Copious cooling work table, copious cooling laser shock peening experiment system and control method thereof

A technology of laser shock strengthening and workbench, which is applied in laser welding equipment, heat treatment process control, manufacturing tools, etc. It can solve the problems of low temperature adjustment response speed, large amount of liquid nitrogen usage, and optimal cryogenic temperature difference. The effect of improving temperature control accuracy, reducing processing costs, and widening the temperature adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

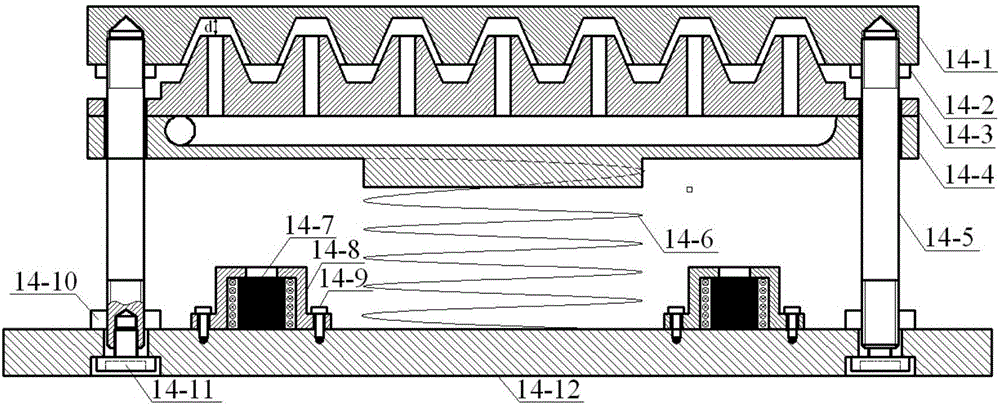

[0037] like figure 1 , figure 2 As shown, the cryogenic laser shock strengthening experiment system of the present invention mainly includes a casing 33, a laser device 1, an optical path adjustment system, a cryogenic workbench 14, a two-axis motion platform 23, a temperature sensor, a liquid nitrogen tank, and an automatic air compressor. Machine 29, PLC integrated control system 30 and master console 32. The outer shell 33 is divided into a cryogenic treatment area, an optical adjustment area, and a large equipment placement area by the insulation layer 16 . The laser 1, liquid nitrogen tank, automatic air compressor 29, and master console 32 are all placed in the large equipment storage area, and the laser 1 is located at the top of the large equipment storage area...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com