Reactor for distribution modulation of Fischer-Tropsch synthesis product and application thereof

A technology of supporting synthesis and modulation fee, which is applied in the field of hypergravity reactors to achieve the effect of precise and controllable temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

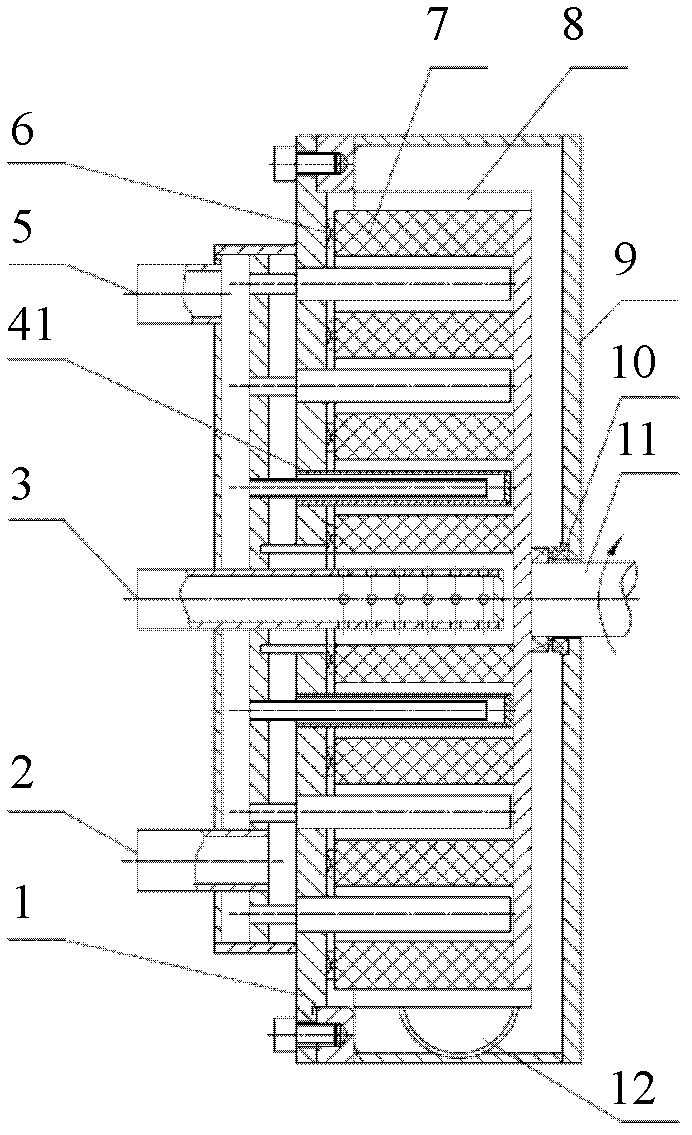

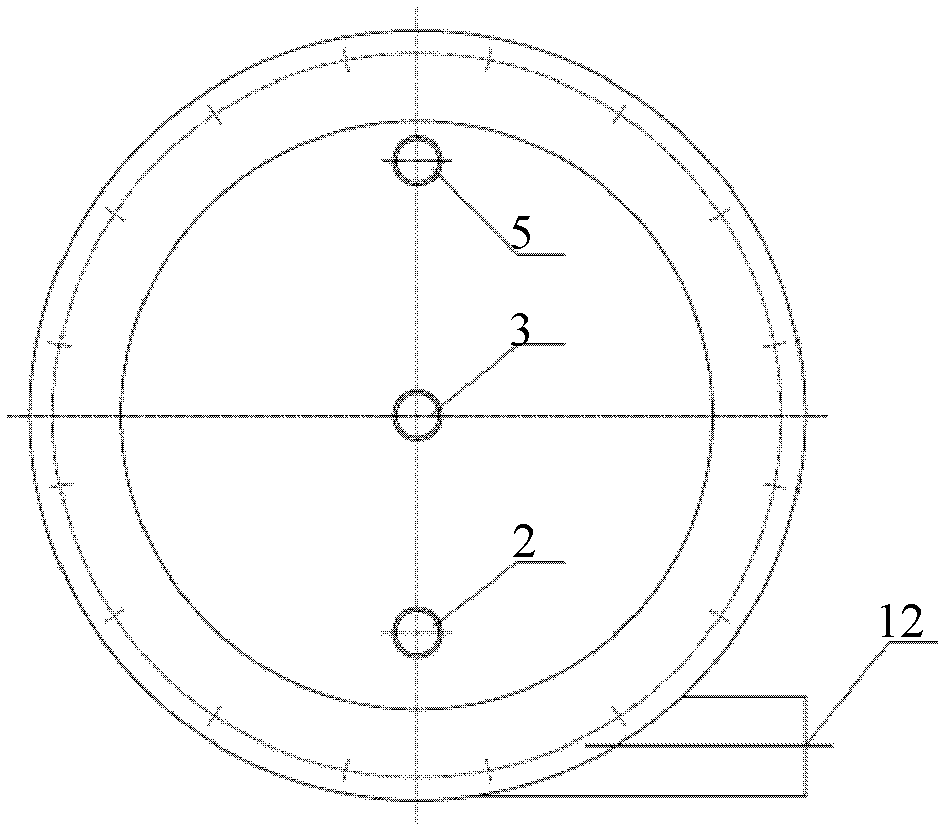

[0031] Fischer-Tropsch synthesis of paraffin wax in a high-gravity reactor. Syngas as CO+H 2 Mixed gas, CO / H 2 = 1 / 2. Co / SiO 2 The Fischer-Tropsch catalyst is put into the mesh support and fixed on the rotor of the supergravity reactor. figure 1 , see side view figure 2 , the casing is made of steel, the heat exchange medium is air, and the flow rate of the heat exchange medium is 1 liter / min.

[0032] The processing conditions of reaction are as follows:

[0033] Synthetic gas air velocity: 1600h -1 , Reaction temperature: 210°C, Reaction pressure: 2.2MPa

[0034] Catalyst bed rotation speed: 10rpm, catalyst bed supergravity level: 3g

[0035] Fischer-Tropsch synthesis to paraffin wax reaction results in high gravity reactor:

[0036]

Embodiment 2

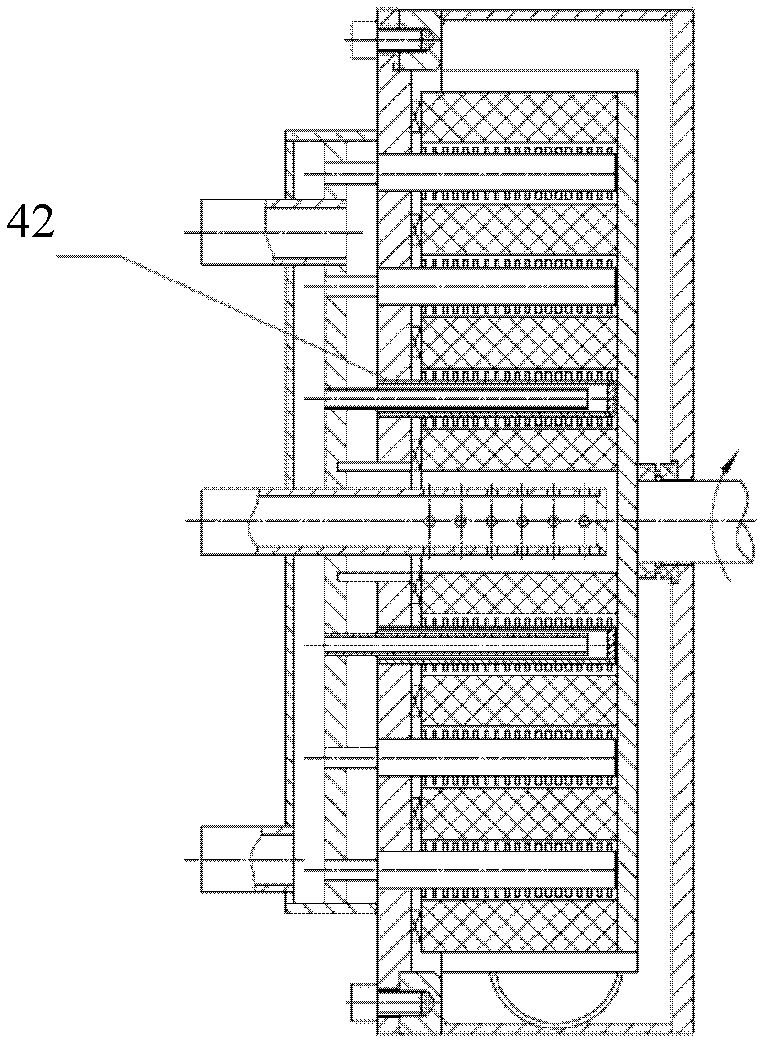

[0038] Fischer-Tropsch synthesis of paraffin wax in a high-gravity reactor. Syngas as CO+H 2 Mixed gas, CO / H 2 = 1 / 2. Ru / SiO 2 The Fischer-Tropsch catalyst is placed in a mesh support and fixed on the rotor of the supergravity reactor. A vertical supergravity reactor with finned sleeve heat exchange is used, see image 3 . The casing is made of aluminum, the heat exchange medium is air exchange, and the flow rate of the heat medium is 2 liters / minute.

[0039] The processing conditions of reaction are as follows:

[0040] Synthetic gas air velocity: 5000h -1 , Reaction temperature: 190°C, Reaction pressure: 6.0MPa

[0041] Catalyst bed speed: 80rpm, catalyst bed supergravity level: 10g

[0042] Fischer-Tropsch synthesis to paraffin wax reaction results in high gravity reactor:

[0043]

Embodiment 3

[0045] Fischer-Tropsch synthesis of paraffin wax in a high-gravity reactor. Syngas as CO+H 2 Mixed gas, CO / H 2 = 1 / 1. Put the iron-based Fischer-Tropsch catalyst into the mesh support, fix it on the rotor of the supergravity reactor, and use the heat pipe to exchange heat for the vertical supergravity reactor, see Figure 5 . The heat pipe is made of steel, the heat medium is heat transfer oil, and the flow rate of the heat exchange medium is 1 liter / min.

[0046] The processing conditions of reaction are as follows:

[0047] Syngas air velocity: 2000h -1 , Reaction temperature: 280°C, Reaction pressure: 3.0MPa

[0048] Catalyst bed speed: 100rpm, catalyst bed supergravity level: 20g

[0049] Fischer-Tropsch synthesis to paraffin wax reaction results in high gravity reactor:

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com