Self-repairing compound titanium-based grease and preparation method thereof

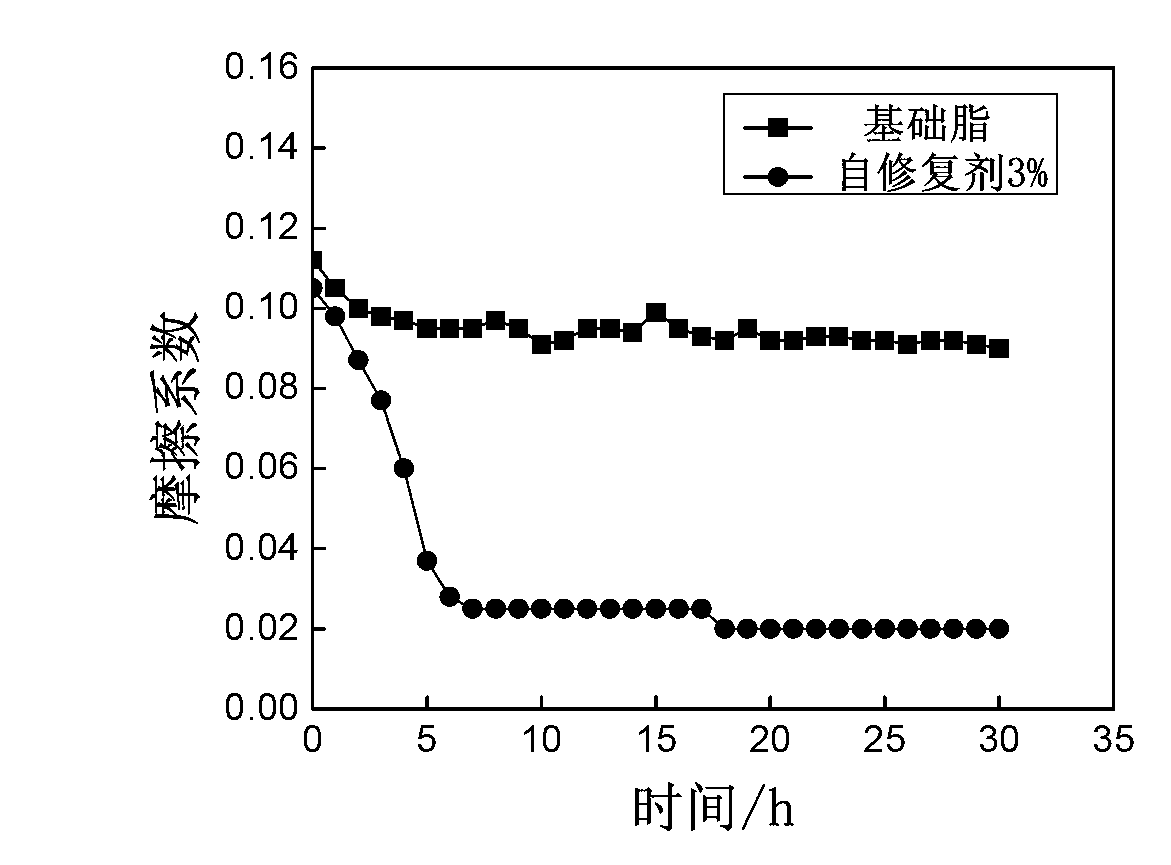

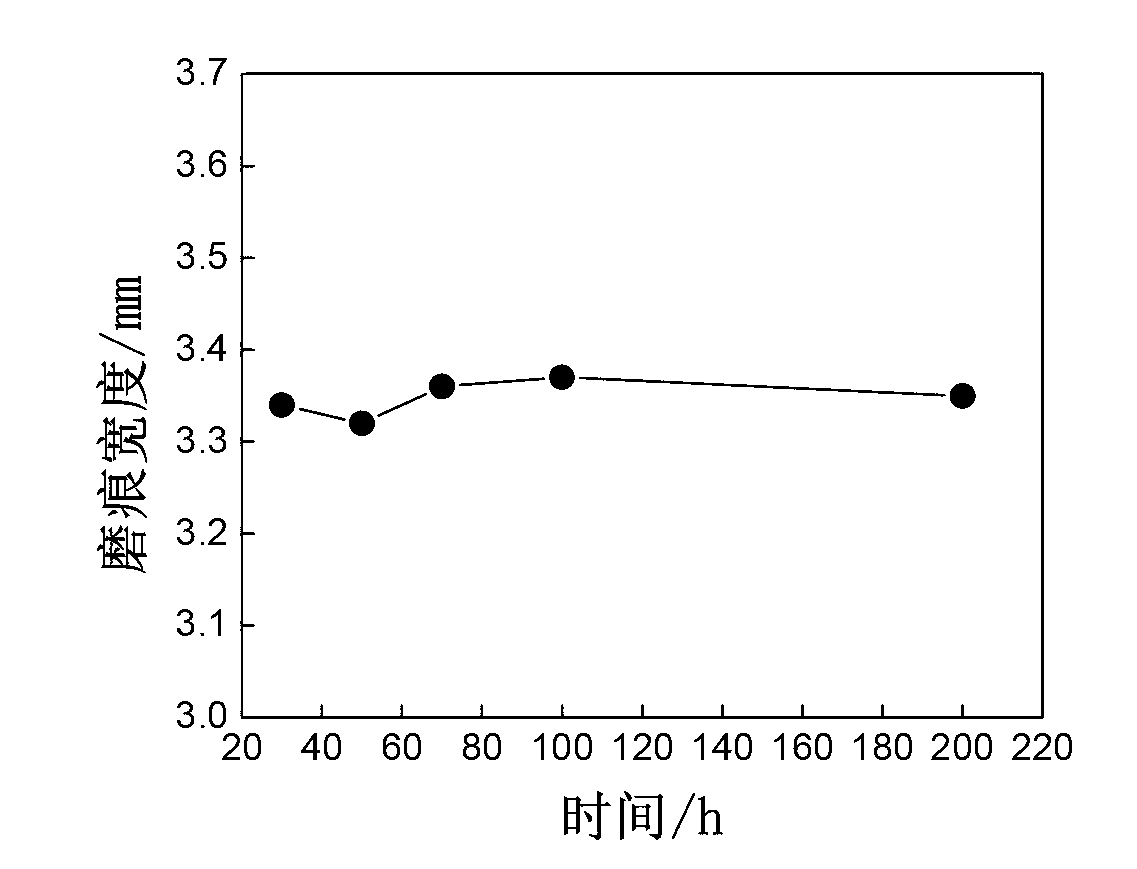

A self-repairing and lubricating grease technology, which is applied in the field of lubricating grease, can solve the problem of not considering the reasonable matching of extreme pressure wear-resistant additives and wear self-repairing additives, the oxidation and load-bearing properties cannot be guaranteed at the same time, and the composite titanium-based grease does not have self-repairing properties. And other problems, to achieve the effect of improving utilization rate and service life, good carrying capacity, and strong resistance to water splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

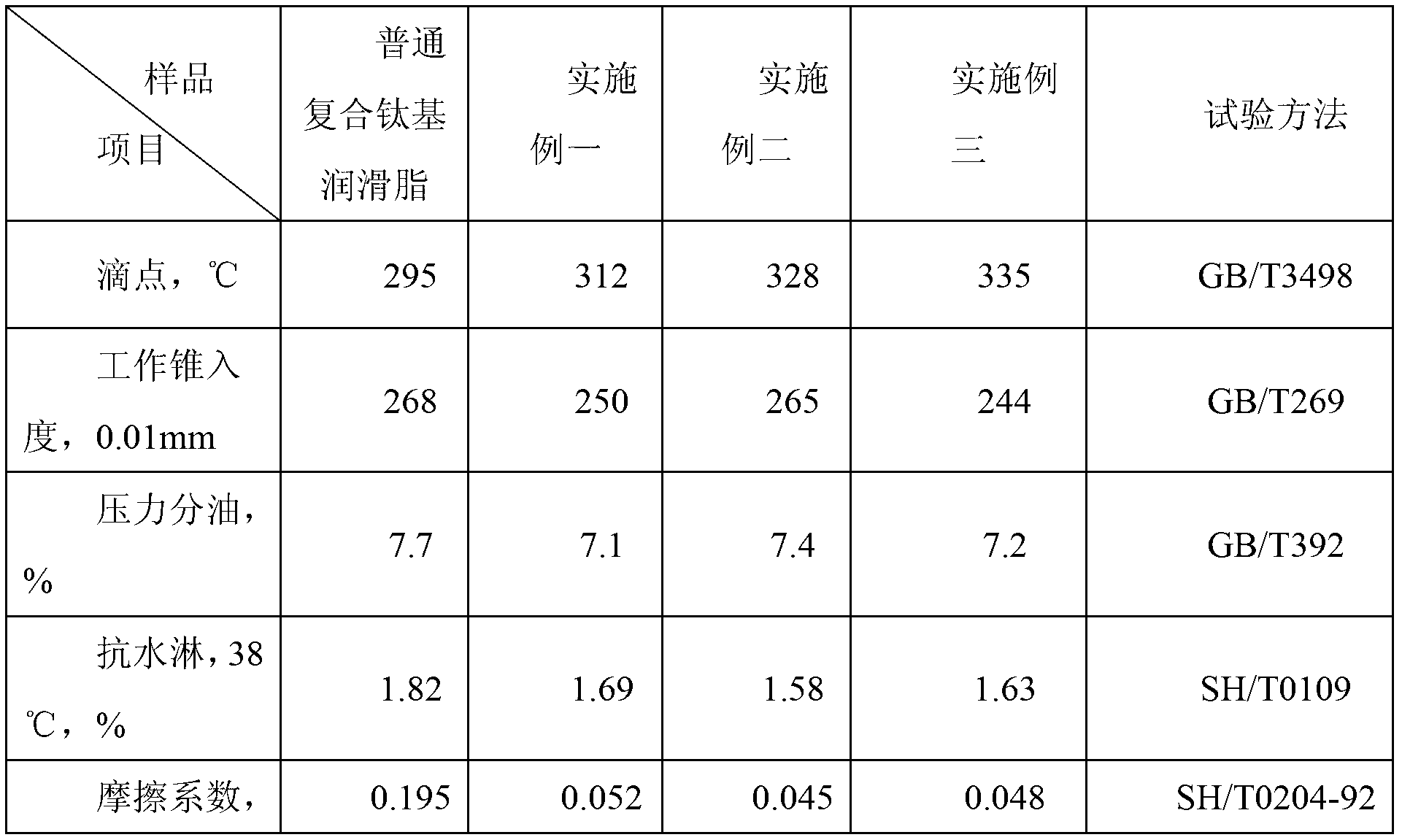

Embodiment 1

[0024] In this embodiment, a self-repairing composite titanium-based grease is composed of the following components: paraffin-based mineral oil, which accounts for 70% of the weight of the grease, is refined and has a viscosity index of 96; Soap thickener, the thickener is composed of benzoic acid: stearic acid: tetraisopropyl titanate saponification reaction product with a mass ratio of 1:1:1; extreme pressure antiwear agent accounting for 5% by weight of grease and anti-friction agent, wherein the extreme pressure anti-wear agent and anti-friction agent are zinc dialkyldithiophosphate and flake graphite respectively, the mass ratio is 1:1; the self-healing lubricating material accounting for 9% of the grease weight, the The self-healing lubricating material is composed of serpentine powder; dialkylphenylamine, which accounts for 1.5% by weight of the grease, is an antioxidant.

[0025] The preparation method is as follows: mix 1 / 2-1 / 3 base oil with high molecular acid, stir,...

Embodiment 2

[0027]In this example, a self-healing composite titanium-based grease is composed of the following components: 80% of the weight of the grease is refined, a paraffinic mineral oil with a viscosity index of 100 and a base oil mixed with synthetic polyhydrocarbyl esters and synthetic esters , the mixing mass ratio is mineral oil: synthetic ester is 2:1; the compound titanium soap thickener accounting for 10% of the grease weight is composed of phthalic acid: 12 hydroxy hardener with a mass ratio of 1:1:2 Fatty acid: composed of saponification reaction products of tetraisopropyl titanate; extreme pressure antiwear agent and friction reducer accounting for 3% by weight of grease, among which extreme pressure antiwear agent and friction reducer are dialkyl dithio Molybdenum phosphate and flake graphite, the mass ratio is 1:2; the self-healing lubricating material accounting for 6% of the grease weight, the self-healing lubricating material is composed of serpentine powder and micron...

Embodiment 3

[0031] In this embodiment, a self-healing composite titanium-based grease is composed of the following components: a refined base oil with a viscosity index of 120 paraffinic mineral oil and polyalphaolefin synthetic oil, which accounts for 85% of the grease weight, mixed The mass ratio is mineral oil: synthetic oil is 3:1; the compound titanium soap thickener accounting for 11% of the grease weight is composed of benzoic acid: 12 hydroxystearic acid with a mass ratio of 1:1:3: Composition of saponification reaction products of tetraisopropyl titanate; extreme pressure antiwear agent and friction reducer accounting for 1% by weight of grease, wherein extreme pressure antiwear agent and friction reducer are dialkyl molybdenum dithiophosphate and Micron molybdenum disulfide powder with a mass ratio of 1:3; a self-healing lubricating material accounting for 2.5% of the grease weight, the self-healing lubricating material is composed of serpentine powder and nano-calcium carbonate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com