Preparation method of reaction type halogen-free phosphorous flame retardant polyester polyol

A flame-retardant polyester and polyol technology, which is applied in the field of preparation of organic polymer compounds, can solve the problems of non-environmental protection in the production process, migration of flame retardants, and low flame-retardant performance, and achieve easy industrial production, improved compressive strength, The effect of meeting environmental protection requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

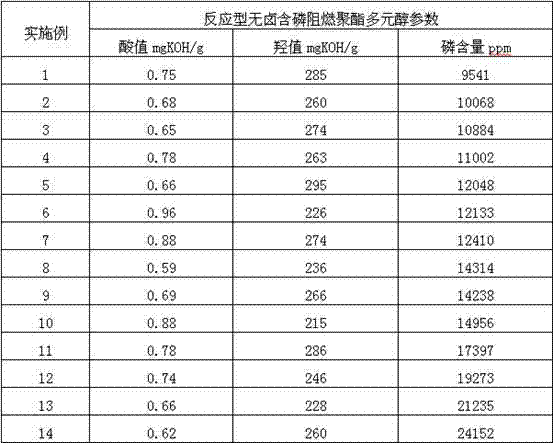

Examples

Embodiment 1

[0026] Mix 200kg of malonic acid, 155kg of ethylene glycol, 17.75kg of hydroxymethylphenyl hypophosphorous acid and 0.37kg of tetramethyl titanate into the reaction kettle, heat up under stirring, when the temperature reaches 60-90°C, fill it with nitrogen Evacuate and continue to heat up. When the temperature reaches 125-155°C, react for 2-8 hours, then continue to heat up to 180°C, vacuumize to 100-5000Pa, and control the reaction temperature to 180-245°C. After reacting for 2 to 4 hours under this condition, take samples to test the acid value every 10 to 40 minutes. When the acid value drops below 2mgKOH / g, stop heating and stop stirring. When the temperature in the kettle drops to 130 to 160°C, stop the vacuum. The material is discharged to obtain a reactive halogen-free phosphorus-containing flame-retardant polyester polyol.

Embodiment 2

[0028] Mix 234kg of malonic acid, 222kg of propylene glycol, 22.8kg of flame retardant (hydroxymethylphenylphosphorous acid: hydroxypropylphenylphosphorous acid = 3:1 mass ratio) and 0.96kg of tetraisopropyl titanate into the reaction In the still, others are with embodiment 1.

Embodiment 3

[0030] 234kg succinic acid, 196kg propylene glycol, 22.8kg hydroxyethyl phenyl hypophosphorous acid and 0.96kg antimony trioxide were mixed into the reactor, and the others were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com