Method for preparing bio-based flame-retardant epoxy resin and prepared bio-based flame-retardant epoxy resin

A technology of epoxy resin and preparation method, which is applied in chemical instruments and methods, compounds of group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problems of non-renewability, poor flame retardancy, and toxic raw materials, and achieve improvement Cross-linking density, improved thermal stability, simple and low toxicity in the reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

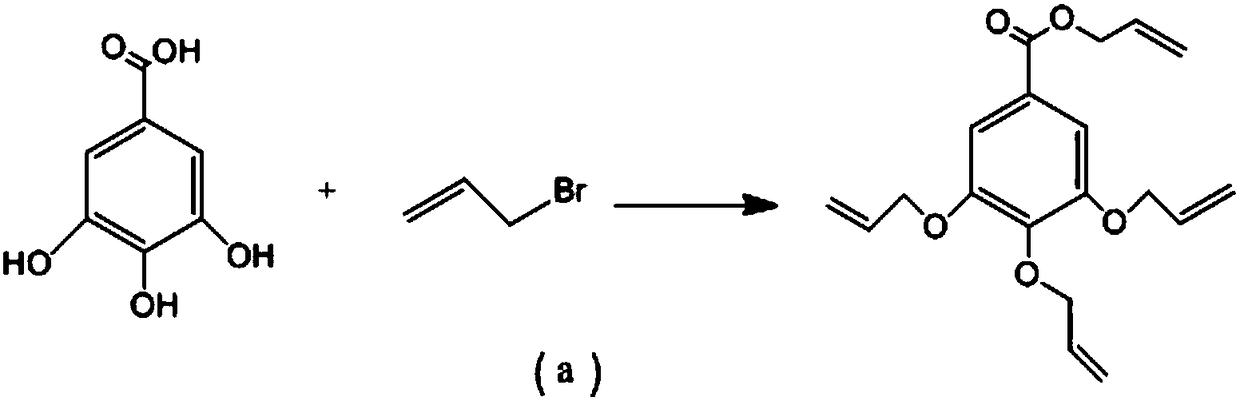

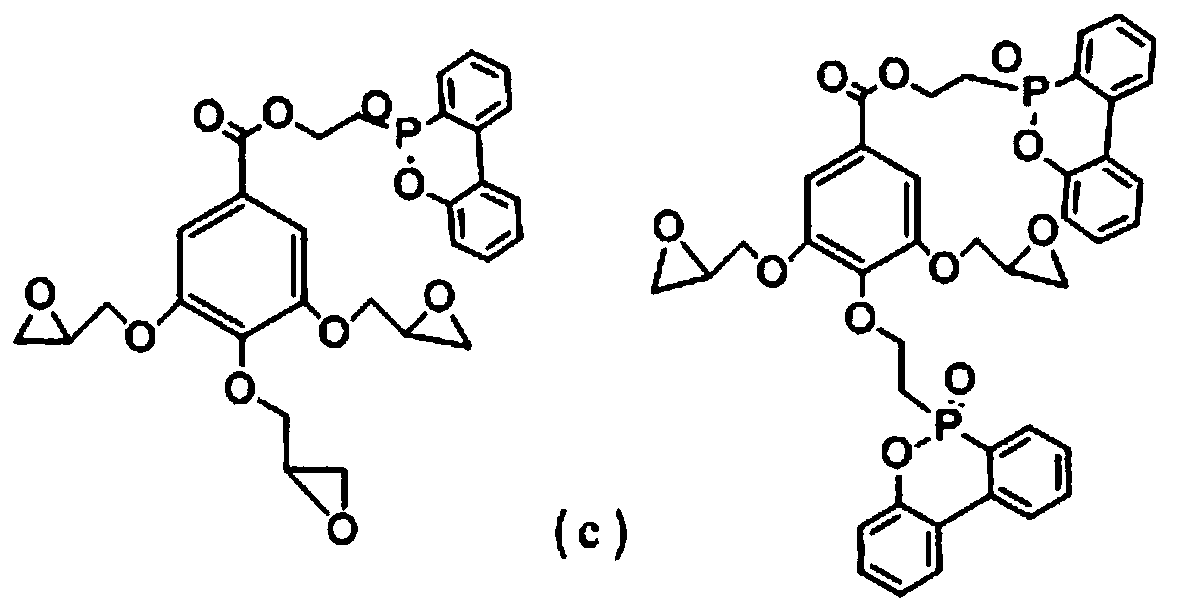

[0029] (1) Put 20ml tetrahydrofuran, 0.088mol potassium carbonate, and 0.0176mol gallic acid into a sealed flask, and vigorously stir for 5 minutes. Then, a solution of allyl bromide was slowly added over 20 min. The mixture was heated to 50 °C and maintained at this temperature for 20 h. The obtained product was filtered to remove impurities in the solution, and then rotary evaporated. Finally, the crude product was dissolved in dichloromethane and washed with saturated brine. The dichloromethane layer was evaporated by rotary evaporation to obtain the refined product, which was dried under vacuum at 50°C for 7 hours to obtain the product 1.

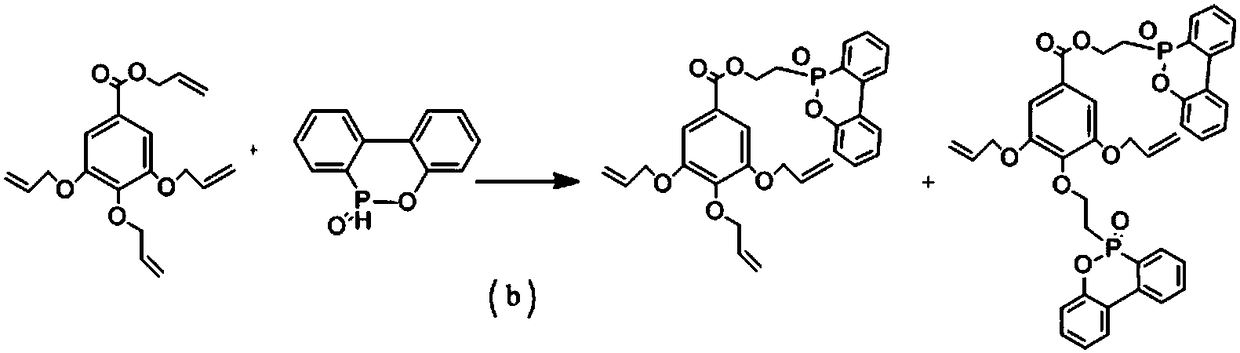

[0030](2) Add 0.0176mol DOPO and 30ml tetrahydrofuran into a round bottom flask with a condenser, and heat to 60°C under an argon atmosphere. After complete dissolution of DOPO, 0.0176 mol of product 1 was added within 30 min and the reaction mixture was kept at this temperature for 10 h. After cooling to room temperature, the produ...

Embodiment 2

[0038] (1) Put 20ml of dichloromethane, 0.088mol of potassium carbonate and 0.0176mol of gallic acid into a sealed flask, and vigorously stir for 20min. Then, a solution of allyl bromide in dichloromethane was slowly added over 60 min. The mixture was heated to 80 °C and maintained at this temperature for 48 h. The resulting product was filtered and rotary evaporated. Finally, the crude product was dissolved in dichloromethane and washed with saturated brine. The dichloromethane layer was evaporated by rotary evaporation to obtain the refined product, and the product 1 was obtained by vacuum drying at 80° C. for 15 h.

[0039] (2) Add 0.0176 mol of DOPO and 80 ml of dichloromethane into a round bottom flask with a condenser, and heat the flask to 100° C. under an argon atmosphere. After complete dissolution of DOPO, 0.0176 mol of product 1 was added within 80 min, and the reaction mixture was kept at this temperature for 40 h. After cooling to room temperature, the product...

Embodiment 3

[0047] (1) Put 30ml of acetone, 0.088mol of potassium carbonate and 0.0176mol of gallic acid into a sealed flask, and stir vigorously for 15min. Then, a solution of allyl bromide in acetone was slowly added within 40 min. The mixture was heated to 60 °C and maintained at this temperature for 30 h. The resulting product was filtered and rotary evaporated. Finally, the crude product was dissolved in dichloromethane and washed with saturated brine. The dichloromethane layer was evaporated by rotary evaporation to obtain the refined product, and the product 1 was obtained by vacuum drying at 70° C. for 10 h.

[0048] (2) Add 0.0176mol DOPO and 50ml acetone to a round bottom flask with a condenser, and heat the flask to 80°C under an argon atmosphere. After complete dissolution of DOPO, 0.0176 mol of product 1 was added within 50 min, and the reaction mixture was kept at this temperature for 30 h. After cooling to room temperature, the product was obtained by filtration, washed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com