Immersion on-line multiphase measuring instrument and measuring method

一种测量仪、浸入式的技术,应用在测量流量/质量流量、测量装置、液体/流体固体测量等方向,能够解决影响测量结果、光照强度指数衰减、光纤易断丝损毁等问题,达到体积小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

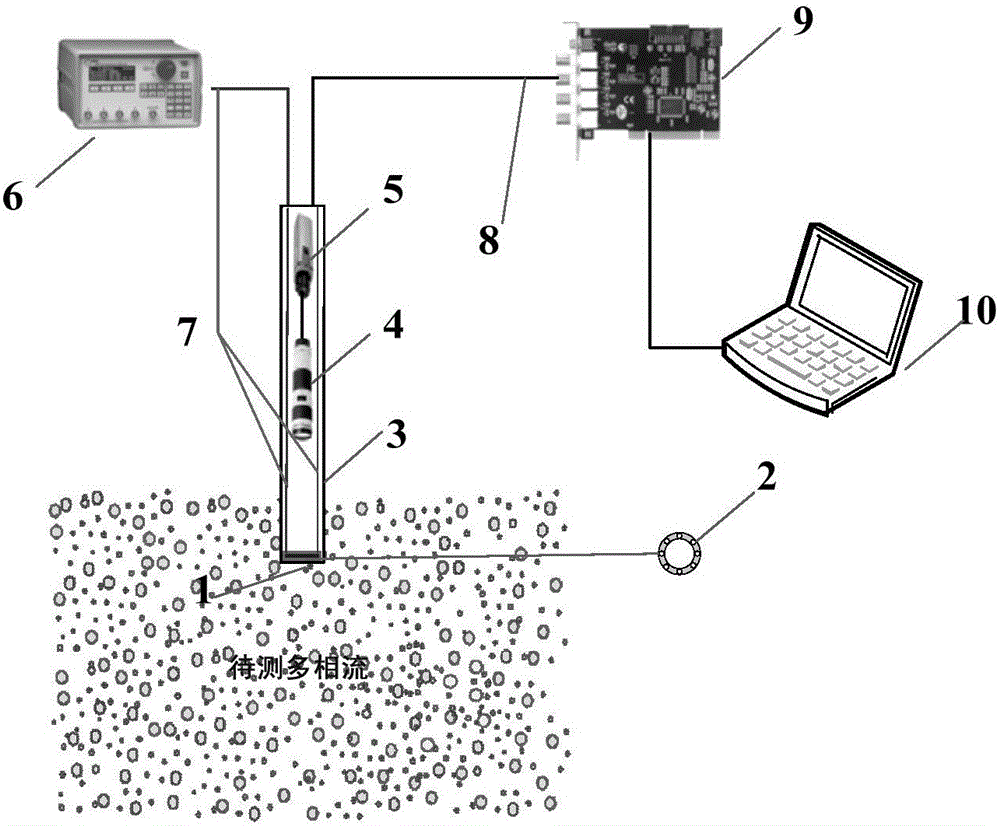

[0051] An immersion in-line polyphase meter such as figure 1 shown. The polyphase meter includes:

[0052] Stainless steel packaging tube 3;

[0053] The viewing window 1 is sealed and connected to one end of the stainless steel packaging tube 3;

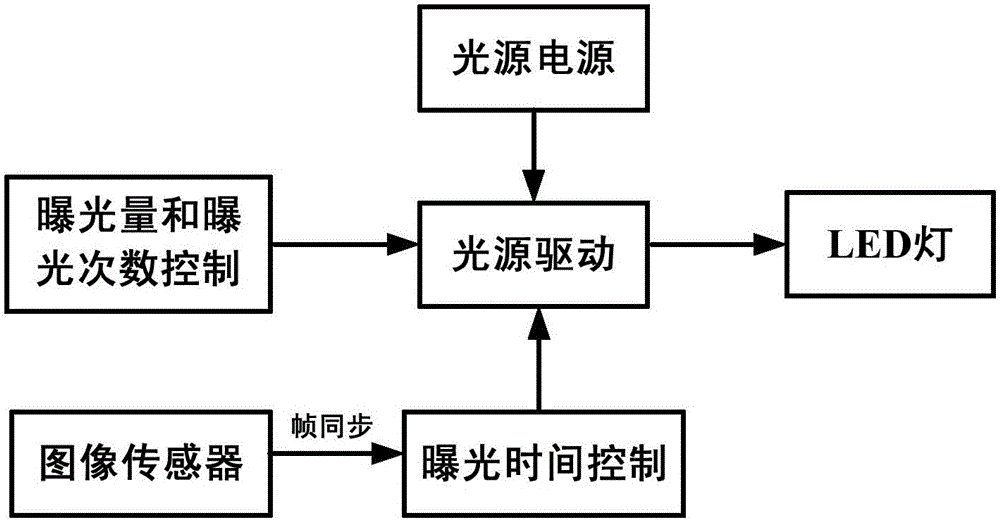

[0054] A lighting system for illuminating a multiphase flow, including an LED lamp 2 and a modulatable light source connected to the LED lamp 2, where the modulatable light source includes a power supply, a signal generator and an oscilloscope;

[0055] A camera system for taking pictures, including a telecentric lens 4 and an image sensor, the image sensor is a miniature high-speed CMOS camera 5;

[0056] A controller connected to the signal generator and the image sensor;

[0057] Signal processing and output system connected to the image sensor;

[0058] A display system connected to the signal processing and output system;

[0059] Among them, the LED lamp, telecentric lens and image sensor are located in the stainless ste...

Embodiment 2

[0063] Embodiment 2: Using the immersion type online multiphase measuring instrument provided in embodiment 1 to measure the velocity distribution of solid particles in the liquid-solid system

[0064] The experiment was carried out in an organic glass stirring tank with an elliptical bottom with an inner diameter T=280 mm, and the stirring speed was 480 rpm. The height of the static liquid level is H=1.2T, the agitating impeller is a down-pressing six-blade open turbine impeller, the diameter of the impeller is D=T / 3, the height of the impeller from the bottom is C=T / 3, and 4 baffles are evenly distributed around the stirring tank. Baffle width B=T / 10. The solid particles used are white plastic beads with a particle size of about 1 mm, and the overall average solid content (volume ratio) is 0.01. The measuring point positions are r=0.025, 0.045, 0.065, 0.085, 0.105, 0.125m, z=0.045, 0.090, 0.135, 0.180, 0.220, 0.260, 0.300m.

[0065] The measurement method includes the foll...

Embodiment 3

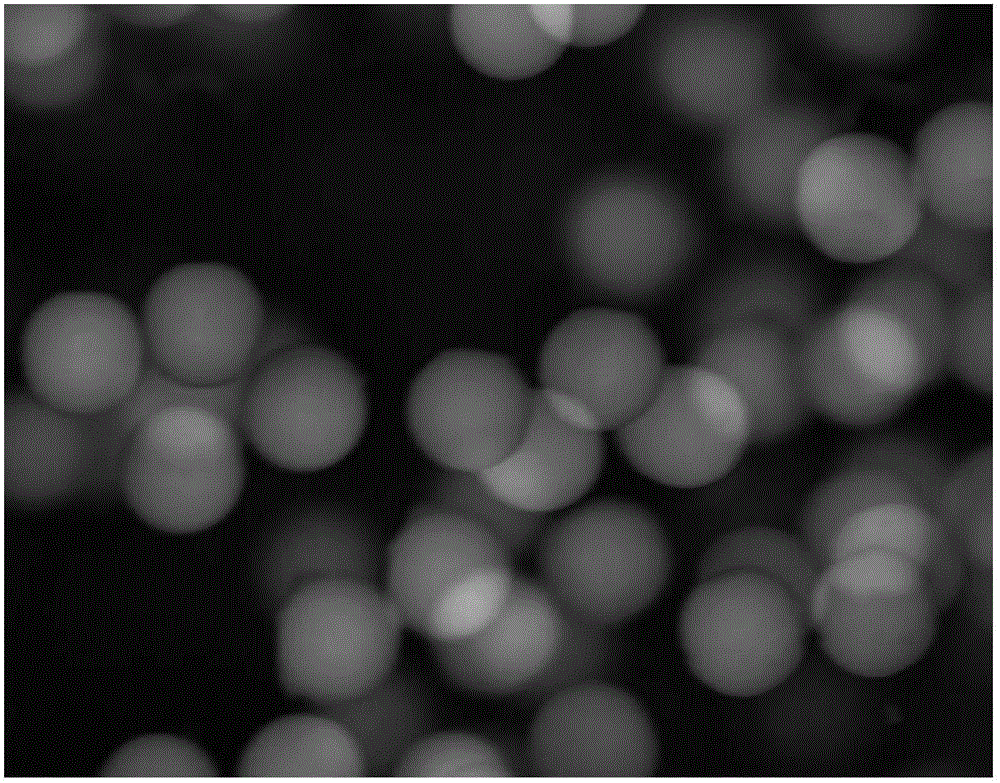

[0072] Example 3: Using the immersion type online multiphase measuring instrument described in Example 1 to measure the particle size distribution of solid particles and air bubbles in the gas-liquid-solid three-phase stirred tank

[0073] The experiment was carried out in a stirred tank. The solid particles used were white plastic beads with a particle size of about 1 mm. The overall average solid content (volume ratio) was 0.01. The measurement point was r=0.07m, z=0.055m. Intake air through the annular gas distributor, the ventilation volume is 800L / h. The stirring speed is 480rpm.

[0074] Described measurement method comprises the steps:

[0075] (1) Place the online multiphase measuring instrument in the gas-liquid-solid system to obtain an image, such as Figure 6 - as shown in (a);

[0076] (2) Determine effective particles:

[0077] First, determine the focal plane position: place a scale with an accuracy of at least 0.1 mm in the same medium as the multiphase sys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com