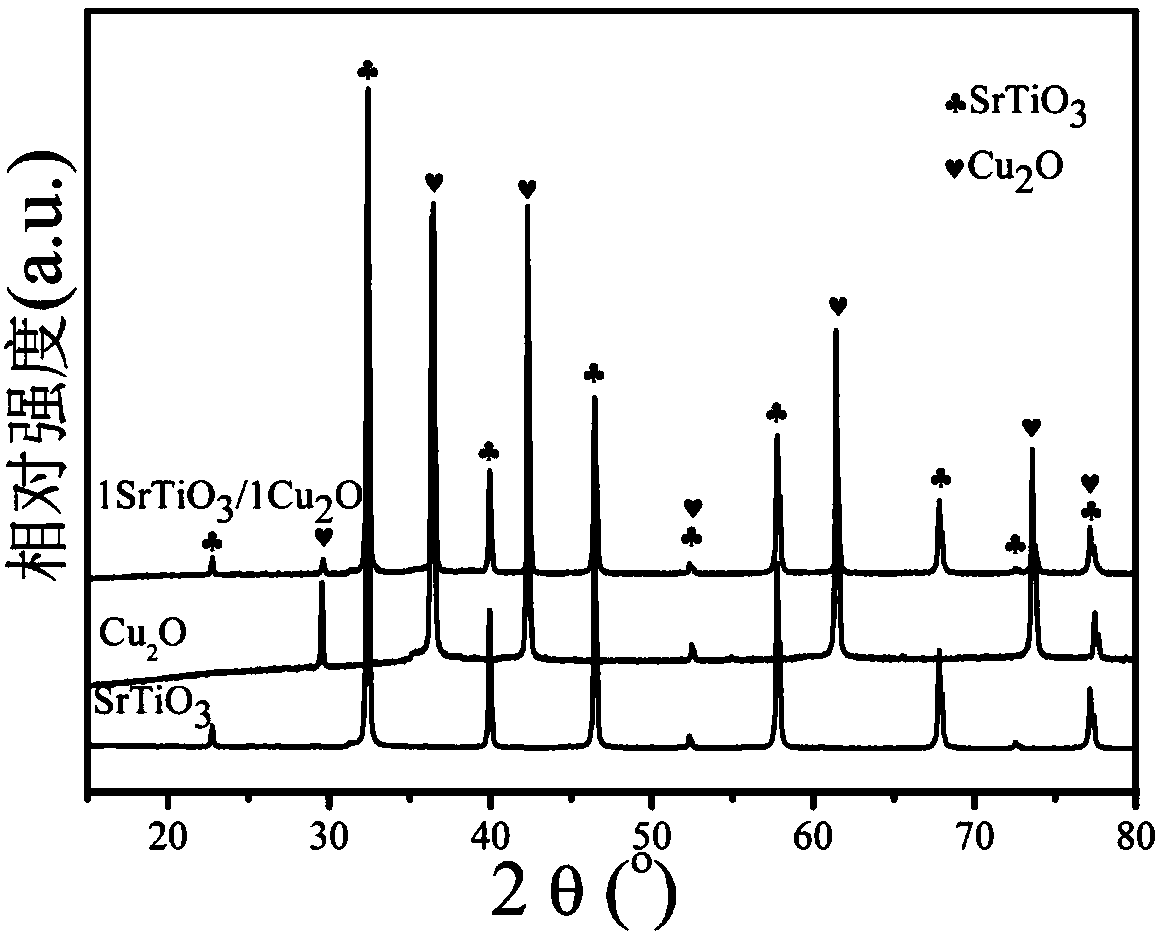

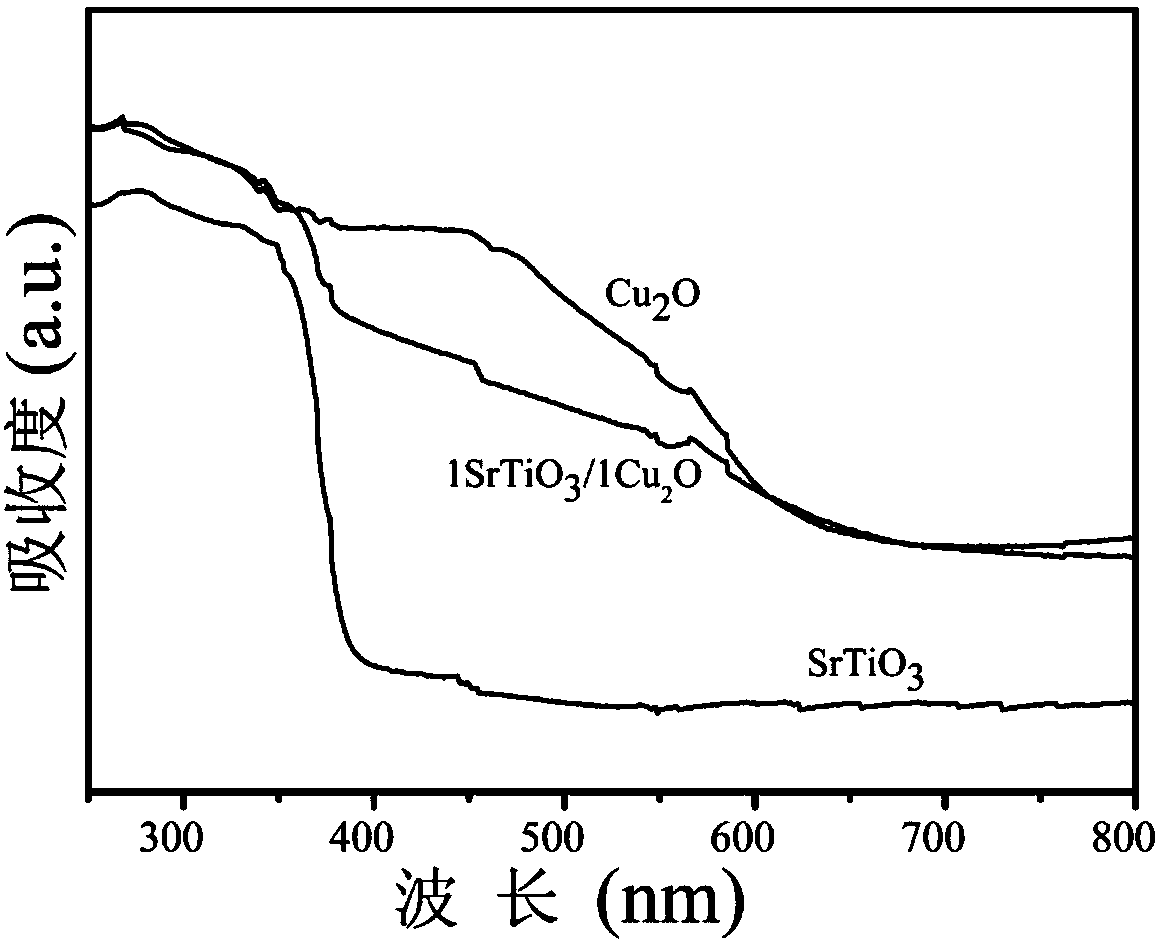

Novel preparation method and application of SrTiO3/Cu2O junction composite nanomaterial

A composite nanomaterial and a new technology are applied in the field of preparation and application of new optical SrTiO3/Cu2O junction composite nanomaterials, which can solve the problems of low catalytic efficiency and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] A new type of SrTiO 3 / Cu 2 The preparation method of O junction composite nanomaterial comprises the following steps:

[0030] 1) Weigh 2.8422 g of (tetra)isopropyl titanate and dissolve in 24 ml of acetic acid solution, and keep stirring for 10 to 20 minutes, while adding 20 ml of deionized water;

[0031] Weigh 2.6662 g of strontium chloride hexahydrate and dissolve in 4 mol / l citric acid respectively, and stir for 10-20 minutes;

[0032] 2) Mix the (tetra)isopropyl titanate solution and the strontium chloride hexahydrate solution, stir evenly, adjust the pH to 3.5, heat to 90°C, keep the temperature for 3 hours, and then transfer to the reaction kettle;

[0033] 3) Heat the reactor to 400-500°C and keep it warm for 5 hours; separate, wash and dry the obtained powder solid to obtain SrTiO 3 catalyst;

[0034] 4) At 35°C, 1.9965g of copper acetate dihydrate was stirred and dissolved in 100mL of glycol methyl ether, stirred for 15 minutes, and ultrasonically treate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com