Spherical high pressure multiple phase reactor

A multi-phase reactor and reactor technology, which is applied to pressure vessels used in chemical processes and other directions, can solve the problems of harsh wall thickness and material selection requirements, infeasible mechanical and design processing, and low interphase mass transfer efficiency. Improve fluid short-circuit or uneven distribution, enhance contact and mixing, and prevent dead zones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

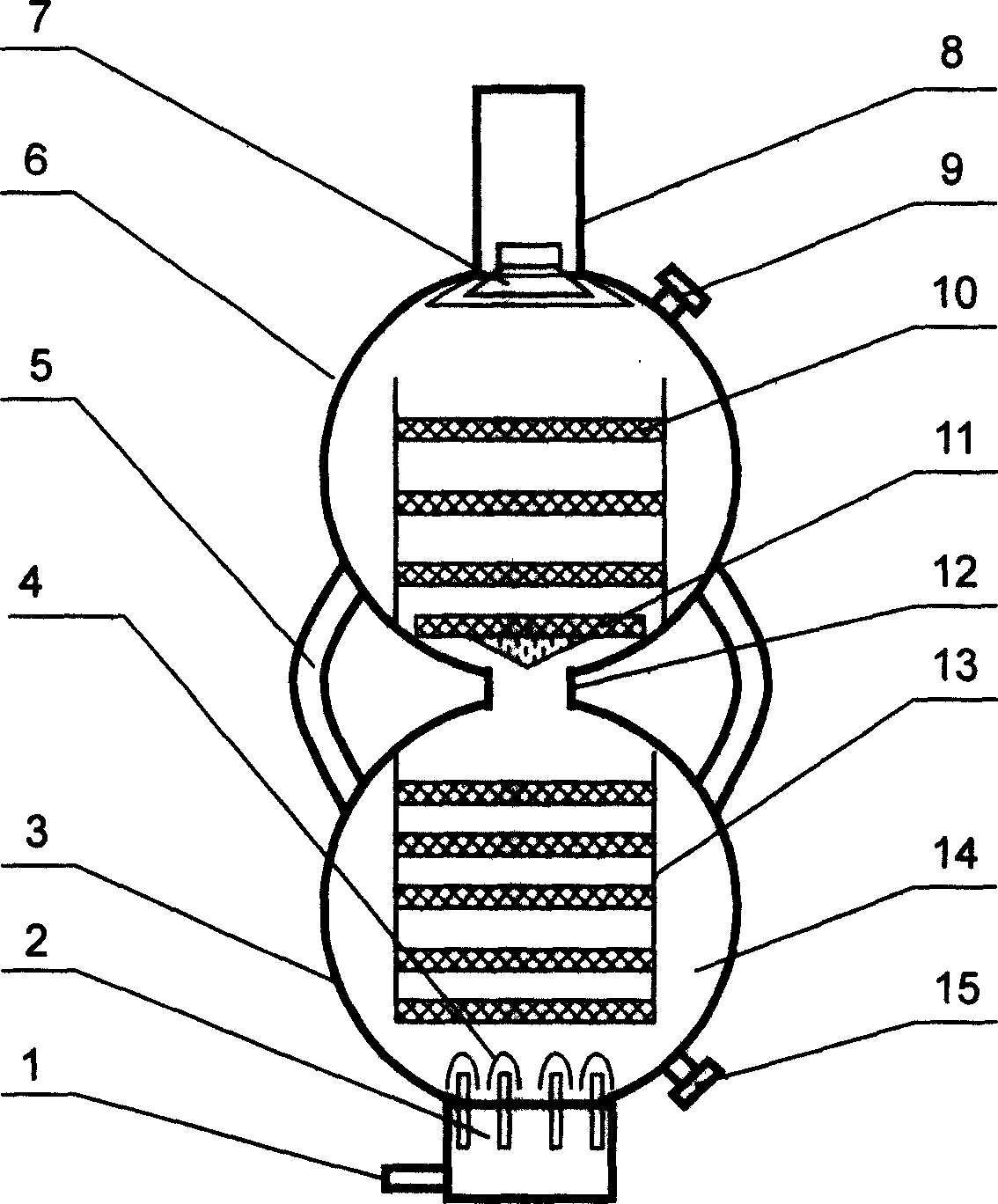

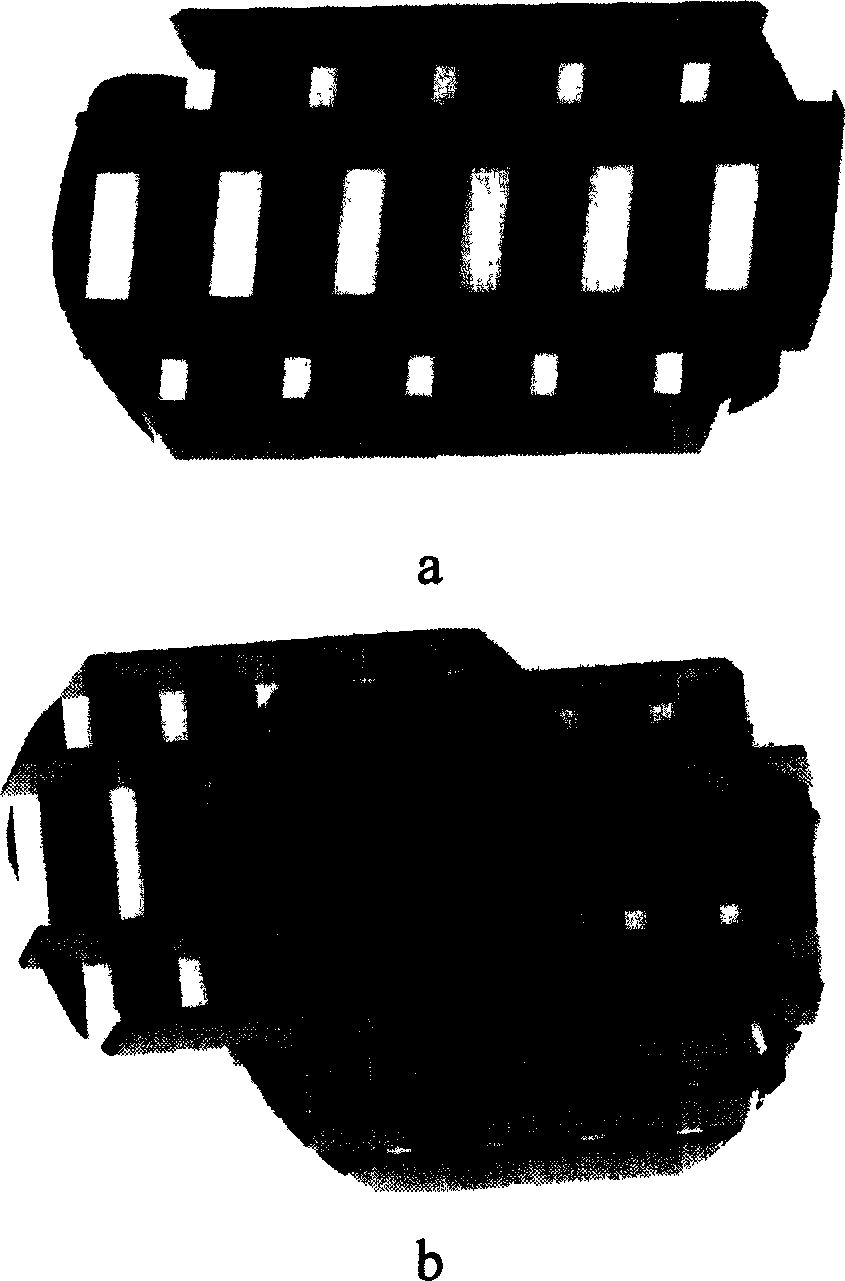

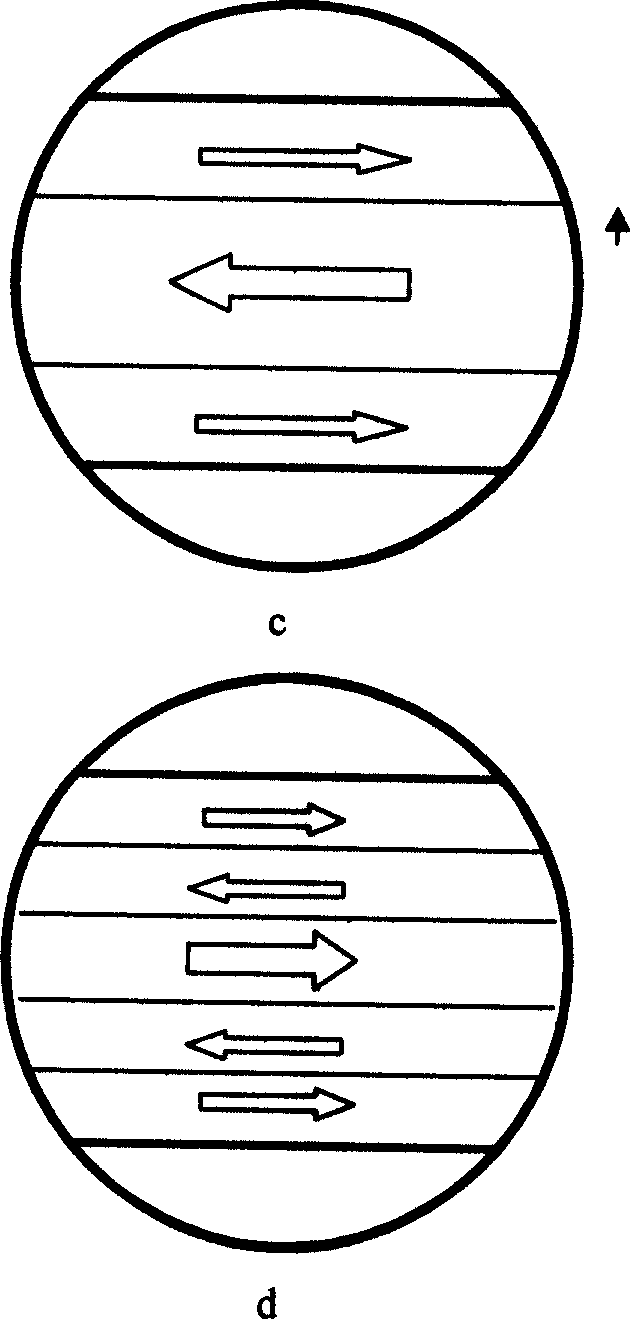

[0013] The invention provides a spherical high-pressure multiphase reactor. This spherical high-pressure multiphase reactor is a kind of gas-liquid or gas-liquid solid-slurry state spherical reactor, and this reactor is formed by connecting pipe 12 in series by lower spherical container 3 and upper spherical container 6 or a plurality of spherical containers (as figure 1 As shown), the gas distributor 2 is fixed on the bottom of the lower spherical container 3, the internal partition baffle 13 of the spherical container is supported above the gas distributor 2 in the lower spherical container 3, and the multi-layer interlaced inner member 10 is fixed on the internal partition baffle of the spherical container In the plate 13, the internal member 11 with the central blunt body diversion function is directly fixed on the mouth connecting the upper spherical container 6 and the lower spherical container 3, the swirl plate 7 and the gas-liquid separator 8 are arranged at the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com