Multiphase reactor used in ethylene carbonate synthesis

An ethylene carbonate and reactor technology, applied in the field of gas-liquid-solid three-phase reactors, can solve problems such as cavitation, unfavorable reaction process, damage to downstream equipment, etc., to improve reaction performance, increase residence time, and ensure utilization rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

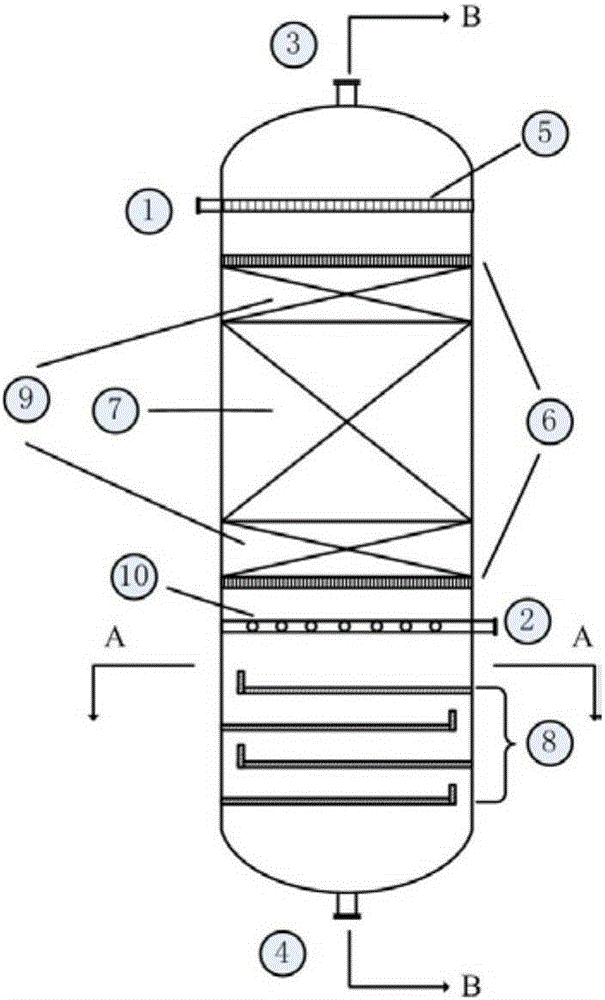

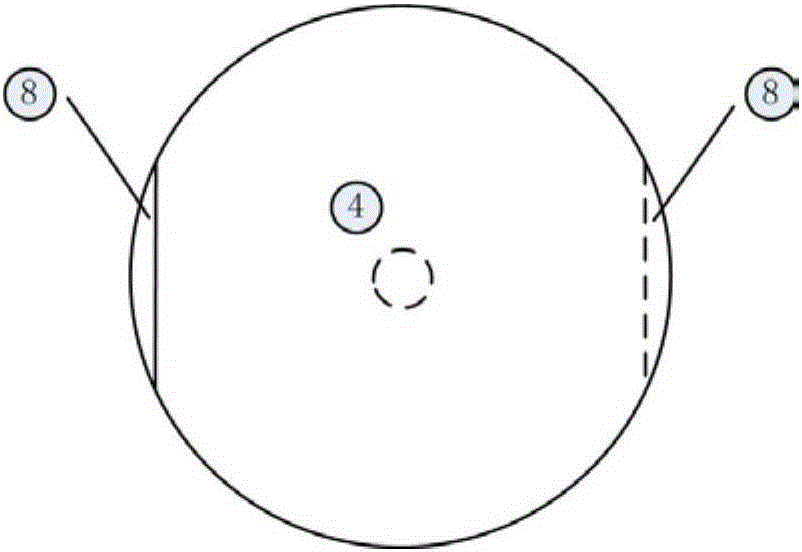

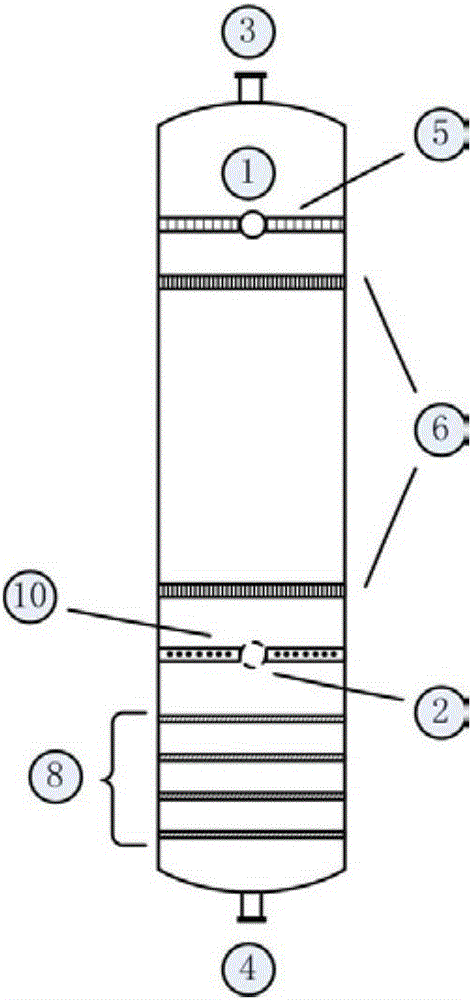

[0020] according to figure 1 , figure 2 , the diameter of the gas-liquid-solid three-phase reactor is 500 mm, the catalyst bed is one layer, the branch pipes and the main pipe of the liquid inlet distributor and the gas inlet distributor are circular pipes, which are distributed in a cross intersection, and the liquid inlet distributors are each The branch pipes are installed at intervals of 60°, and the branch pipes of the gas inlet distributor are installed at intervals of 30°. One row of small holes is set on the branch pipe of the liquid inlet distributor, and two rows of small holes are opened on the branch pipe of the gas inlet distributor, and the angle between the opening directions of each row is 90°. The upper opening ratio of the branch pipe of the gas inlet distributor is 30%. The number of liquid phase baffles in the lower part of the reactor is 2, each baffle has the same spacing, and forms an angle of 90° with the shell. The cross-sectional area of the baf...

Embodiment 2

[0022] according to figure 1 , figure 2 , the diameter of the gas-liquid-solid three-phase reactor is 1000mm, the catalyst bed is 2 layers, and the gas inlet distributor is set between the layers. Cross-intersecting distribution, install the branch pipes of the liquid inlet distributor at an angle of 45°, and install the branch pipes of the gas inlet distributor at an angle of 30°. Two rows of small holes are set on the branch pipe of the liquid inlet distributor, and the angle between the opening directions of each row is 90°; 3 rows of small holes are opened on the branch pipe of the gas inlet distributor, and the angle between the opening directions of each row is 45° °. The upper opening ratio of the branch pipe of the gas inlet distributor is 25%. The number of liquid-phase baffles in the lower part of the reactor is 5, and the distance between each baffle is the same, and they form an angle of 90° with the shell. The cross-sectional area of the baffle plate accoun...

Embodiment 3

[0024] according to figure 1 , figure 2 , the diameter of the gas-liquid-solid three-phase reactor is 1500mm, the catalyst bed is 3 layers, and the gas inlet distributor is set between the layers. Cross-intersecting distribution, the liquid inlet distributor is installed at an angle of 60° between each branch pipe, and the gas inlet distributor is installed at an angle of 30° between each branch pipe. Two rows of small holes are set on the branch pipe of the liquid inlet distributor, and the angle between the opening directions of each row is 60°; 3 rows of small holes are opened on the branch pipe of the gas inlet distributor, and the angle between the opening directions of each row is 30° °. The upper opening ratio of the branch pipe of the gas inlet distributor is 40%. The number of liquid-phase baffles in the lower part of the reactor is 6, and the distance between each baffle is the same, and they form an angle of 90° with the shell. The cross-sectional area of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com