Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

81 results about "Multiphase reactor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

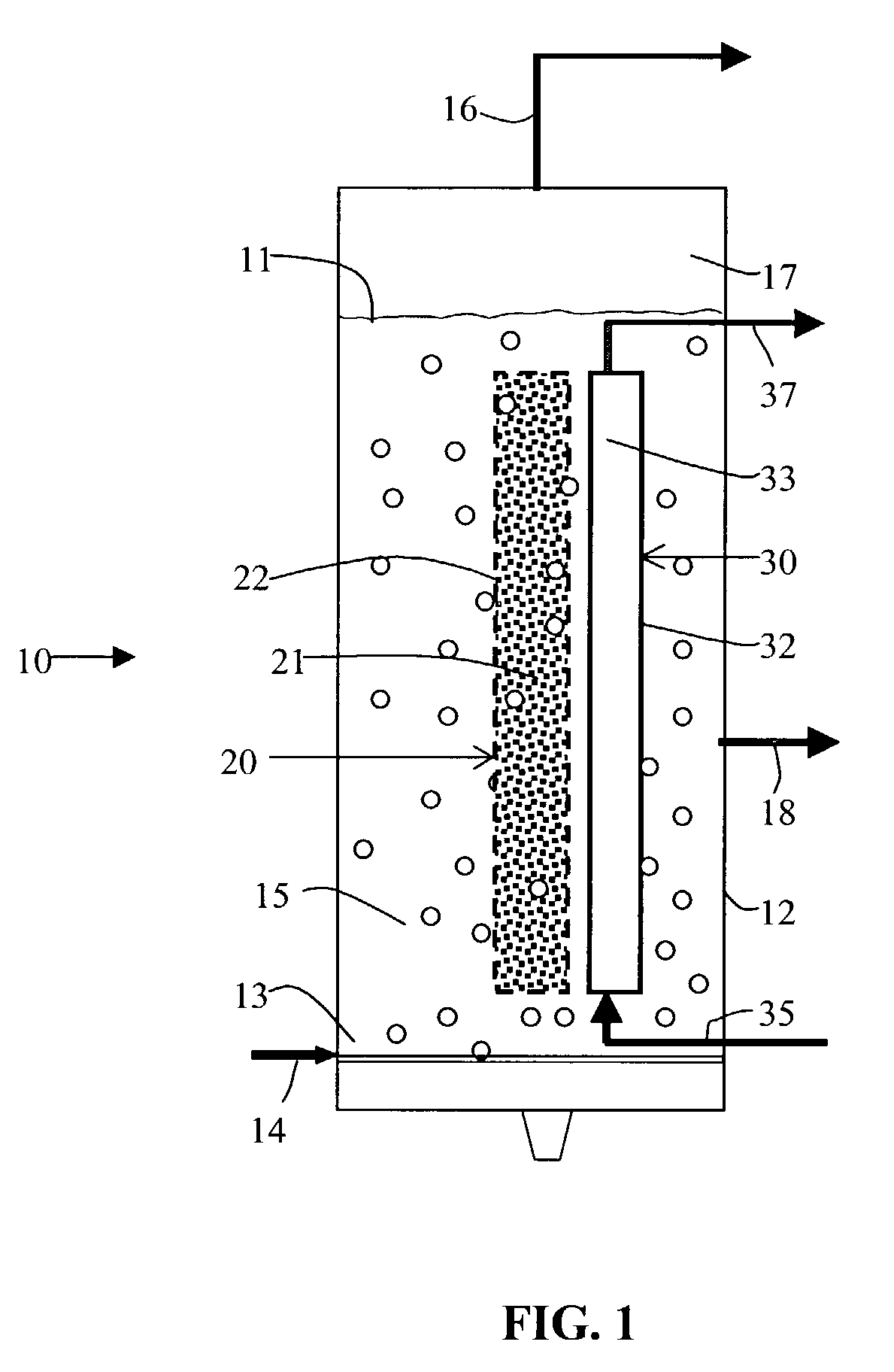

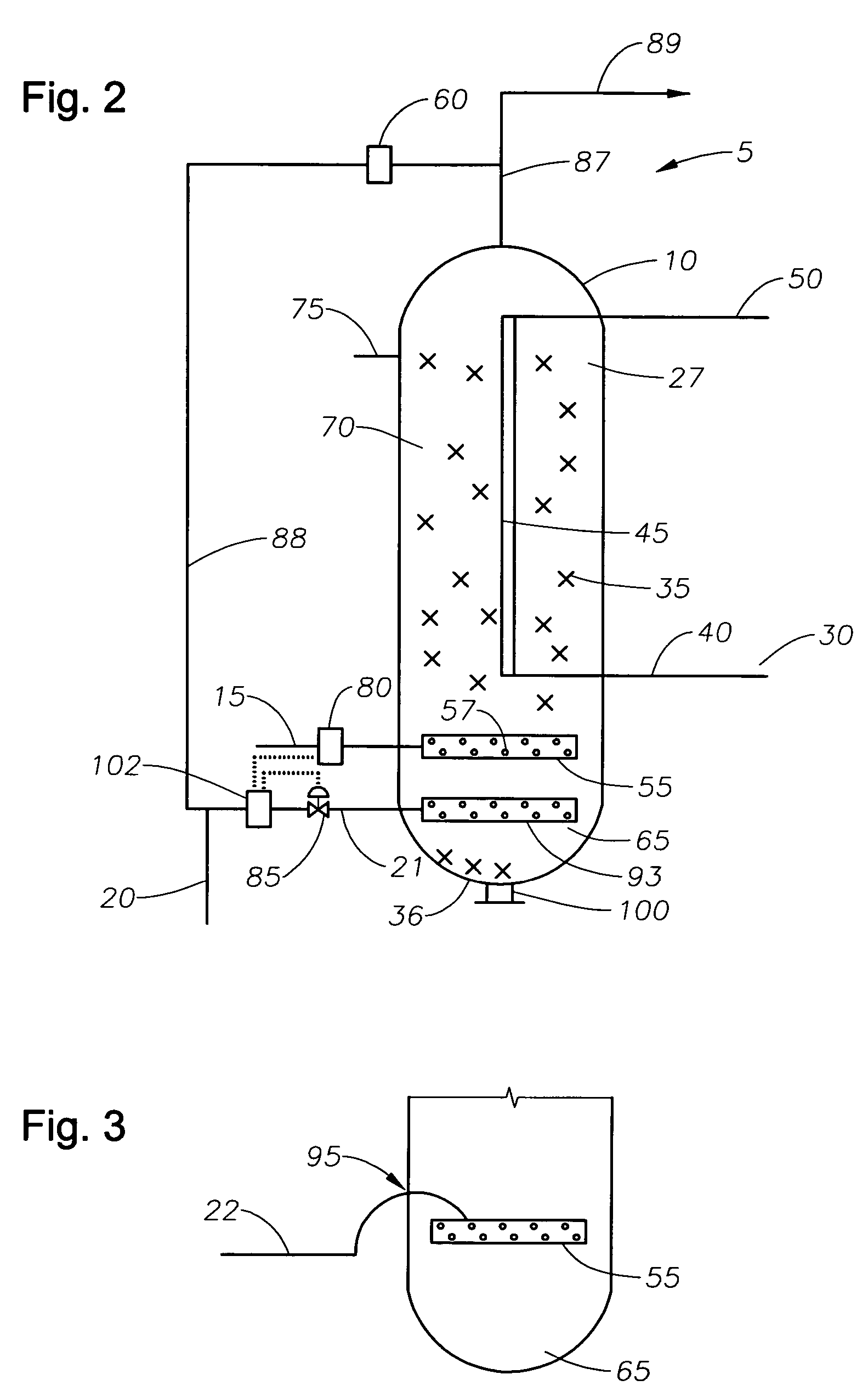

Gas agitated multiphase catalytic reactor with reduced backmixing

InactiveUS7022741B2Optimizing degree of backmixingImproved gas distributionOrganic compounds purification/separation/stabilisationOrganic compound preparationProduct gasEngineering

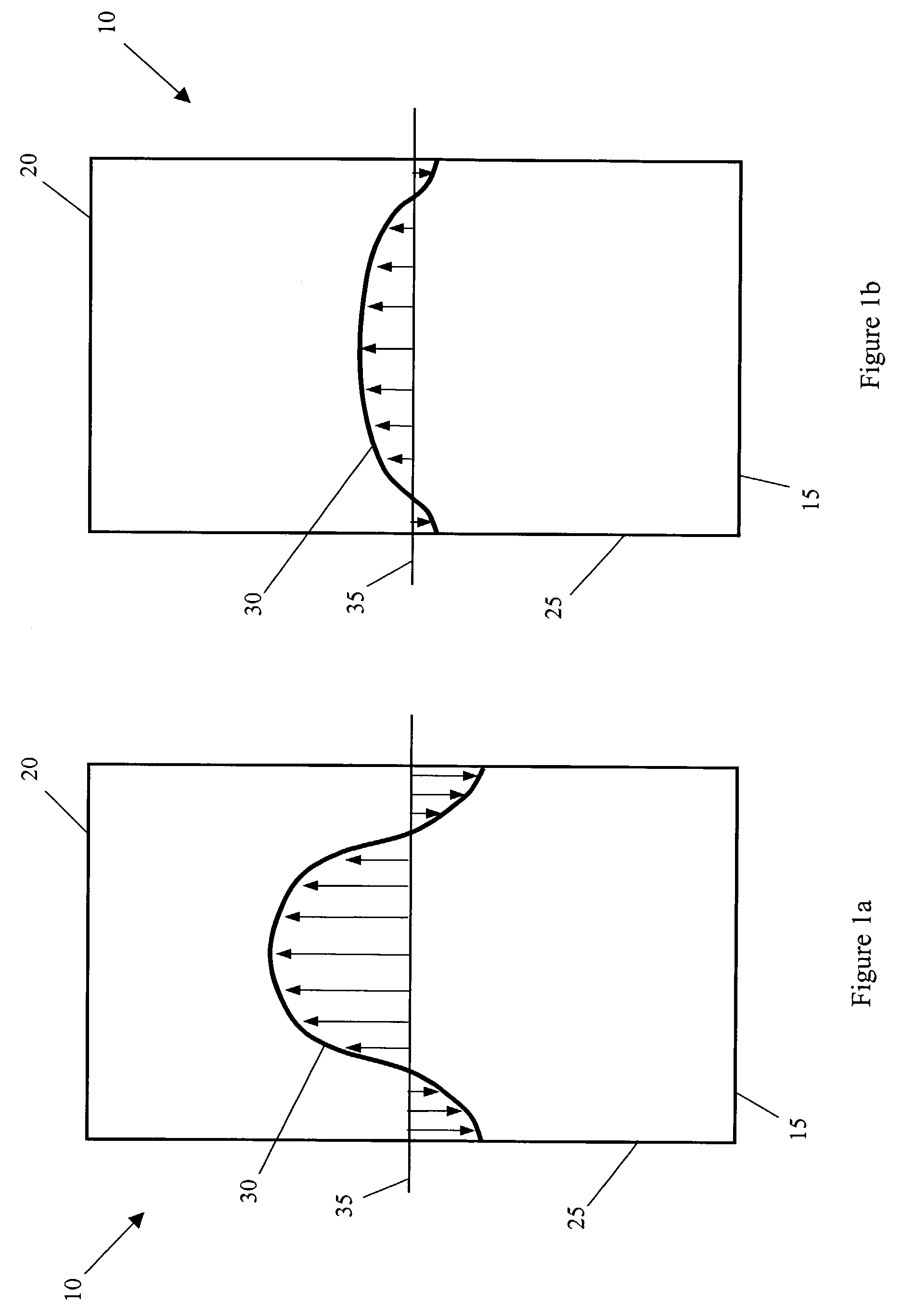

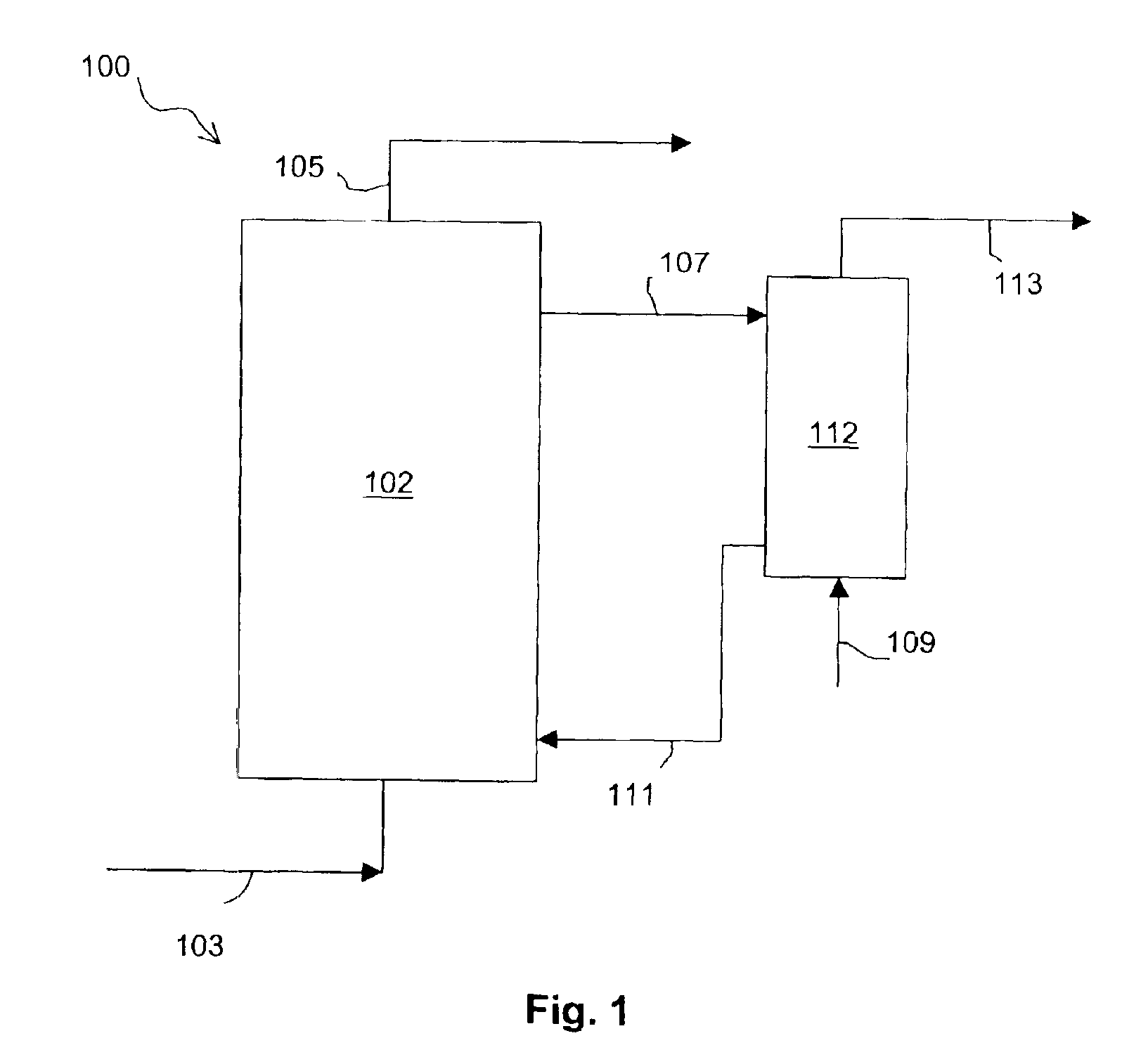

The present invention provides an apparatus and method for optimizing the degree of backmixing within a gas agitated multiphase reactor at a given gas linear velocity. The embodiments of the present invention involve novel configurations of the multiphase reactor internal structures. In general, the configurations comprise creating a dense area of internal structures in the central region and / or wall regions of the multiphase reactor.

Owner:CONOCOPHILLIPS CO

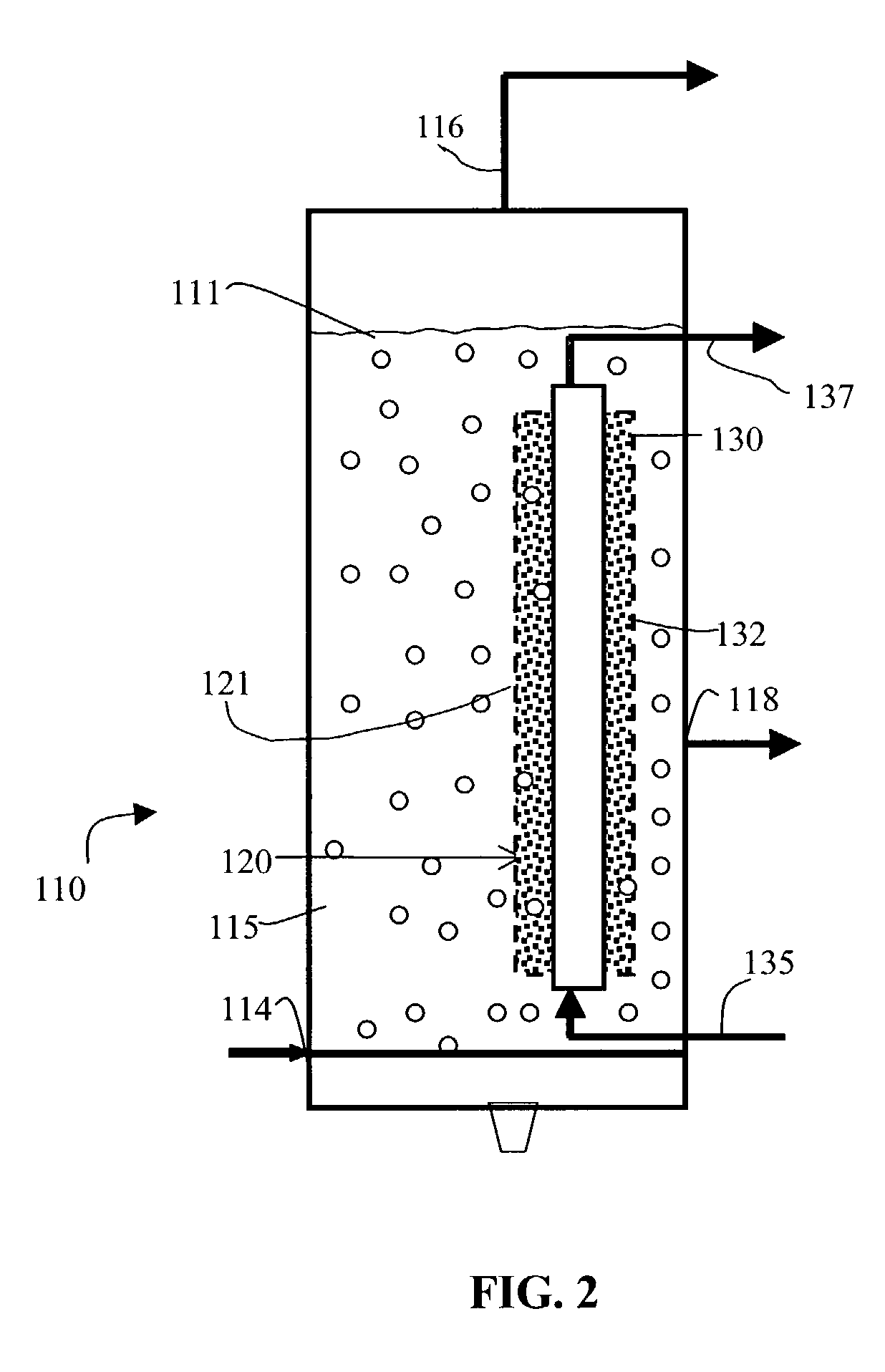

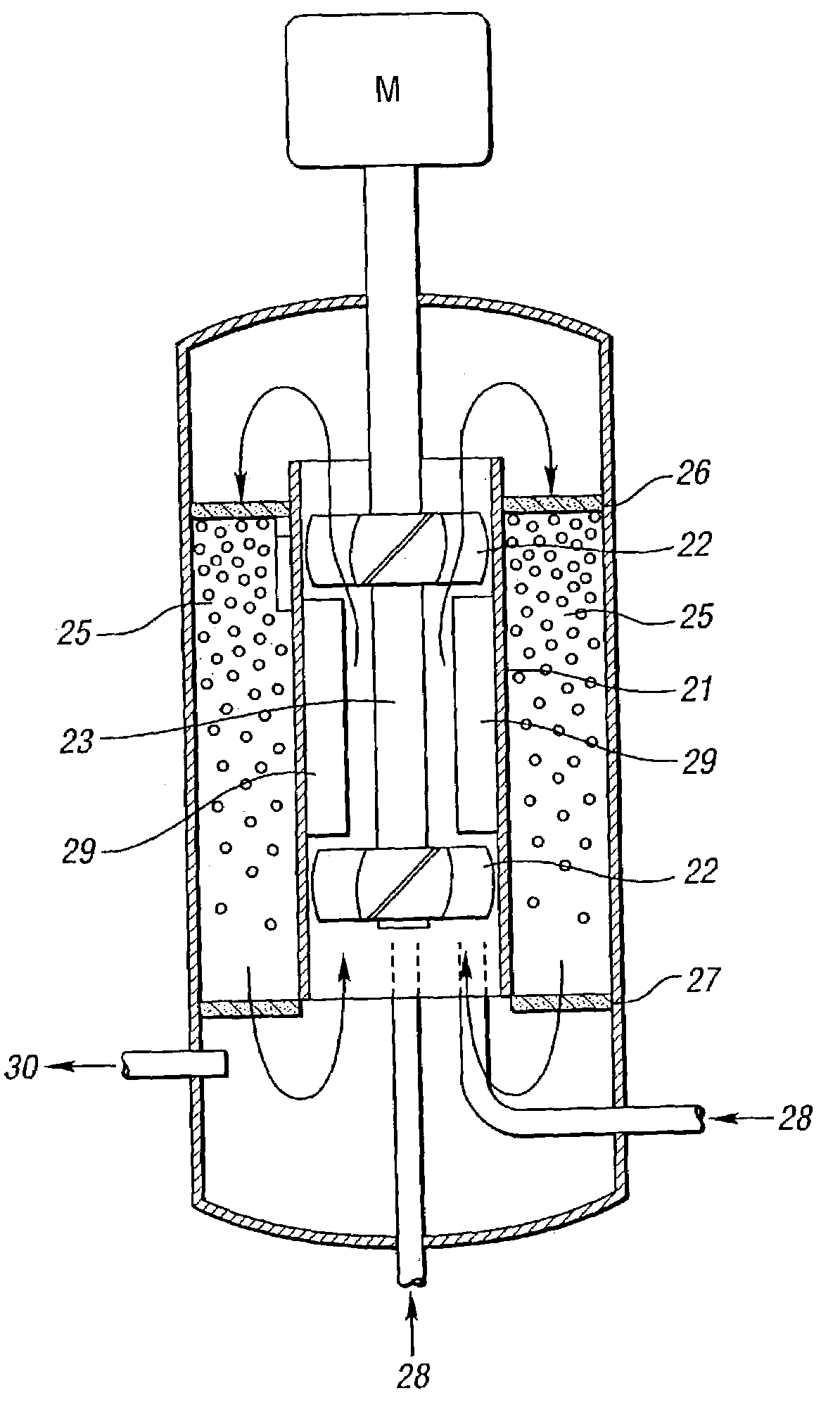

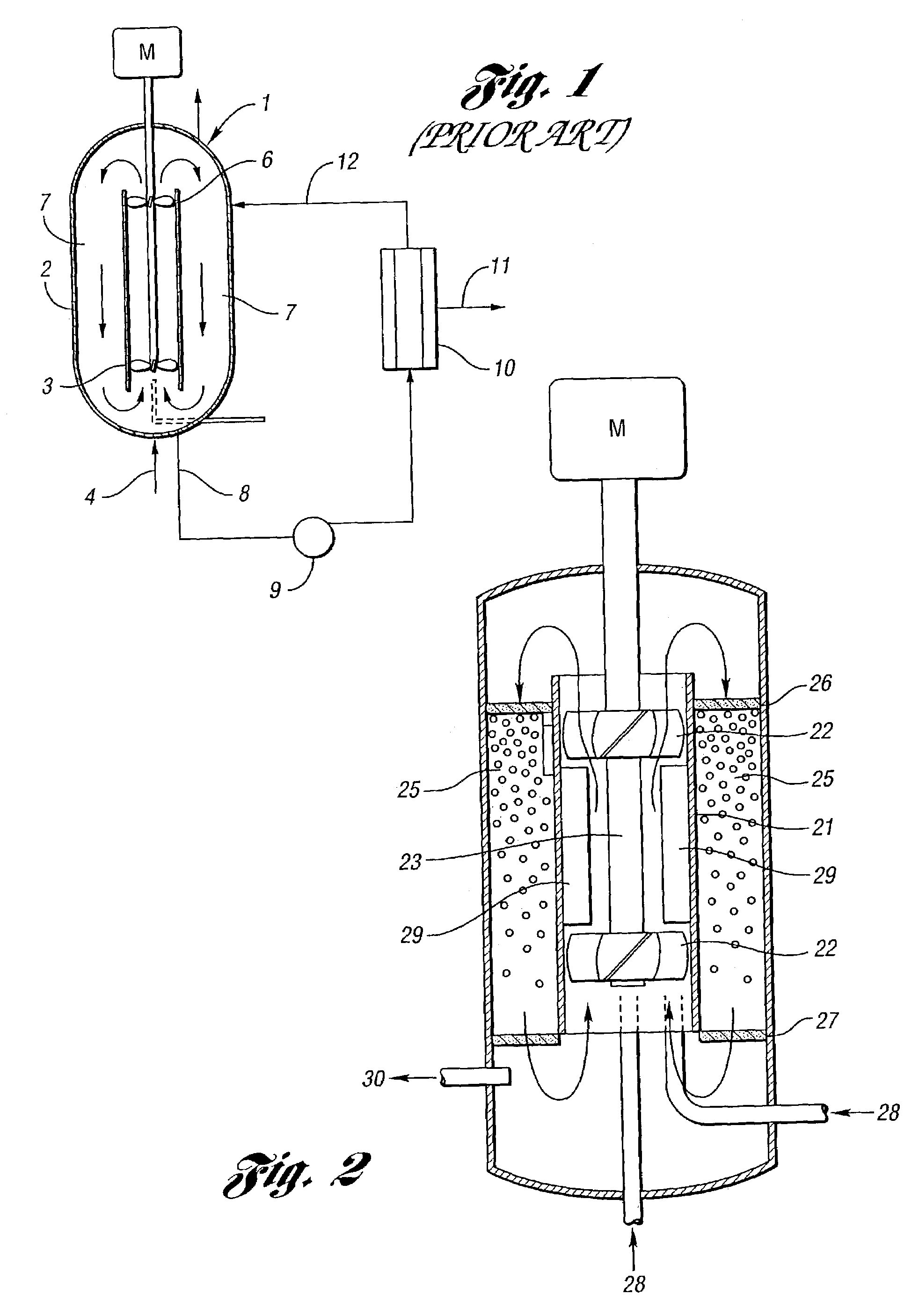

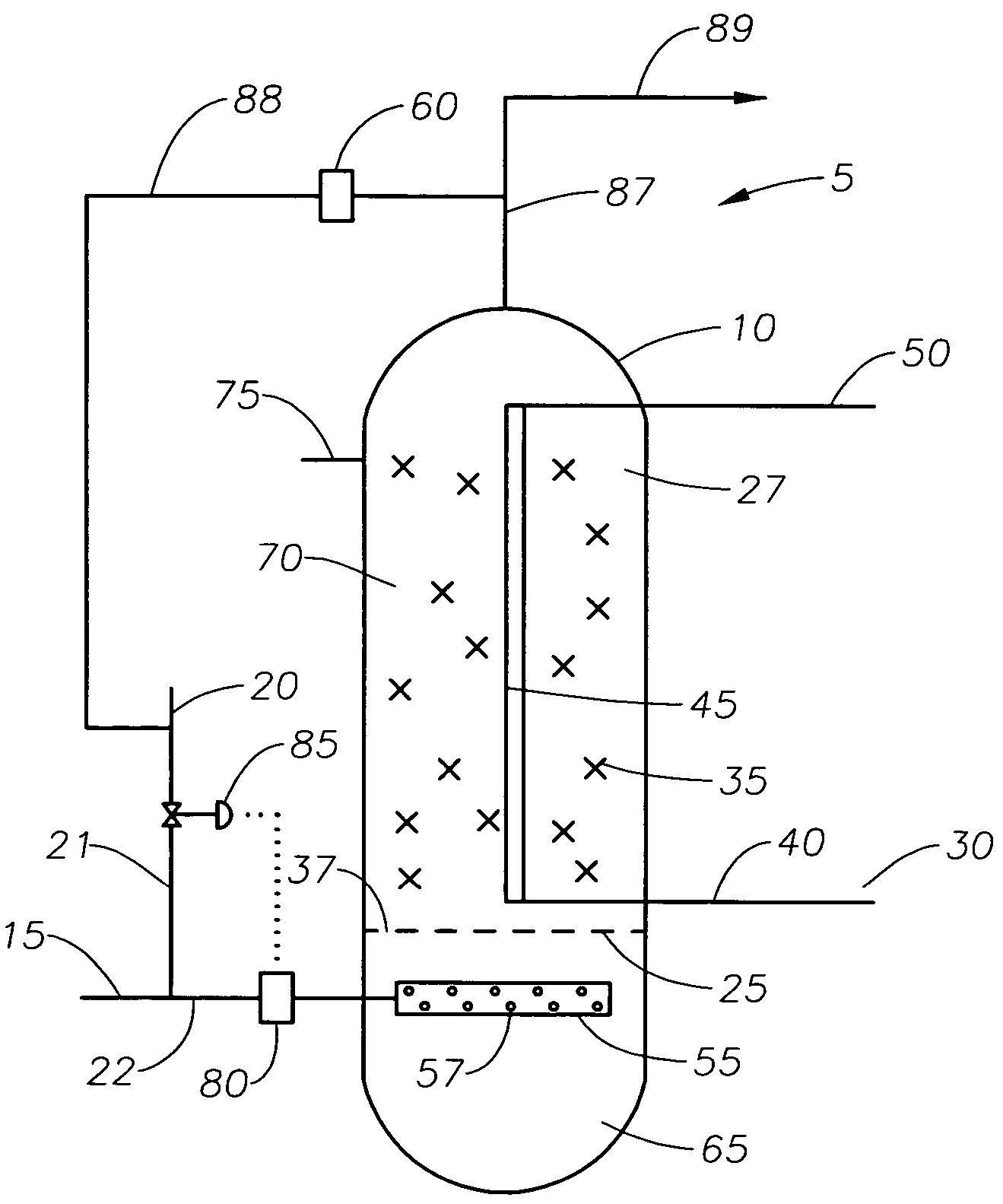

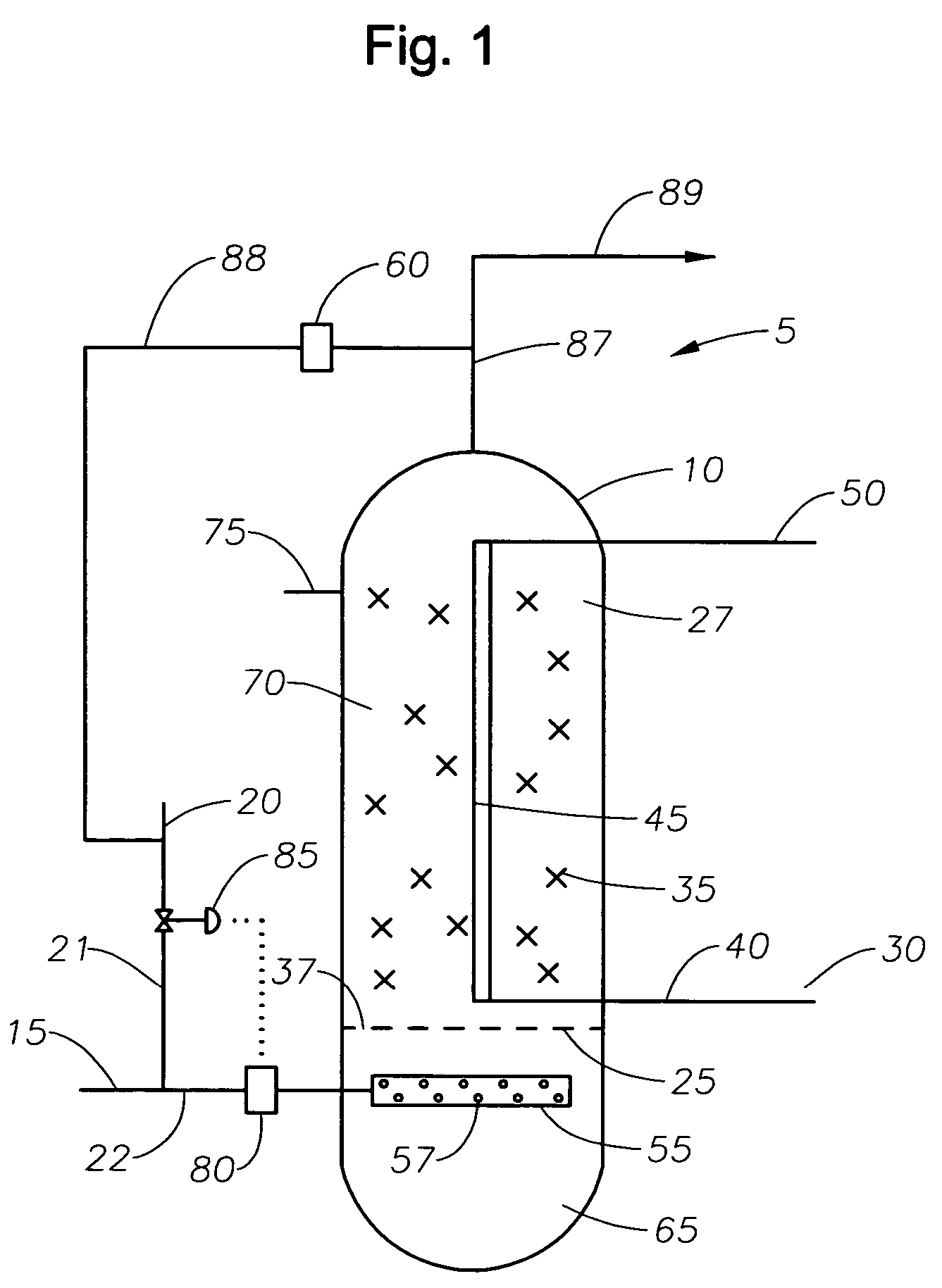

Gas agitated multiphase reactor with stationary catalyst solid phase

ActiveUS7232848B2Improve heat transfer performanceMinimizing catalyst attritionCombination devicesExhaust apparatusLiquid productThermal contact

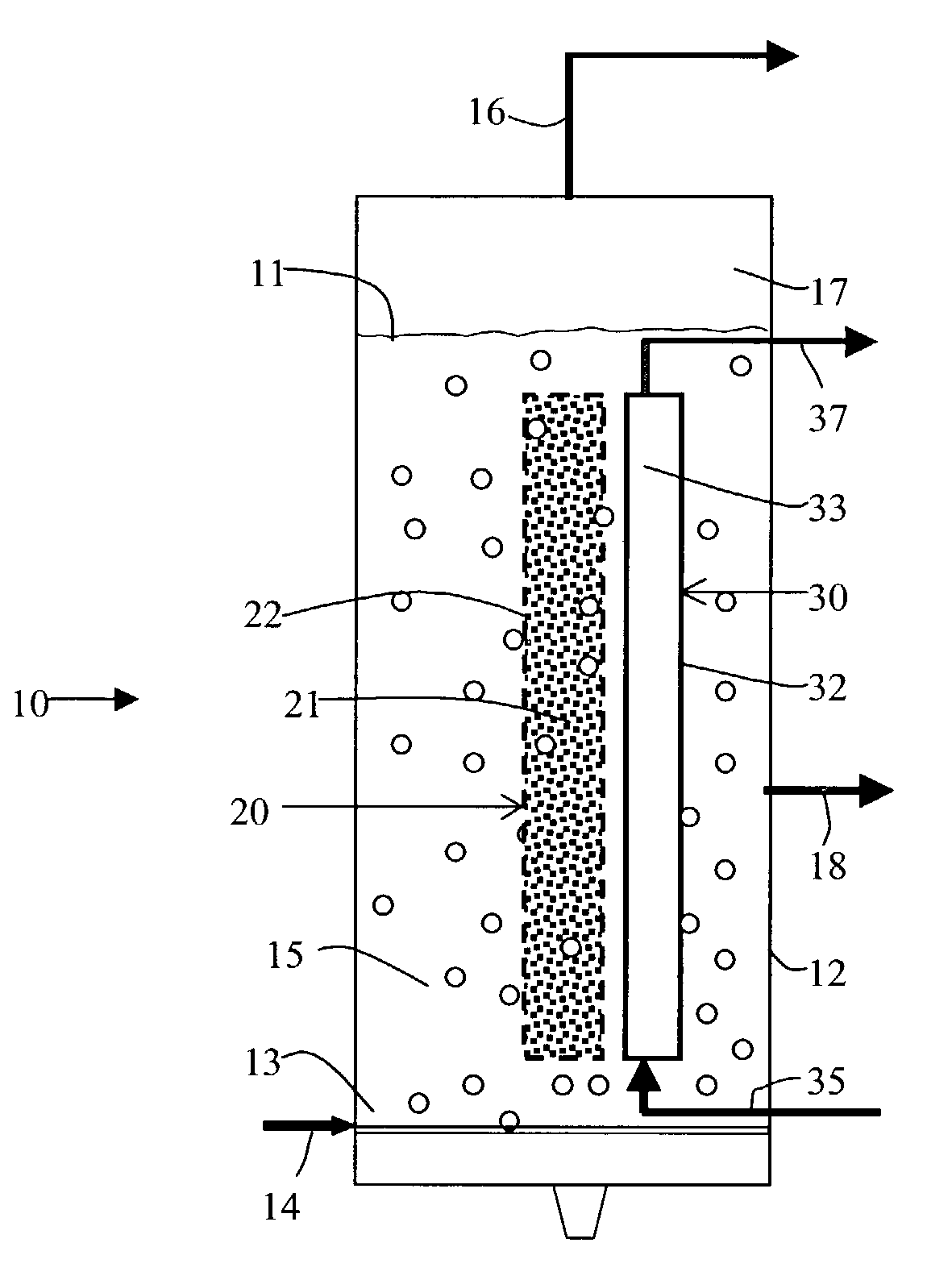

An apparatus for converting a gaseous and / or liquid feed fluid to gaseous and / or liquid products using a solid catalyst comprises a reactor, a liquid phase disposed within the reactor volume, a fixed catalyst at least partially disposed in the liquid phase, a cooling system having a cooling element in thermal contact with the liquid phase, a feed inlet positioned to feed the feed fluid into the reactor volume, and a fluid outlet in fluid communication with the liquid phase. The catalyst is contained in a catalyst container and the container may be adjacent to said cooling element, extend through said cooling element, or may surround the catalyst container. The catalyst may be a Fischer-Tropsch catalyst.

Owner:PHILLIPS 66 CO

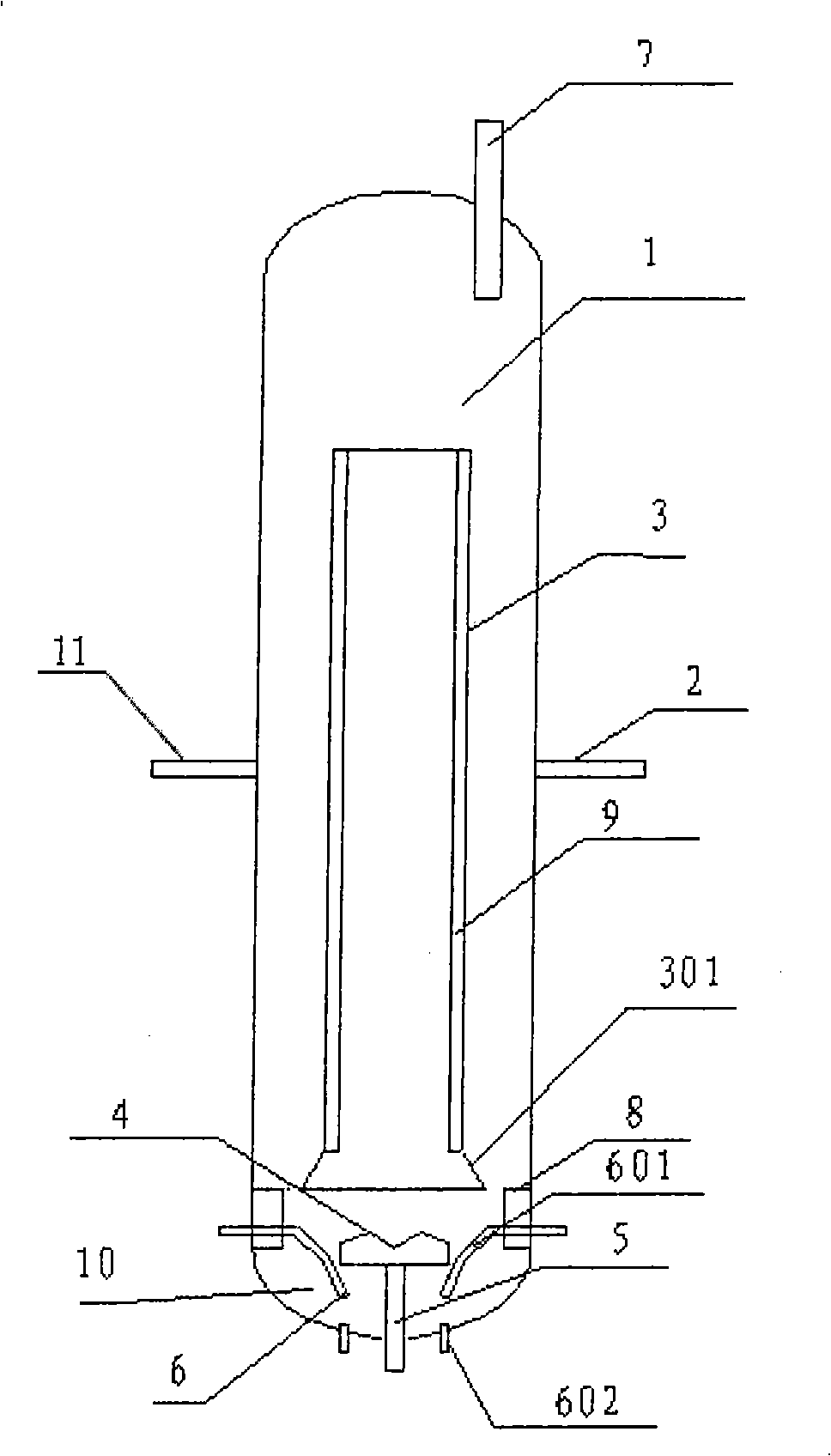

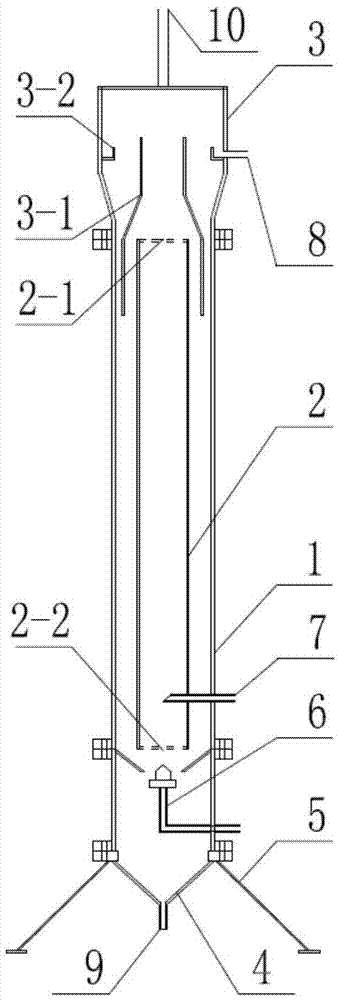

Novel liquid-liquid heterophase reactor

ActiveCN101274249ASimple structureIncrease contact areaChemical/physical/physico-chemical nozzle-type rreactorsLiquid-liquid reaction processesFiberLiquid jet

The invention provides a novel liquid-liquid multi-phase reactor device, comprising three different structures: an injection-typed circumfluence reactor, an impact flow lifting pipe reactor and a reinforced mass transfer gathering beam fibre filling material reactor; wherein, the injection-typed external circumfluence reactor (shown as figure 1) uses kinetic energy generated by the liquid injection to lead the reaction liquid which can be circulated used to circularly flow in the reactor, to be excellently mixed and reacted; the impact flow lifting pipe reactor (shown in figure 5) leads three reaction liquids to pass through multi-time butt-impact, crushing and mixing and carry out the reaction in the lifting pipe; the reinforced mass transfer gathering beam fibre filling material reactor (shown in picture 9) is internally provided with a plurality of fibre silks, so as to lead the reaction liquid to flow downwards from the surface of the fibre silk and to form two liquid film layer to carry out the reaction. The reactor of the invention has good liquid crushing and mixing effect and large liquid-liquid contact area, is widely applied to the fields of petroleum, chemicals, environments, etc., is especially suitable for the reaction between high viscosity liquid and liquid, such as ion liquid catalysis alkylation, P-noke method oil product catalytic oxidation reaction, etc.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

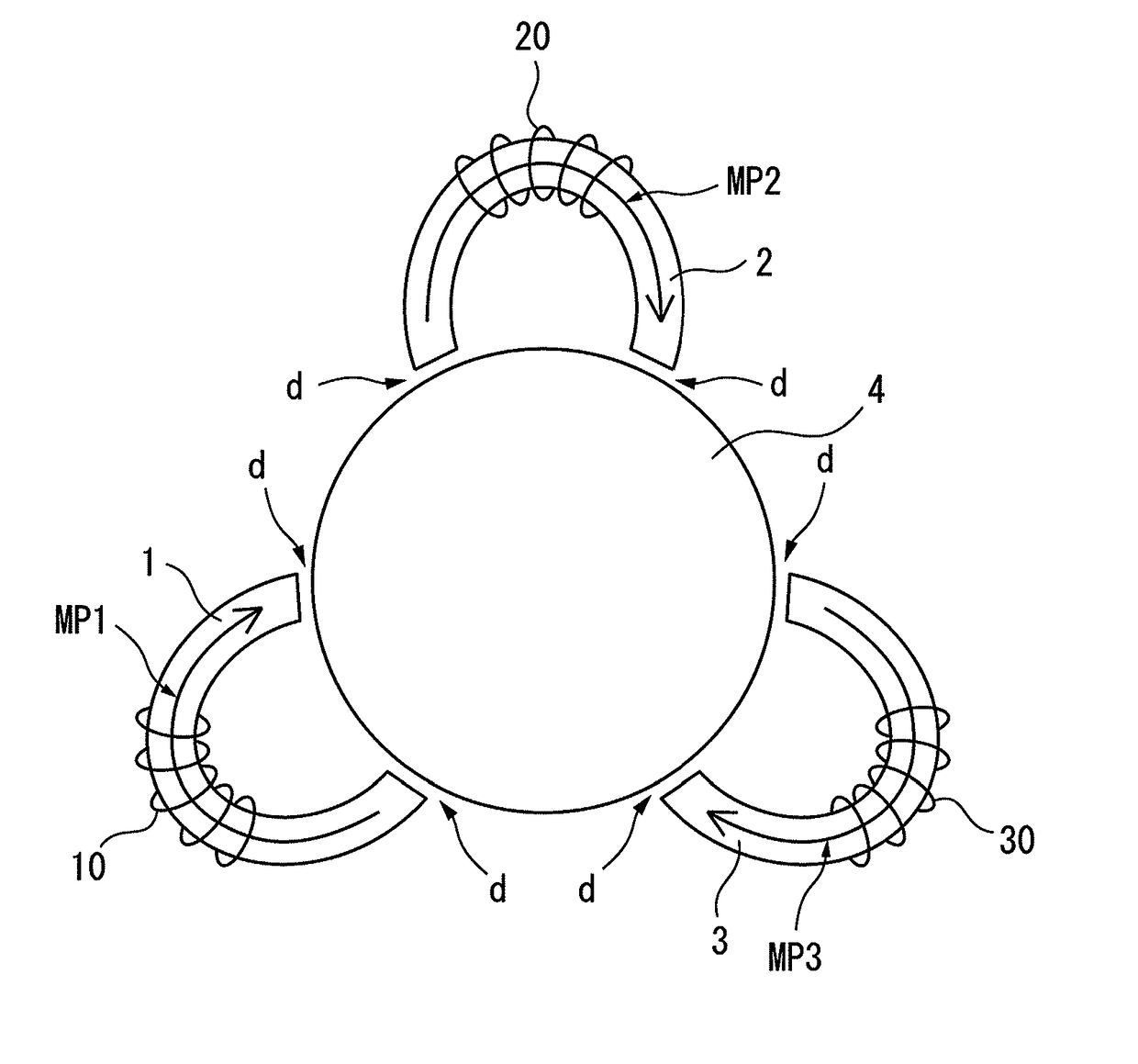

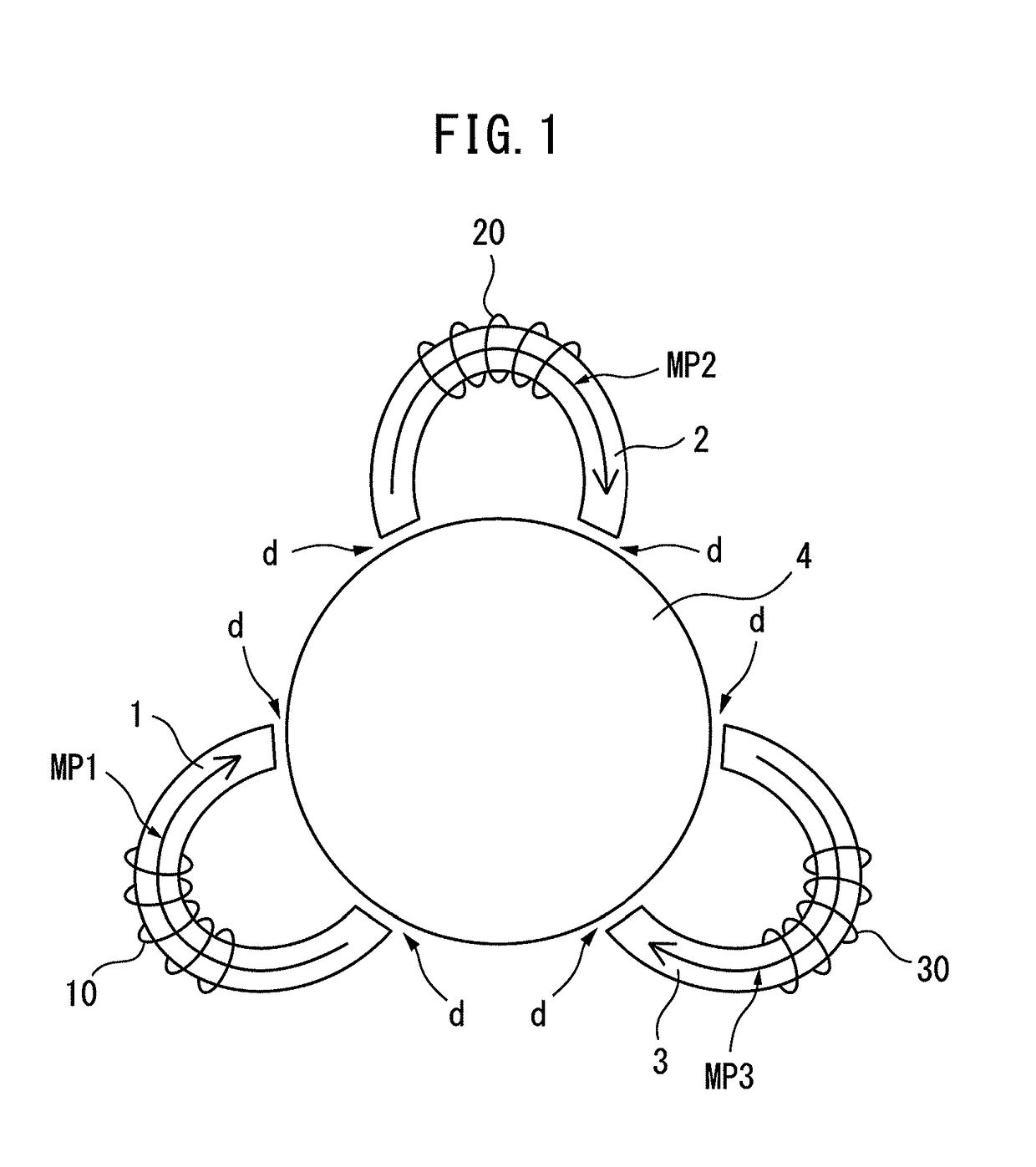

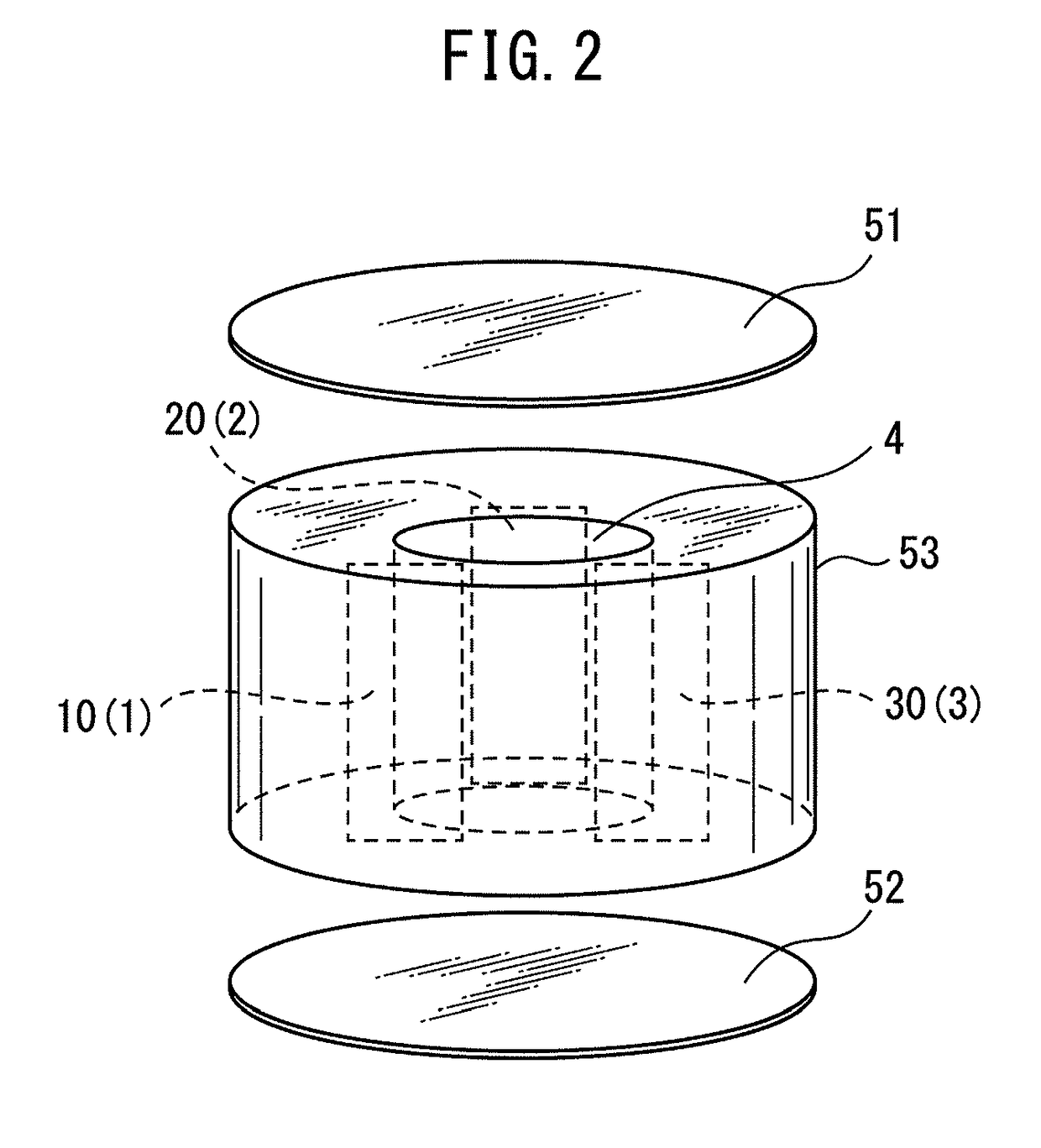

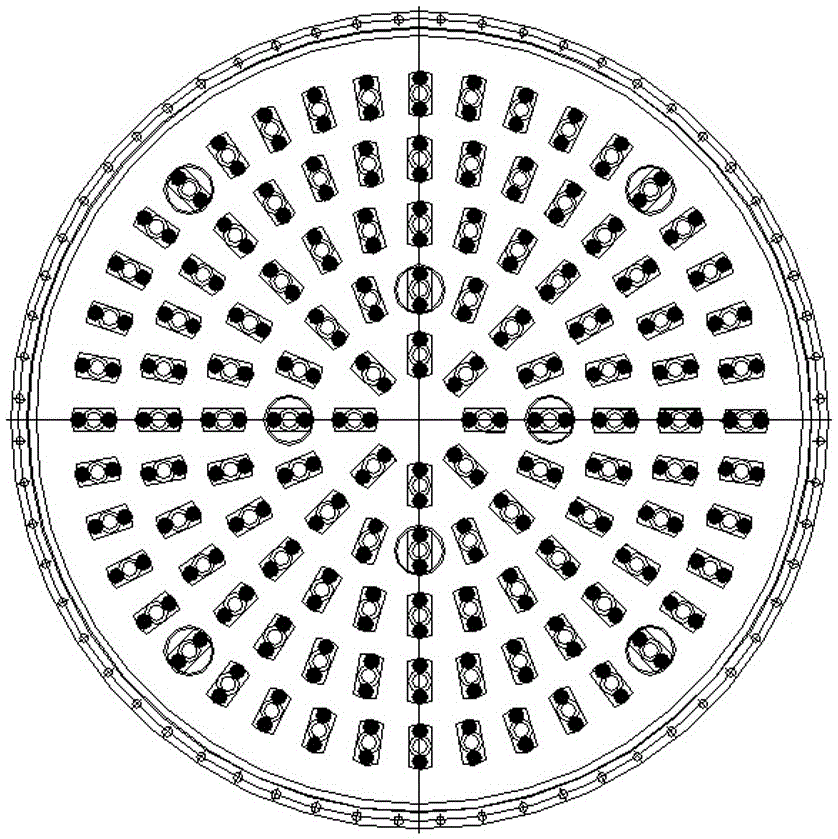

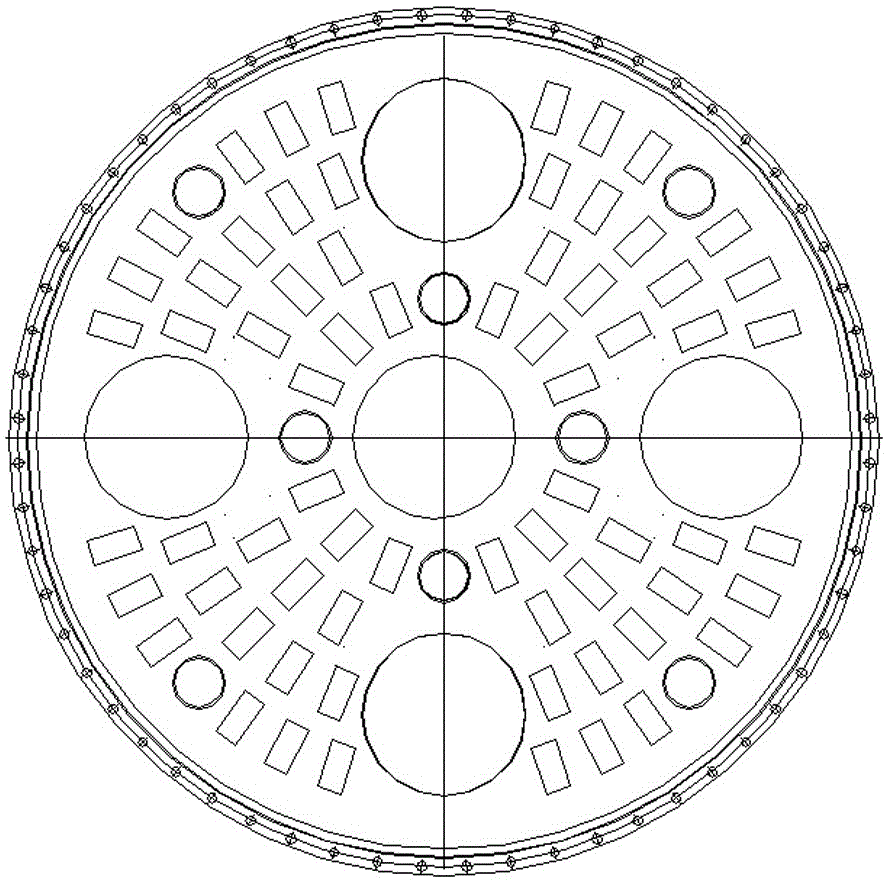

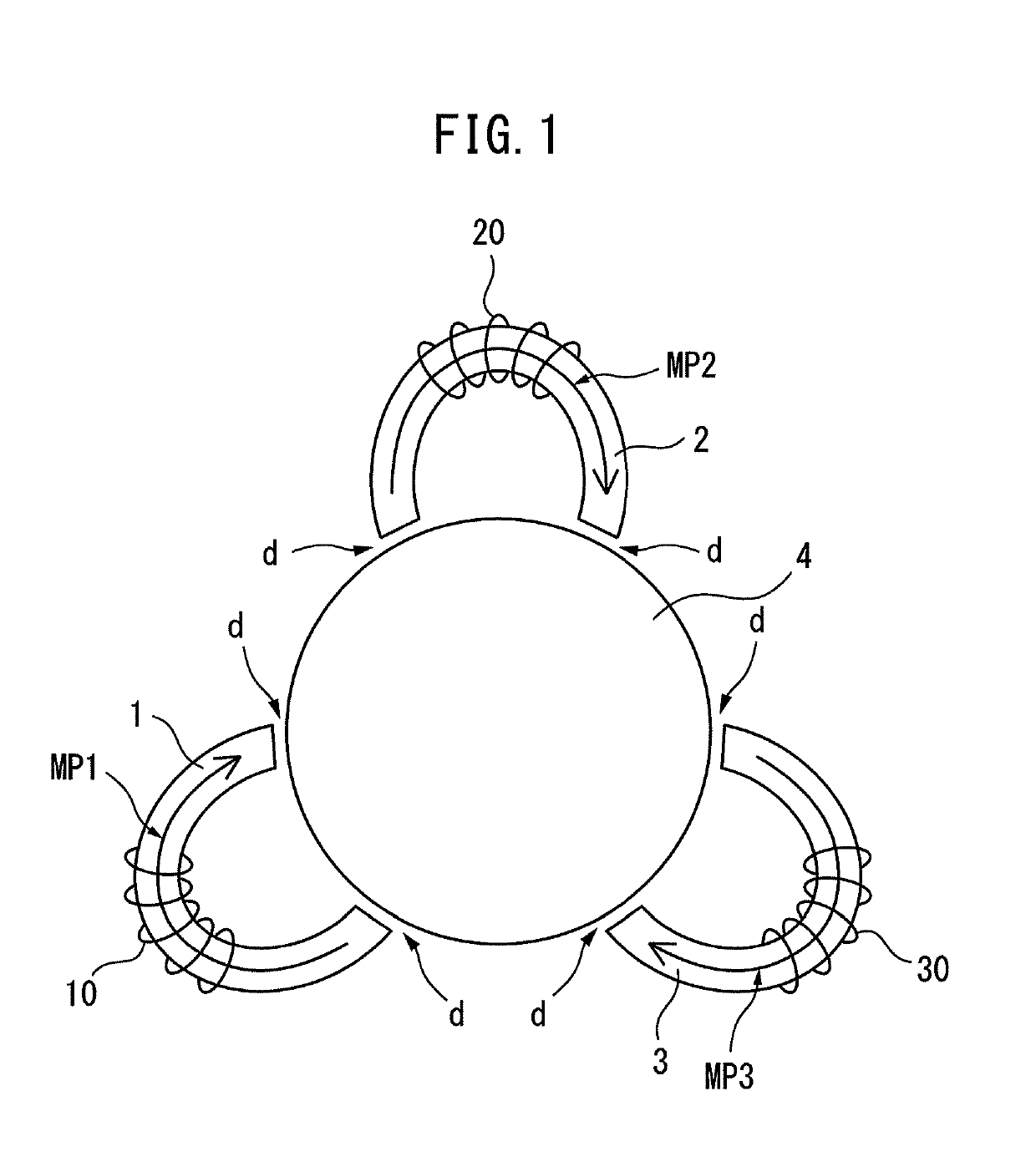

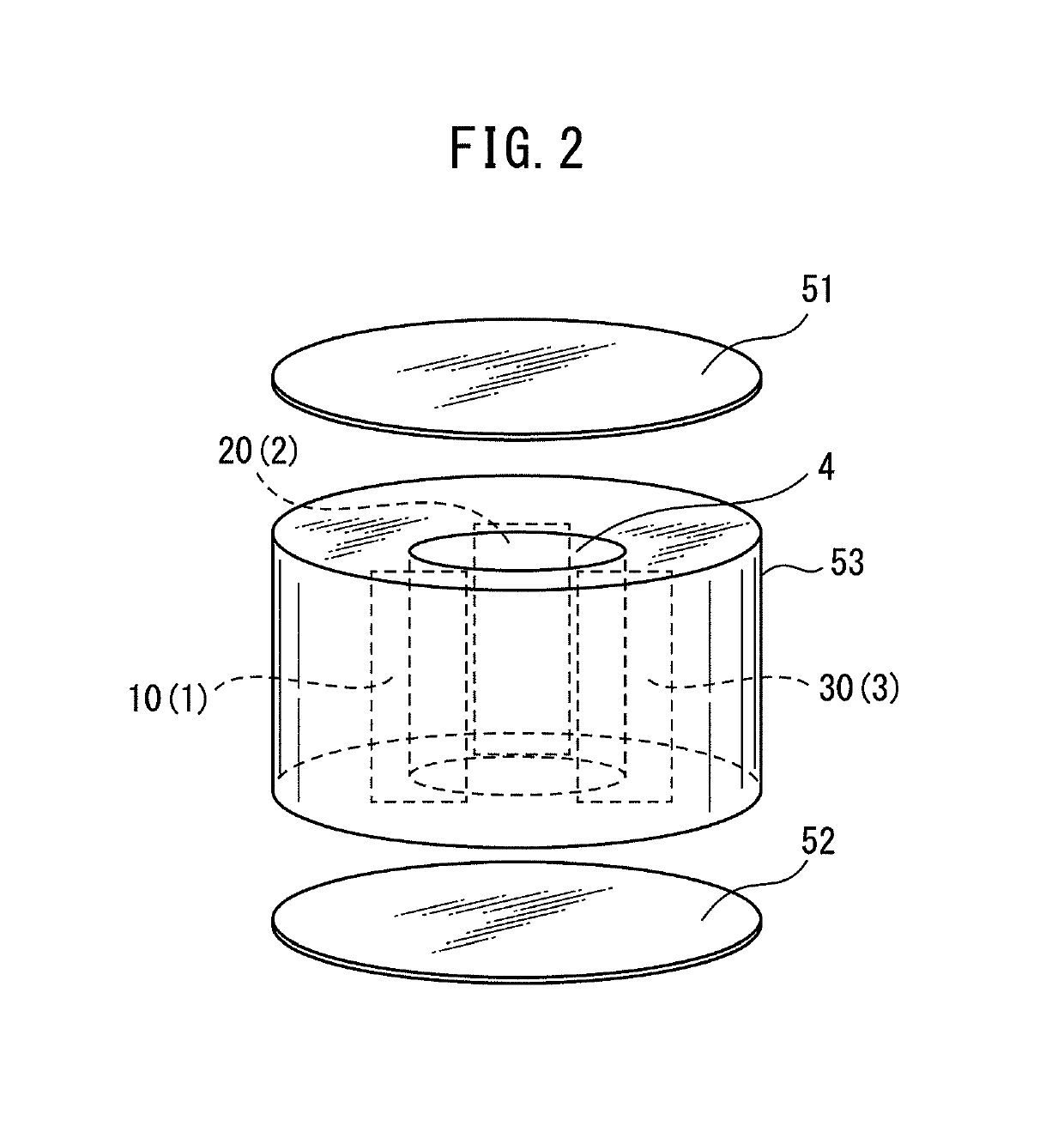

Multi-phase reactor capable of obtaining constant inductance for each phase

ActiveUS20170154718A1Transformers/inductances magnetic coresInductance with magnetic coreNuclear engineeringConductor Coil

A multi-phase reactor is configured to include a first core arranged at a center of the reactor; a plurality of second cores provided outside the first core and arranged so that each of magnetic paths with respect to the first core is in a loop shape; and one or a plurality of windings wound around each of the second cores. With this configuration, the multi-phase reactor capable of setting a constant value of inductance for each phase is provided.

Owner:FANUC LTD

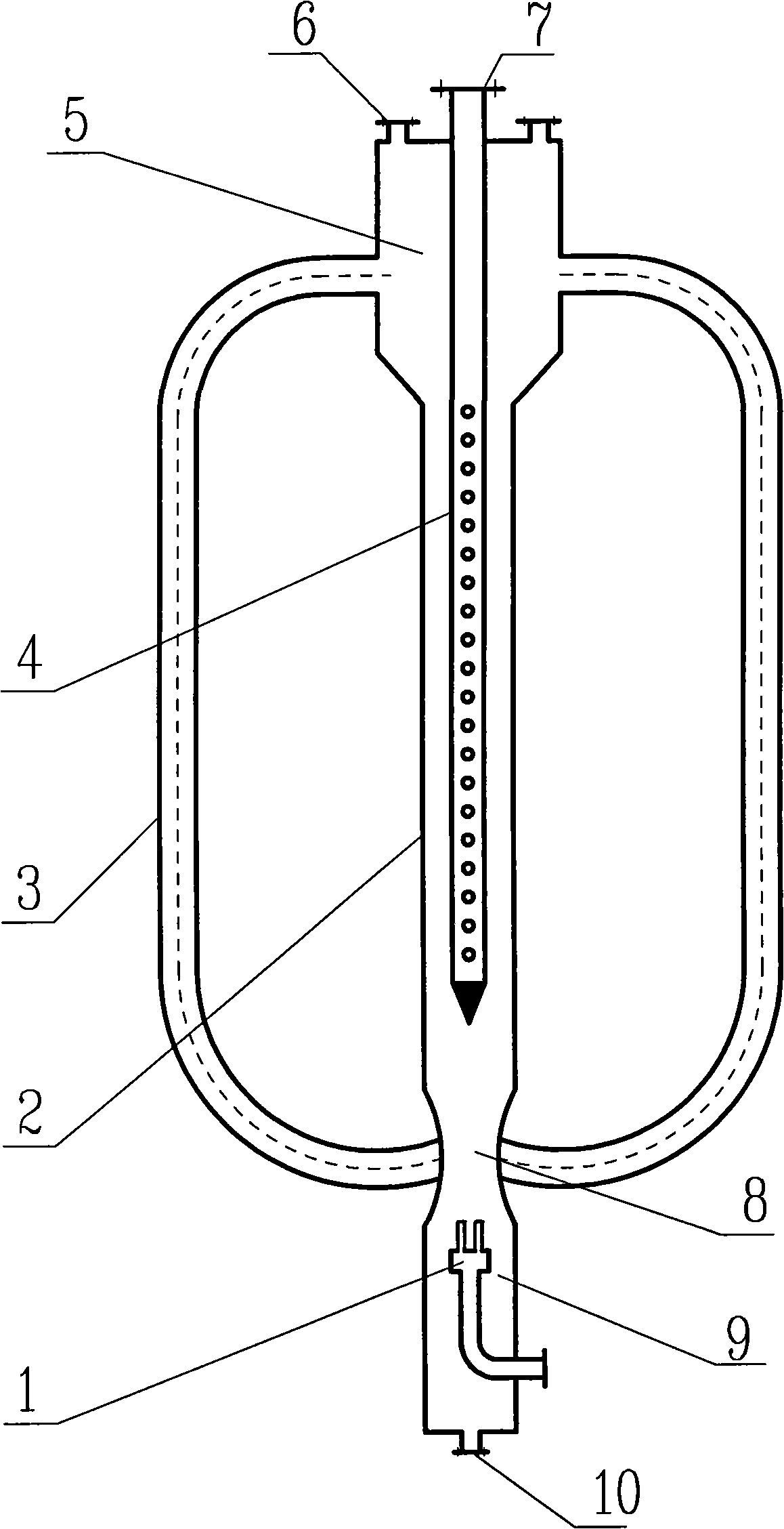

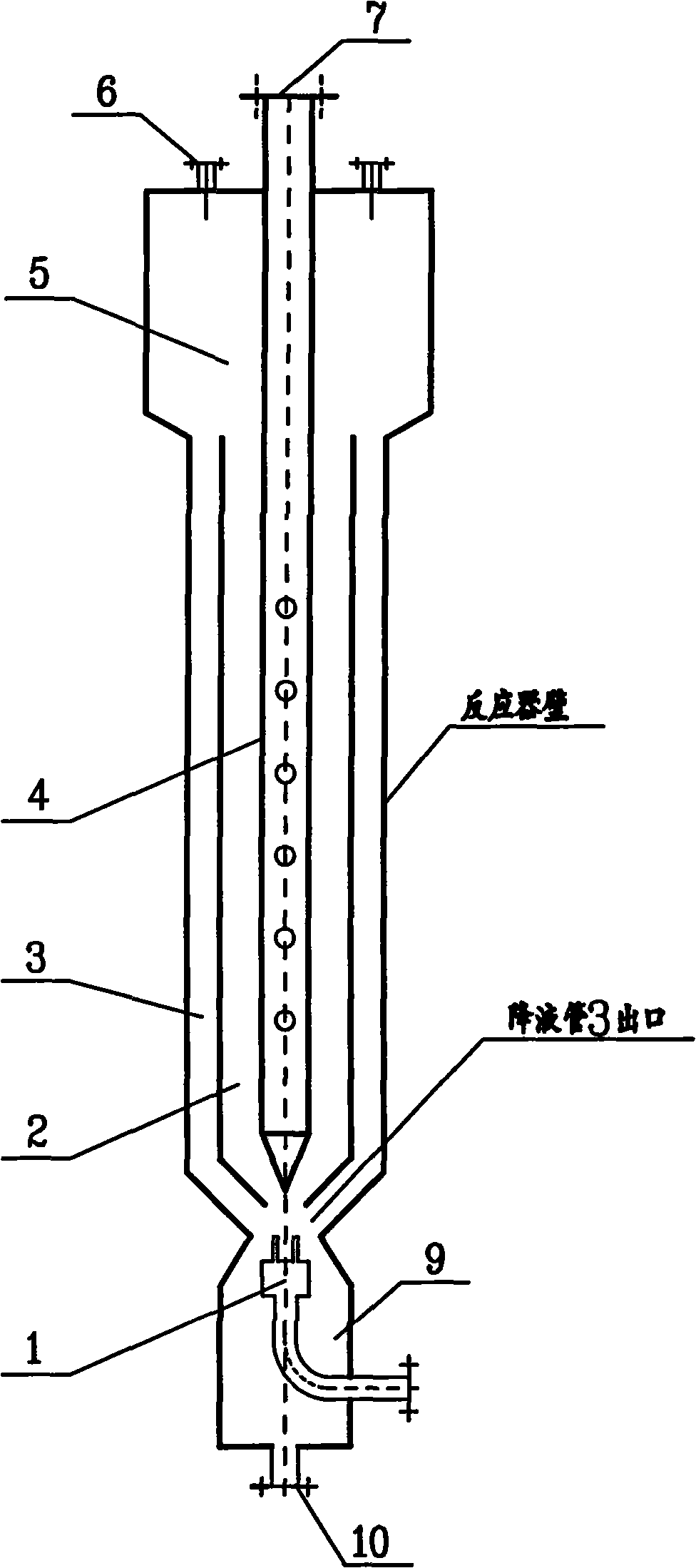

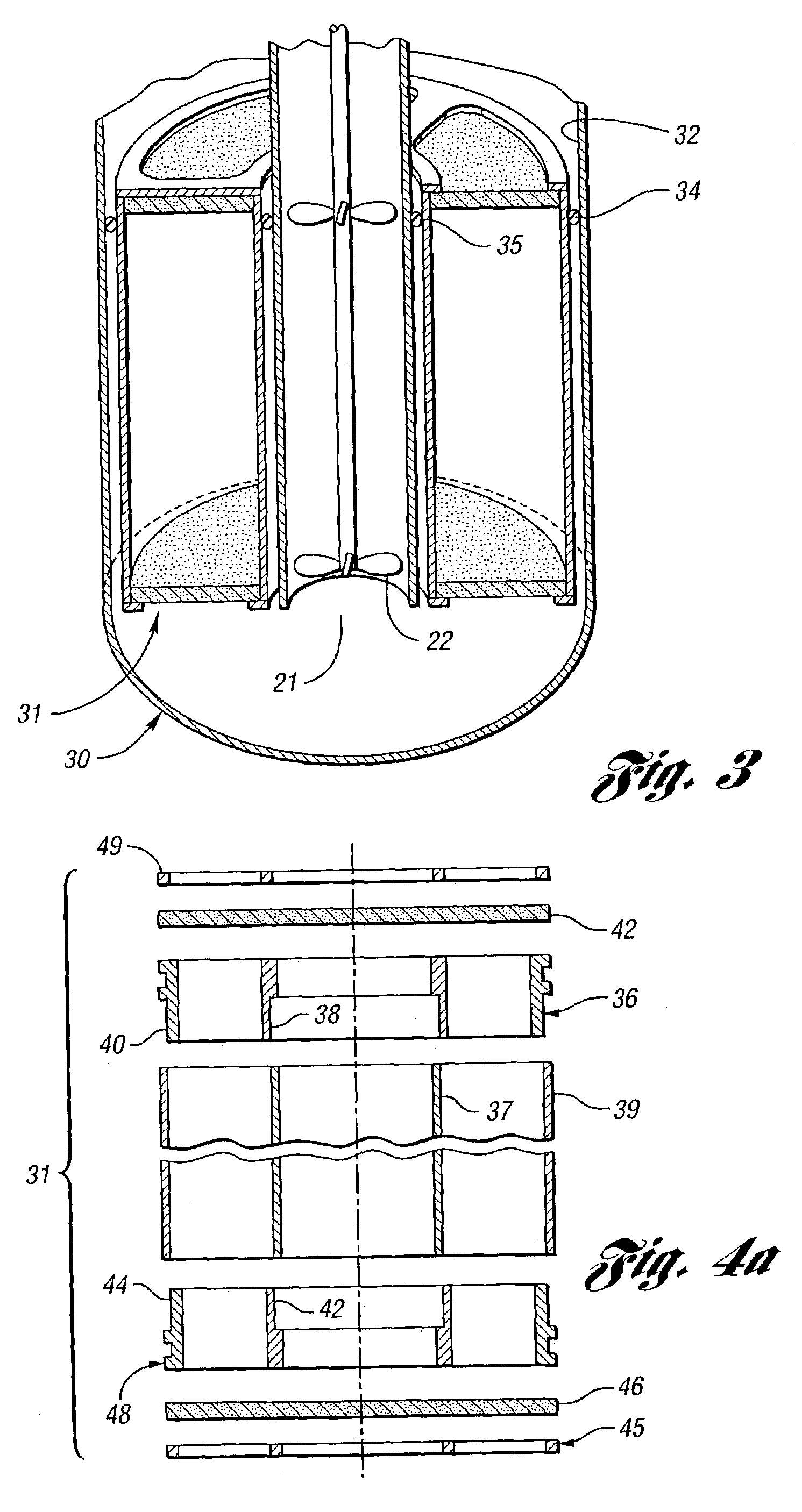

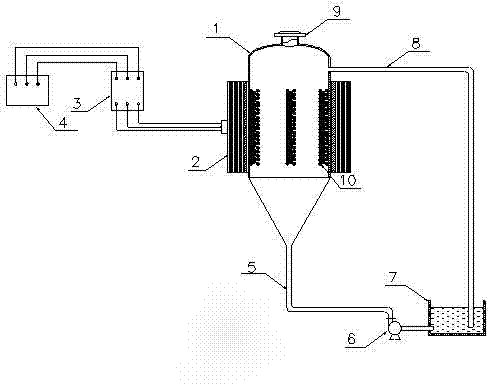

Multiphase reactor design incorporating filtration system for fixed--bed catalyst

InactiveUS7279145B2Minimizes attritionMolecular sieve catalystsRotary stirring mixersFiltrationMultiphase reactor

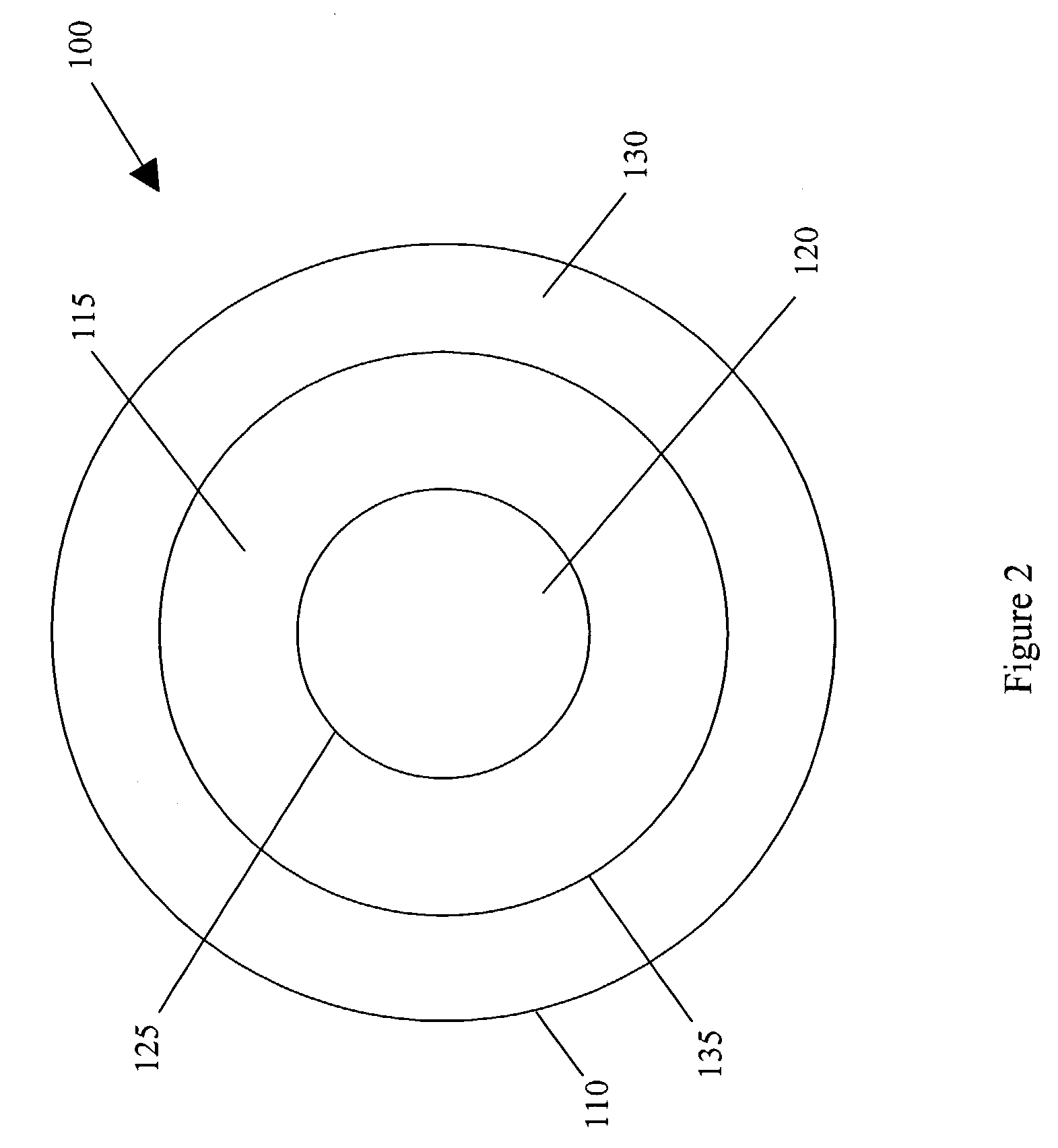

A unique reactor configuration especially suitable for interphase mass transfer and mixing of multiple phases, i.e. gas(es), liquid(s), and solid(s) where reaction is catalyzed by a solid catalyst comprises a draught tube reactor wherein the solid catalyst particles are maintained in an annular space between the draught tube of the reactor and an annulus-defining wall by means of filter elements positioned downstream and optionally also upstream from the catalyst bed.

Owner:LYONDELL CHEM TECH LP

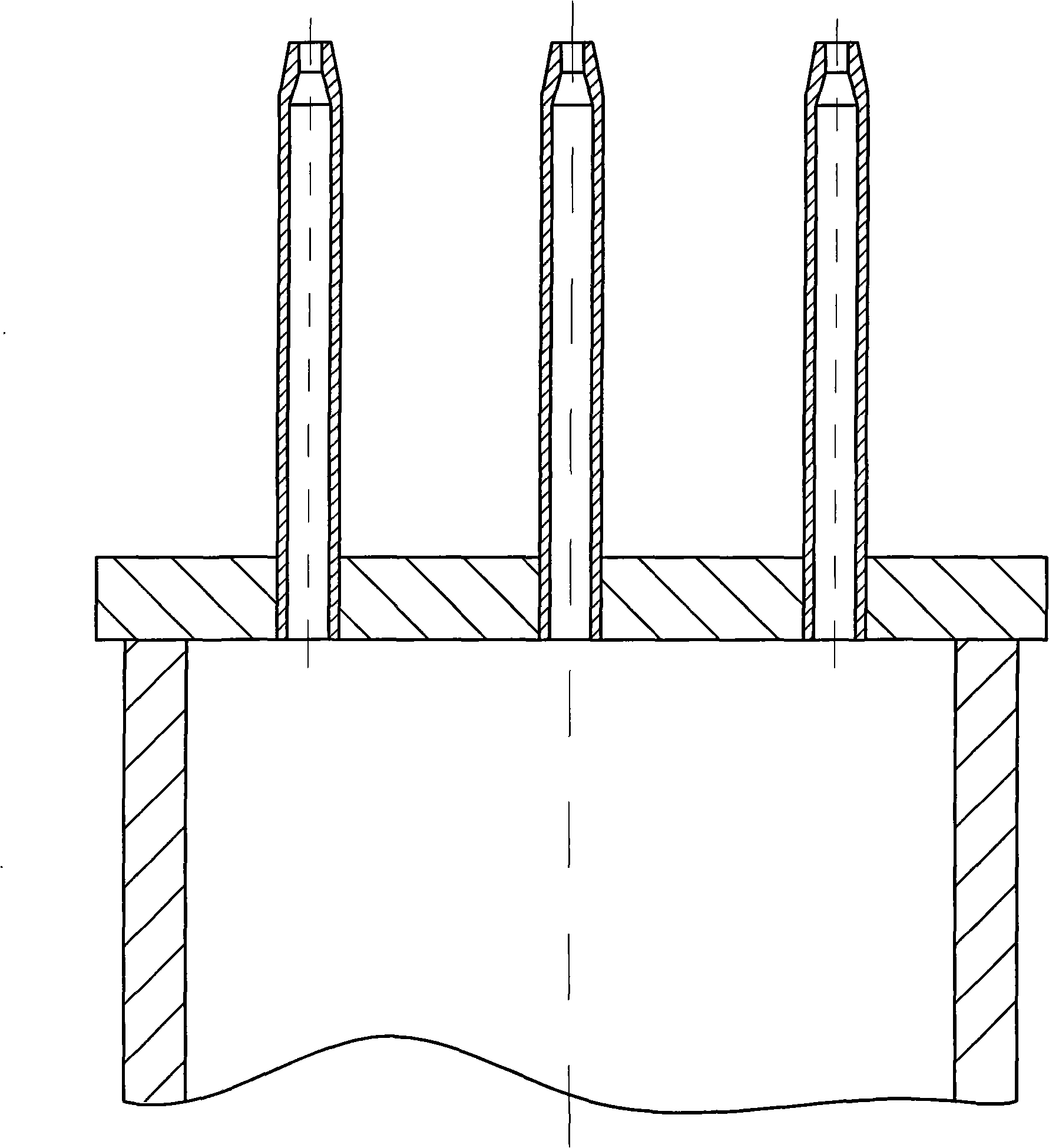

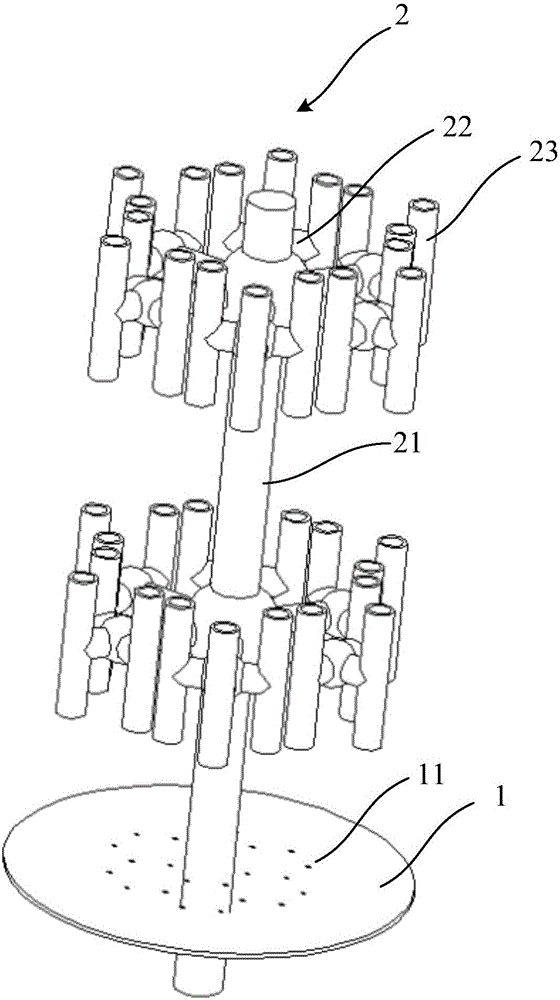

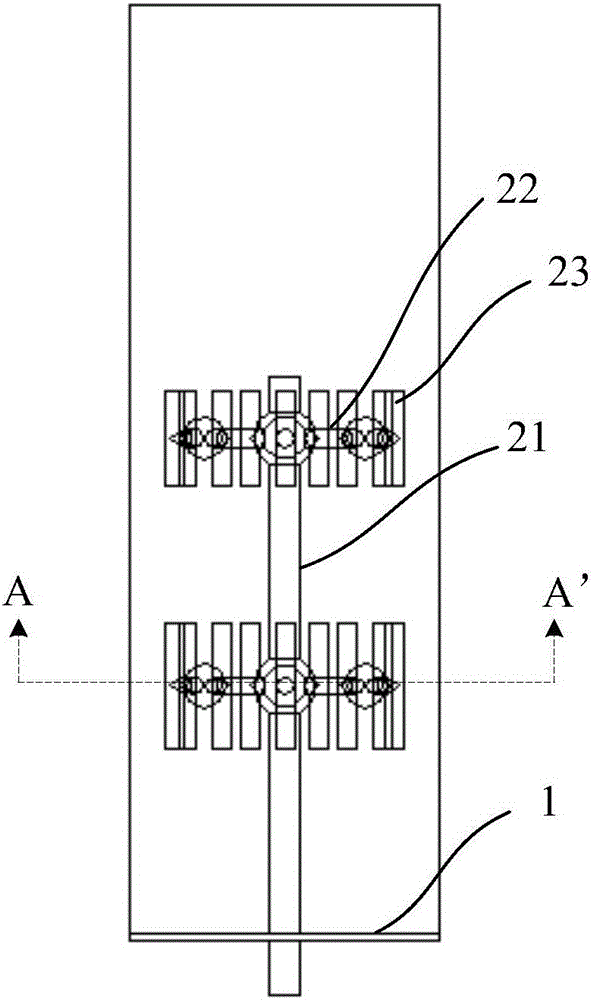

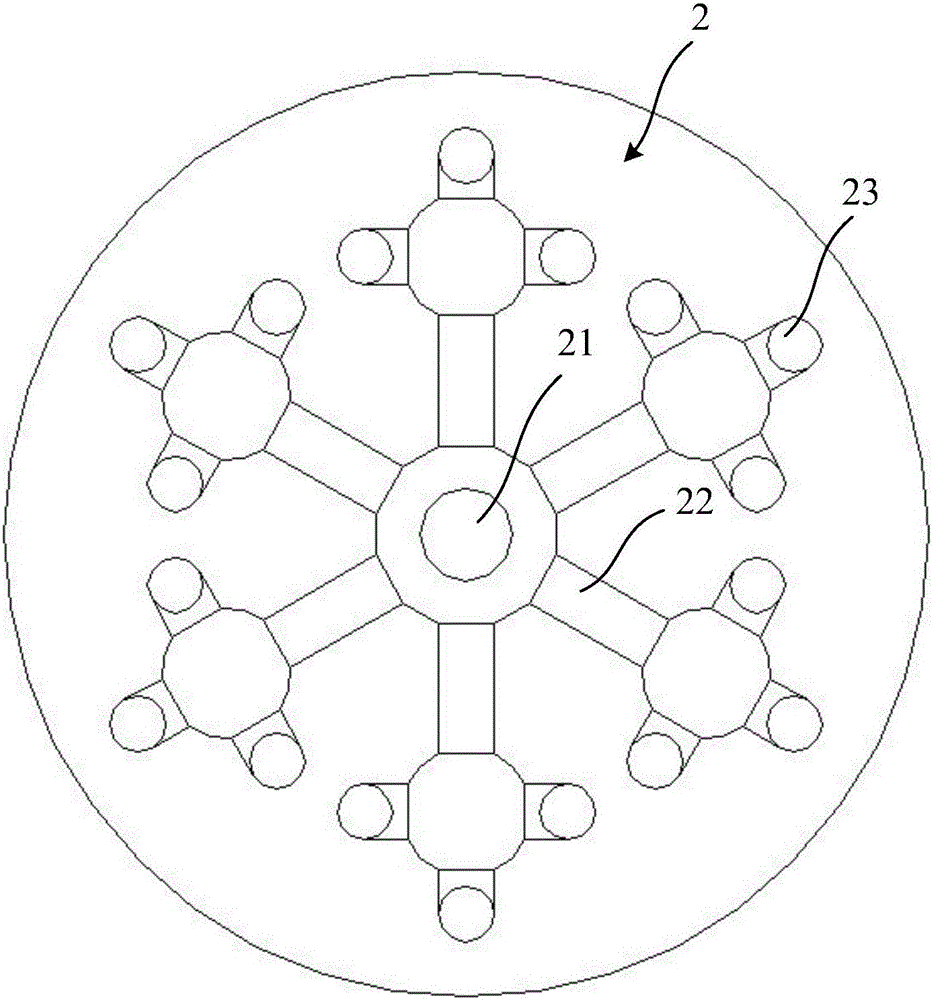

Fluid uniform distribution device with fractal structure

InactiveCN106512869APlay the role of secondary air distributionImprove uneven fluidizationChemical/physical processesMultiphase reactorEngineering

The invention provides a fluid uniform distribution device with a fractal structure. The fluid uniform distribution device is arranged in a multi-phase reactor, and at least comprises a distribution plate and a fractal member, wherein the distribution plate is arranged at the bottom of the multi-phase reactor, and the fractal member penetrates through the distribution plate to be arranged in the multi-phase reactor. The fluid uniform distribution device can reduce the pressure drop of the distribution plate, further can reduce the energy consumption, also can enable fluid which enters the reactor to be distributed more evenly and improves a fluidization effect; in addition, the standing time for the fluid in the reactor is adjustable, and the fluid uniform distribution device is strong in operation flexibility.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

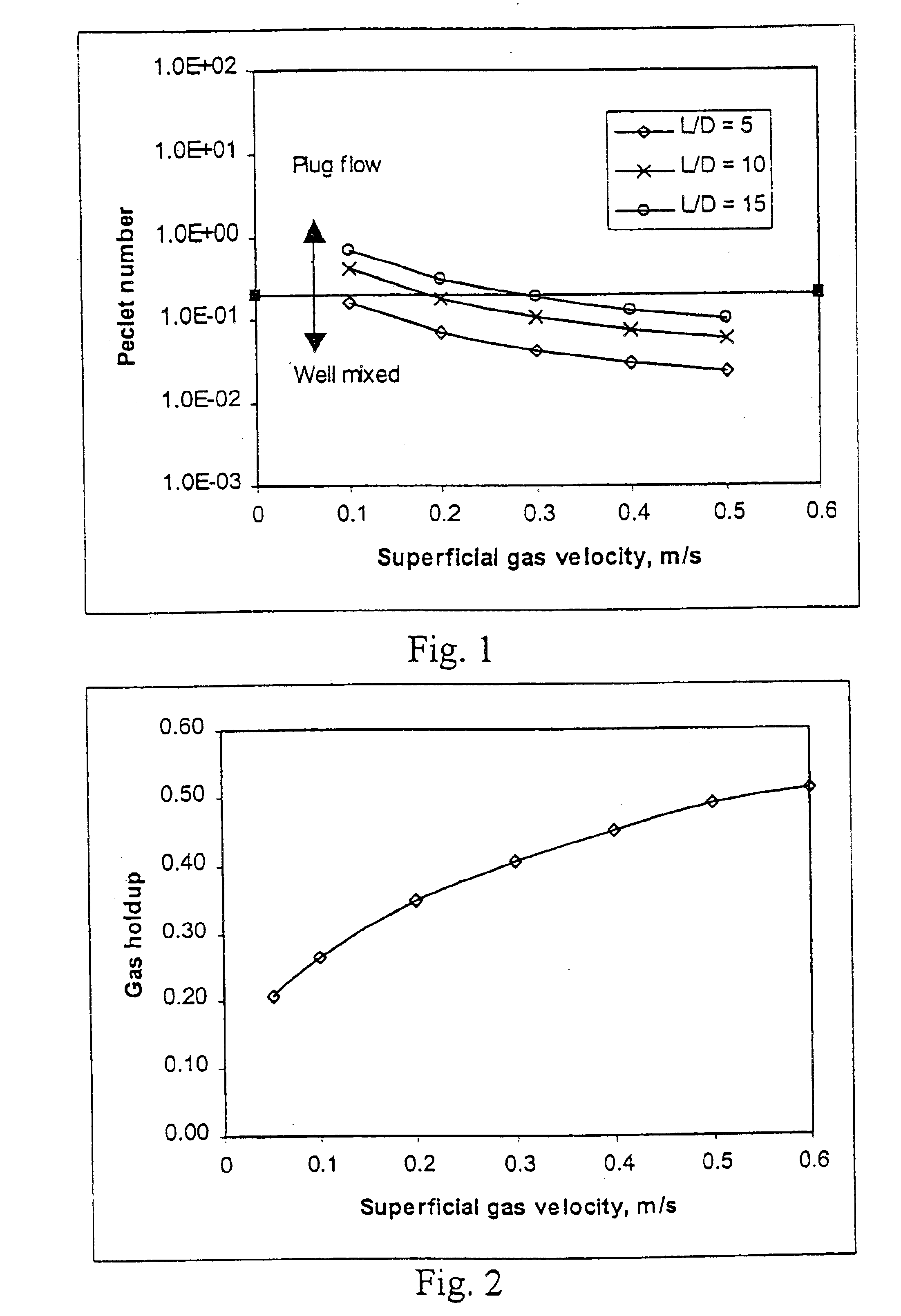

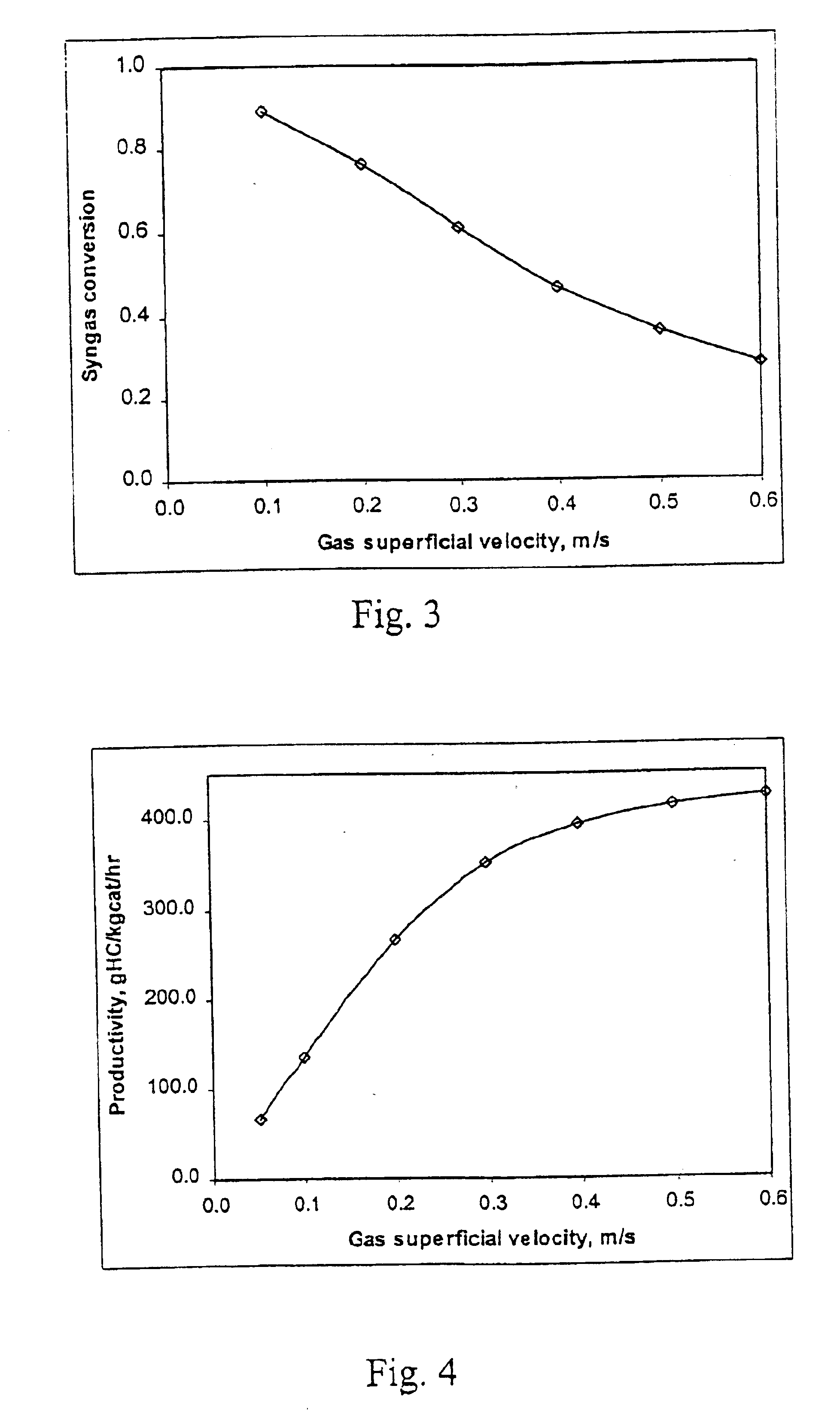

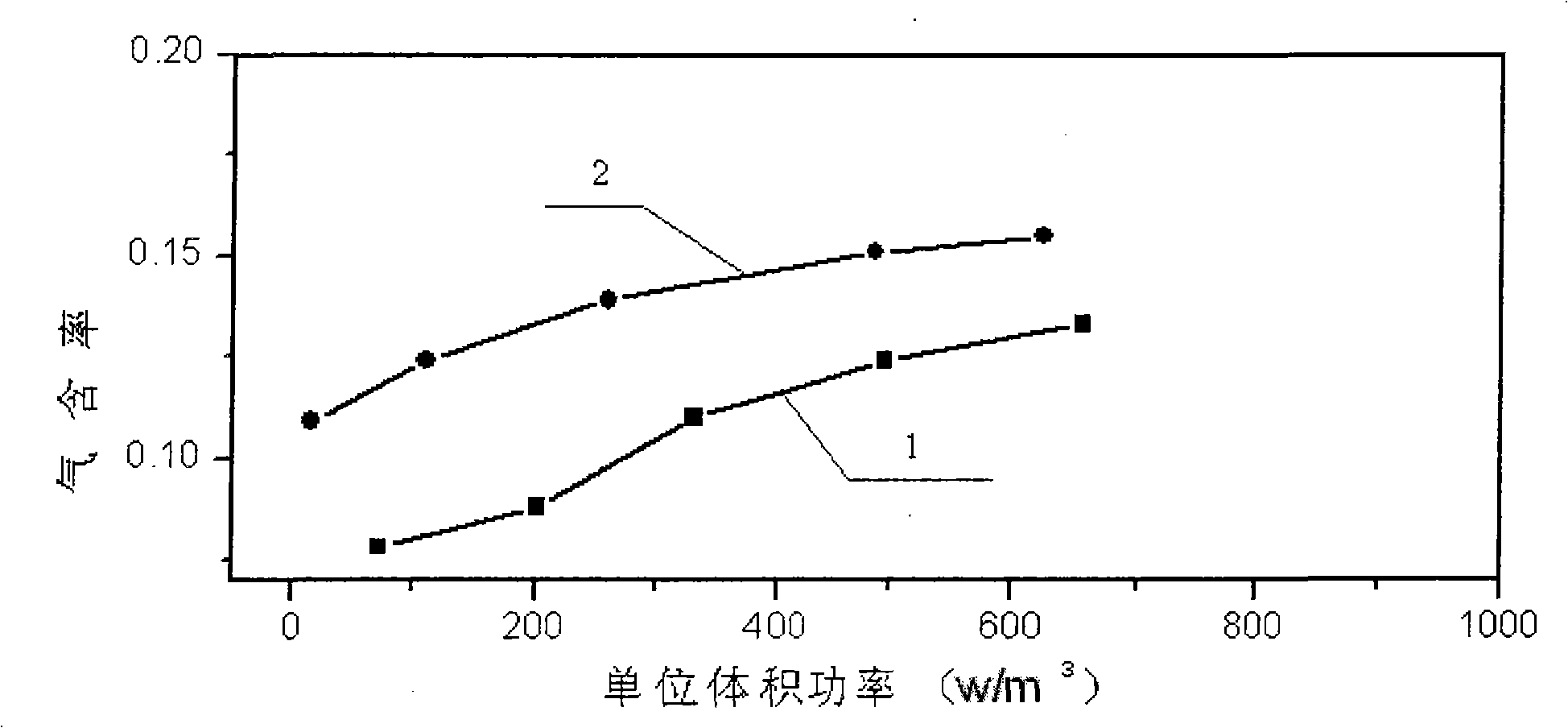

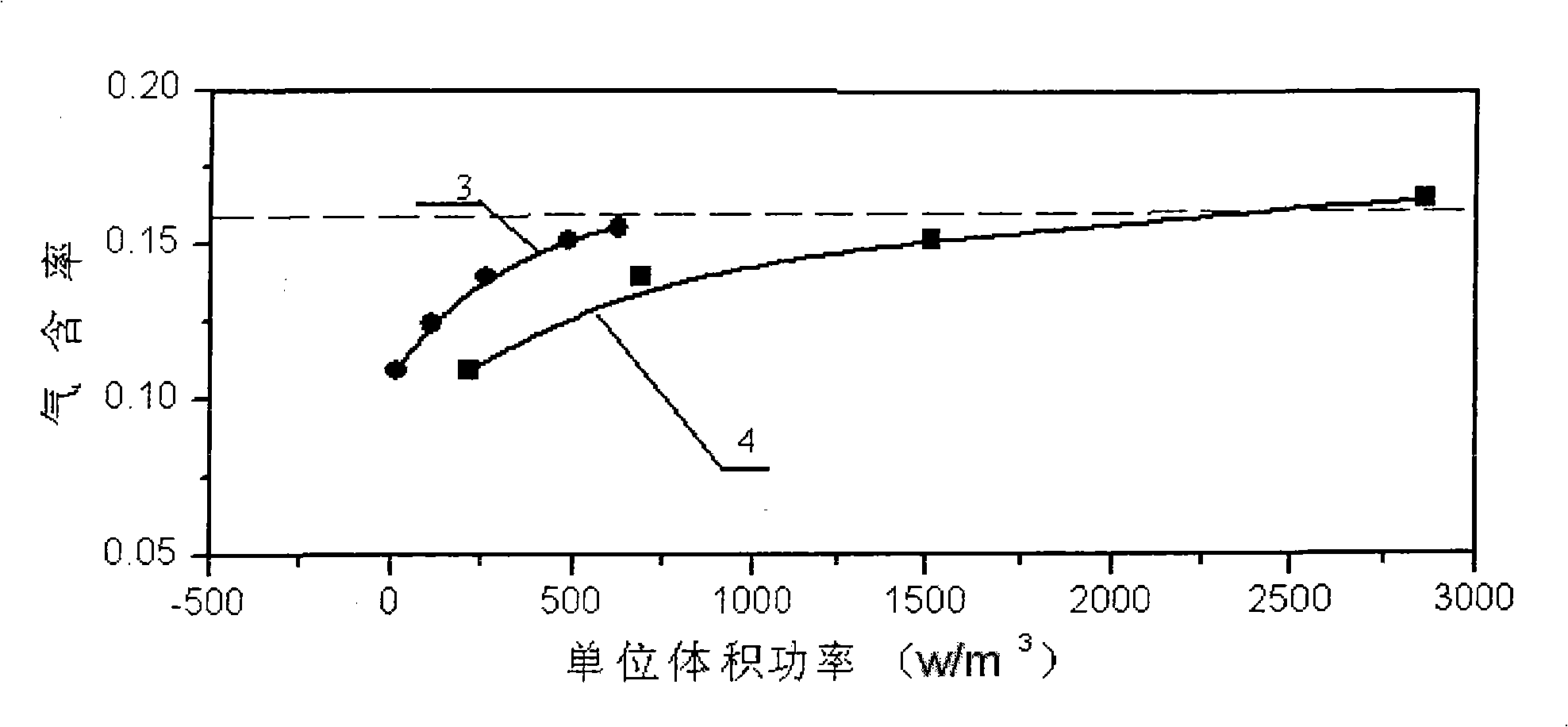

Slurry bubble reactor operated in well-mixed gas flow regime

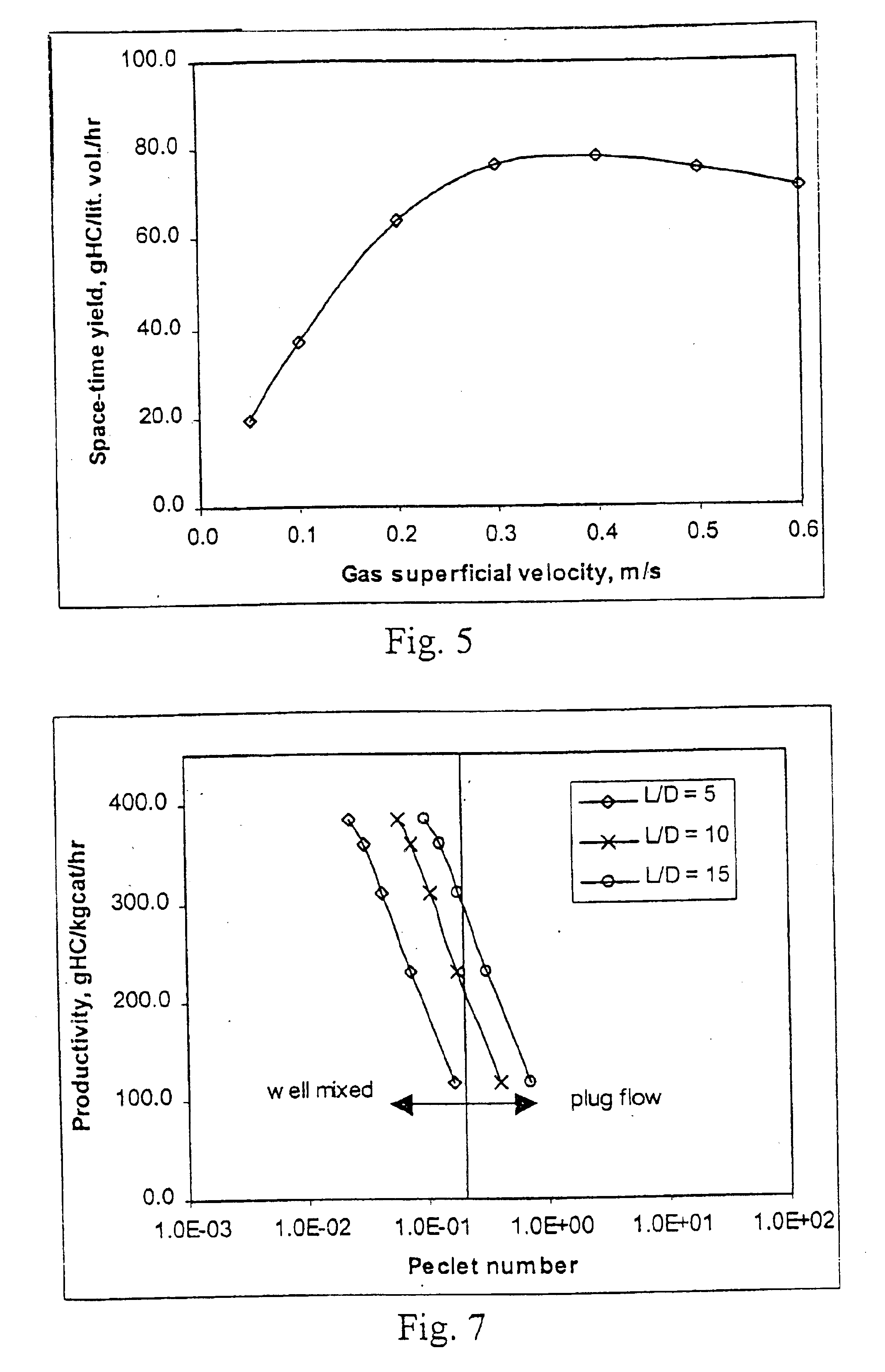

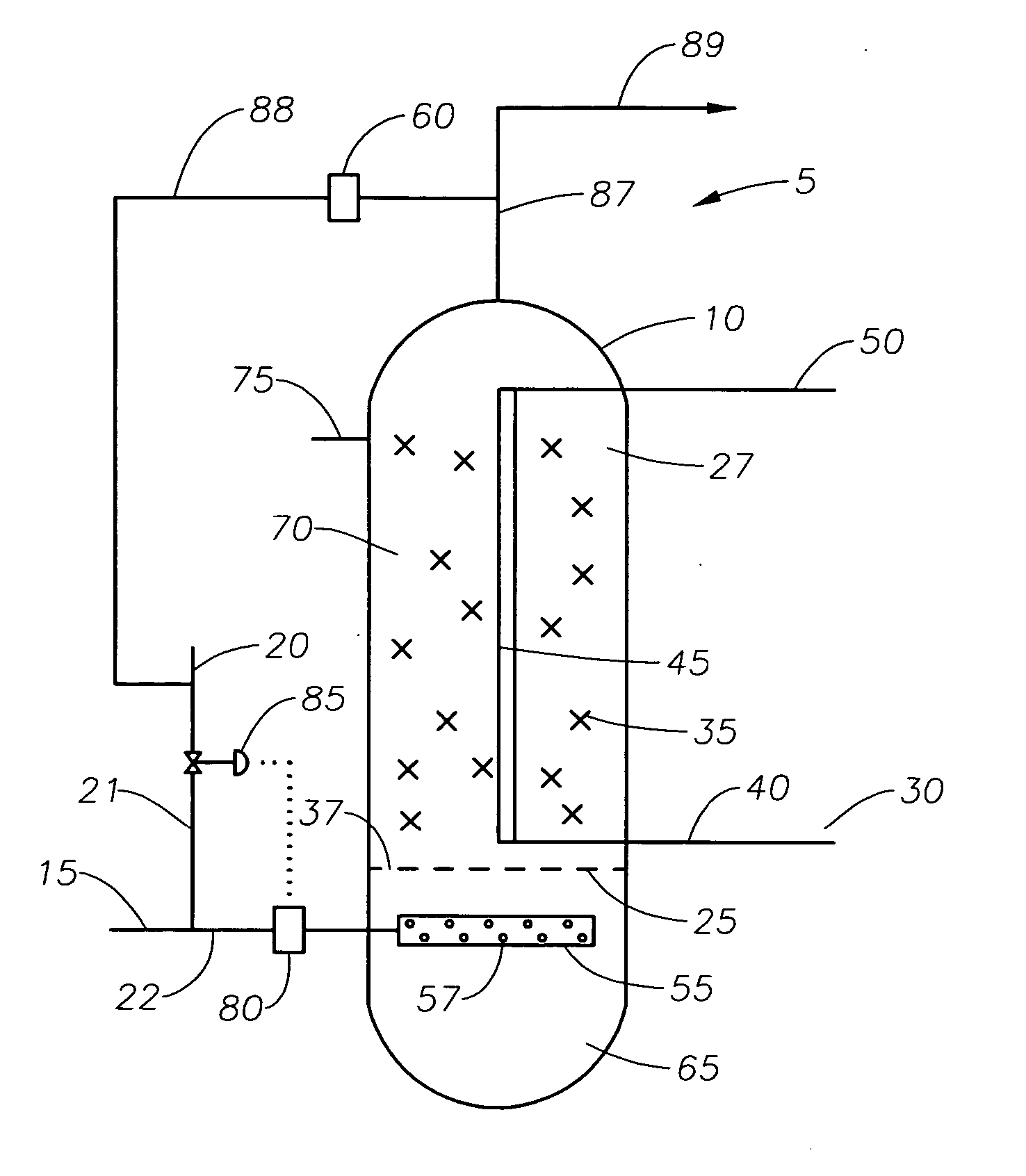

InactiveUS6914082B2High catalytic productivityMaximum productivityMechanical apparatusHydrocarbon from carbon oxidesProduction rateNuclear engineering

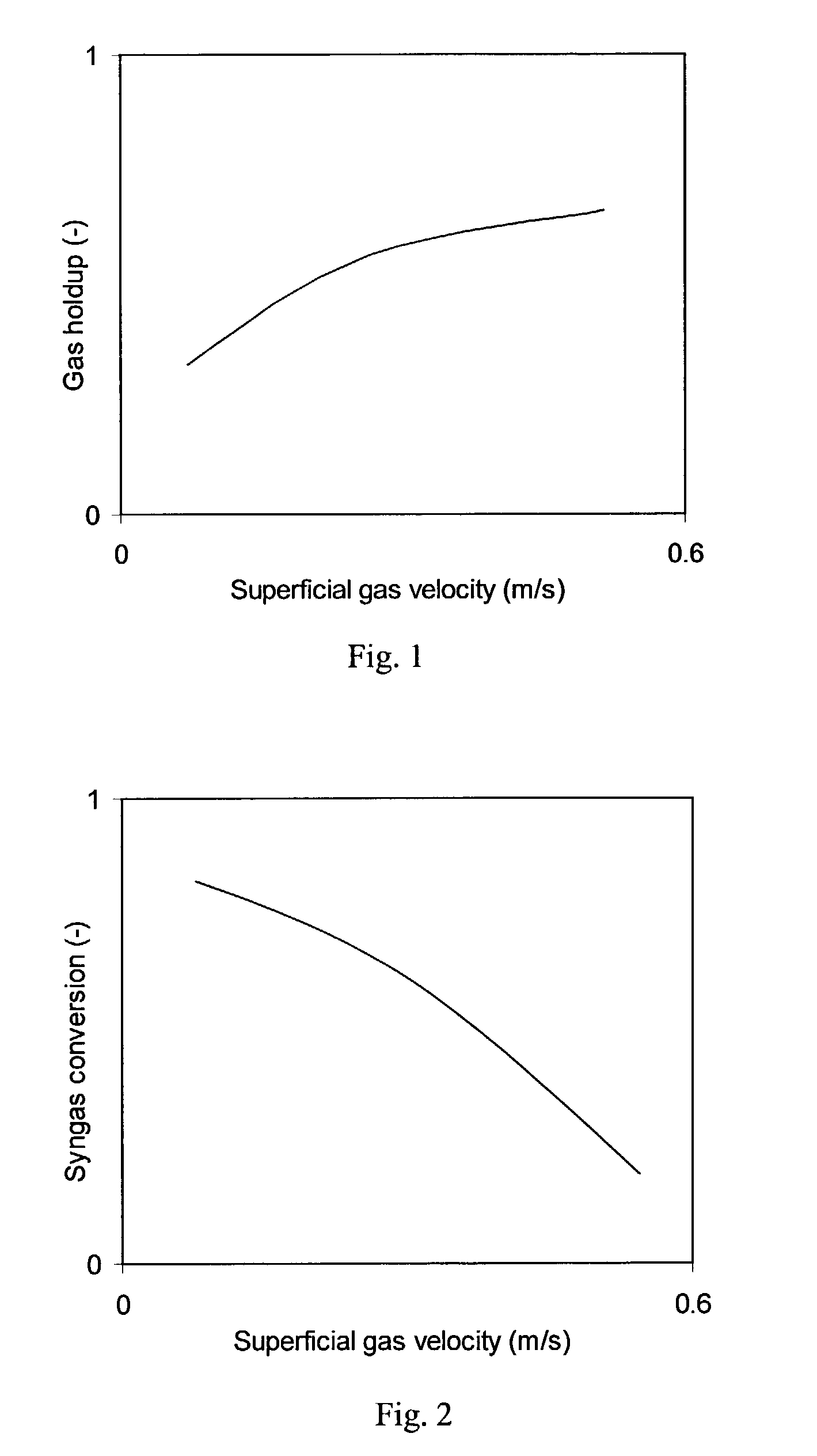

A gas-agitated multiphase reactor system for the synthesis of hydrocarbons gives high catalyst productivity and reactor capacity. The system includes operating a multi-phase reactor in the well-mixed gas flow regime, with a Peclet number less than 0.175 and a single pass conversion ranging from 35% to 75%, wherein the inlet superficial gas velocity decreases with the decreasing of the reactor aspect ratio, and is preferably at least 20 cm / sec.

Owner:CONOCOPHILLIPS CO

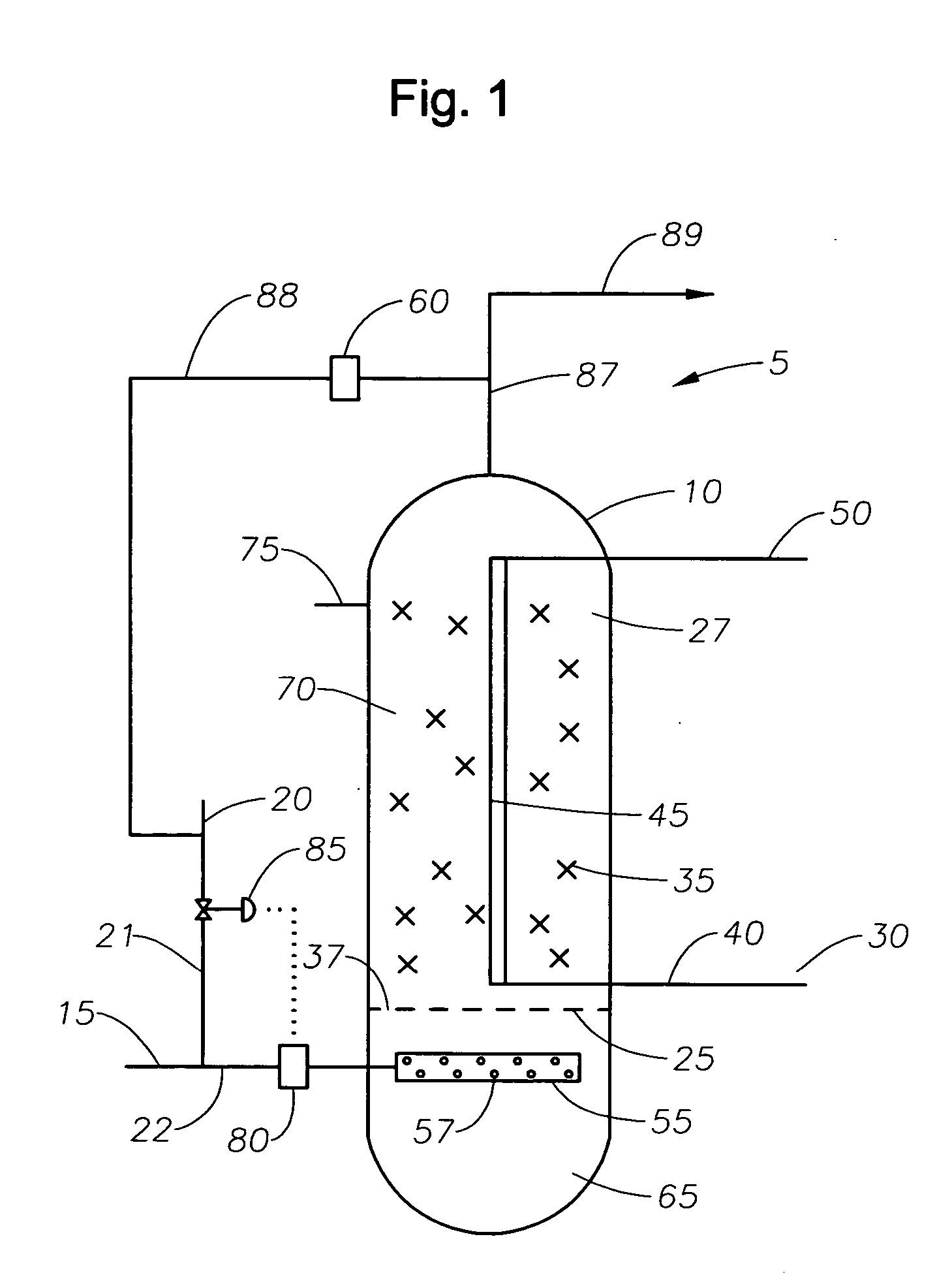

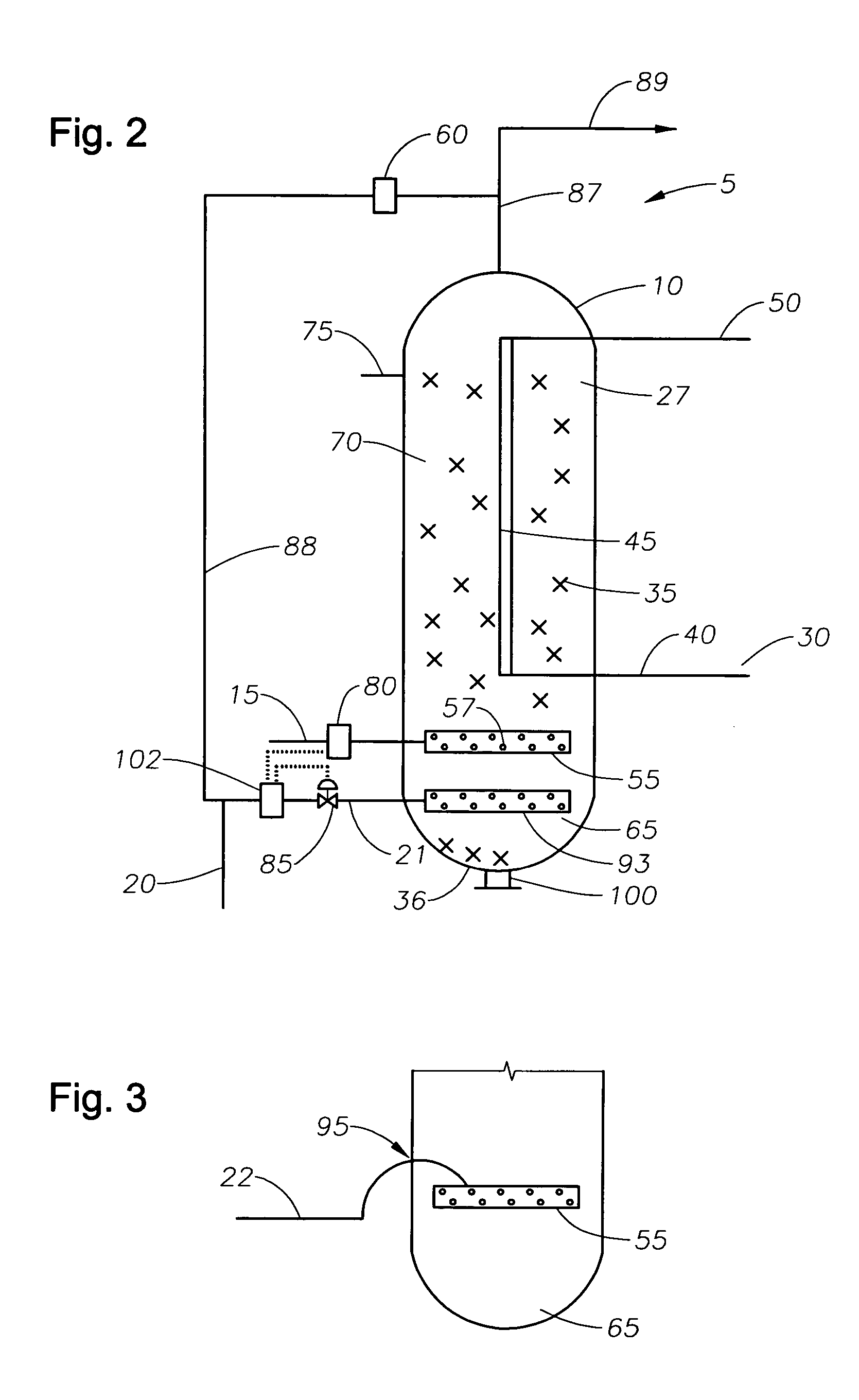

Prevention of and recovering from a catalyst bed slumping in a gas-agitated multiphase reactor

ActiveUS20050209351A1Reduce cloggingPrevents a catalyst bed from slumpingOrganic compounds purification/separation/stabilisationOrganic compound preparationSyngasDistributor

The invention relates to methods for prevention of and recovery from a catalyst bed slumping in a gas-agitated multiphase hydrocarbon synthesis reactor, while the reactor is either under non-reactive conditions or under reaction promoting conditions when syngas is converted to products. The reactor contains a catalyst bed comprising catalyst particles and a gas injection zone suitable for injecting a reactor gas feed. A method for preventing bed slumping comprises supplying a supplemental gas to the gas-agitated multiphase reactor to prevent the catalyst bed from slumping due to insufficient reactor gas feed flow. The method may include recycling some or all of the supplemental gas to the reactor. The method may further comprise separating the gas injection zone from the catalyst bed with a porous plate so as to prevent migration of catalyst particles into the gas injection zone and to minimize plugging of gas distributor(s) present in said zone.

Owner:PHILLIPS 66 CO

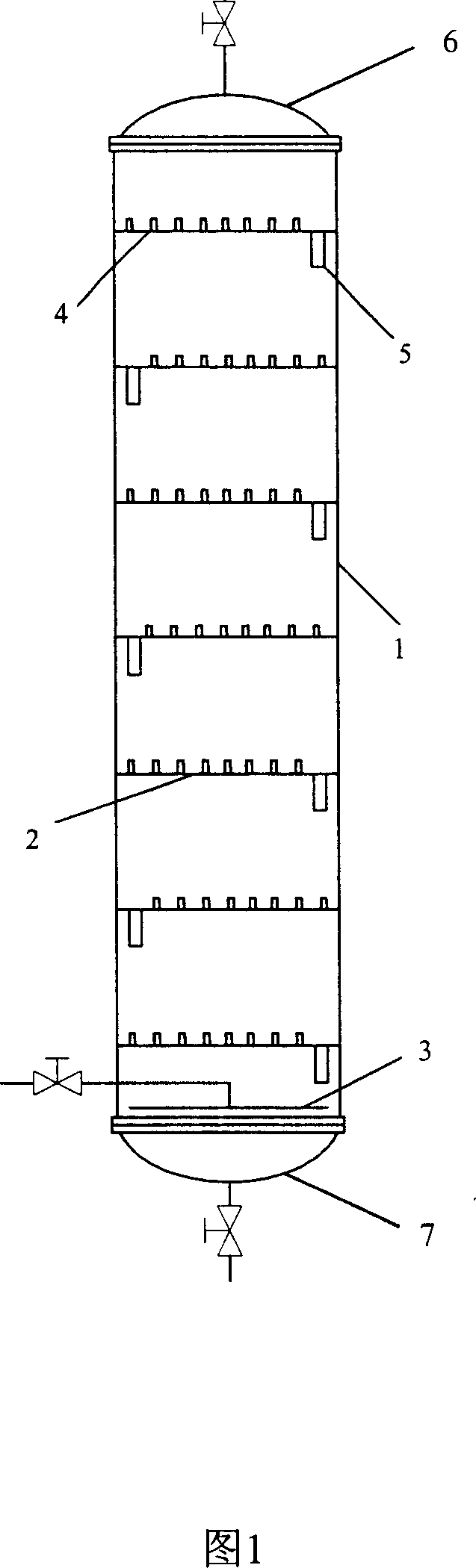

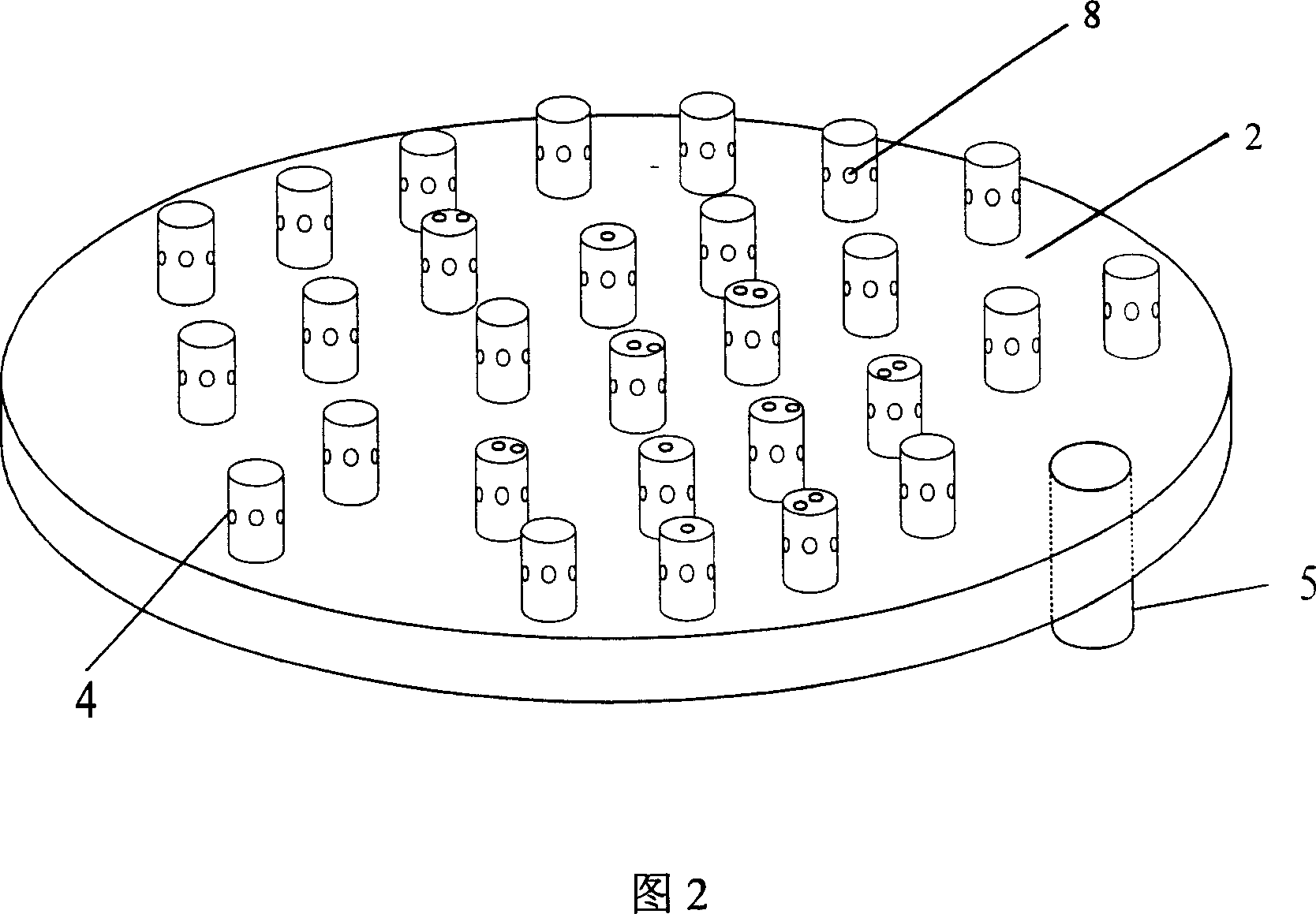

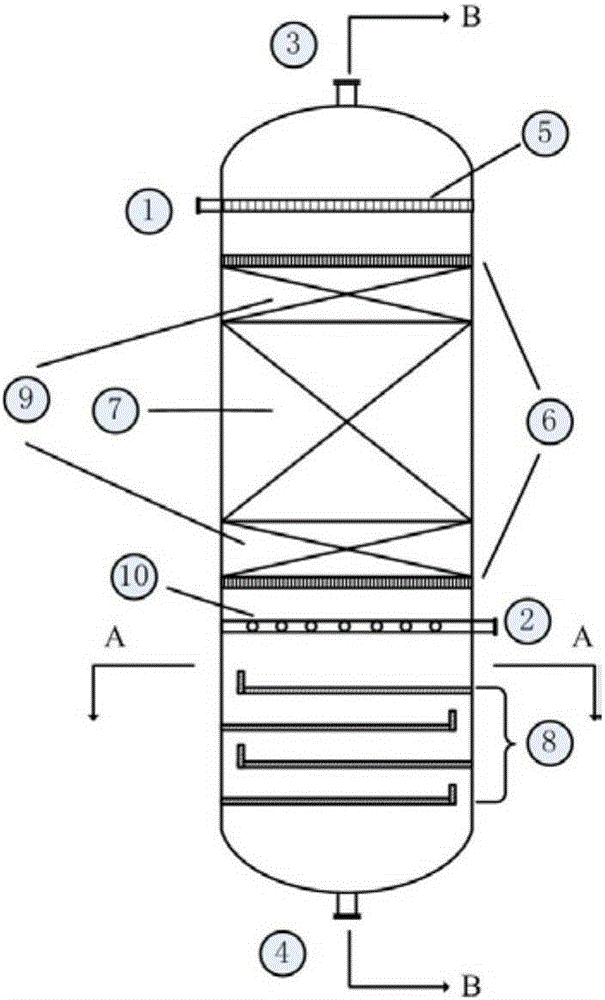

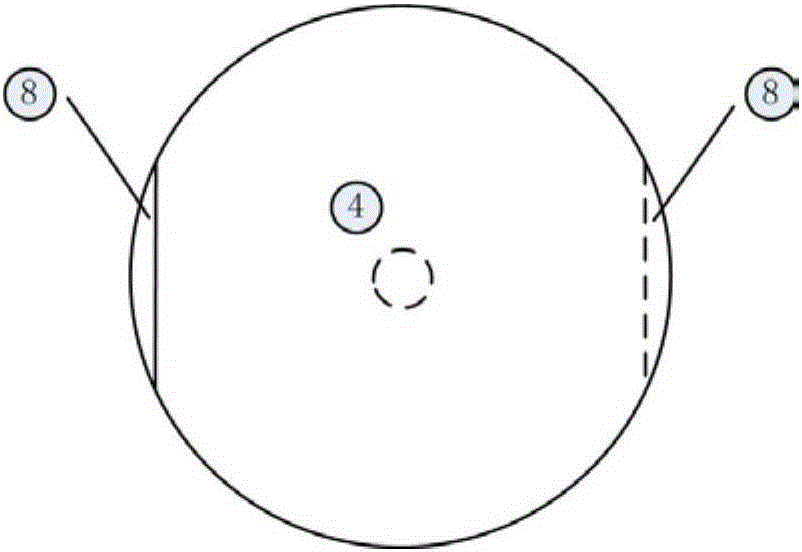

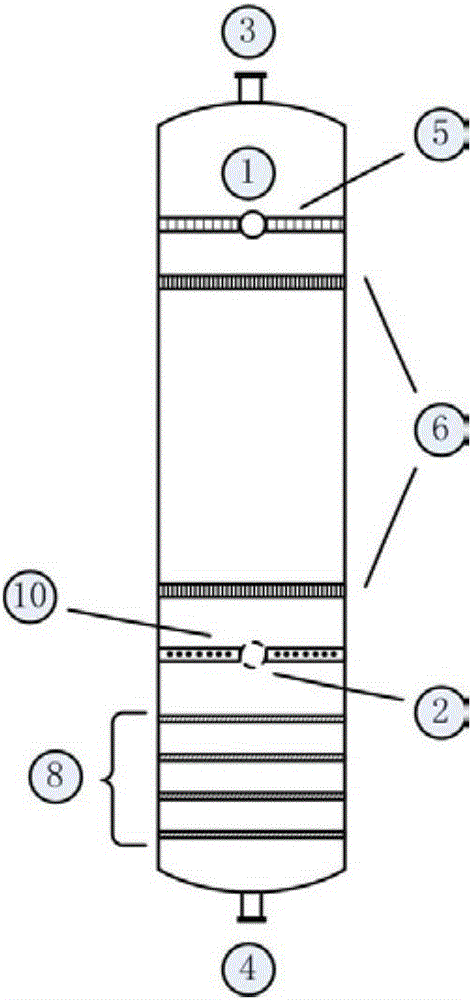

Multi-phase bubbling reactor

ActiveCN101028586AEvenly distributedImprove solubilityLiquid-gas reaction processesProduct gasProcess engineering

A bubbling-type multi-phase reactor for the gas-liquid or gas-liquid-solid reaction with high reaction efficiency and mass transfer efficiency and excellent hydromechanical performance is composed of a tower body, 2-8000 tower trays with 10-200 gas-rising tubes and 1-5 down-flow spouts on each tower tray, and gas distributor.

Owner:CHINA COAL RES INST +1

Magnetic drive impact mixing and grinding combined multi-phase reactor

InactiveCN103203214AEasy to achieve corrosion resistanceEasy to realize the problem of anti-leakageMixersChemical/physical/physico-chemical stationary reactorsMultiphase reactorInterior space

The invention discloses a magnetic drive impact mixing and grinding combined multi-phase reactor which comprises a nonmetal reaction tube (or tank), wherein the nonmetal reaction tube (or tank) is respectively externally and internally provided with an alternating magnetic field device and a magnetic oscillator or a magnetic grinding material. The magnetic drive impact mixing and grinding combined multi-phase reactor is characterized in that excitation coils which are uniformly distributed outside the nonmetal reaction tube (or tank) are used; the controllable alternating magnetic field inside the inner space of the reactor is generated by adopting an AC (Alternating Current) power supply or an alternating DC power supply; and when reaction materials pass through the space of the reactor through the inlet and outlet of the nonmetal reaction tube (or tank), the magnetic oscillator or the magnetic grinding material moves under the action of the alternating magnetic field, so that the purpose of mixing or grinding the reaction materials is achieved, and the reaction is promoted. The multi-phase reactor disclosed by the invention ingeniously integrates the mixing and grinding of the reaction materials into a whole, shortens the process flow and has the characteristics of zero leakage, no abrasion, simple structure, reliability in property, and the like.

Owner:SICHUAN UNIV

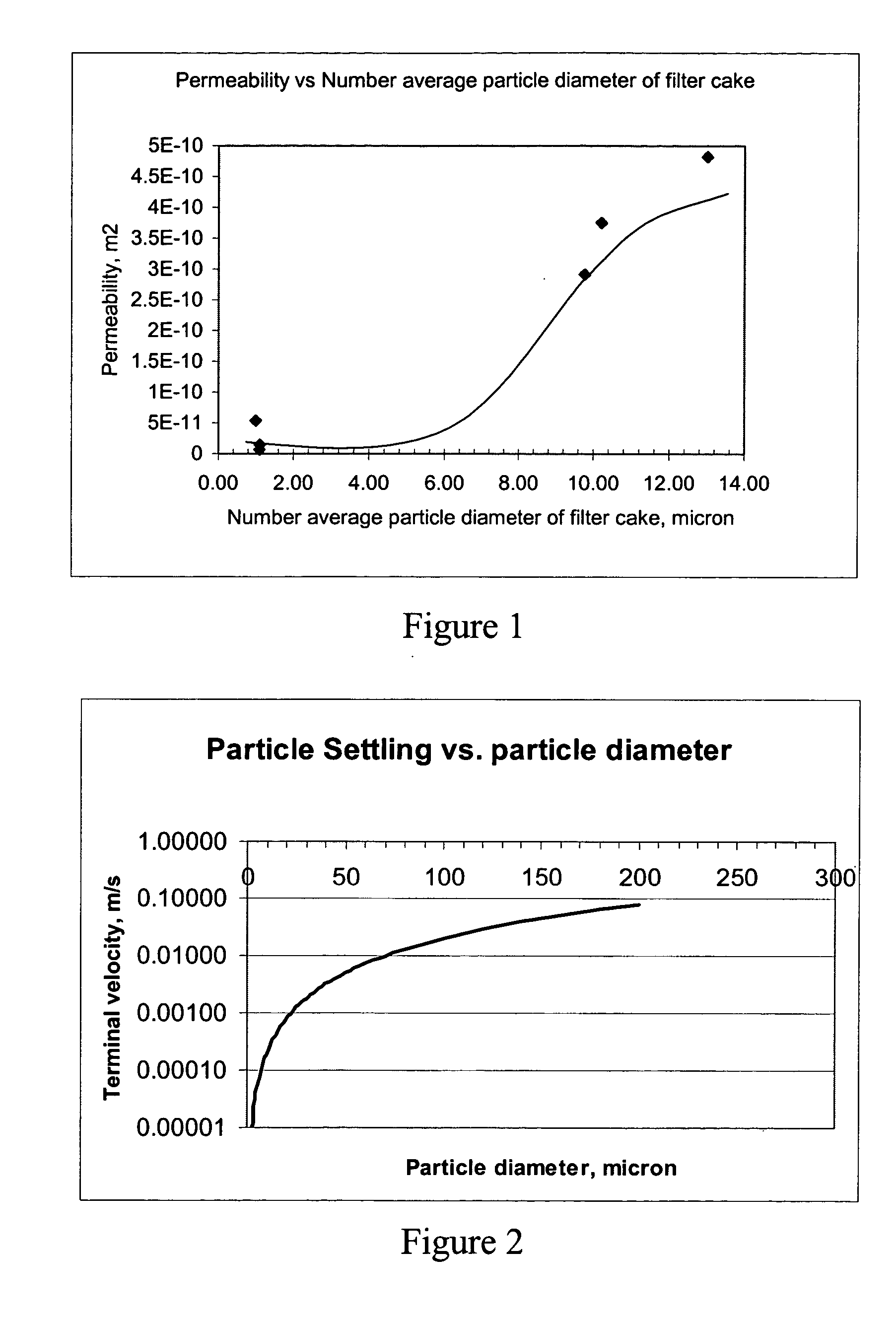

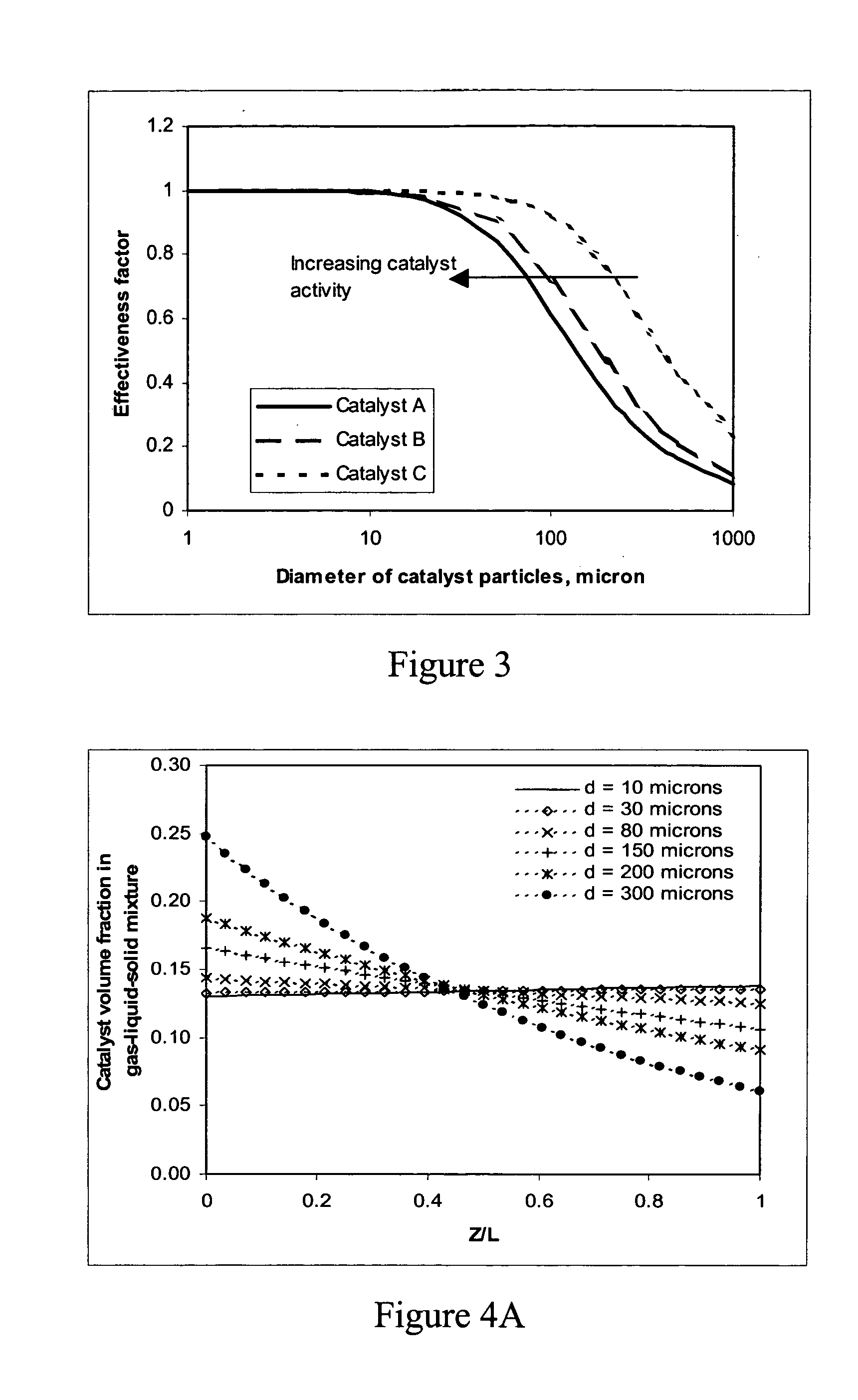

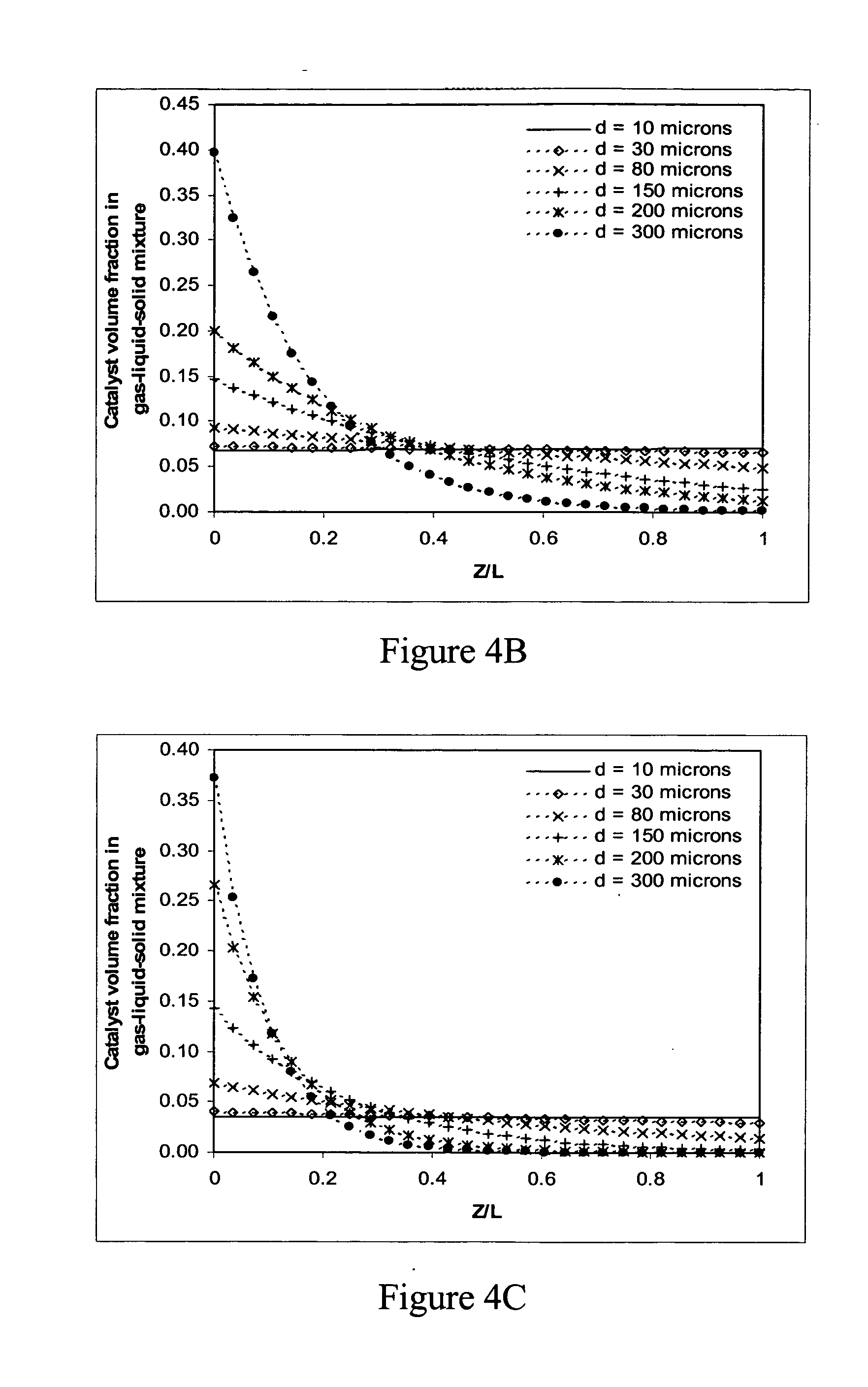

Optimized particle distribution for slurry bubble column reactors

InactiveUS20050209350A1Organic compounds purification/separation/stabilisationOrganic compound preparationSyngasProcess engineering

A method for selecting maximum and minimum catalyst particle sizes for use in a multiphase reactor that reflects optimum operating conditions of the reactor is based on a maximum Archimedes number for estimating the maximum particle size and a property of a separation system linked to the reactor to determine the minimum particle size. The maximum Archimedes number could be selected based on a maximum catalyst non-uniformity in the reactor. Additionally, a method for producing hydrocarbons from syngas in a slurry bubble column reactor comprises the use of a plurality of fresh catalyst particles with an optimum size distribution based on a range of Archimedes numbers between about 0.02 and 250 or alternatively based on an average Reynolds number less than about 0.1.

Owner:CONOCOPHILLIPS CO

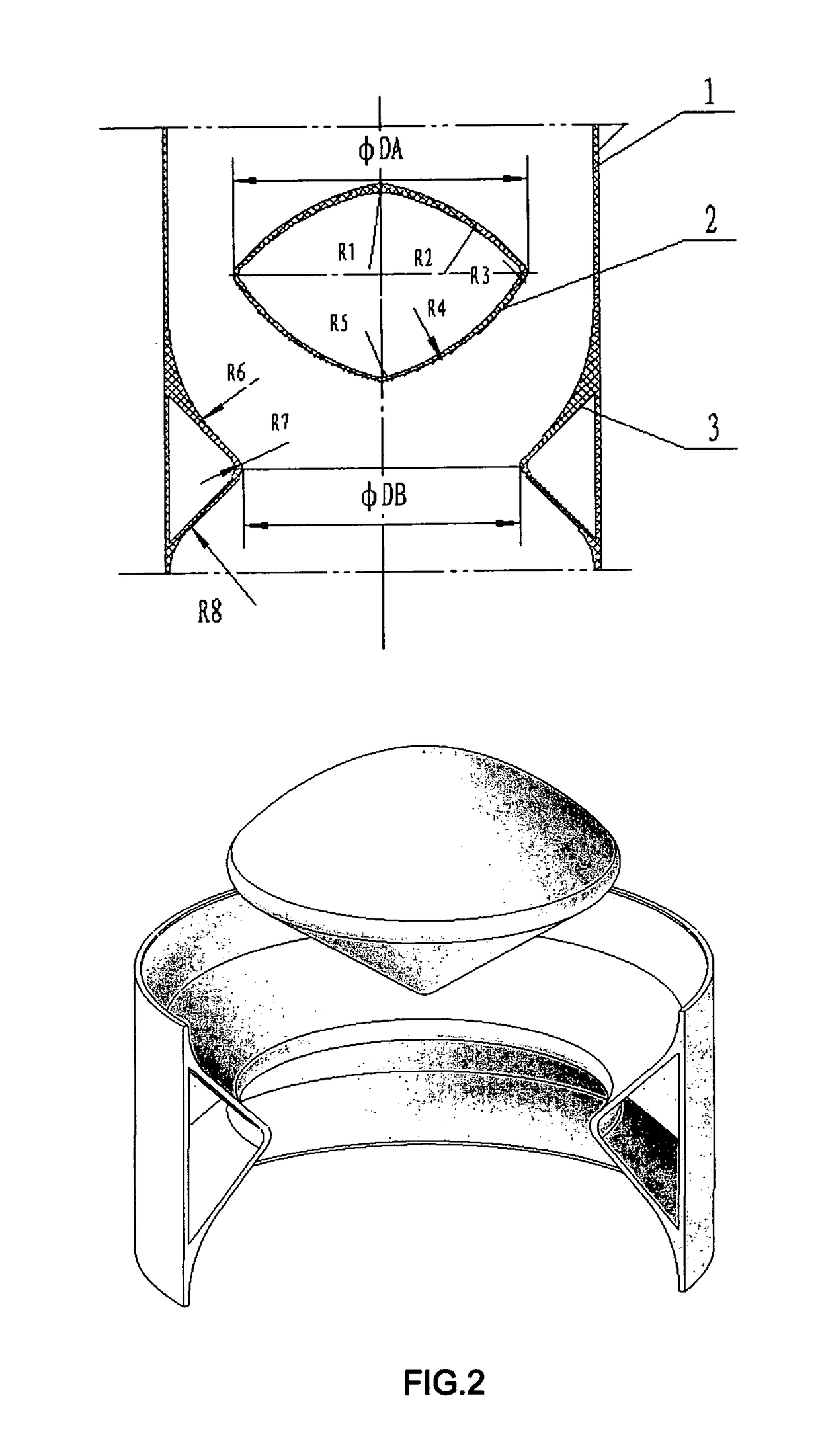

Multiphase reactor

ActiveUS8119083B2Simple structureIncrease reaction strengthFlow mixersDispersed particle separationFlue gasMaximum diameter

This invention relates to a multiphase reactor which is especially suitable for desulfurization of flue gas. A rotary build-in member comprising a axisymmetric body and an annular axisymmetric body is fixed on the shell of the reactor. The shell is cylindrical, and its surface is smooth or waved. The maximum diameter of the axisymmetric body is no less than the inner diameter of the annular axisymmetric body. The axisymmetric body is installed on the annular axisymmetric body coaxially. One rotary build-in member and its corresponding shell constitute an unit, and the reactor may have one or more such units. The multiphase reactor can effectively improve the flow pattern of the fluid and the contact of gas-liquid-solid three-phase of the reactants, speed up the mass transfer, and prevent deposition of the solid phase. The reactor is simple in structure and convenient for use. It can be used in the fields such as environmental protection, chemical engineering, metallurgy, and architectural industries.

Owner:SHI HANXIANG

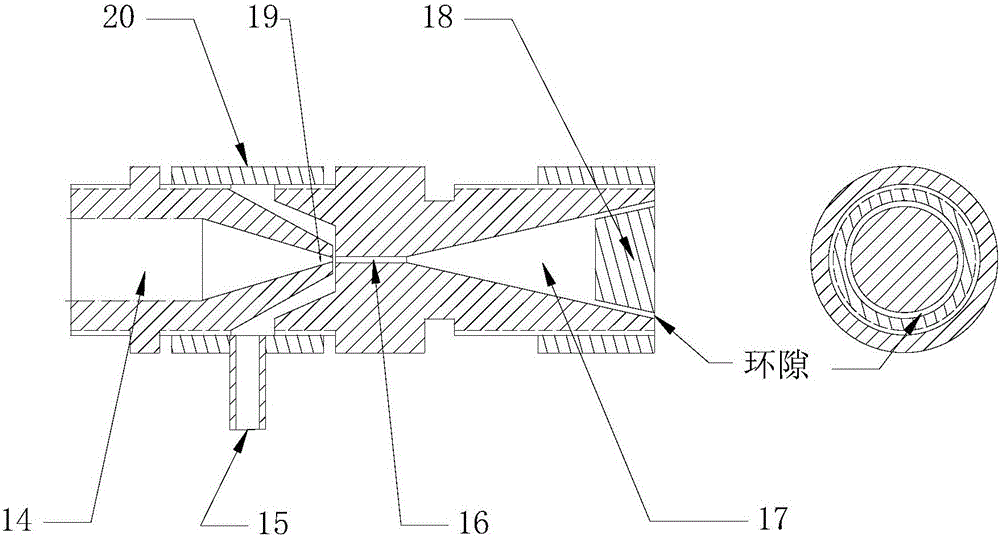

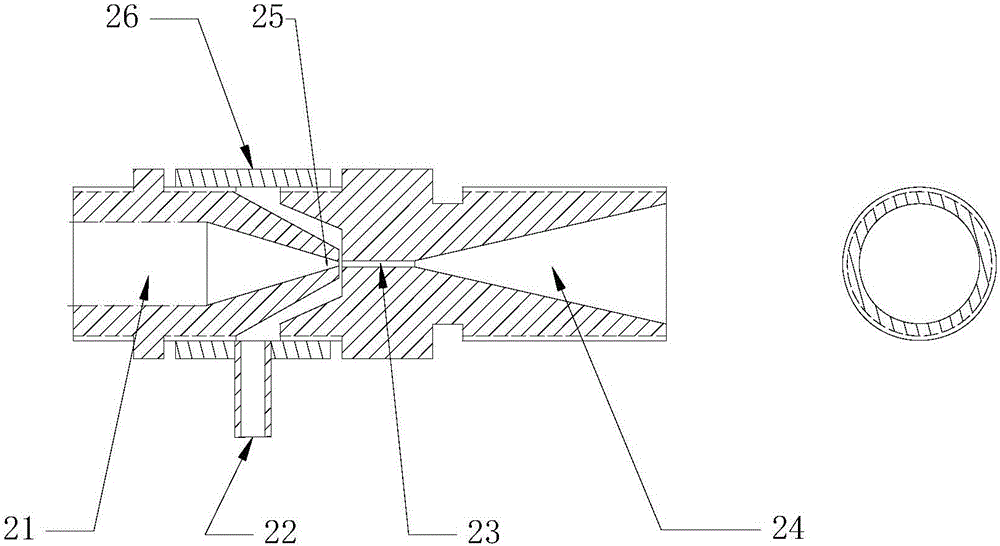

Impinging stream polyphase reactor

ActiveCN106179146ASimple structureAdded convective mixing sectionLiquid hydrocarbon mixtures productionChemical/physical/physico-chemical nozzle-type rreactorsAlkyl transferEmulsion

The invention is an impingement flow multiphase reactor, which relates to liquid-liquid mixed multiphase reaction. The reactor mixes the high-viscosity and low-viscosity fluids uniformly into a low-viscosity emulsion at a lower temperature and in a short period of time through the raw material injection premixer, and then sprays out a ring-shaped liquid film at high speed through multiple jets hitting the nozzles of the reactor The phase impact strengthens the reaction, so that the reaction can be carried out quickly and fully. The impinging flow multiphase reactor introduced by the invention has simple structure, no stirring parts, is not easy to leak, has a large contact area of reaction liquid, can realize rapid and efficient mixed reaction of immiscible fluids in large-scale production, and has high product selectivity. It can be applied to reaction devices with high fluid viscosity, liquid-liquid immiscibility and rapid mixing reaction between liquids in fine chemical industry, petrochemical industry, pharmaceutical industry, biochemical industry and other industrial processes, especially liquid acid catalyzed isobutane alkylation reaction .

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

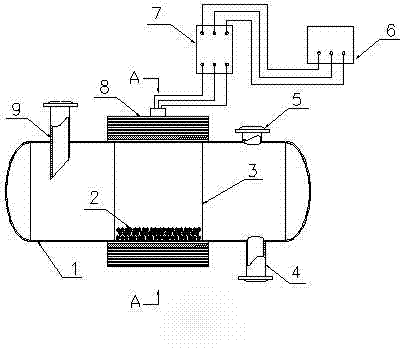

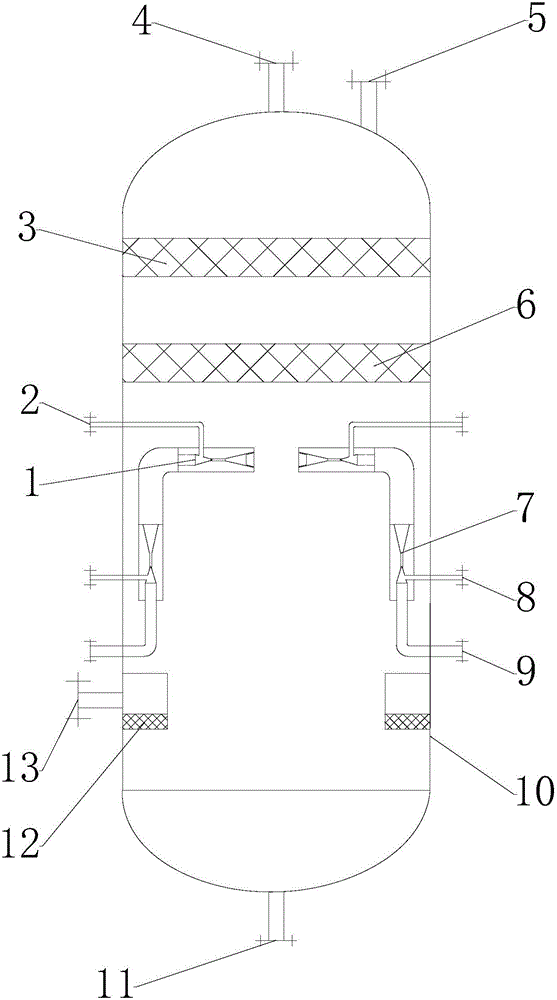

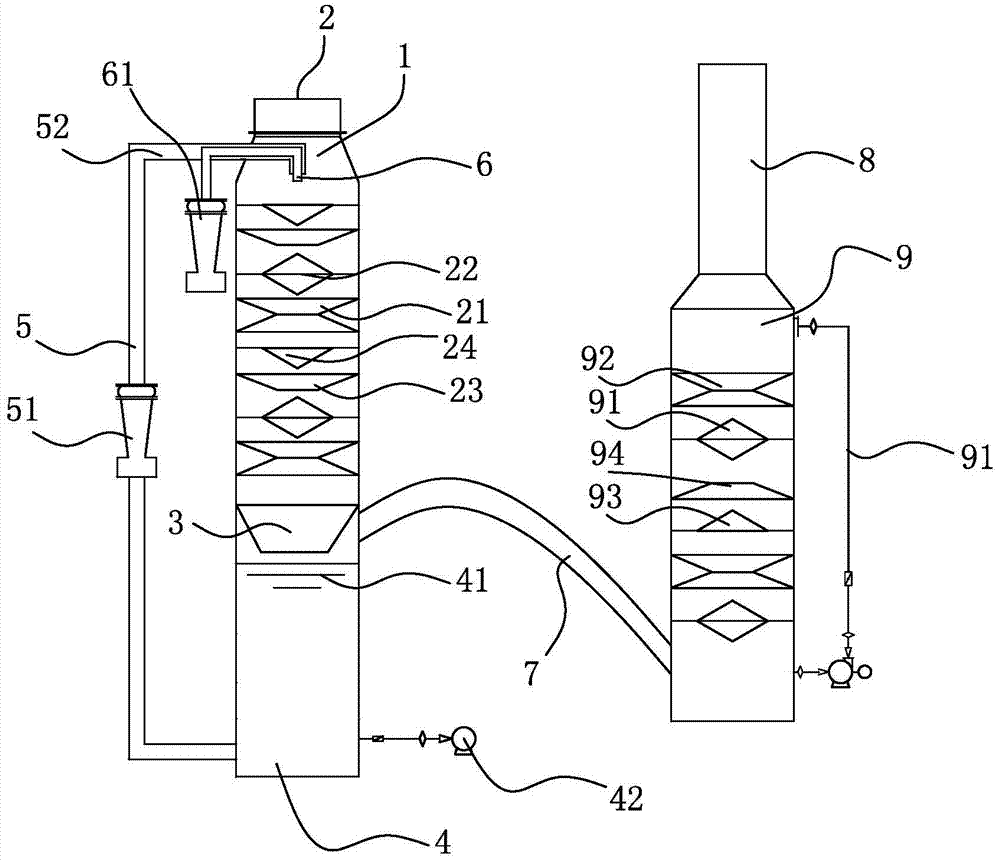

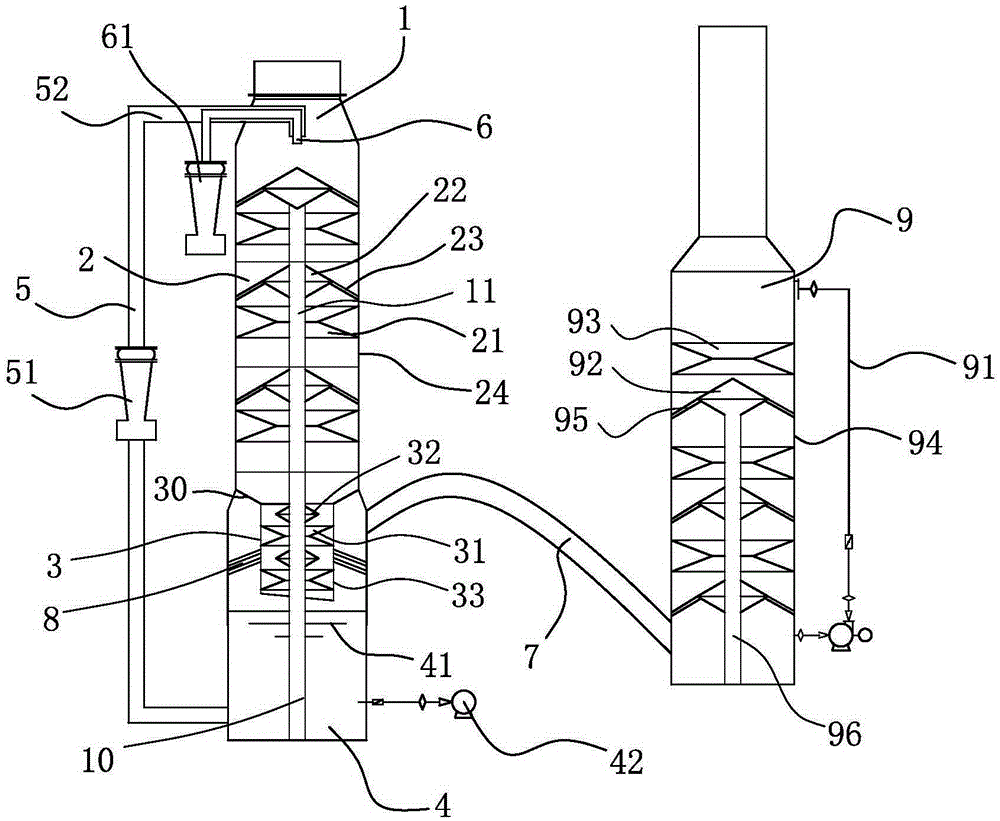

Device for flue gas desulfurization and denitrification

ActiveCN105435617AHigh desulfurization rateImprove denitrification rateGas treatmentUsing liquid separation agentFlue gasWater circulation

The invention relates to the field of air purification devices and discloses a device for flue gas desulfurization and denitrification. The device comprises a primary multi-phase reactor, a water circulation system, an isolation hood, a slurry pool, a slurry discharge device, a gas outlet pipe, a second multi-phase reactor and a water spraying device, wherein the water circulation system comprises a water pump and a water pipe; the water inlet end of the water pipe of the water pump is communicated with the circulation slurry pool; the water outlet end of the water pipe is positioned in the center of the primary multi-phase reactor and positioned above a first conical ring; the water pipe is internally provided with a gas inlet pipe and sleeves the outer side of the gas inlet pipe; the outer end of the gas inlet pipe is connected with the gas pump; the gas outlet end of the gas inlet pipe is positioned below the water outlet end of the water pipe; the gas outlet pipe is n-shaped; the water spraying device sprays water into the secondary multi-phase reactor, the temperature in the secondary multi-phase reactor does not exceed 35 DEG C. The device for flue gas desulfurization and denitrification has the advantages that the desulfurization and denitrification effect and dust removal effect on flue gas generated by burning are good, the desulfurization rate and the denitrification rate for flue gas are high, the dust purification rate for fine particles PM2.5 is high, and especially the CO2 emission amount can be effectively controlled.

Owner:史汉祥

Stirring/flow-guiding multi-phase reactor

InactiveCN101293195ARaise the stirring shaftEasy to operateRotary stirring mixersChemical/physical/physico-chemical stationary reactorsBiochemical engineeringBlend time

The present invention provides a stirring / guide multi-phase reactor, comprising a cylindrical sealed shell, a guide cylinder, a stirring device, air inlet device and an air outlet device; wherein, the cylindrical sealed shell is provided with a material inlet and outlet device; the lower part inside the shell is provided with the guide cylinder with an external diameter smaller than the internal diameter of the shell, a clearance is left between the guide cylinder and the shell bottom; the stirring device is arranged in the clearance between the guide cylinder and the shell bottom and comprises a stirring shaft and a blade fixed on the stirring shaft; the stirring shaft passes through the shell bottom and extends out of the shell; the air inlet device is arranged on the shell bottom and / or a lateral wall and the air outlet of the air inlet device is arranged below the blade; the air outlet device is arranged on the shell top. The stirring / guide multi-phase reactor provided by the present invention, which adopts the combination of the bottom-type stirring device and the guide cylinder, only needs comparatively low energy consumption to reach and even surpass the air rate the multi-layer or single-layer stirring reactor requires a plurality of times of energy consumption. Due to short mixing period and high effective energy utilization, the reactor is suitable for various industrial processes.

Owner:SINOPEC OILFIELD SERVICE CORPORATION +1

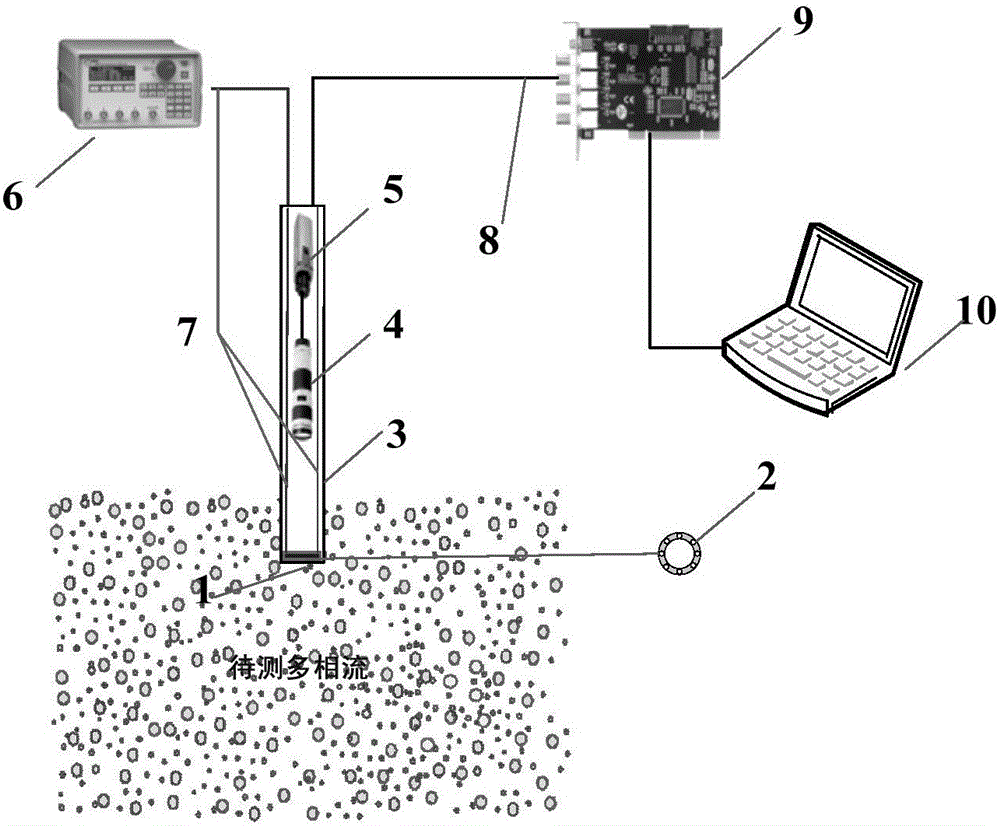

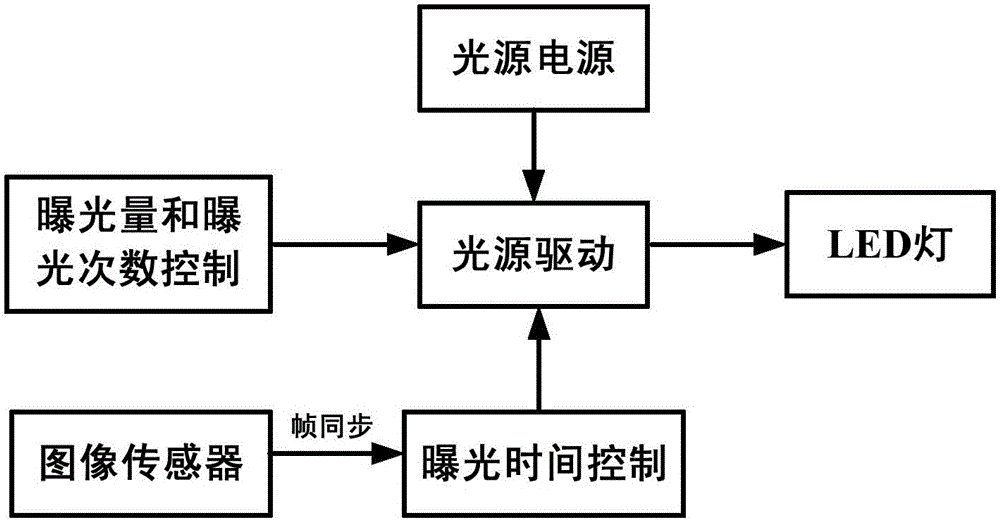

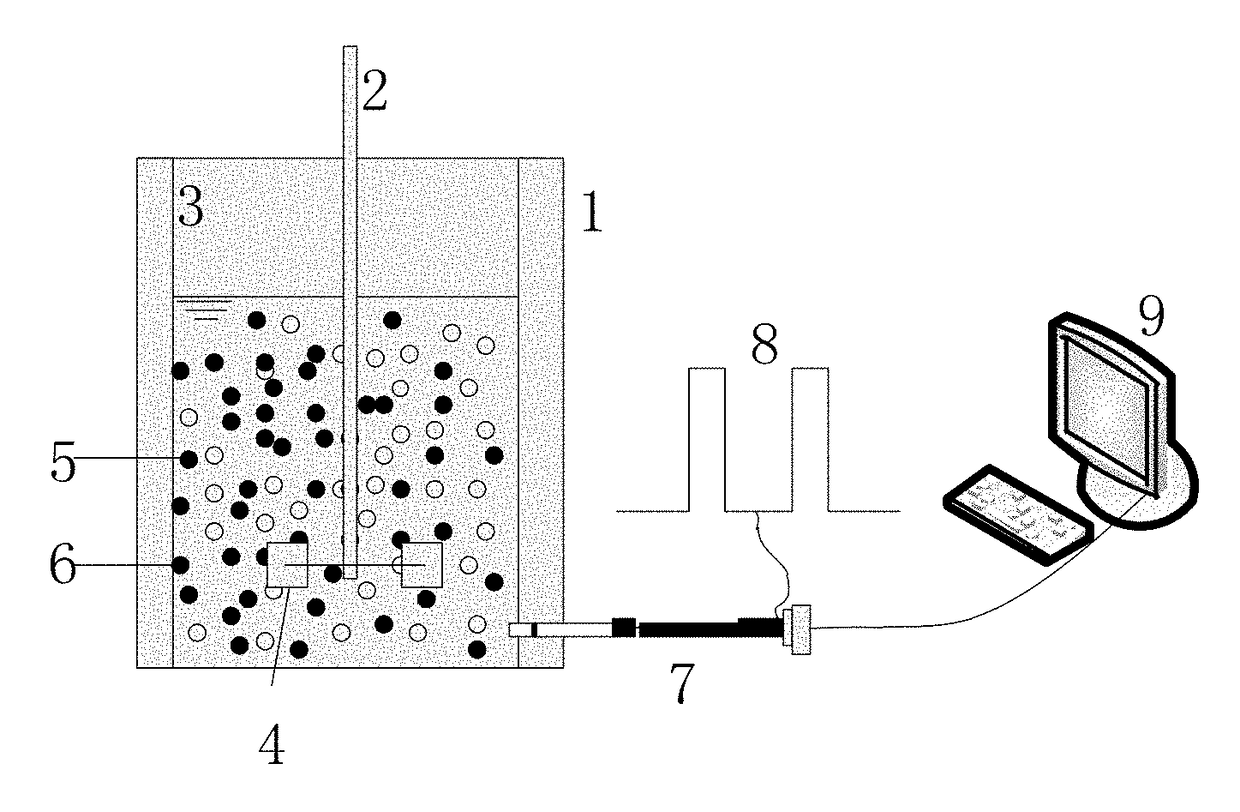

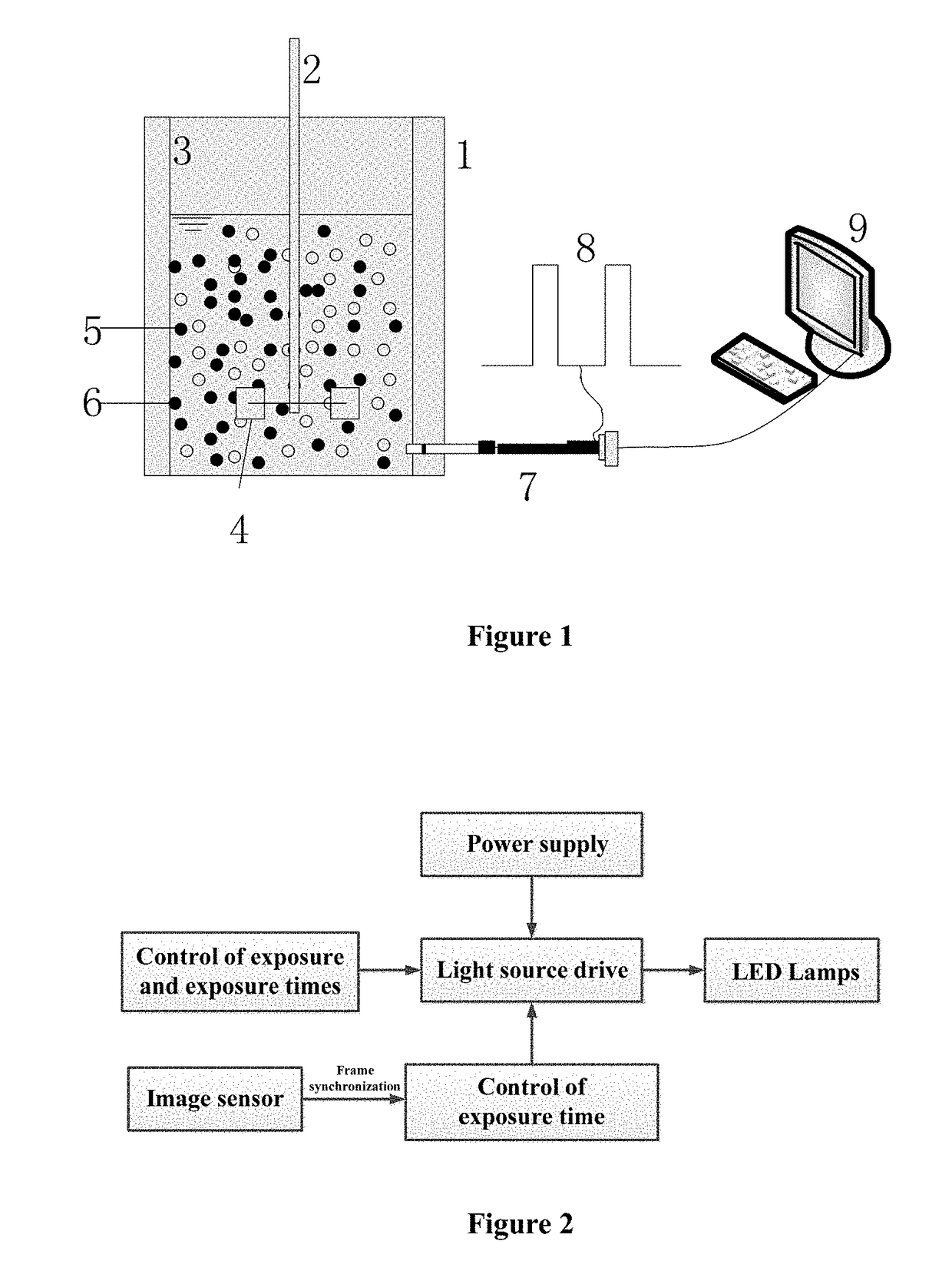

Immersion on-line multiphase measuring instrument and measuring method

ActiveCN105928841AReduce volumeVolume/mass flow measurementParticle size analysisMeasuring instrumentExposure period

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

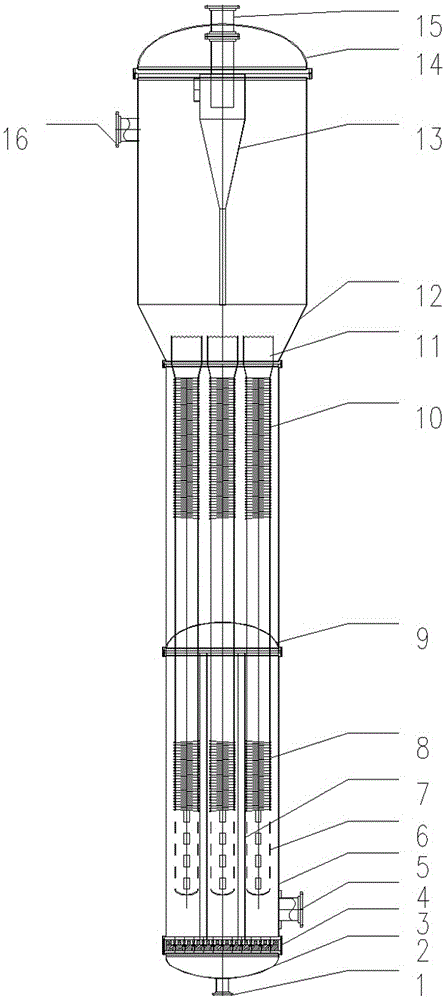

High-efficient multi-phase reactor

By using a slurry-state bed as a design idea, a slurry-state bed reactor is characterized in that a reactor shell is formed by a flanged cylinder body of standard equipment. The slurry-state bed reactor comprises a diameter-varied shell, an upper closure head, a lower closure head, a bottom air inlet pipe hole, a top gas outlet, a slurry inlet and a slurry outlet; the following parts, including an inner draft tube, a coiled pipe heat exchanger, a gas clamp plate distributor, a gas-rising pipe, a re-distributor and a cyclone separator, are arranged in the shell. The gas is uniformly ejected through the clamp plate distributor, and reaction between the gas and catalyst slurry inside the reactor shell is carried out to obtain a reactant; the reactant is subjected to gas-liquid separation at the upper end of the reactor and then flows out of the gas outlet; slurry which is borne on a free fluid surface flows from the inner part of the draft tube to the downside, flows out of the side surface of the bottom of the draft tube and then carries out reaction with the gas to flow upwards for circulation. According to the slurry-state bed reactor disclosed by the invention, by analyzing a flow state, the matching design of the slurry-state bed is carried out, so that a high-efficient internal recycling effect is achieved.

Owner:WUYI UNIV

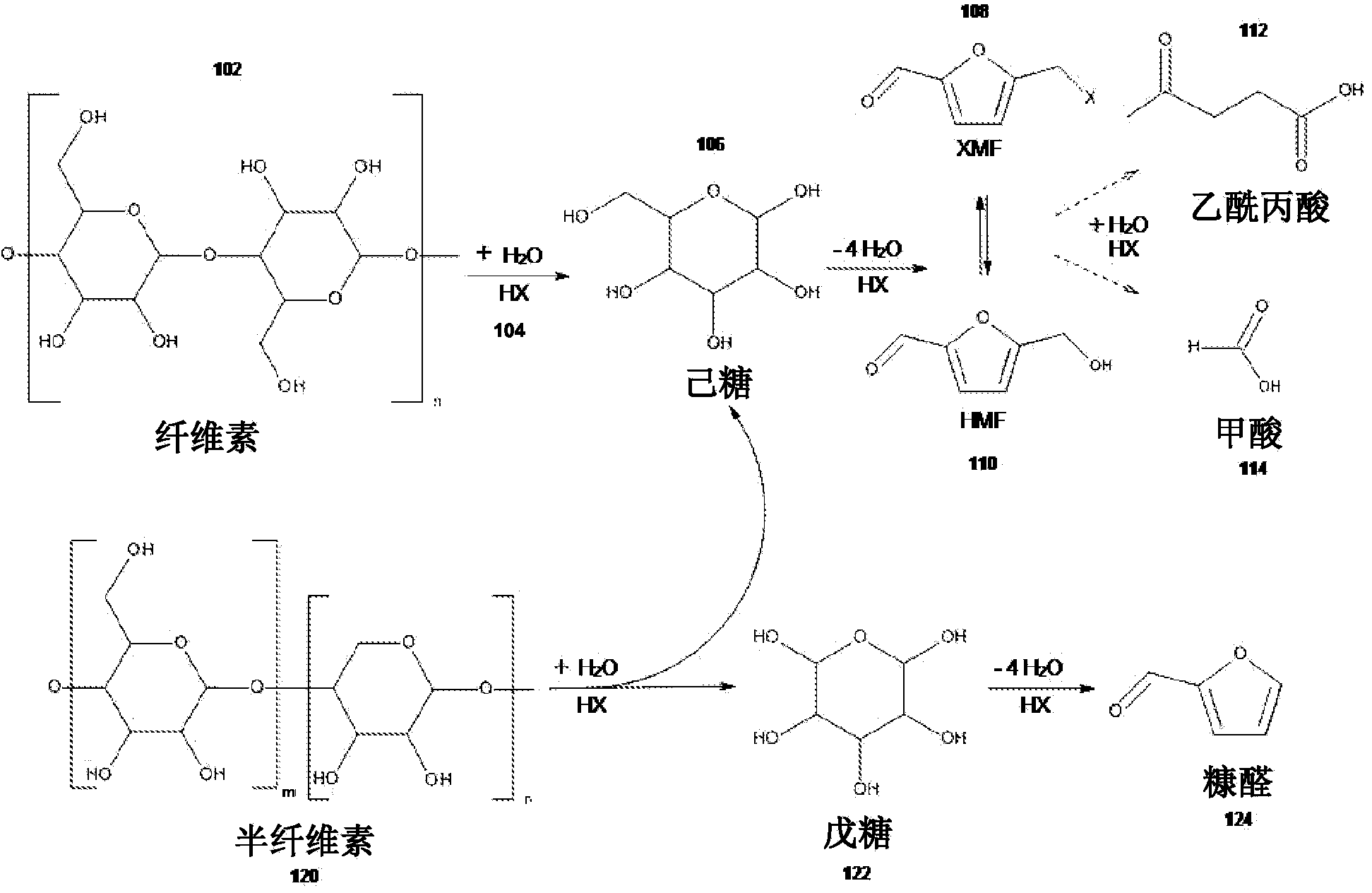

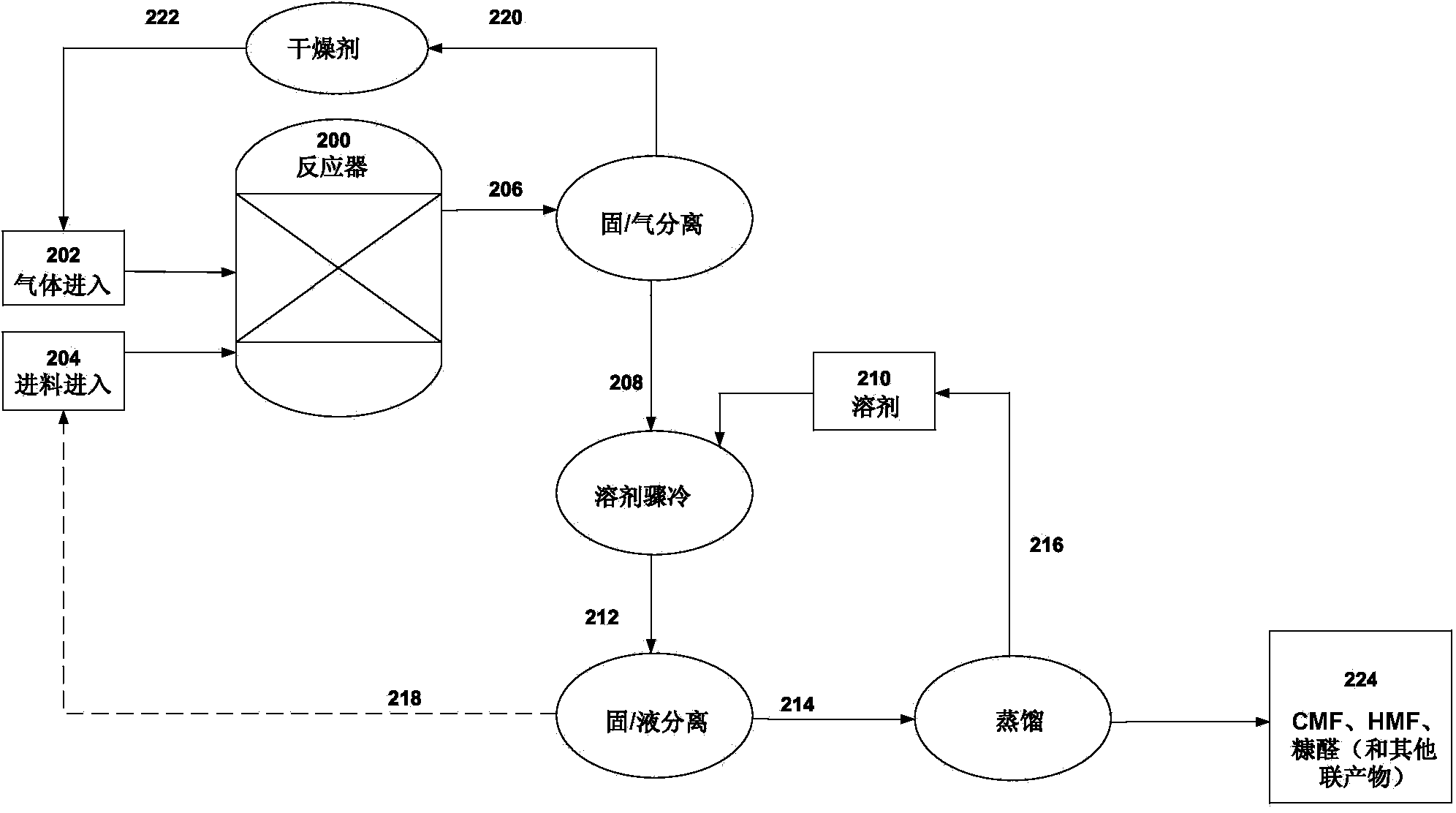

Utilizing a multiphase reactor for the conversion of biomass to produce substituted furans

ActiveCN103930411ACost effectiveEfficient industrial methodsOrganic chemistryFermentationFuranFluidized bed

The present disclosure provides methods to produce substituted furans (e.g., halomethylfurfural, hydroxymethylfurfural, and furfural), by acid-catalyzed conversion of biomass using a gaseous acid in a multiphase reactor, such as a fluidized bed reactor.

Owner:起源材料运营公司

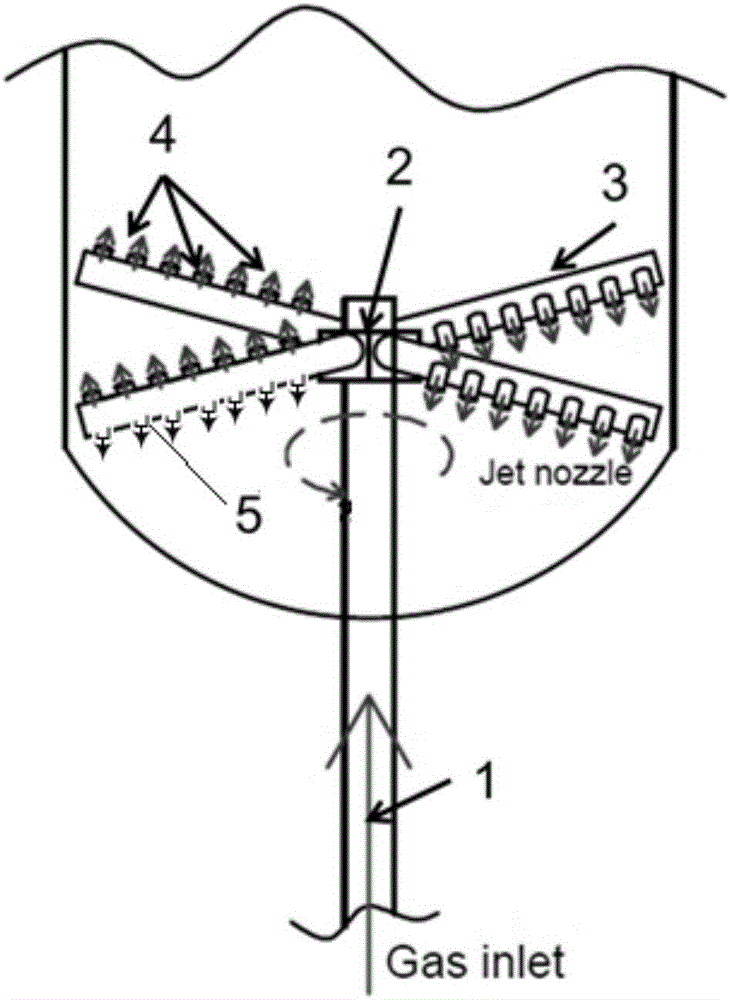

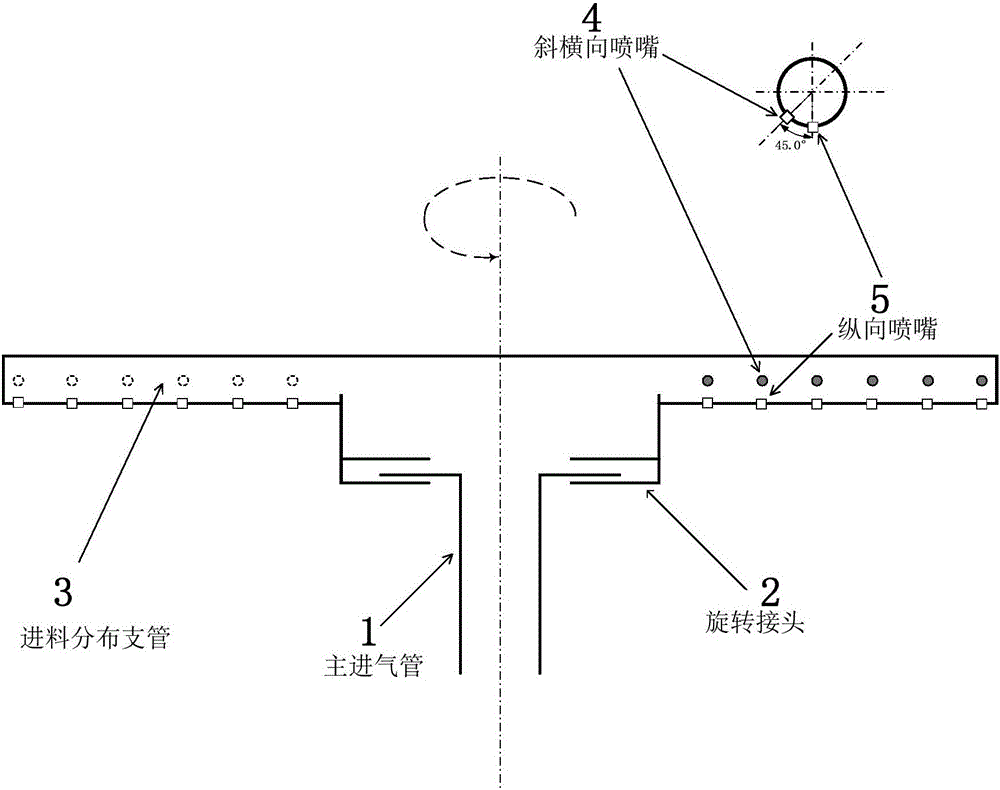

Rotary gas feed distributor suitable for multi-phase reactor

ActiveCN105817185AImprove uniformityReduce wearLiquid hydrocarbon mixture productionChemical/physical processesEngineeringDistributor

The invention discloses a rotary gas feed distributor suitable for a multi-phase reactor. The distributor comprises a main gas inlet pipe, a rotary connector, feed distribution branch pipes, inclined transverse nozzles and longitudinal nozzles. The main gas inlet pipe is located at the center of the distributor, is of a cylindrical structure and perpendicularly penetrates through the whole distributor. The rotary connector is located in the middle of the main gas inlet pipe and can freely rotate. The rotary connector can keep the lower portion of the main gas inlet pipe still, but the upper portion of the main gas inlet pipe can freely rotate. The feed distribution branch pipes are connected and communicated with the upper portion of the main gas inlet pipe. The inclined transverse nozzles and the longitudinal nozzles are located on the feed distribution branch pipes. When the longitudinal nozzles spray out gas, sprayed gas generates lateral counter-acting force to push the feed distribution branch pipes and the upper portion of the main gas inlet pipe to rotate. By means of the distributor, the uniformity of gas distribution can be improved, abrasion to catalysts is reduced, and reaction efficiency is improved.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Prevention of and recovering from a catalyst bed slumping in a gas-agitated multiphase reactor

ActiveUS7230034B2Prevents a catalyst bed from slumpingAvoid problemsOrganic compounds purification/separation/stabilisationOrganic compound preparationSyngasProduct gas

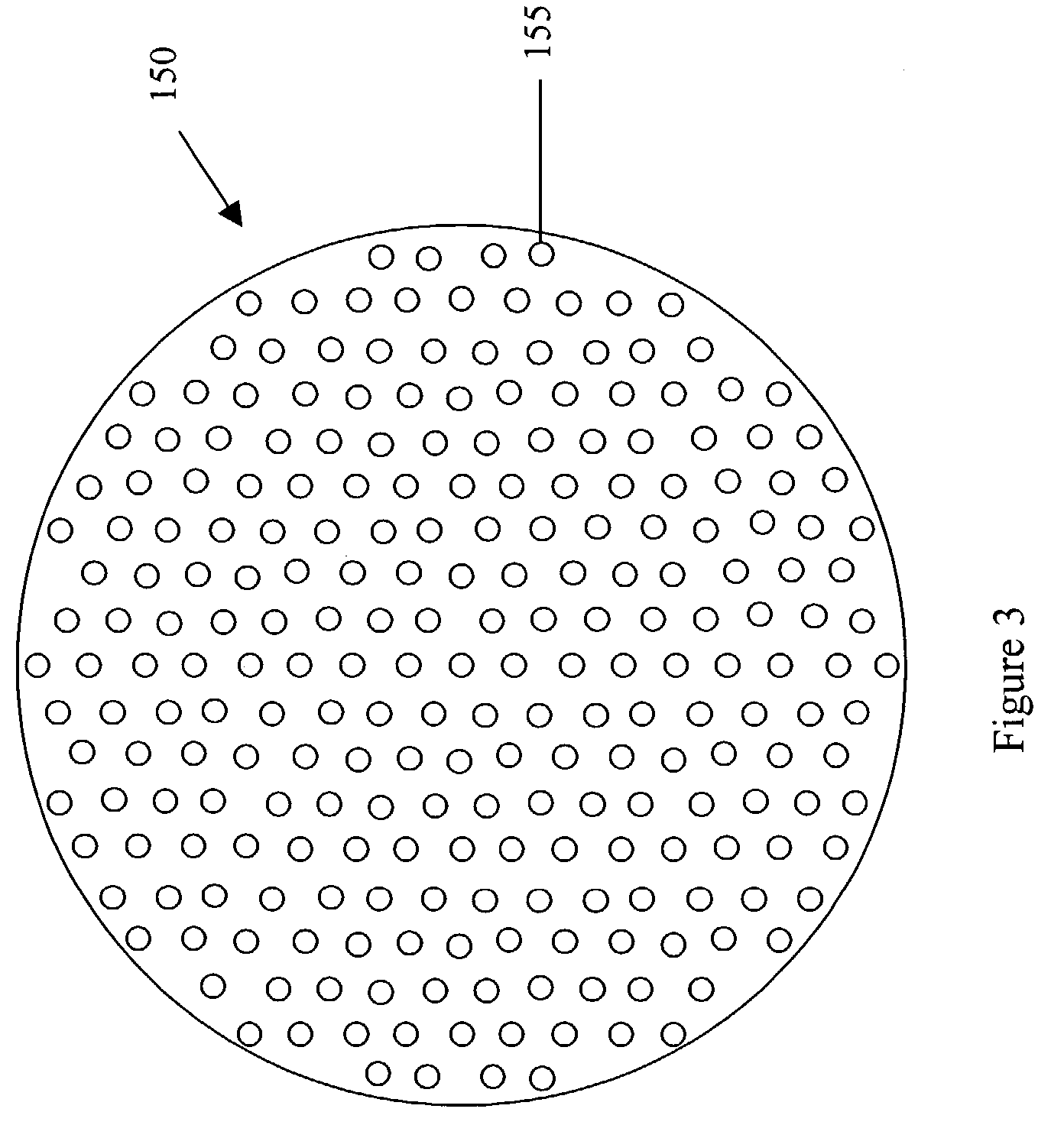

The invention relates to methods for prevention of and recovery from a catalyst bed slumping in a gas-agitated multiphase hydrocarbon synthesis reactor, while the reactor is either under non-reactive conditions or under reaction promoting conditions when syngas is converted to products. The reactor contains a catalyst bed comprising catalyst particles and a gas injection zone suitable for injecting a reactor gas feed. A method for preventing bed slumping comprises supplying a supplemental gas to the gas-agitated multiphase reactor to prevent the catalyst bed from slumping due to insufficient reactor gas feed flow. The method may include recycling some or all of the supplemental gas to the reactor. The method may further comprise separating the gas injection zone from the catalyst bed with a porous plate so as to prevent migration of catalyst particles into the gas injection zone and to minimize plugging of gas distributor(s) present in said zone.

Owner:PHILLIPS 66 CO

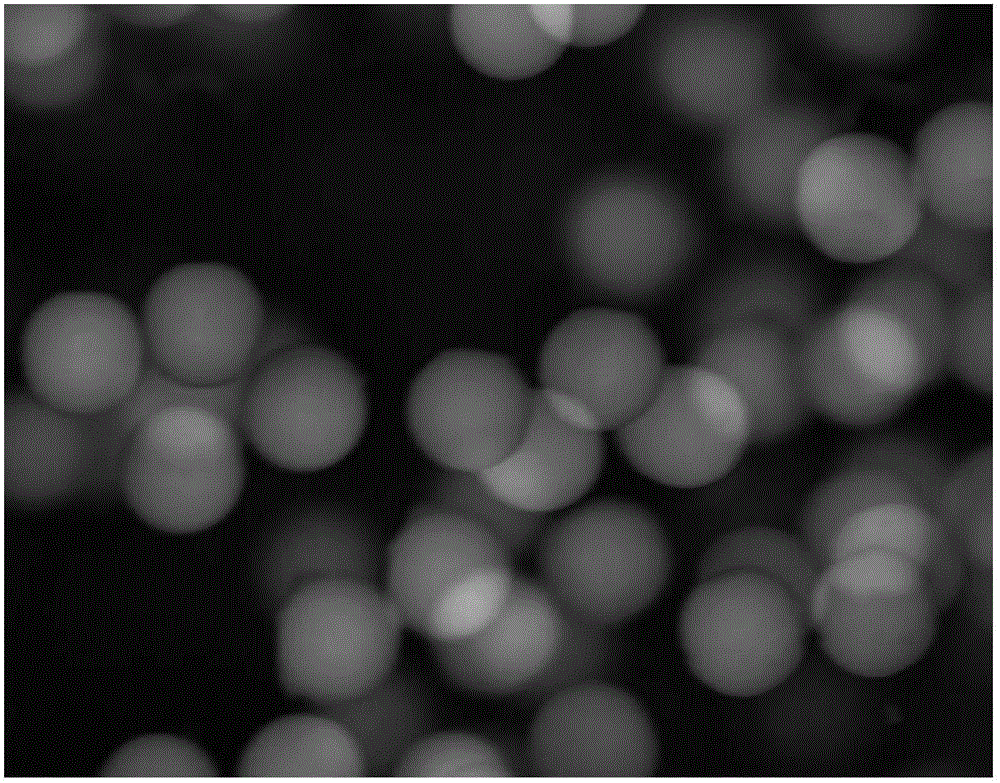

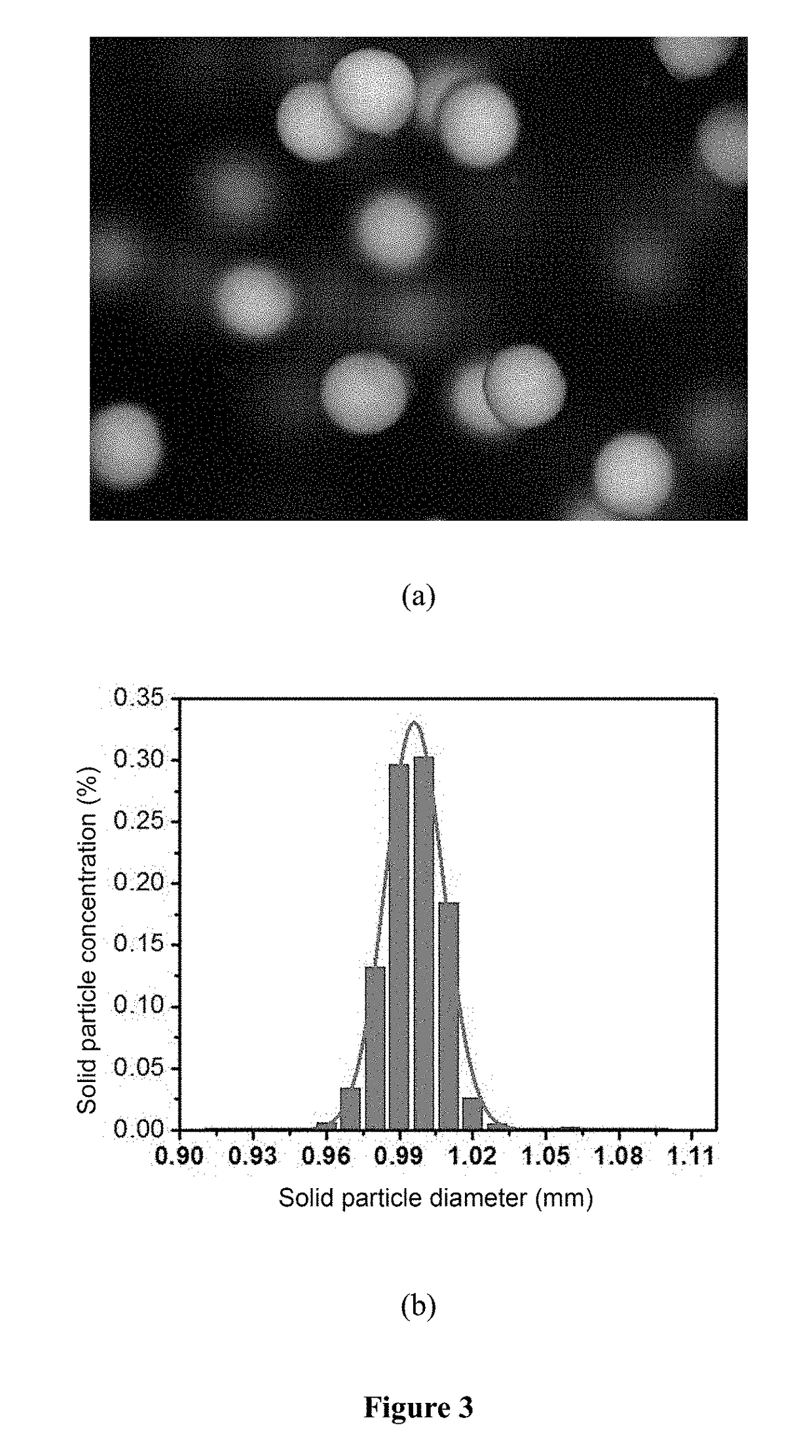

Online measuring method of concentration and diameter of particles in multiphase system

ActiveUS20170299382A1High measurement accuracyTelevision system detailsImage enhancementMeasuring instrumentSolid particle

An online multiphase measuring method of concentration and diameter distribution of dispersed phase particles in a multiphase reactor is provided in the present invention. The method is based on an online multiphase measuring instrument. The method described herein includes the following steps: (1) the online multiphase measuring instrument is placed in a multiphase system, and an image of the particles in the multiphase system is obtained; (2) valid particles are determined as: the particle that its Grad(Φ) is greater than or equal to Grad(Φl / 2) is labeled as a valid one; (3) the particle diameter is calculated by di=10×ni / N10; according to the equationα=VcV=∑in16πdi3S×l,the concentration of the valid particles is calculated. The concentration and diameter of bubbles, droplets or solid particles can be obtained in real time and online measurement. The accuracy of this method is high.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Multiphase reactor used in ethylene carbonate synthesis

ActiveCN106475017AGuaranteed utilizationGuaranteed separation effectOrganic chemistryChemical/physical processesLiquid productDistributor

The invention relates to a gas-liquid-solid three-phase reactor used for synthesizing ethylene carbonate with ethylene oxide and carbon dioxide. The reactor comprises, from bottom to top, a liquid discharge port, liquid baffles; a gas inlet port, a gas inlet distributor, a catalyst lower supporting sieve plate, a lower ceramic ball layer, a catalyst layer, an upper ceramic ball layer, a catalyst upper supporting sieve plate, a liquid inlet port, a liquid feed distributor, and a gas discharge port. Gas and liquid feeds respectively radially and uniformly enter the catalyst bed layer through the gas distributor and the liquid distributor. The catalyst bed layer is fixed in the reactor with the upper and lower ceramic balls and the upper and lower supporting sieve plates. The plurality sets of baffles are arranged in the lower part of the reactor. Overflow weirs are arranged on the two sides. With prior arts, gas and liquid phase feeds are not uniformly distributed, which does not facilitate sufficient reaction; and liquid products contain gas entrainments. With the reactor provided by the invention, the above problems can be solved. The multiphase reactor can be used in industrial productions for producing ethylene carbonate with ethylene oxide and carbon dioxide.

Owner:CHINA PETROLEUM & CHEM CORP +1

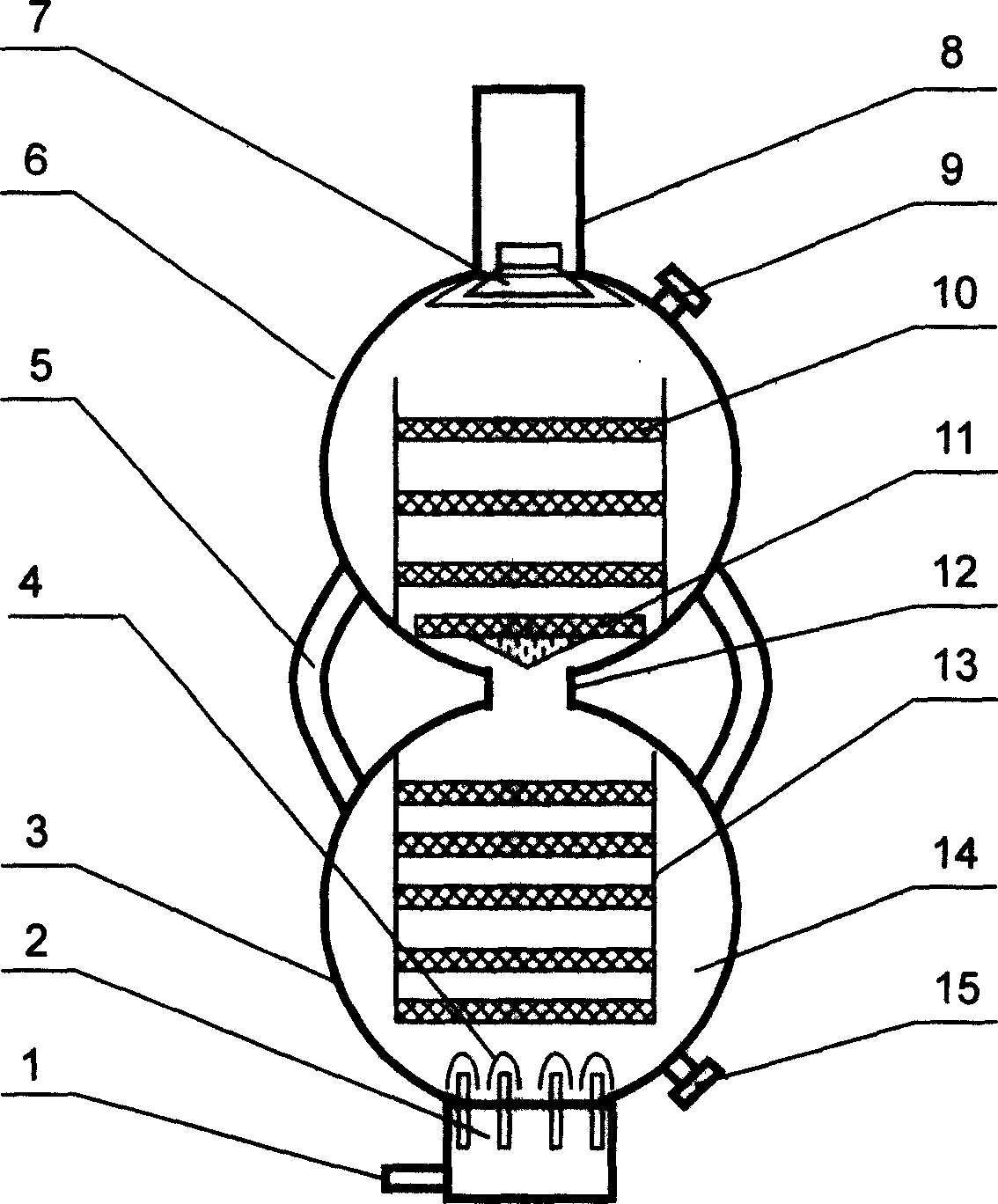

Spherical high pressure multiple phase reactor

InactiveCN1586703AAvoid cloggingImprove pressure resistancePressure vessels for chemical processGas phaseSlurry

The spherical high-pressure multiple phase reactor is one chemical apparatus for gas-liquid or gas-liquid-solid slurry reaction. The reactor consists of two or more spherical reactors connected serially. It has gas distributor fixed in the bottom of the lower spherical container, separating baffles supported inside the spherical container, and laminated inner members fixed inside the separating baffles for realizing the homogeneous phase distribution of the gas phase in different spherical parts of different cross section areas to promote the homogeneous distribution and raised contact efficiency of different phases. The inner members have functions of guiding flow, re-distributing and inhibiting bubble growth. Compared with cylindrical reactor, the present invention has one half reduced wall thickness, easy construction and reduced investment, and is suitable for large high pressure reaction process.

Owner:TSINGHUA UNIV

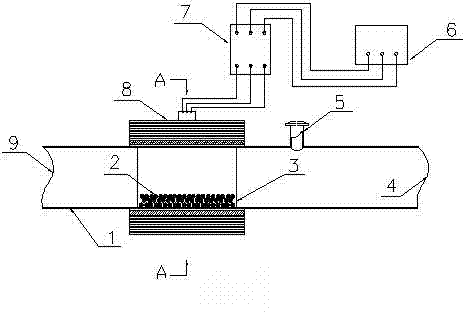

Apparatus for flue gas desulfurization and denitrification

ActiveCN105344218APrevent direct passageReduce the temperatureHuman health protectionUsing liquid separation agentReactor systemFlue gas

The invention relates to the field of air purifying apparatuses, and relates to an apparatus for flue gas desulfurization and denitrification. The apparatus for flue gas desulfurization and denitrification comprises a first polyphase reactor system, a water circulation system, a slurry pool, a slurry discharge device, a gas outlet pipeline, a second polyphase reactor and a water spraying device; and a necking ring is arranged between the first polyphase reactor system and the slurry pool, the bottom of the necking ring is provided with an auxiliary polyphase reactor, a demister is arranged between the auxiliary polyphase reactor and the slurry pool, and the gas inlet end of the gas outlet pipeline is positioned between the demister and the necking ring. The apparatus for flue gas desulfurization and denitrification has the advantages of novel structure, good desulfurization, denitrification and dust removal effects on flue gas generated in the combustion process, and high desulfurization rate, denitrification rate and fine particle PM2.5 dust purifying rate of the flue gas.

Owner:史汉祥

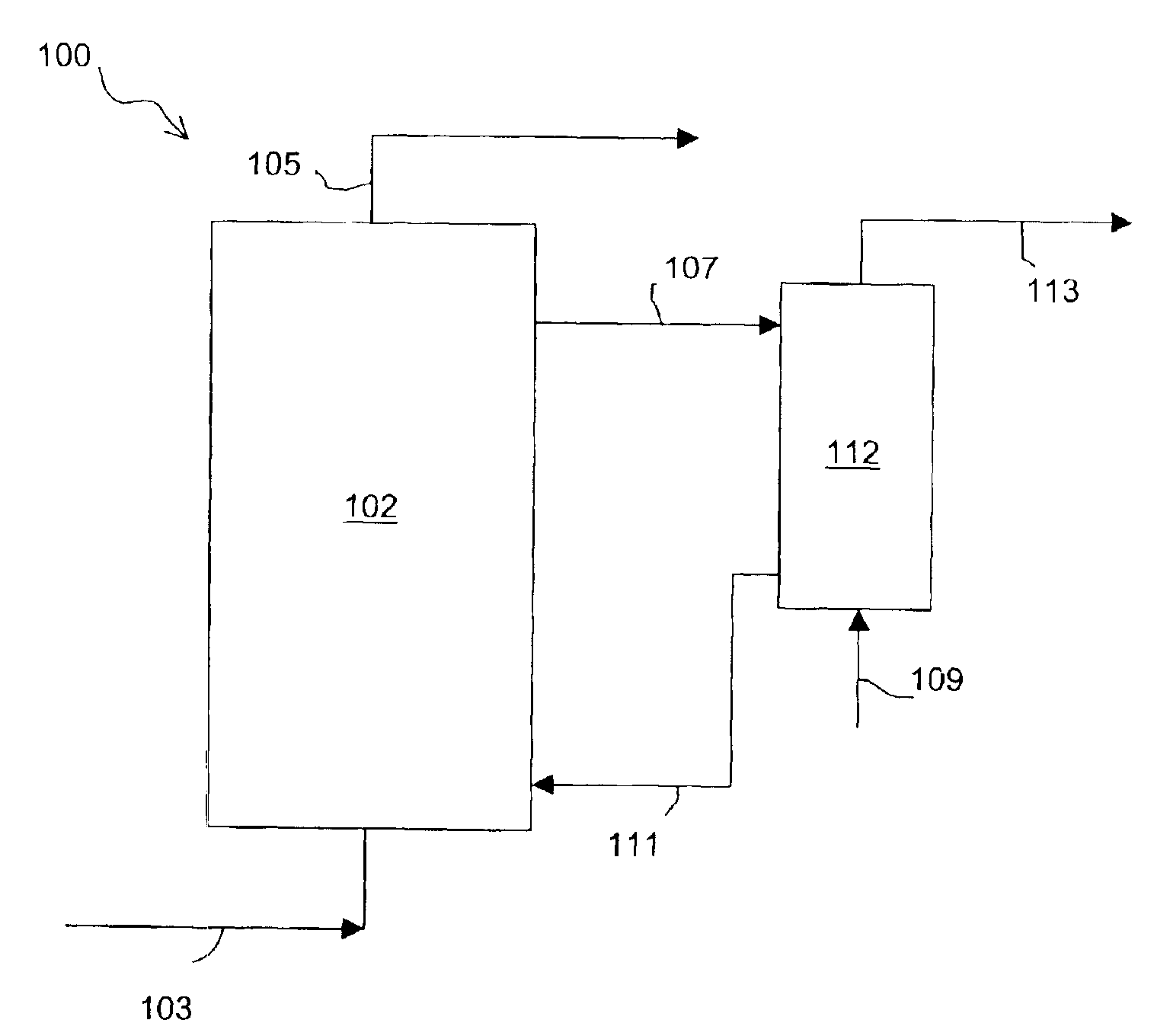

Method for reducing water concentration in a multi-phase column reactor

InactiveUS6956063B2Speed up the conversion processExcessive oxidationSolvent extractionDistillation regulation/controlWater concentrationSlurry

The present invention relates to a method and apparatus for water removal in multi-phase reactors operating at Fischer-Tropsch conditions. In a preferred embodiment of the present invention, a method of reducing the concentration of water in a multi-phase reactor for Fisher-Tropsch synthesis containing an expanded slurry bed and a water-rich slurry region includes removing a portion of water from the water-rich slurry from a predetermined region in the reactor, removing the water from the water-rich slurry to form a water-reduced slurry, and returning the water-reduced slurry back to the reactor. Preferably the water-rich slurry region is located between ½ H to H and ½ R to R, where H is the height of the expanded slurry bed and R is the radius of the expanded slurry bed.

Owner:PHILLIPS 66 CO

Method for preparing low-carbon olefins through co-catalytic cracking of Fischer-Tropsch synthesis light oil and methyl alcohol

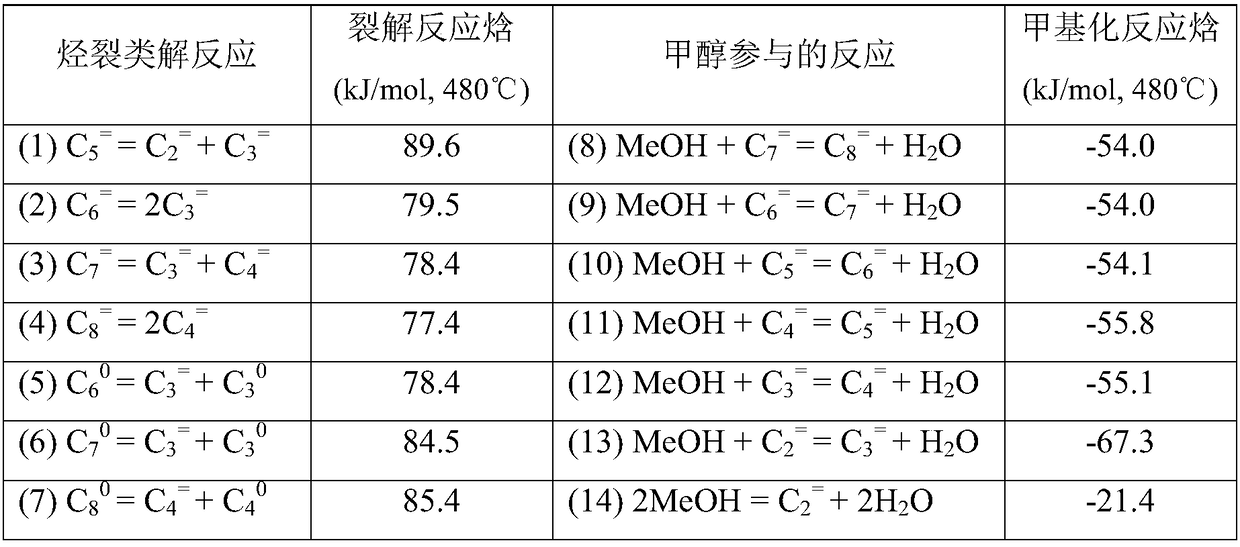

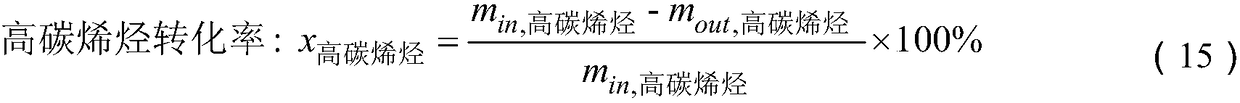

The invention discloses a method for preparing low-carbon olefins through co-catalytic cracking of Fischer-Tropsch synthesis light oil and methyl alcohol. The method comprises the steps of mixing andfeeding the Fischer-Tropsch synthesis light oil and a methyl alcohol water solution; feeding into a heterogeneous reactor containing a molecular-sieve-based catalysts bed for carrying out catalytic cracking reaction; after the cracking reaction, carrying out gas-phase recovery to obtain C2-C5 low-carbon olefin products. By adopting the method, Fischer-Tropsch synthesis light oil catalytic crackingreaction absorbing heat and methanol conversion reaction releasing heat can be thermally coupled, a heat-supplying problem of a system is simplified; on the other hand, the raw material conversion rate and the product selectivity are improved, and the low-carbon olefin products can be efficiently obtained.

Owner:ZHEJIANG UNIV

Multi-phase reactor capable of obtaining constant inductance for each phase

ActiveUS10373753B2Transformers/inductances magnetic coresInductance with magnetic coreNuclear engineeringConductor Coil

A multi-phase reactor is configured to include a first core arranged at a center of the reactor; a plurality of second cores provided outside the first core and arranged so that each of magnetic paths with respect to the first core is in a loop shape; and one or a plurality of windings wound around each of the second cores. With this configuration, the multi-phase reactor capable of setting a constant value of inductance for each phase is provided.

Owner:FANUC LTD

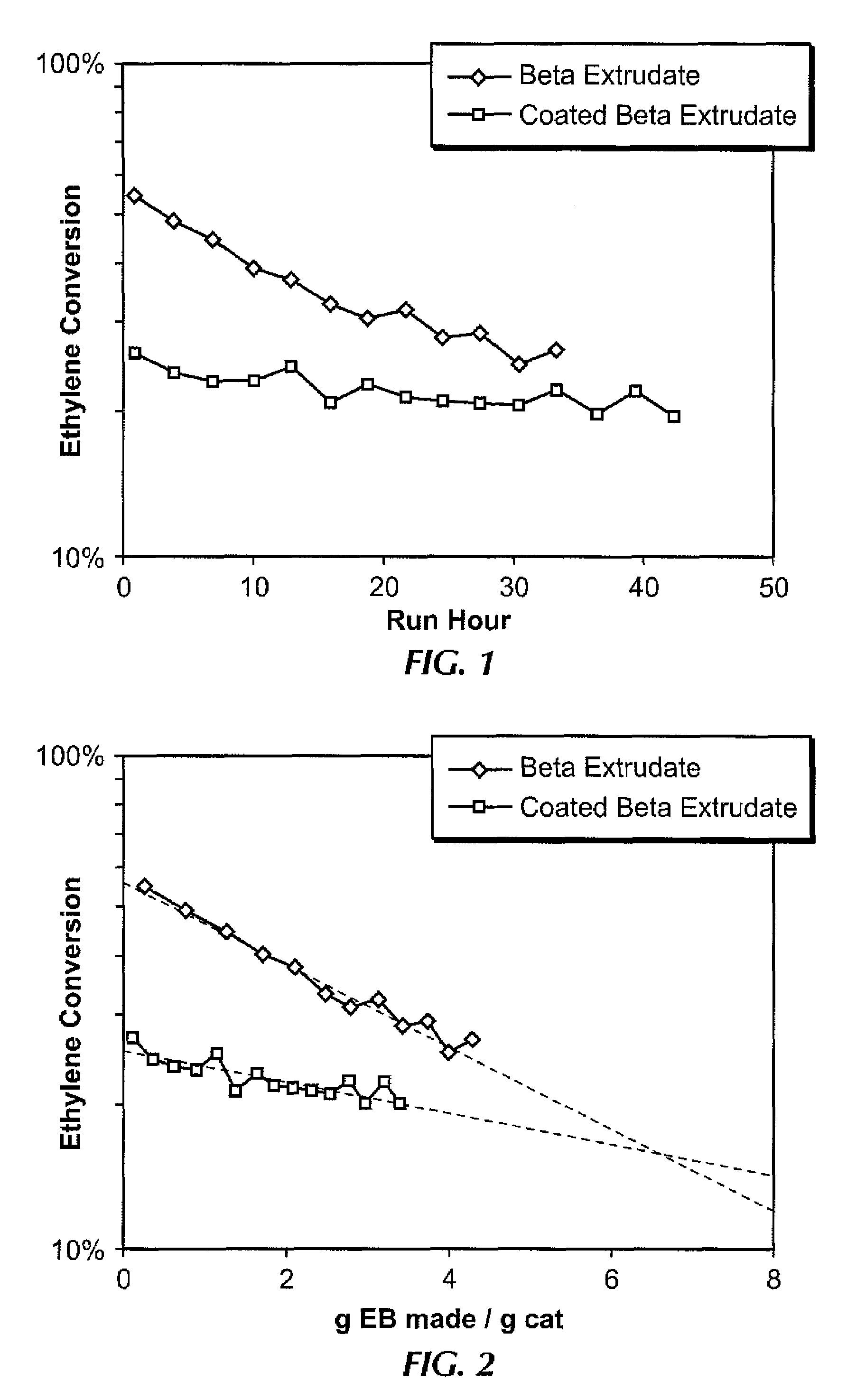

Coated catalyst for aromatic alkylation

ActiveUS7476637B1Extended service lifeCatalyst protectionMolecular sieve catalystsAlkyl transferActive component

A catalyst useful for multi-phase reactors that includes an active component surrounded by a coating on a surface of the active component, wherein the coating provides a liquid film around the active component to increase the useful life of the active component as compared to an uncoated active component.

Owner:CHEM RES & LICENSING CO

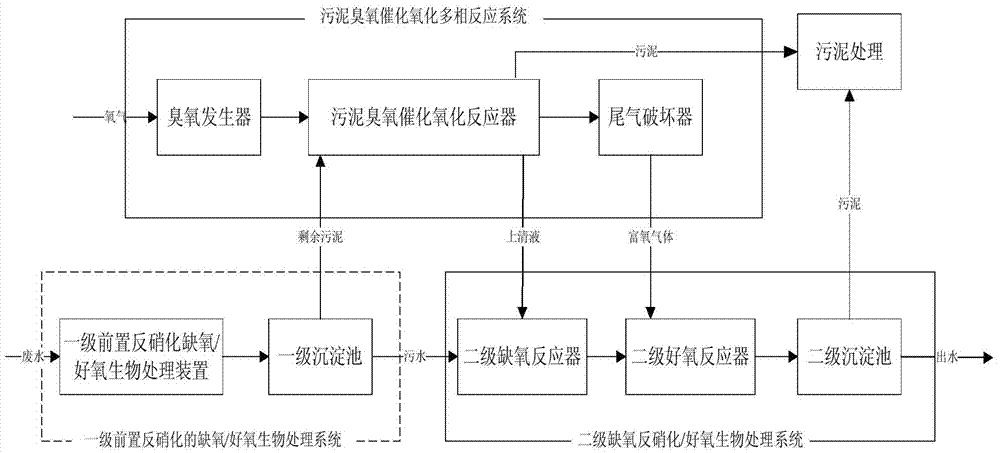

Coal chemical wastewater biological treatment system based on sludge catalytic ozonation and treatment method thereof

ActiveCN106915861AImprove digestionReduce the content of organic matterWater treatment parameter controlSludge treatment by oxidationSludgeOxygen

The invention provides a coal chemical wastewater biological treatment system based on sludge catalytic ozonation and a treatment method thereof. The system comprises an anoxic / aerobic biological treatment system for first-grade predenitrification, a sludge catalytic ozonation multiphase reaction system and a second-grade anoxic denitrification / aerobic biological treatment system. The method comprises the following steps: subjecting to-be-treated coal chemical wastewater to anoxic / aerobic biological treatment of first-grade predenitrification, subjecting one part of treated sludge to refuxing and the other part of the treated sludge to ozone catalytic digestion, mixing a supernatant generated by ozone catalytic digestion with the sewage obtained by anoxic / aerobic biological treatment of first-grade predenitrification, and subjecting the obtained mixture to second-grade anoxic denitrification / aerobic biological treatment so as to obtain effluent water, wherein tail gas generated by catalytic digestion is used for aeration treatment for second-grade anoxic denitrification / aerobic biological treatment. According to the invention, a sludge catalytic ozonation multiphase reactor is adopted, so highly-efficient and low-cost oxidation digestion of the sludge can be realized, and functions of a novel method are guaranteed to be realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

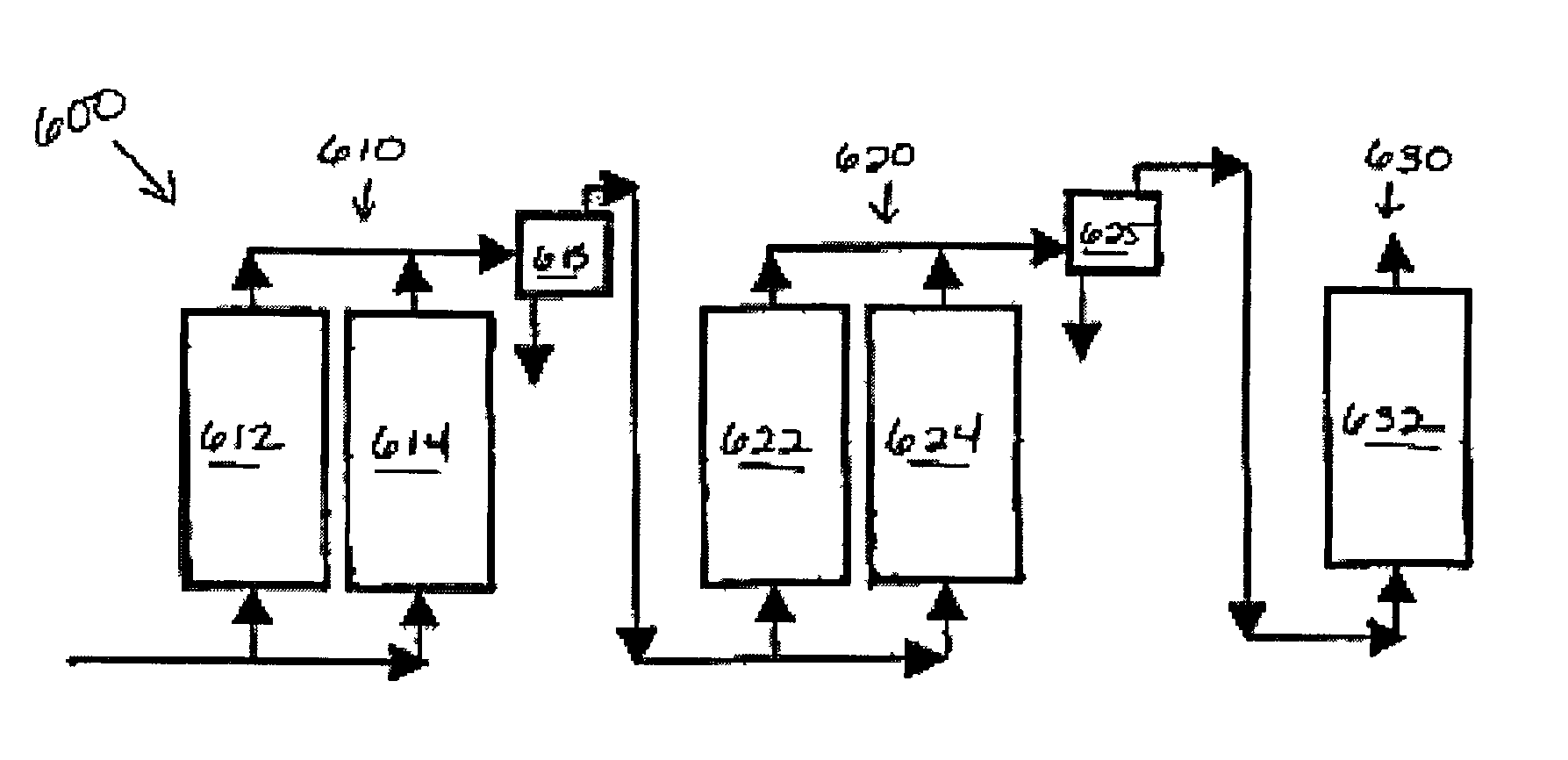

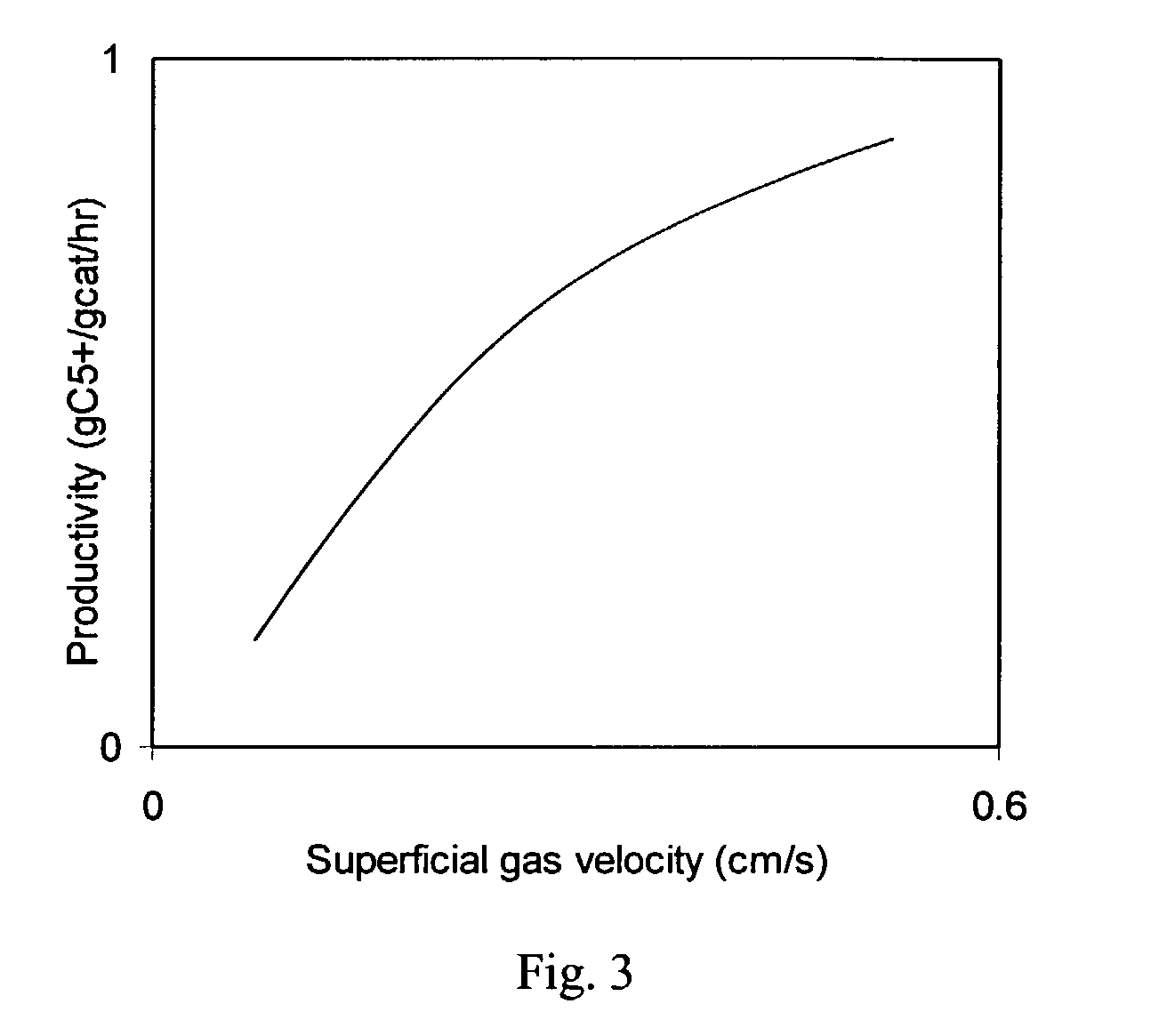

Minimizing the volume or maximizing the production rate of slurry bubble reactors by using large gas flow rates and moderate single pass conversion

InactiveUS7115669B2Minimized volumeMaximize productivityOrganic compound preparationOxygen compounds preparation by reductionProduction rateSyngas

Owner:CONOCOPHILLIPS CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com