Magnetic drive impact mixing and grinding combined multi-phase reactor

A multiphase reactor and reactor technology, applied in mixers, chemical/physical/physicochemical fixed reactors, chemical instruments and methods, etc., can solve difficult reaction temperature and atmosphere condition adjustment, difficult sealing, etc. problems, to achieve the effect of anti-corrosion and anti-leakage, temperature control and adjustment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

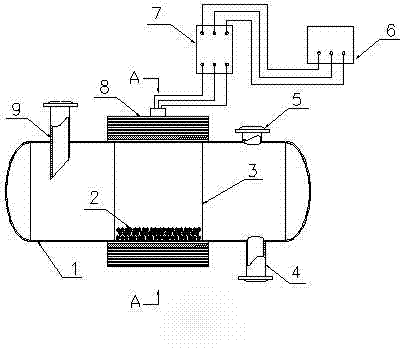

[0025] Example 1: Please refer to figure 1 , The reactor of the present invention includes a reaction tank, the reaction tank includes a non-metal tank body (size: length 3840mm; φ3200mm×20mm) 1 and the material inlet pipe (pipe diameter of φ600mm×10mm) 9 and an outlet pipe of the tank body (The pipe diameter is φ600mm×10mm) 4. The reaction material enters the reactor through the inlet pipe 9. There are two barrier nets 3 in the middle area of the tank body 1. The material after the reaction is discharged by the outlet pipe 4, and the upper right of the tank is a manhole (size φ800mm×10mm) 5. The external alternating magnetic field device 8 of the reactor is provided by an alternating power supply or an alternating direct current power supply 6, which is input to the alternating magnetic field device 8 after being adjusted by a frequency converter 7 to provide its energy, The excitation coil 10 and the iron core 11 generate an alternating magnetic field under the action of a...

Embodiment 2

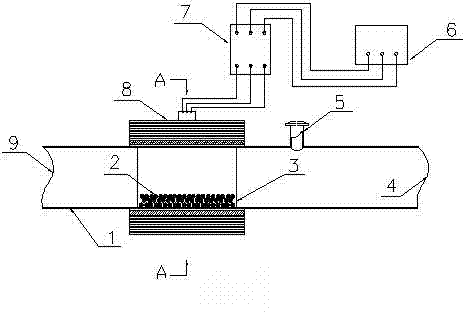

[0026] Example 2: Same as Example 1, except that the reaction tank of the reactor is changed to a reaction tube (length is 8000mm; tube diameter is φ750mm×20mm), the material is still non-metallic material, and the inlet tube 9 and outlet tube 4 are reacting Both ends of the tube.

Embodiment 3

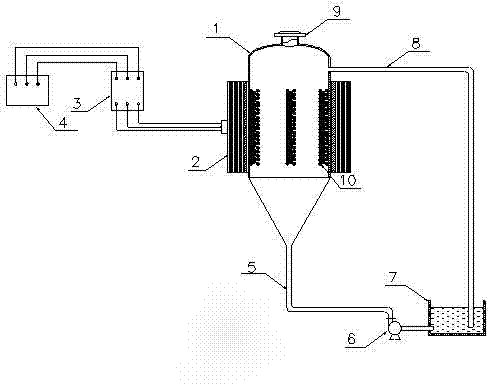

[0027] Example 3: Please refer to image 3 , The reactor of the present invention includes a reaction tank, the reaction tank includes a non-metallic tank body (size: length 3840mm; φ3200mm×20mm) 1, the lowermost end of the non-metallic tank body 1 is a sharp cone with an angle of 45° , It is convenient for the materials in the reactor to be impacted by the fluid in the lowermost inlet pipe (pipe diameter of φ325mm×10mm) 5 without staying in the dead zone. The feed in the inlet pipe 5 is saved by the feed pump 6 Pool 7 scored. The upper end of the tank body 1 is a manhole (size φ800mm×10mm) 9 and the upper right end is a discharge pipe (pipe diameter is φ500mm×10mm) 8 through which the reacted materials are recycled back to the reservoir 7. In the middle and outside of the tank 1 is an alternating magnetic field device 2. The alternating magnetic field device 2 is provided by an alternating power source or an alternating direct current power source 4, which is adjusted by a fre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com