Inorganic adhesive composition and hermetic sealing method using same

A technology of inorganic adhesives and compositions, applied in the direction of inorganic adhesives, chemical instruments and methods, non-polymer adhesive additives, etc., to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

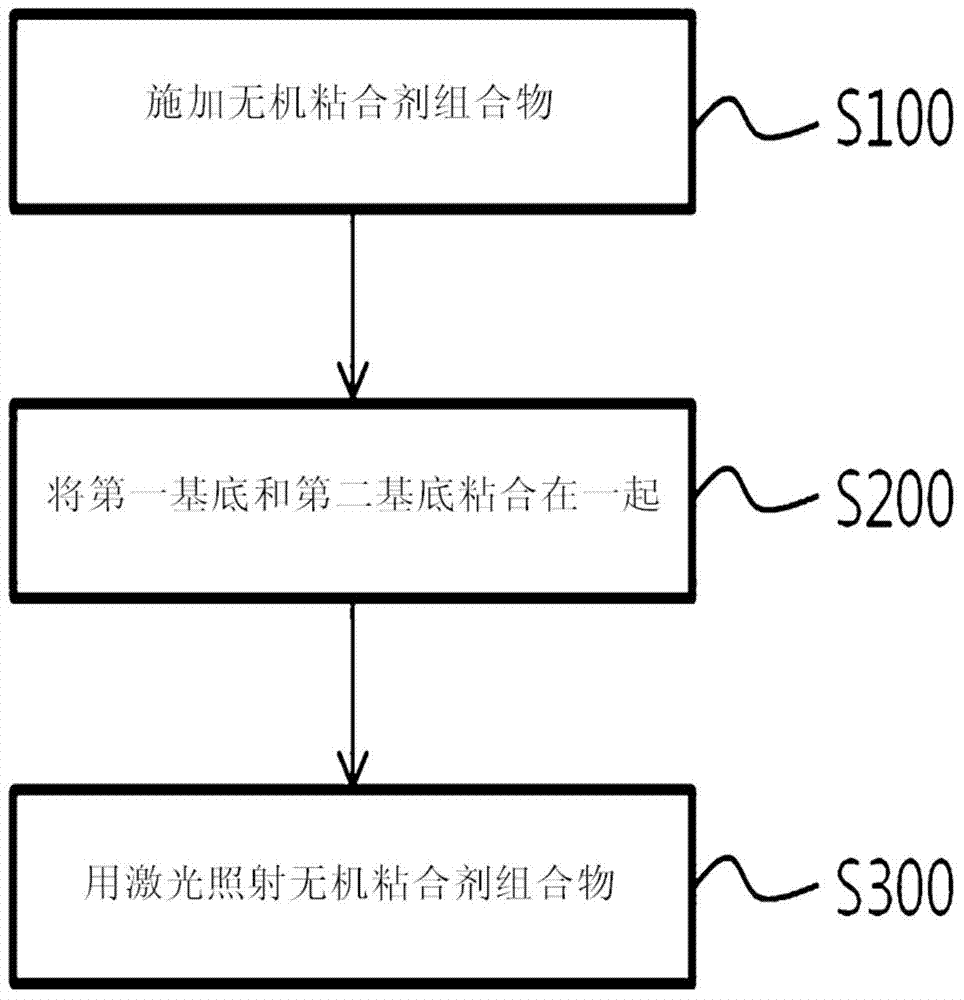

Method used

Image

Examples

Embodiment approach 1

[0055] The inorganic binder composition was produced from the following components by mixing with a stirrer: adding refractory inorganic filler as a mixture of alumina 20gr, cordierite 10gr and eucryptite 10gr, and 3 parts by weight of black pigment to 60gr including 70 Parts by weight of water glass and 30 parts by weight of distilled water in a mixed solution.

Embodiment approach 2

[0057] The inorganic binder composition is produced from the following components by mixing with a stirrer: a refractory inorganic filler that is a mixture of zircon 30gr, silica 20gr, and eucryptite 20gr, and 2 parts by weight of black pigment are added to 30gr including 83 weight Parts of water glass and 17 parts by weight of a mixed solution of distilled water.

Embodiment approach 3

[0059] The inorganic binder composition is produced by mixing with a stirrer from the following components: a refractory inorganic filler as a mixture of alumina 10gr, zircon 10g and cordierite 50gr, and 3 parts by weight of black pigment are added to 30gr including 83 weight Parts of water glass and 17 parts by weight of a mixture solution of distilled water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com