Method for producing isobutene from MTO byproduct C4

An isobutene and by-product technology, applied in the field of isobutene production, can solve the problems of accelerated catalyst deactivation, low isobutene yield per pass, etc., and achieve the effects of low cost, high yield per pass, and low carbon deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

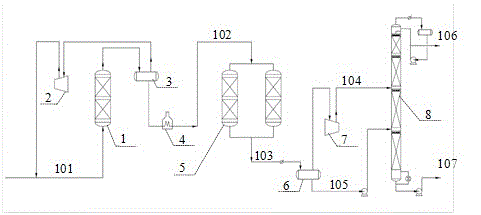

Method used

Image

Examples

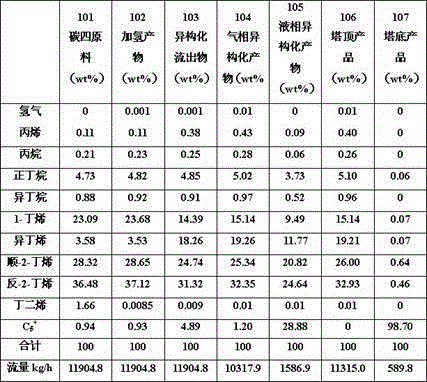

Embodiment 1

[0033] (1) The operating pressure of the hydrogenation reactor is 2.0MPa, the operating temperature is 65°C, and the space velocity is 5h -1 , H 2 The / butadiene molar ratio is 2.0, the diameter of the reactor is 1200mm, and the height is 3600mm. It is filled with two stages of amorphous nickel phosphide catalysts, a total of 3.9m 3 . Catalyst composition: Ni loading is based on the weight percentage of Ni metal weight in the total catalyst weight, P content and Ce content are expressed by P / Ni, Ce / Ni molar ratio respectively, Ni content is 10.12%, P / Ni=2.35, Ce / Ni Ni=0.01. Catalyst specific surface area 276m 2 / g, pressure test strength ≮60N / cm. The preparation process of the catalyst is as follows: 1) Weigh 49.5 grams of nickel nitrate and add 500 ml of deionized water, then add 0.05 mol / L nitric acid to adjust the pH value to 2-3, then add metered diammonium phosphate, cerium nitrate and citric acid ( CA), make P / Ni=2.5, Ce / Ni=0.01, CA / Ni=1 in the solution, and then st...

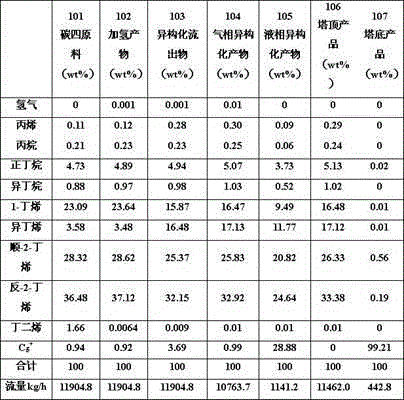

Embodiment 2

[0041] (1) The operating pressure of the hydrogenation reactor is 2.0MPa, the operating temperature is 95°C, and the space velocity is 5h -1 , H 2 The / butadiene molar ratio is 1.5, the diameter of the reactor is 1200mm, and the height is 3600mm. It is filled with two stages of amorphous nickel phosphide catalyst, a total of 3.9m 3 . Catalyst composition: Ni loading is based on the weight percentage of Ni metal weight in the total catalyst weight, P content and Ce content are expressed by P / Ni, Ce / Ni molar ratio respectively, Ni content is 14.96%, P / Ni=2.06, Ce / Ni Ni=0.03. Catalyst specific surface area 245m 2 / g, pressure test strength ≮60N / cm. The preparation process of the catalyst is as follows: 1) Weigh 74.3 grams of nickel nitrate and add 500 ml of deionized water, then add 0.05 mol / L nitric acid to adjust the pH value to 2-3, then add measured diammonium phosphate, cerium nitrate and citric acid ( CA), make P / Ni=3, Ce / Ni=0.03, CA / Ni=1.5 in the solution, and then st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com