Flame-retardant nanometer film and preparation method and application thereof

A nanomembrane and nanocellulose technology, applied in the field of nanomaterials, to achieve the effects of increasing the formation speed, improving flame retardancy, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

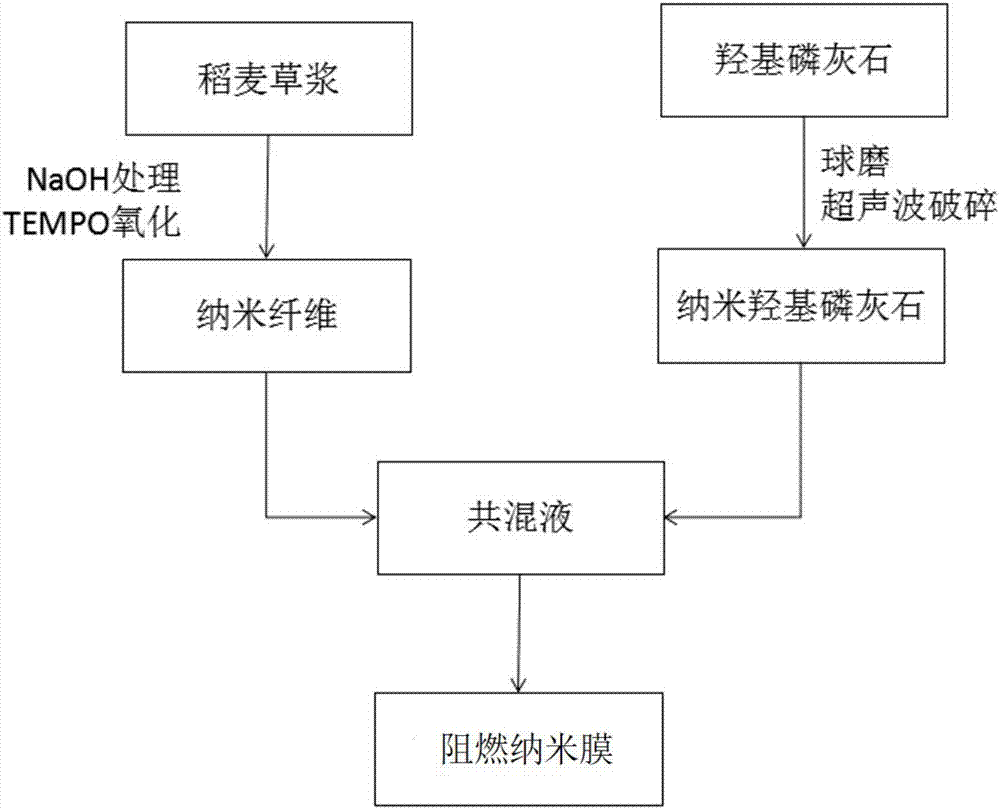

Method used

Image

Examples

Embodiment 1

[0029] A flame retardant nano film, its preparation method is as follows:

[0030] (1) After treating rice-wheat straw pulp with 15wt% NaOH solution, the additions of NaBr, TEMPO and NaClO in the rice-wheat straw fiber after per gram of absolute dry alkali treatment are 0.15g, 0.015g and 0.6g respectively, and the pulp concentration is 2wt %, the reaction time is 1.5h, the pH=10.0~10.3, and the rotation speed is 500r / min. After the TEMPO oxidation treatment, use a high-pressure homogenizer to process twice at a pressure of 10,000 psi, and then process five times at a pressure of 25,000 psi to obtain nanocellulose.

[0031] (2) The nanocellulose is formulated into a solution, and the flame-retardant nano-film is obtained after forming a film for 48 hours under constant temperature and humidity conditions with a temperature of 30° C. and a humidity of 90%.

[0032] The limiting oxygen index of the prepared nano-film is 24.4% as measured by an oxygen index measuring instrument, ...

Embodiment 2

[0034] A flame retardant nano film, its preparation method is as follows:

[0035] (1) After treating rice-wheat straw pulp with 15wt% NaOH solution, the additions of NaBr, TEMPO and NaClO in the rice-wheat straw fiber after per gram of absolute dry alkali treatment are 0.15g, 0.015g and 0.6g respectively, and the pulp concentration is 2wt %, the reaction time is 1.5h, the pH=10.0~10.3, and the rotation speed is 500r / min. After the TEMPO oxidation treatment, use a high-pressure homogenizer to process twice at a pressure of 10,000 psi, and then process five times at a pressure of 25,000 psi to obtain nanocellulose.

[0036] (2) Dry the hydroxyapatite at 110° C. for 12 hours, take it out, and then perform ball milling for 72 hours, then use an ultrasonic cell crusher with a power of 800 w, and adjust the output power to 30%, and process it for 20 minutes to obtain a nano-hydroxyapatite emulsion.

[0037] (3) According to the mass addition ratio of nano-hydroxyapatite relative t...

Embodiment 3

[0040] (1) After treating rice-wheat straw pulp with 15wt% NaOH solution, the additions of NaBr, TEMPO and NaClO in the rice-wheat straw fiber after per gram of absolute dry alkali treatment are 0.15g, 0.015g and 0.6g respectively, and the pulp concentration is 2wt %, the reaction time is 1.5h, the pH=10.0~10.3, and the rotation speed is 500r / min. After the TEMPO oxidation treatment, use a high-pressure homogenizer to process twice at a pressure of 10,000 psi, and then process five times at a pressure of 25,000 psi to obtain nanocellulose.

[0041] (2) Dry the hydroxyapatite at 100°C for 24 hours, take it out, and then perform ball milling for 48 hours, then use an ultrasonic cell crusher with a power of 800w, and adjust the output power to 40%, and process for 10 minutes to obtain a nano-hydroxyapatite emulsion.

[0042] (3) According to the mass addition ratio of nano-hydroxyapatite relative to the dry nano-cellulose 8%, the nano-hydroxyapatite emulsion is added to the nano-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com