Method for preparing 2-chloro-5-chloromethylthiazole by jet loop reactor

A loop reactor, chloromethylthiazole technology, applied in organic chemistry and other directions, can solve the problems of high reaction temperature control requirements, complex production process, many side reactions, etc., and achieves wide reaction temperature range, high yield, and side reactions. less reactive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method utilizing a jet loop reactor to prepare 2-chloro-5-chloromethylthiazole, comprising the following steps:

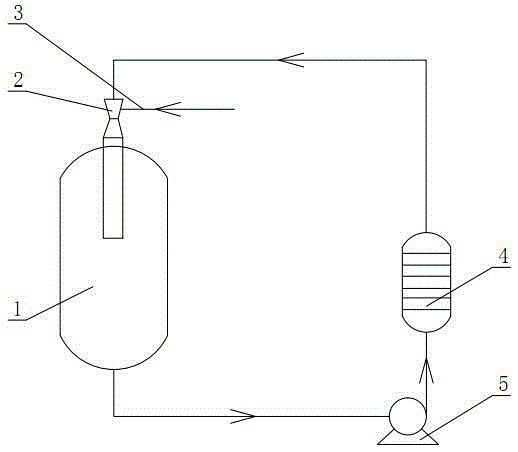

[0032] 1. Using a jet loop reactor, see figure 1 As shown, the jet loop reactor includes a reactor 1, an injector 2, an air intake pipe 3, a heat exchanger 4 and a circulation pump 5, the injector 2 is installed on the upper part of the reactor 1, and the outlet of the lower part of the reactor 1 passes through a pipeline and a circulation pump 5. The inlet of the pump 5 is connected, the outlet of the circulating pump 5 is connected with the inlet of the heat exchanger 4 through a pipe, the outlet of the heat exchanger 4 is connected with the top inlet of the ejector 2 through a pipe, and the side of the ejector 2 is provided with an inlet Trachea 3, air intake pipe 3 is provided with intake valve. The injector 2 is a jet-type Venturi injector. The heat exchanger 4 is a jacketed tank heat exchanger.

[0033] Two, 1-isothiocyanato-2-chloro-2-propene is ...

Embodiment 2

[0036] A method utilizing a jet loop reactor to prepare 2-chloro-5-chloromethylthiazole, comprising the following steps:

[0037] 1. A jet loop reactor is adopted. The difference between the jet loop reactor and Example 1 is that the heat exchanger 4 is a plate heat exchanger.

[0038] 2. Dissolve 1-isothiocyanato-2-chloro-2-propene in 1,2-dichloroethane to form a liquid phase material with a mass concentration of 40%, add it to reaction kettle 1, and start the cycle Pump 5, the liquid phase material is pressurized by the circulating pump 5, heat exchanged by the heat exchanger 4 to control the temperature, and enters from the top inlet of the injector 2; the intake valve is opened, and the gaseous chlorine gas enters the injector 2 and the liquid phase material through the intake pipe 3 Mix and react, the mixed and reacted materials pass through the reactor 1, the circulation pump 5, the heat exchanger 4 and then return to the top inlet of the injector 2, and circulate the re...

Embodiment 3

[0041] A method utilizing a jet loop reactor to prepare 2-chloro-5-chloromethylthiazole, comprising the following steps:

[0042] 1. A jet loop reactor is adopted. The difference between the jet loop reactor and Embodiment 1 is that the heat exchanger 4 is a tube-and-tube heat exchanger.

[0043] 2. Dissolve 1-isothiocyanato-2-chloro-2-propene in dichloromethane to form a liquid phase material with a mass concentration of 70%, add it to the reaction kettle 1, open the circulation pump 5, and the liquid phase The material is pressurized by the circulation pump 5, heat exchanged by the heat exchanger 4 to control the temperature, and enters from the top inlet of the injector 2; the intake valve is opened, and the gaseous chlorine enters the injector 2 through the intake pipe 3 to mix and react with the liquid phase material. The mixed and reacted materials pass through the reactor 1, the circulation pump 5, and the heat exchanger 4, and then return to the top inlet of the ejecto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com