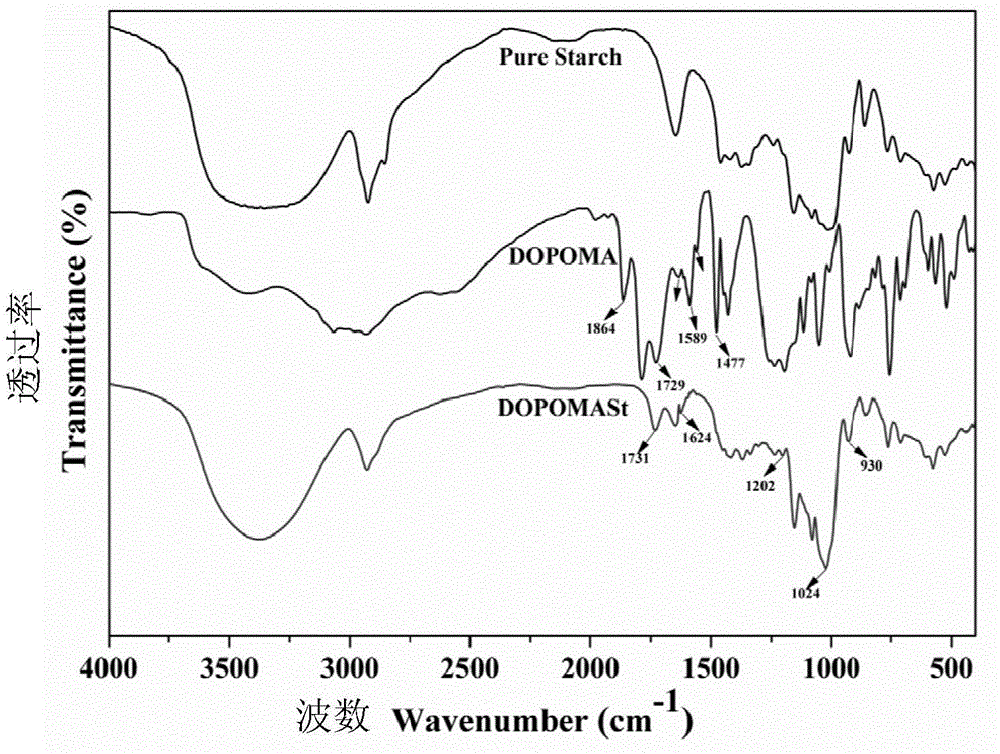

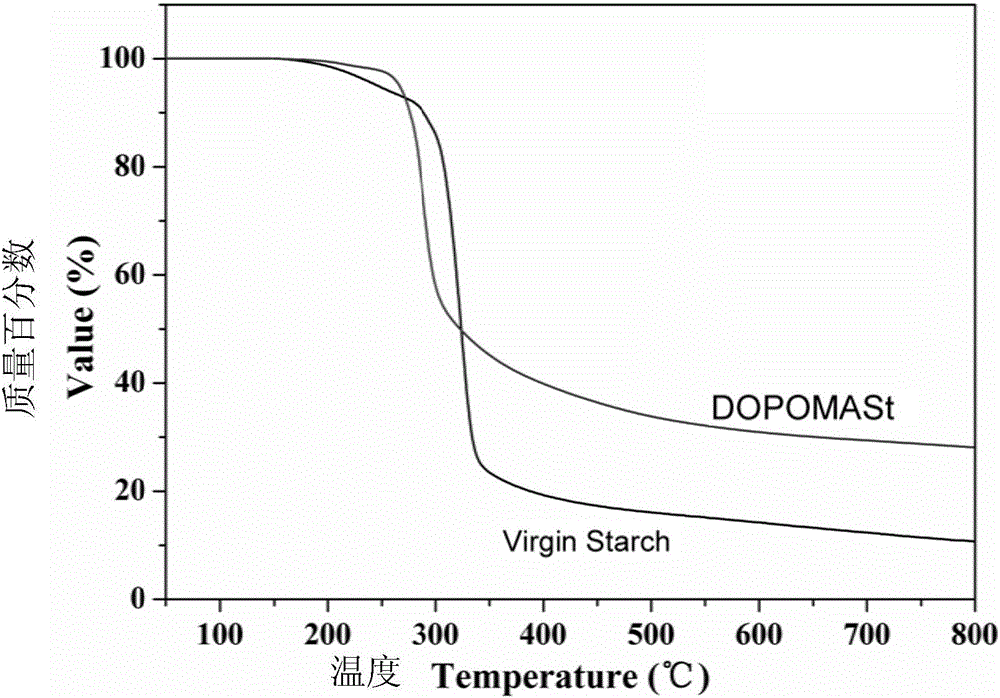

[0061] In a 250mL three-necked flask, 20g 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide (DOPO) and 15g maleic anhydride (MA) were dissolved in 50mL toluene and 20mL dioxy In the six ring, heated to 40°C, protected by nitrogen, and reacted at reflux for 12h. After the completion of the reaction, the solvent was removed by rotary evaporation, and the product 1 was obtained after vacuum drying, which was ready for use.

[0062] In a 250mL three-necked flask, 20g starch (corn starch) and 40mL pyridine were heated to 65°C under nitrogen protection and refluxed for 2h. After the temperature dropped to 50°C, 20g of product 1 (dissolved in DMSO) was added with the catalyst 4-dimethylaminopyridine, protected by nitrogen, and reacted at 50°C under reflux for 12h. After the reaction is completed, it is washed, purified, and dried in vacuum to obtain bio-based phosphorous starch, that is, modified starch.

Embodiment 2

[0064] In a 250 mL three-necked flask, 20 g DOPO and 18 g maleic anhydride (MA) were dissolved in 50 mL xylene and 20 mL THF (tetrahydrofuran) respectively, heated to 50° C., protected by nitrogen, and reacted under reflux for 24 hours. After the completion of the reaction, the solvent was removed by rotary evaporation, and the product 1 was obtained after vacuum drying, which was ready for use.

[0065] In a 250mL three-necked flask, 20g starch (corn starch) and 60mL pyridine were heated to 75°C and refluxed for 4h under nitrogen protection. After the temperature dropped to 50°C, 25g of product 1 (dissolved in DMSO) was added with the catalyst 4-dimethylaminopyridine, protected by nitrogen, and reacted under reflux for 24h. After the reaction is completed, it is washed, purified, and dried in vacuum to obtain bio-based phosphorous starch, that is, modified starch.

Embodiment 3

[0067] In a 250mL three-necked flask, 20g DOPO and 21g maleic anhydride (MA) were dissolved in 70mL xylene, heated to 60°C, protected by nitrogen, and reacted under reflux for 24h. After the completion of the reaction, the solvent was removed by rotary evaporation, and the product 1 was obtained after vacuum drying, which was ready for use.

[0068] In a 250mL three-necked flask, 20g starch (corn starch) and 80mL pyridine were heated to 85°C and refluxed for 8h under nitrogen protection. After the temperature dropped to 65°C, 35g of product 1 (dissolved in DMSO) was added with the catalyst 4-dimethylaminopyridine, protected by nitrogen, and reacted under reflux for 24h. After the reaction is completed, it is washed, purified, and dried in vacuum to obtain bio-based phosphorous starch, that is, modified starch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com