Method for preparing polyimide intercalated grafted magnesium hydroxide flame retardant

A technology of magnesium hydroxide and polyimide, applied in the direction of fire-resistant coatings, etc., can solve the problems of great influence on physical-mechanical properties and processing properties, large specific surface area, low tensile strength and limiting oxygen index, etc., to achieve flame retardancy The effect is remarkable, the preparation process is simple, and the effect of good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

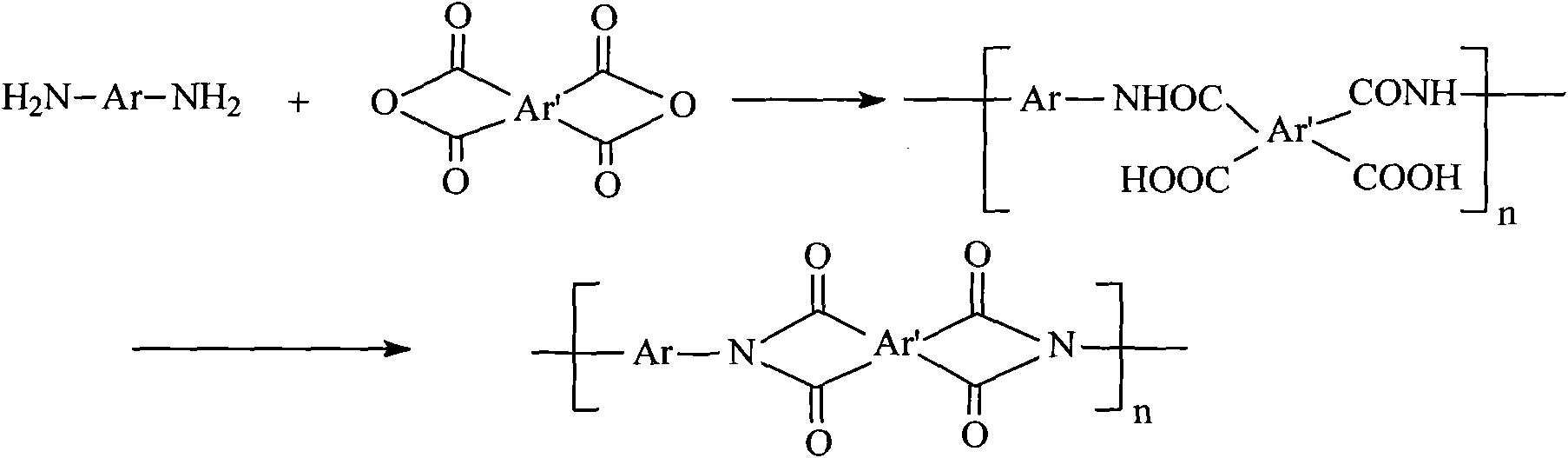

Method used

Image

Examples

Embodiment 1

[0040] 2.0 g (0.01 mol) of 4,4'-diaminodiphenyl ether aromatic dibasic primary amine, 1.2 g of aminopropyltrimethoxysilane (KH-550) amino-terminated coupling agent and 1000 ml of N, N-dimethylacetamide mixed with a strong polar aprotic organic solvent, stirred evenly at room temperature, added 100.0 grams of magnesium hydroxide powder, and dispersed by high-speed emulsification machine (6000-10000r / min) for 20min-30min, added 2.18 grams (0.01 moles) of pyromellitic dianhydride powder, stirred and reacted at room temperature for 1-2 hours, added 0.1 grams of toluenesulfonic acid catalyst and 20 ml of toluene aromatic hydrocarbon solvent, heated and refluxed for 6-8 hours after water separation , separate toluene and 20%~40%vol. (relative to the volume of the original strong polar aprotic organic solvent) N, N-dimethylacetamide solvent, cooling, standing, filtering, drying, to obtain 102.9 grams of poly Imide intercalation grafted magnesium hydroxide flame retardant powder.

[...

Embodiment 2

[0046] 21.62 grams (0.1 mole) of 3,3'-diamino-4,4'-dihydroxybiphenyl aromatic dibasic primary amine, the amino terminal group coupling agent of 1.81 gram end aminopropyltriethoxysilane and Mix 4,300 ml of N-methyl-2-pyrrolidone with a strong polar aprotic organic solvent, stir evenly at room temperature, add 216.2 g of magnesium hydroxide powder, and use a high-speed emulsifier (6000-10000r / min) for high-speed shear dispersion for 20min- 30min, add 32.34 grams (0.11 mole) 3,3',4,4'-tetracarboxylic acid biphenyl dianhydride powder, stir and react at room temperature for 1-2 hours, add 2.16 grams of toluenesulfonic acid catalyst and 430 milliliters of xylene Aromatic hydrocarbon solvent, after heating and reflux for water separation for 6-8 hours, separate xylene and 20% to 40% vol. of N-methyl-2-pyrrolidone solvent, cool, stand still, filter, and dry to obtain 266.2 grams Polyimide intercalation grafted magnesium hydroxide flame retardant powder.

[0047] 57.0 grams of the obt...

Embodiment 3

[0050] 2.0 grams (0.01 moles) of 4,4'-diaminodiphenyl ether and 2.48 grams (0.01 moles) of 4,4'-diaminodiphenylsulfone aromatic dibasic primary amines, 1.8 grams of terminal aminopropyl trimethoxy base silane (KH-550) amino terminal coupling agent and 2700 milliliters of N, N-dimethylacetamide strong polar aprotic organic solvent, stir well at room temperature, add 180.0 grams of magnesium hydroxide powder, and use high-speed Emulsifier (6000-10000r / min) high-speed shear dispersion for 20min-30min, add 2.18g (0.01mol) of pyromellitic dianhydride powder and 2.94g (0.01mol) of 3,3',4,4'-tetracarboxylic acid Biphenyl dianhydride powder, stirred and reacted at room temperature for 1-2 hours, added 0.31 g of toluenesulfonic acid catalyst, 20 ml of toluene and 50 ml of xylene aromatic hydrocarbon solvent, heated and refluxed for 6-8 hours, separated Toluene and 20% to 40% vol. of N, N-dimethylacetamide solvent, cooling, standing, filtering, and drying to obtain 188.5 grams of polyim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com