Environment-friendly flame-retardant hard polyurethane foaming plastic

A technology of rigid polyurethane and foamed plastics, applied in the field of foamed plastics, can solve the problems of great influence on the mechanical properties of matrix materials, poor heat resistance of phosphate and phosphonate esters, poor material stability and durability, etc., and achieve excellent flame retardant effect. , Good compatibility, high flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

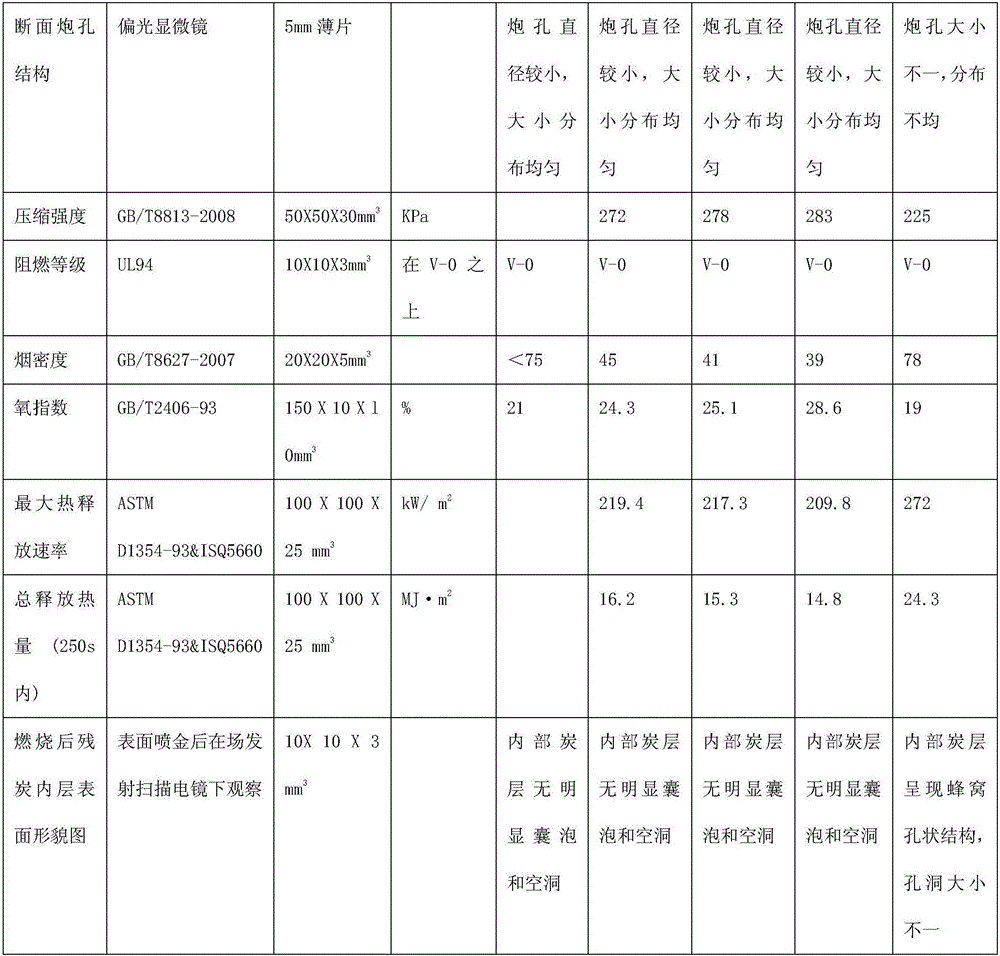

Embodiment 1

[0021] An environmentally friendly flame-retardant rigid polyurethane foam, the raw materials of which are:

[0022] Polyisocyanate: toluene diisocyanate 120Kg;

[0023] Polyether polyol: 95Kg;

[0024] Foaming agent: water 2Kg;

[0025] Foam stabilizer: AK-88012Kg;

[0026] Catalyst: A331Kg;

[0027] Glycerin: 1Kg;

[0028] Flame retardant: [Bmim] DBP 4Kg.

[0029] The steps of preparing environment-friendly flame-retardant rigid polyurethane foam plastics according to above-mentioned raw materials are as follows:

[0030] (1) Mix 1-methylimidazole and tributyl phosphate with a molar ratio of 3:3 in a round-bottomed flask, place the flask in an oil bath at a temperature of 140°C for 9 hours, and then cool naturally to room temperature to obtain Light brown transparent product. After the reaction, purify the reaction product with diethyl ether, add diethyl ether twice the volume of the reaction product each time, shake and separate layers, remove 1-methylimidazole and t...

Embodiment 2

[0036] An environmentally friendly flame-retardant rigid polyurethane foam, the raw materials of which are:

[0037] Polyisocyanate: polymethylene polyphenyl polyisocyanate 130Kg;

[0038] Polyether polyol: 100Kg;

[0039] Foaming agent: n-pentane 3Kg;

[0040] Foam stabilizer: AK-8803 2.5Kg;

[0041] Catalyst: A331.5Kg;

[0042] Glycerin: 1.5Kg;

[0043] Flame retardant: [Bmim] DBP 7Kg.

[0044] The steps of preparing environment-friendly flame-retardant rigid polyurethane foam plastics according to above-mentioned raw materials are as follows:

[0045](1) Mix 1-methylimidazole and tributyl phosphate with a molar ratio of 10:10 in a round-bottomed flask, place the flask in an oil bath at a temperature of 150°C for 10 hours, and then cool naturally to room temperature to obtain Light brown transparent product. After the reaction, purify the reaction product with diethyl ether, add diethyl ether twice the volume of the reaction product each time, shake and separate the l...

Embodiment 3

[0051] An environmentally friendly flame-retardant rigid polyurethane foam, the raw materials of which are:

[0052] Polyisocyanate: diphenylmethane diisocyanate 140Kg;

[0053] Polyether polyol: 105Kg;

[0054] Foaming agent: cyclopentane 5Kg;

[0055] Foam stabilizer: AK-88083Kg;

[0056] Catalyst: A332Kg;

[0057] Glycerin: 2Kg;

[0058] Flame retardant: [Bmim] DBP10Kg.

[0059] The steps of preparing environment-friendly flame-retardant rigid polyurethane foam plastics according to above-mentioned raw materials are as follows:

[0060] (1) Mix 1-methylimidazole and tributyl phosphate with a molar ratio of 10:10 in a round-bottomed flask, place the flask in an oil bath at a temperature of 160°C for 11 hours, and then cool naturally to room temperature to obtain Light brown transparent product. After the reaction, purify the reaction product with diethyl ether, add diethyl ether twice the volume of the reaction product each time, shake and separate layers, remove 1-me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com