Method for preparation of silicon oil by silicon oil byproduct

A silicone oil by-product, silicone oil technology, applied in the field of production of dimethyl silicone oil, to achieve the effect of easy control of viscosity, simple process and simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

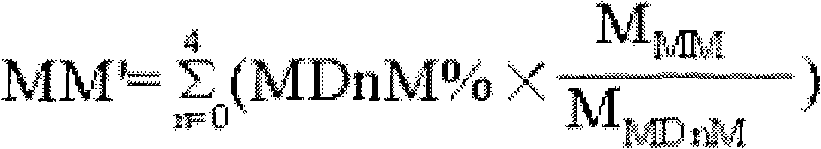

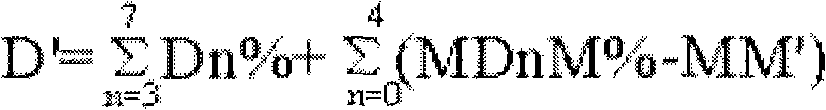

[0041] Through the calculation formula of raw material composition Table 1 and MM' and D', it is calculated that MM' accounts for 44.98%, D' accounts for 44.09%, and unknown substance accounts for 10.93% in the silicone oil by-product; MM' accounts for 0.96% in the mixed ring body, D' Accounted for 97.22%, unknowns accounted for 1.82%.

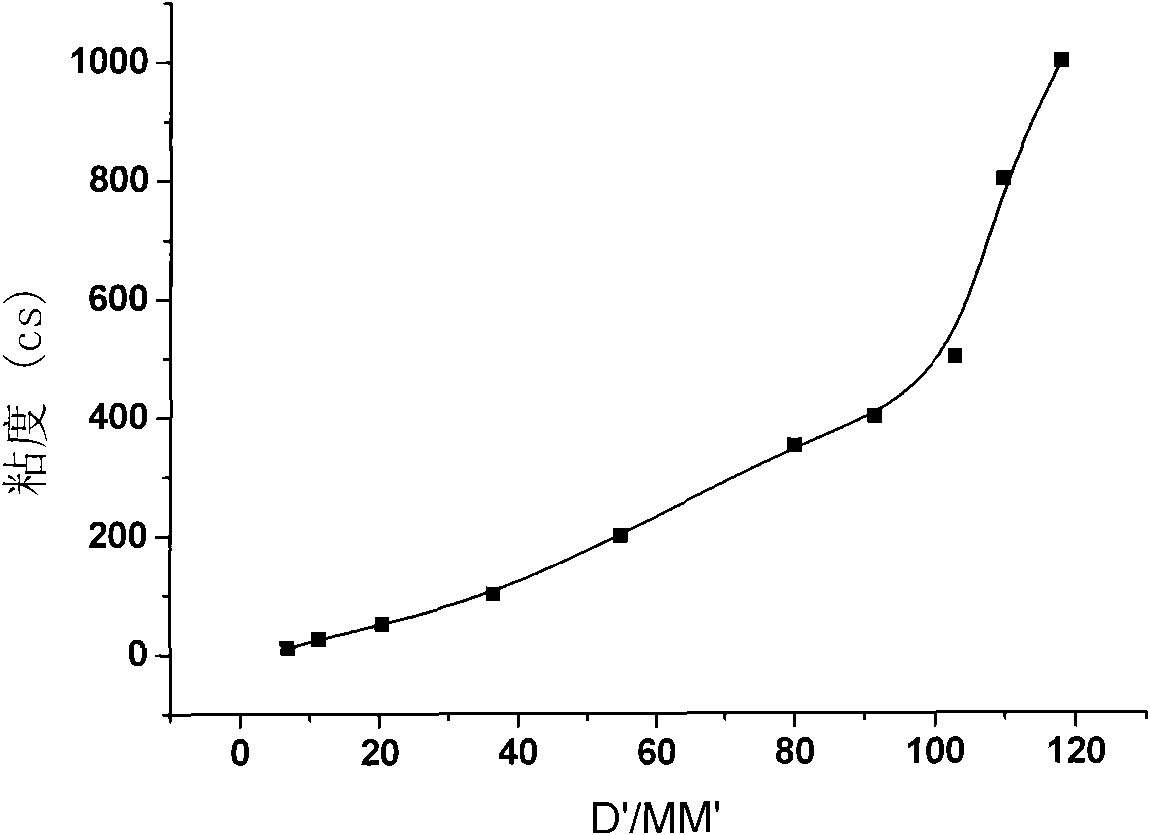

[0042] Taking D' / MM' of different proportions as the abscissa, and the viscosity of the corresponding target product silicone oil as the ordinate, a curve can be obtained, which can show the relationship between the ratio of raw materials (D' / MM') and the viscosity of silicone oil (η ) between the quantitative relationship, such as figure 1 . pass figure 1Raw material ratio D' / MM' and silicone oil viscosity η, design and prepare dimethyl silicone oil with a viscosity of 10cs, calculate the feed ratio of silicone oil by-products and mixed rings to be 90.64 parts of silicone oil by-products and 264.02 parts of mixed rings. Add the calculated ...

Embodiment 2

[0044] Raw material composition is as described in embodiment 1. pass figure 1 Raw material ratio D' / MM' and silicone oil viscosity η, design and prepare dimethyl silicone oil with a viscosity of 100cs, calculate the feed ratio of silicone oil by-products and mixed rings to be 6.21 parts of silicone oil by-products and 159.95 parts of mixed rings. Add the calculated silicone oil by-products and mixed rings into the three-necked flask, add styrene-divinyl macroporous strong acid cation exchange resin with 5% of the total mass of reactants as a catalyst, heat to 80°C, and telomerize for 3.5 hours. After the polymerization is completed, the obtained solid-liquid mixture is filtered under pressure, and the product is separated from the catalyst macroporous strong acidic cation exchange resin. The obtained filtrate is delowered under reduced pressure at 180°C and the pressure is -1.033KPa, and the time is 3 hours. Removal of low molecular weight results in obtaining simethicone oi...

Embodiment 3

[0046] Raw material composition is as described in embodiment 1. Through raw material ratio D' / MM' and silicone oil viscosity η figure 1 , designed to prepare dimethyl silicone oil with a viscosity of 500cs, and calculated the feed ratio of silicone oil by-products and mixed rings to be 9.72 parts of silicone oil by-products and 457.90 parts of mixed rings. Add the calculated silicone oil by-products and mixed rings into the three-necked flask, add styrene-divinyl macroporous strong acid cation exchange resin with 8% of the total mass of reactants as a catalyst, heat to 100°C, and telomerize for 5 hours. After the polymerization is completed, the obtained solid-liquid mixture is filtered under pressure, and the product is separated from the catalyst macroporous strong acidic cation exchange resin. In addition to low molecular weight, simethicone oil with a viscosity of 495.5 cs was obtained, and the single-pass conversion rate of this simethicone oil was 85.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com