Impinging stream polyphase reactor

A technology of multiphase reactor and impinging flow, applied in chemistry/physics/physicochemistry nozzle reactor, chemical method for liquid-liquid reaction, chemical instrument and method, etc., can solve difficult to achieve mixing effect, reaction product Uneven distribution and other problems, to achieve rapid and efficient mixing reaction, increase effective contact area, and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail, but the present invention is not limited thereby:

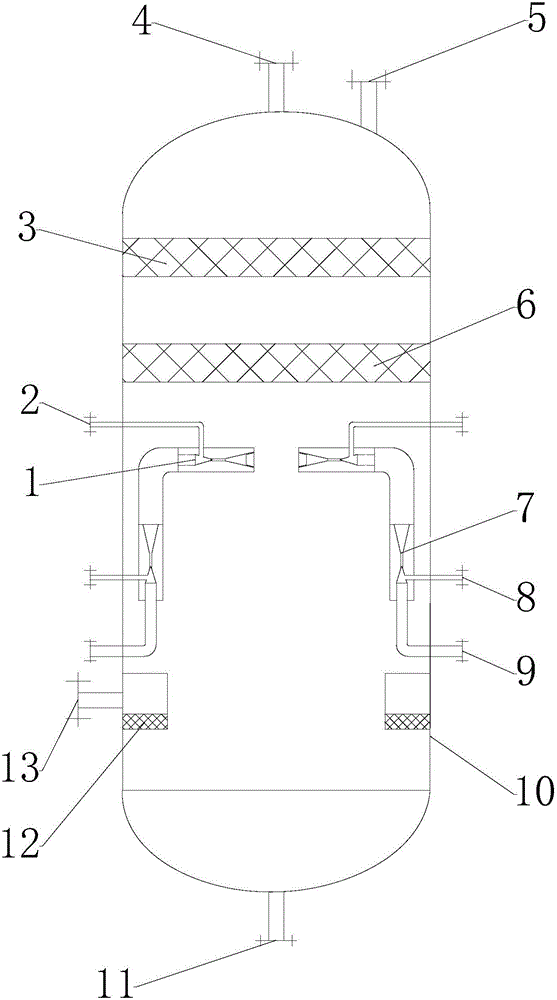

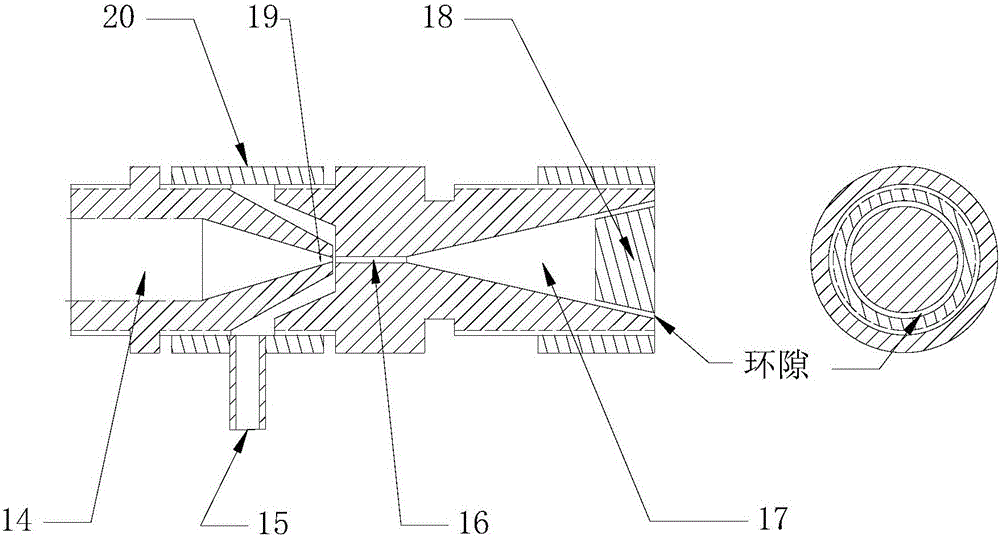

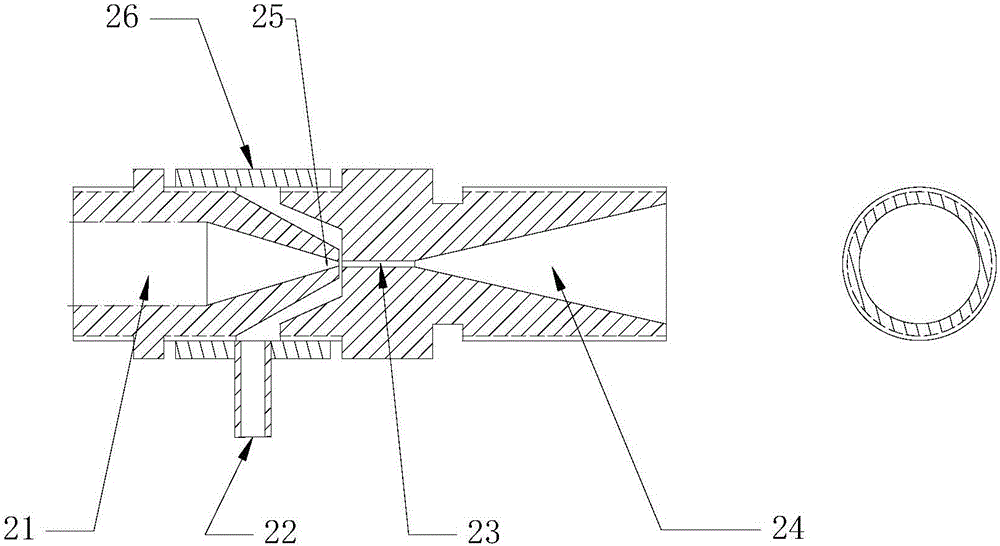

[0019] attached figure 1 The medium-high viscosity catalyst enters the raw material premixer 7 from pipeline 9 with active flow, and the alkane enters the raw material mixer 7 from pipeline 8. Mix evenly within a short period of time to form a low-viscosity, low-temperature emulsion, and then enter the nozzle system 1. The middle part of the reactor 10 is a symmetrical and evenly distributed nozzle system 1. Olefins are driven into the nozzle system 1 from the pipeline 2. After the catalyst, alkanes, and olefins are mixed, they are sprayed out in a conical shape at a certain angle through the nozzles provided at the outlet end. The liquid ejected from the nozzle at high speed hits each other, the liquid phase of the reactant falls to the bottom of the reactor, the reaction product and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com