Novel liquid-liquid heterophase reactor

A multi-phase reactor and reactor technology, which is applied in chemical environment, petroleum, and biological fields, can solve the problems of insufficient compact structure, unsatisfactory mixing, and huge equipment, and achieve simple structure, not easy to leak, and large contact area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

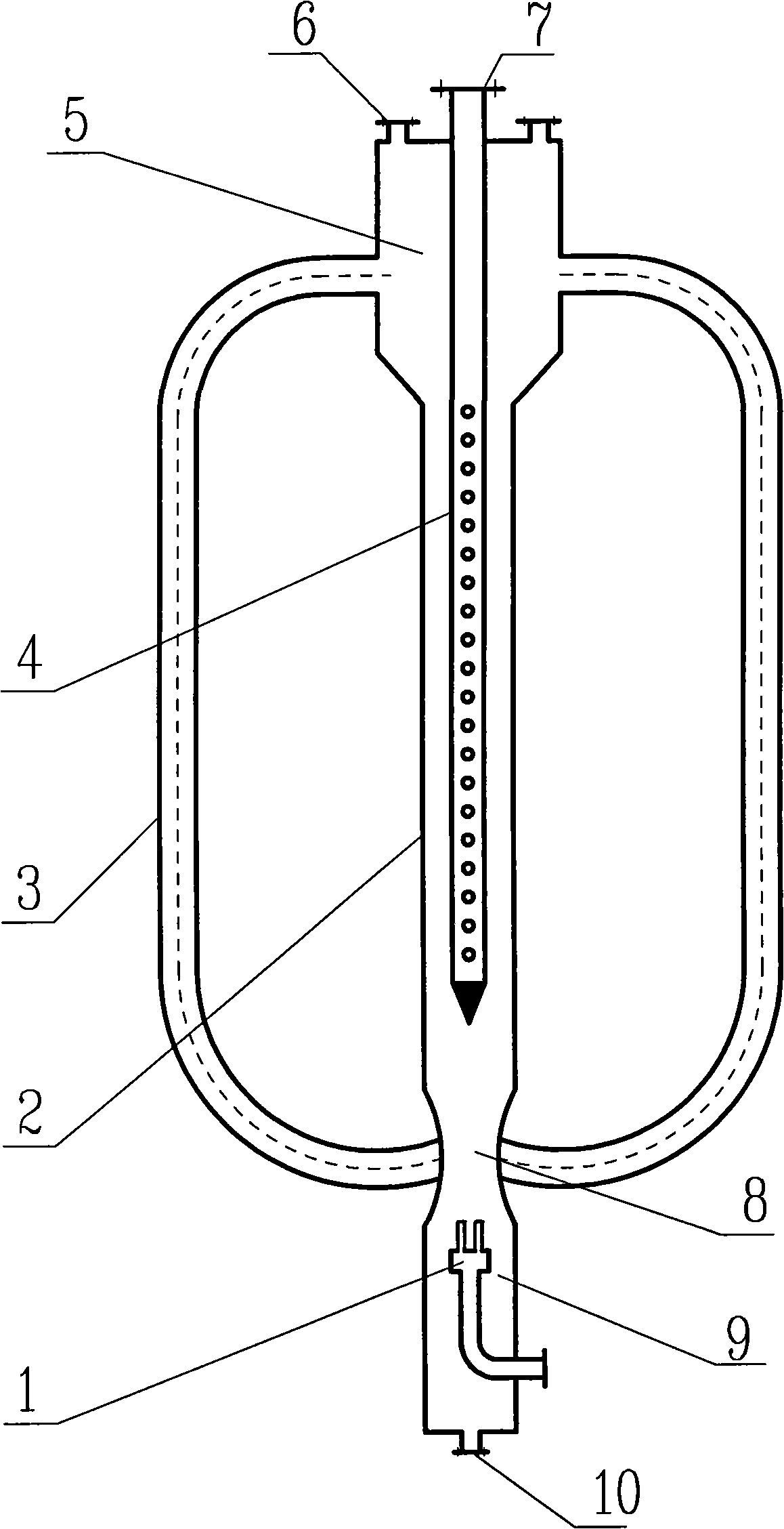

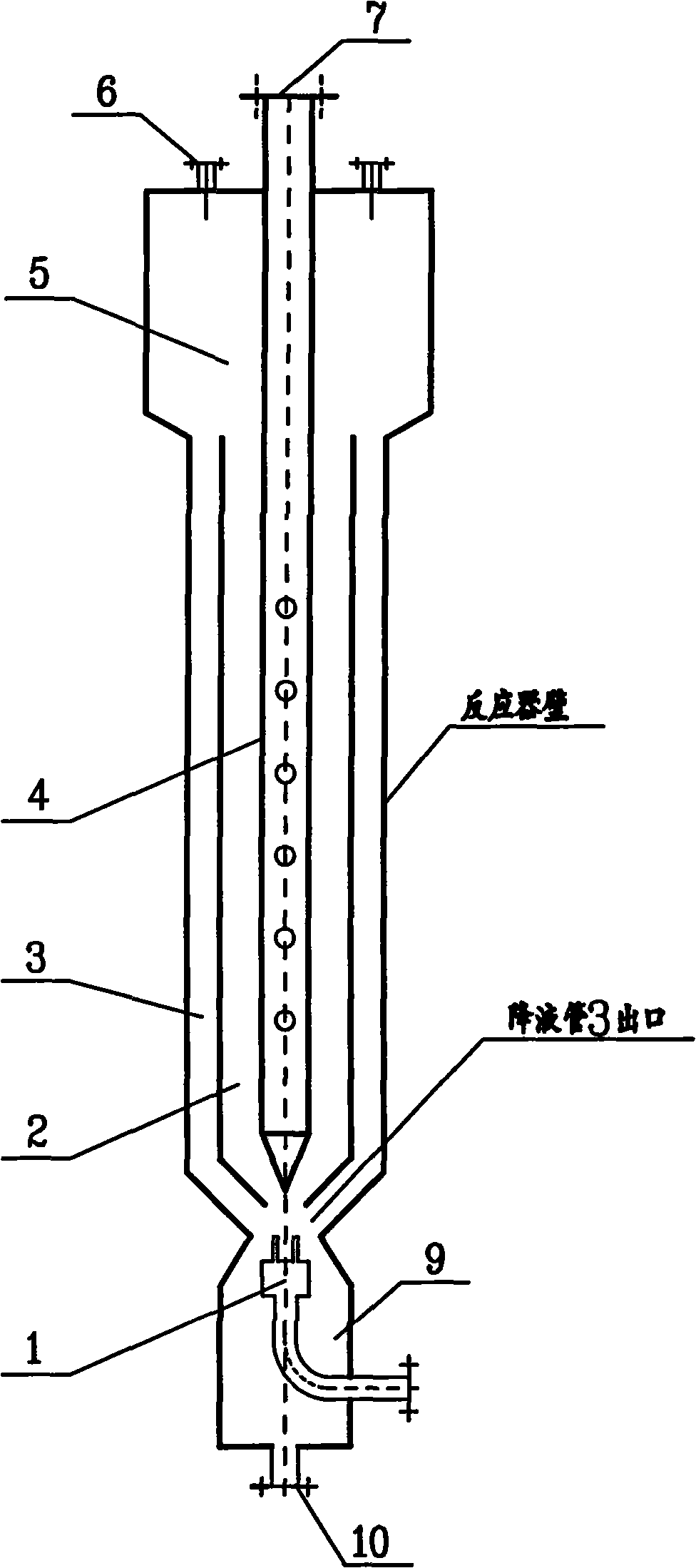

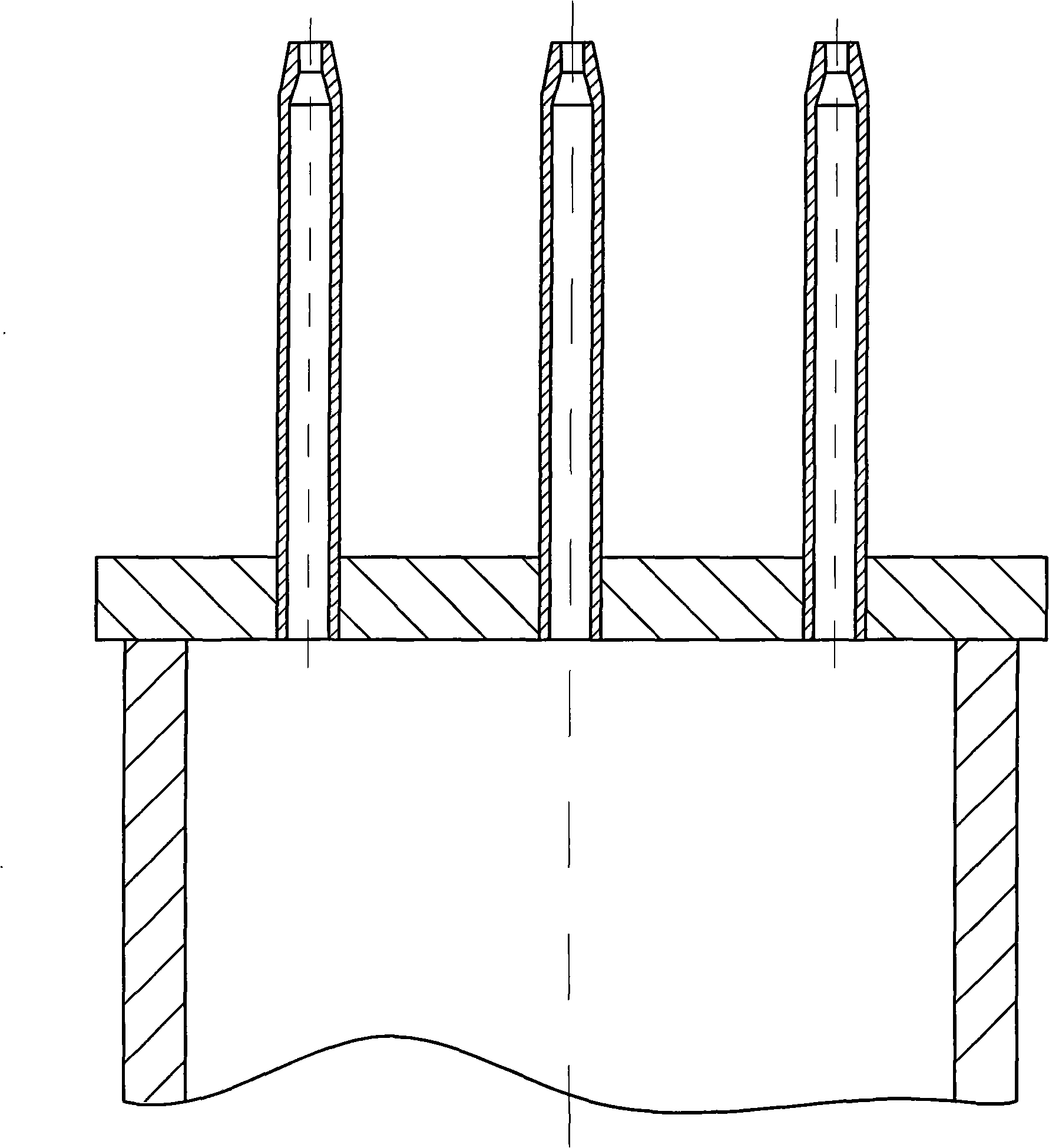

[0021] The novel liquid-liquid multiphase reactor described in the present invention is realized through the following approach: the reactor includes three different structures. Respectively, the jet-type outer loop reactor ( Figure 1a ), jet inner loop reactor ( Figure 1b ), impinging flow riser reactor ( Figure 5 ) and enhanced mass transfer bundled fiber packing reactor ( Figure 9 ). Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0022] attached Figure 1a Shown is the implementation example 1 of the present invention, that is, a schematic diagram of a jet-type outer loop reactor. It at least includes: nozzle system 1 , riser 2 , downcomer 3 , liquid distribution pipe 4 , stratification chamber 5 , reaction product outlet 6 , liquid distribution pipe inlet 7 , throat 8 , mixing chamber 9 and liquid inlet 10 . It is characterized in that: the mixing chamber 9 is located at the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com