Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2664results about How to "Improve operational convenience" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

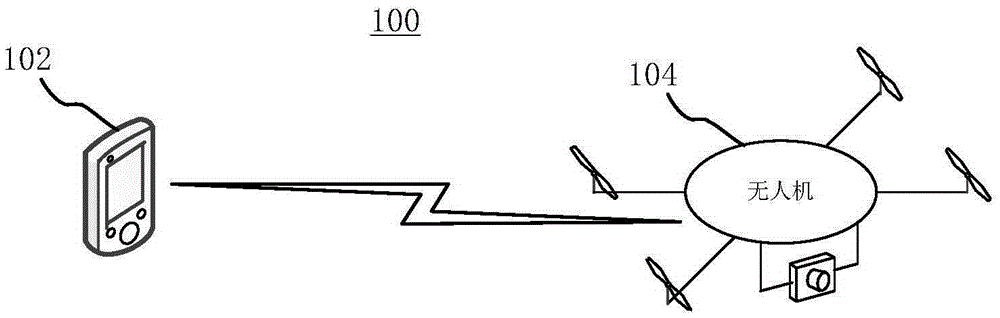

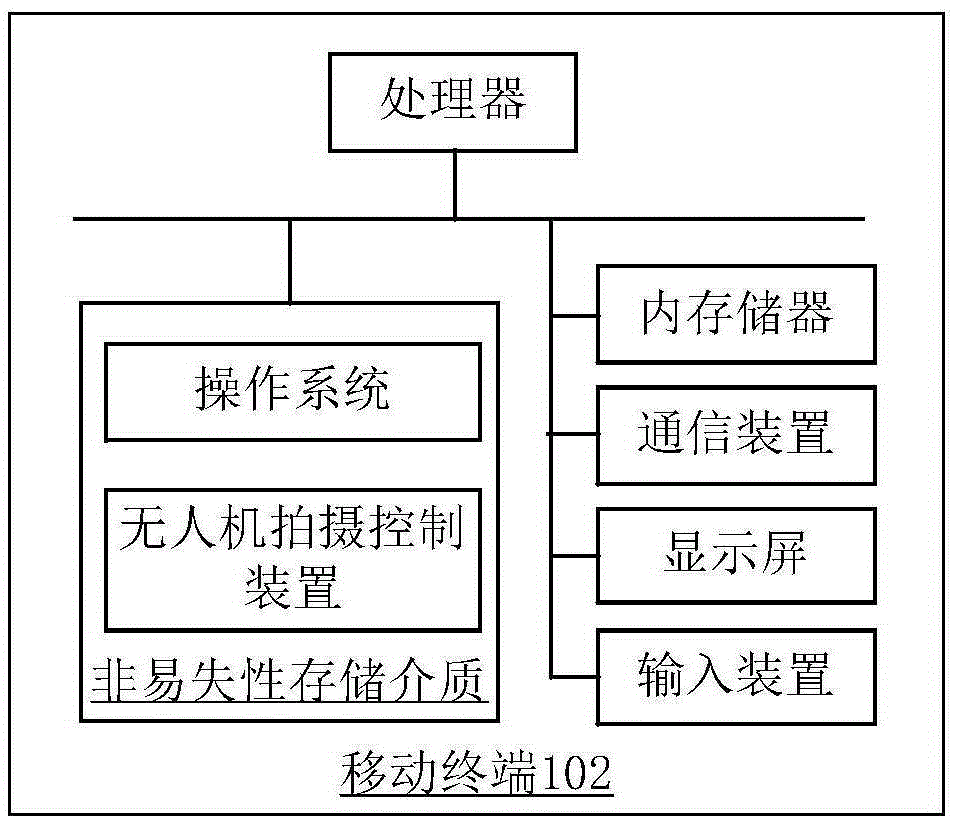

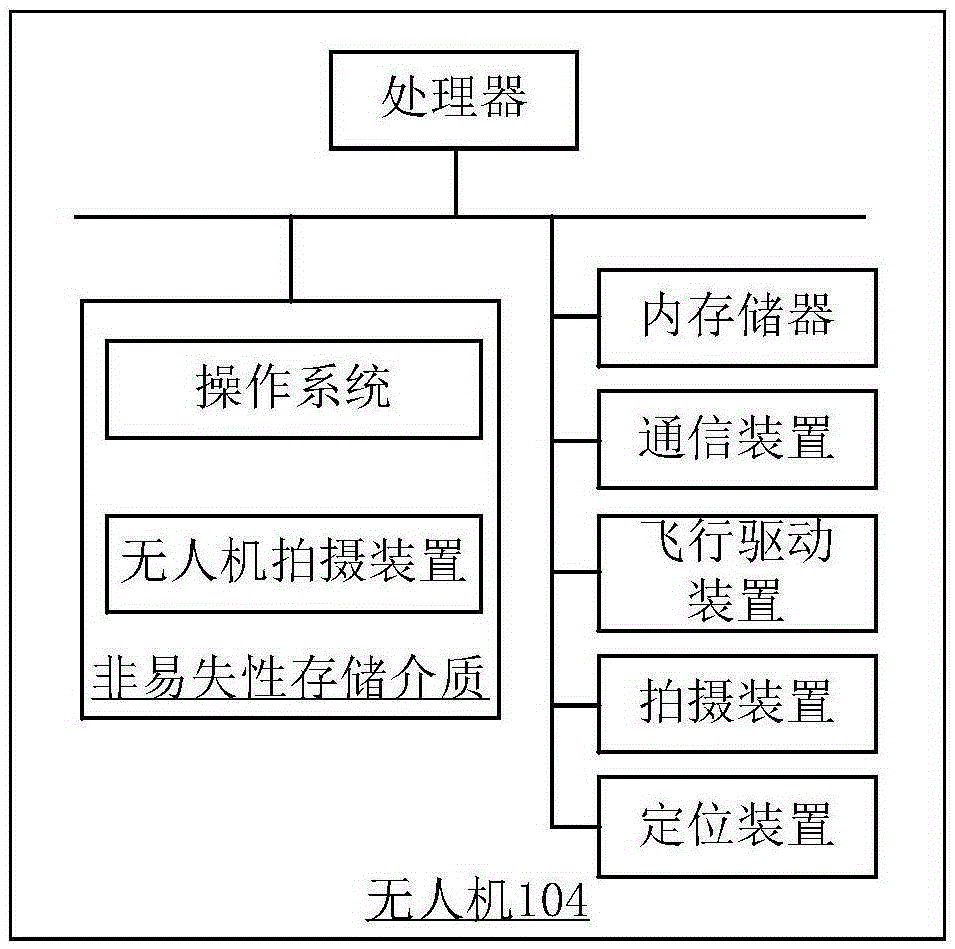

Unmanned aerial vehicle shooting control method, device, unmanned aerial vehicle shooting method and unmanned aerial vehicle

ActiveCN105391939AEasy to operateImprove operational convenienceTelevision system detailsColor television detailsUncrewed vehicleShooting method

The invention relates to an unmanned aerial vehicle shooting control method, a device, an unmanned aerial vehicle shooting method and an unmanned aerial vehicle. The unmanned aerial vehicle shooting control method comprises steps: a shooting starting instruction is acquired; according to the shooting starting instruction, a preset combined operation and control instruction associated with a preset automatic shooting mode is read; the combined operation and control instruction is sent to the unmanned aerial vehicle to enable the unmanned aerial vehicle to sequentially execute a corresponding series of actions according to the combined operation and control instruction to shoot an image; and the image shot and returned by the unmanned aerial vehicle is received and stored. According to the unmanned aerial vehicle shooting control method and the device provided by the invention, the user can not be required to directly control the unmanned aerial vehicle to fly and shoot, the operation is simplified, and operation convenience is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

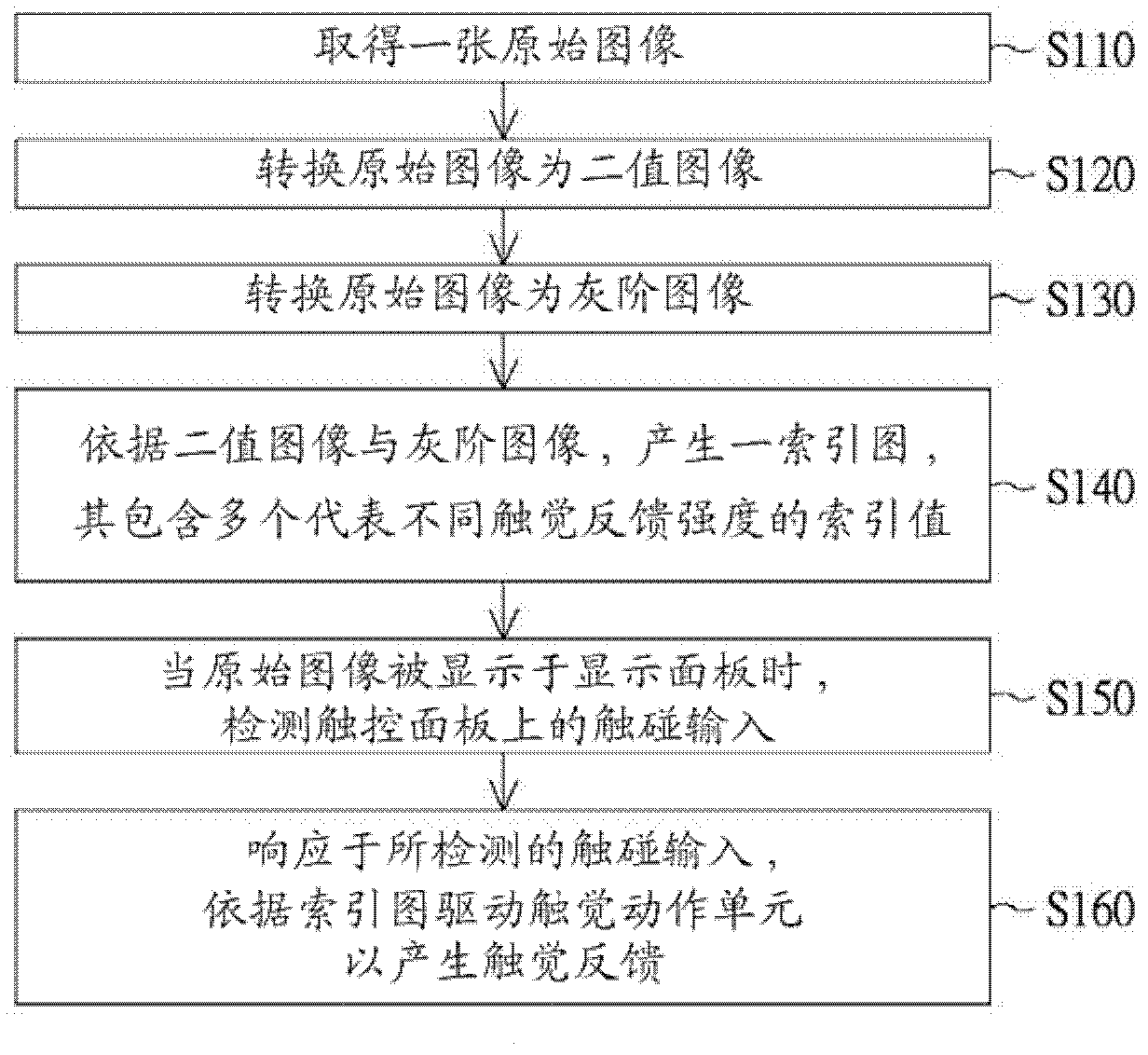

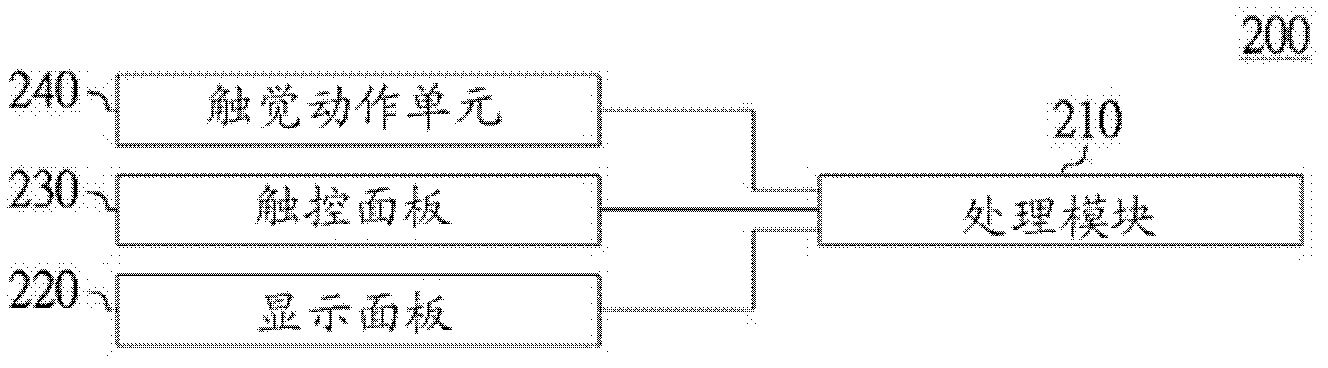

Method and electronic device for tactile feedback

InactiveCN102841677AImprove operational convenienceInput/output for user-computer interactionCharacter and pattern recognitionGray levelBiological activation

A method and an electronic device for tactile feedback are provided. The tactile feedback comprises a plurality of steps. An original image is input and converted to a binary image which includes a first grayscale value and a second grayscale value. The original image is converted to a grayscale image at least including a third grayscale value between the first grayscale value and the second grayscale value. An index map is generated according to the binary image and the grayscale image. The index map includes a plurality of index values indicative of different strengths for tactile feedback. A touch input on a touch panel is detected when the original image is displayed on a display panel. In response to the detected touch input, a tactile activation unit is driven to generate tactile feedback according to the index map.

Owner:QUANTA COMPUTER INC

Method and device for controlling intelligent watch

ActiveCN104777987AImprove operational convenienceEasy to viewInput/output processes for data processingTouch SensesHuman–computer interaction

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

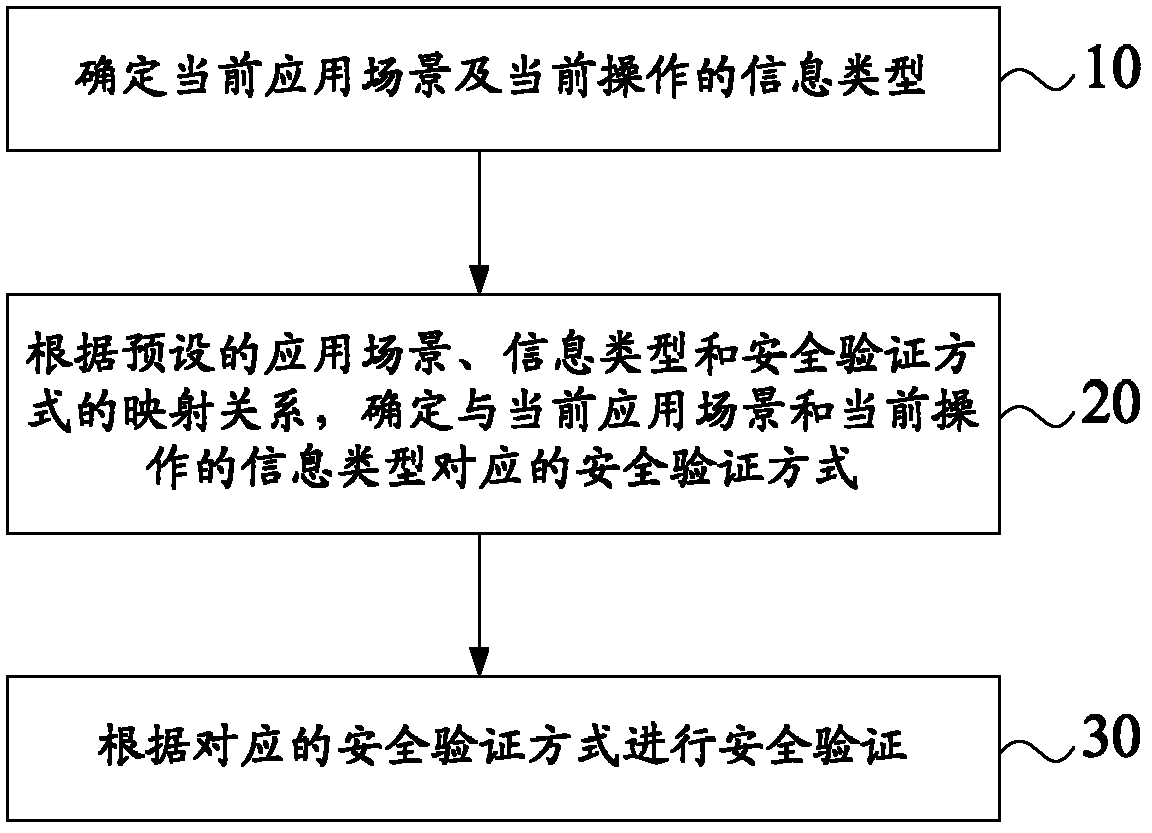

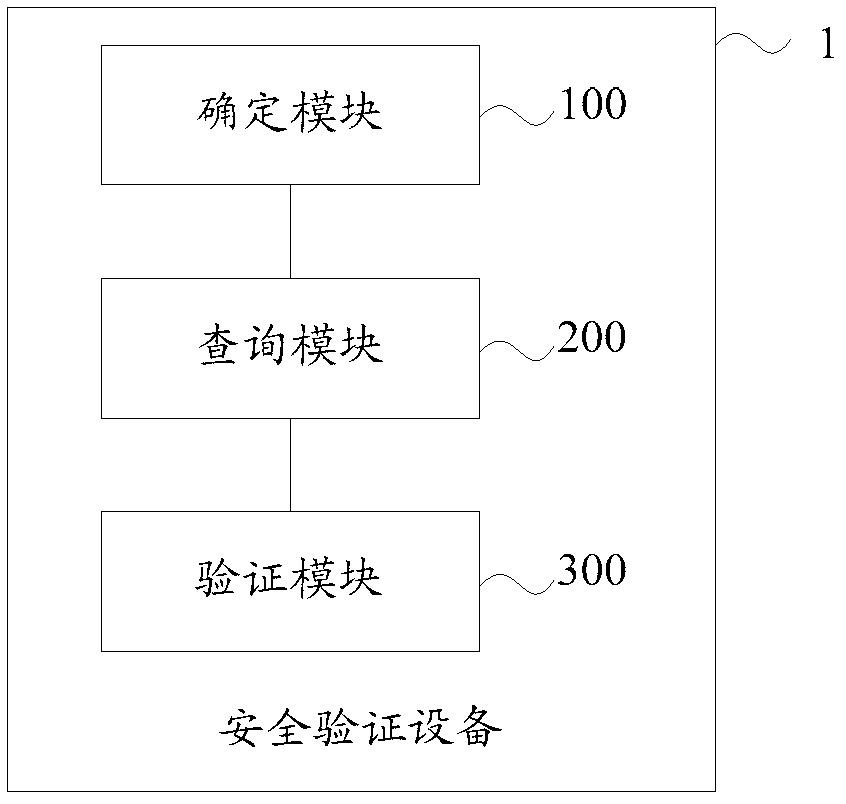

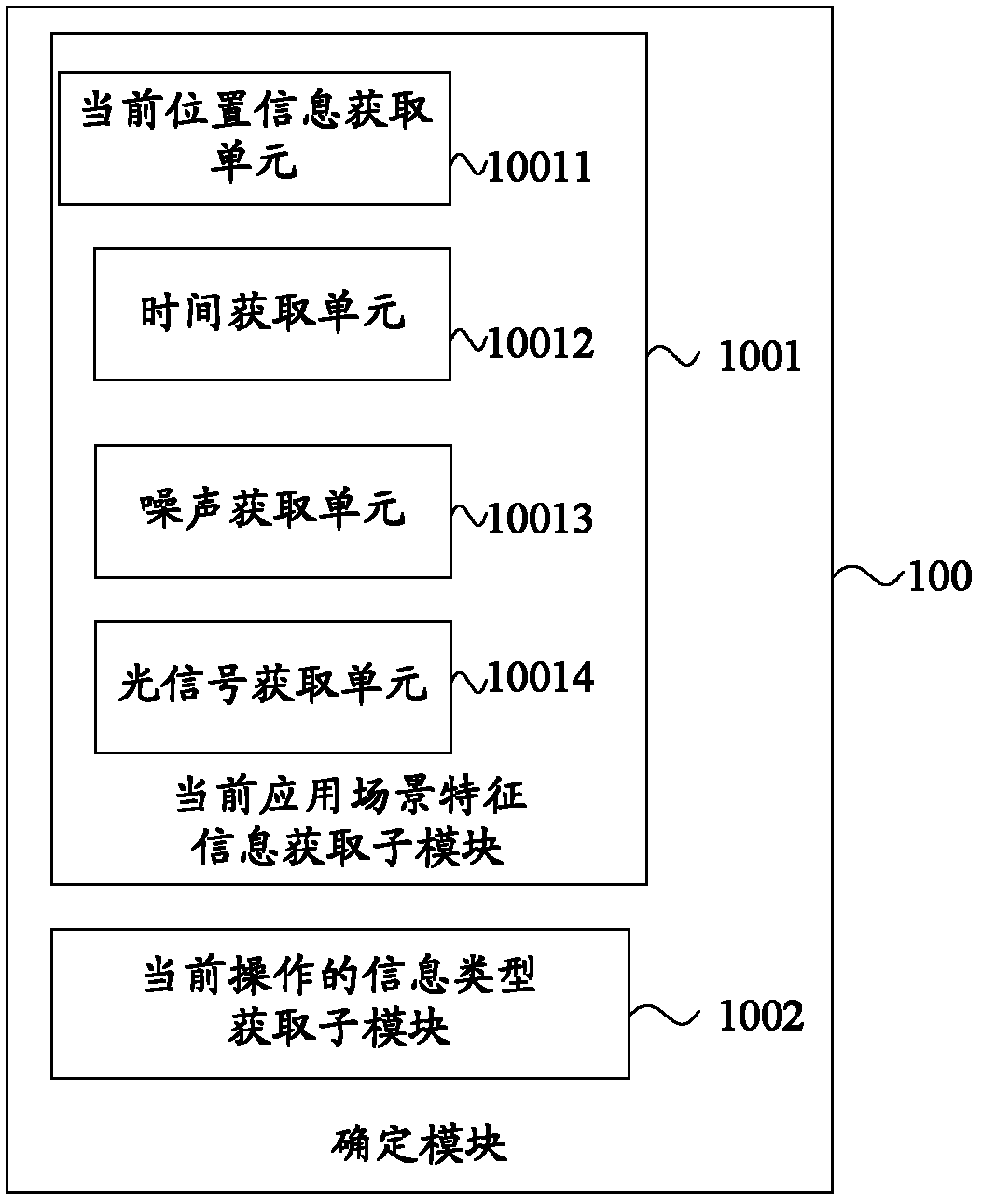

Safety verification method and equipment

InactiveCN102685106AImprove operational convenienceProtection securityUser identity/authority verificationSpeech analysisInformation typeUnsafe environment

The invention provides a safety verification method and equipment. The safety verification method comprises the following steps of: determining a current application scene and an information type of current operation; determining a safety verification mode corresponding to the current application scene and the information type of the current operation according to a mapping relation among the pre-supposed application scene, the information type and the safety verification mode; and performing safety verification according to the corresponding safety verification mode. By adopting the technical scheme, the pre-supposed safety verification mode matched with the current application scene is selected according to the application scene in which a user is located. According to the dynamic safety verification mode, the operation convenience of the user in a safe environment can be enhanced, and the safety of private information and data of the user in an unsafe environment can also be protected as far as possible.

Owner:BEIJING BENY WAVE SCI & TECH

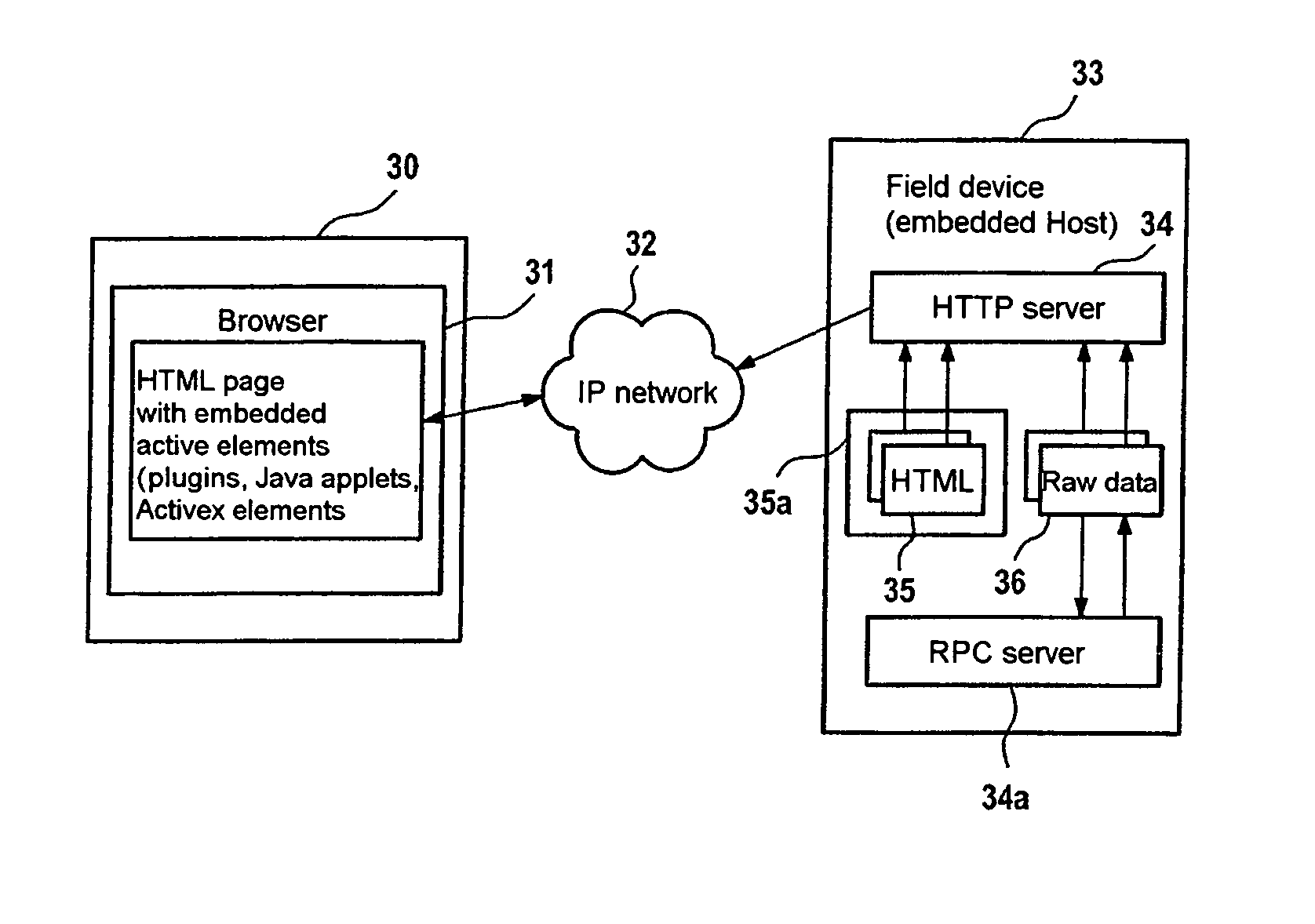

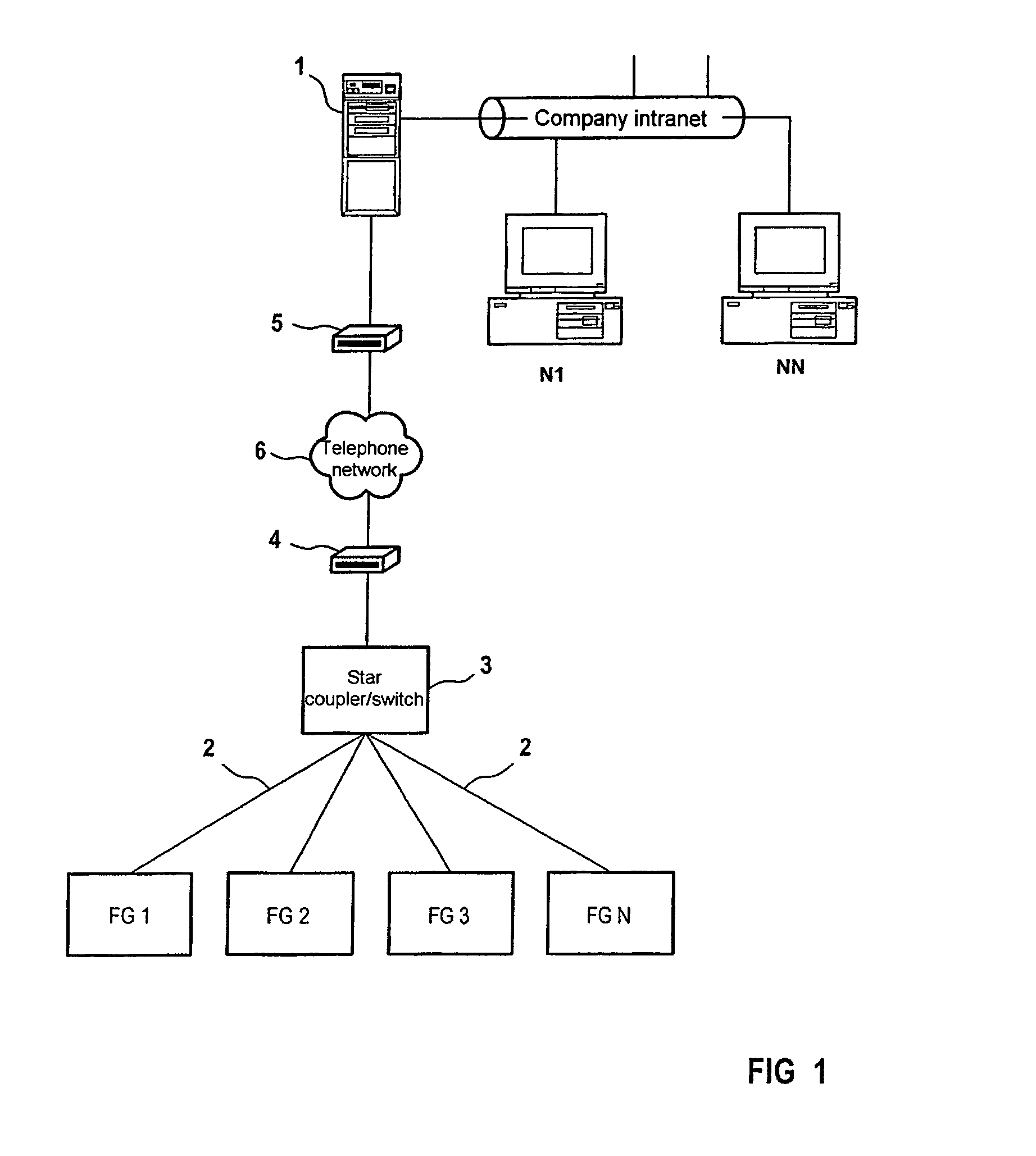

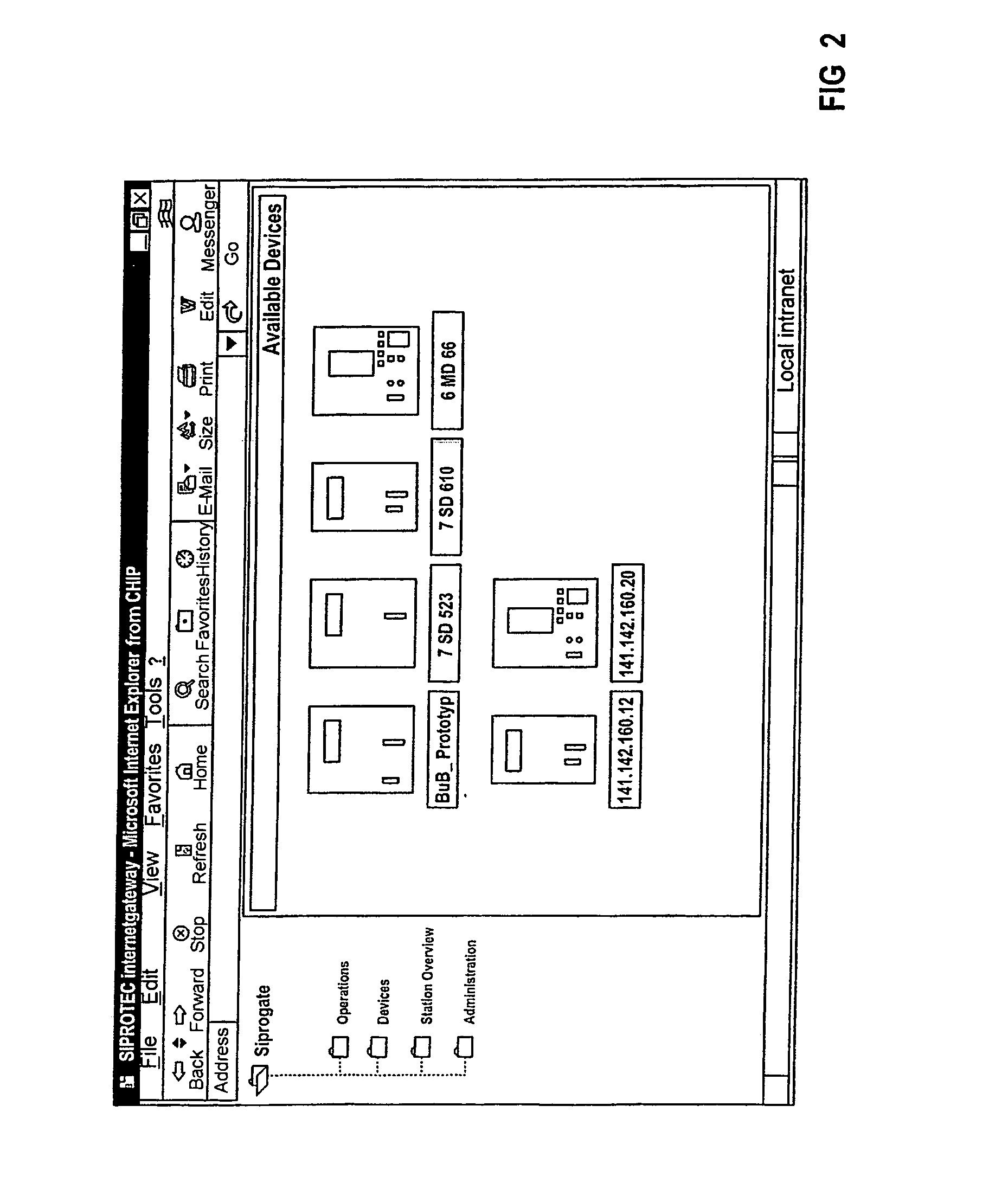

Method for operating and observing field devices

InactiveUS7072987B2Extends application optionImprove operational convenienceComputer controlSimulator controlData packUser device

The invention relates to a method for operating a proxy server device (1) connected to a field device (FG1–FGN), in addition to a proxy server device. The proxy server device can be connected to the field device and a user device (N1–NN) in order to respectively exchange electronic data in order to monitor and / or operate the field device. The electronic data consists of static data which is transmitted according to a first protocol standard and dynamic data which is transmitted according to a second protocol standard.

Owner:SIEMENS AG

Method for selecting functional icons on touch screen

InactiveUS20110138275A1Improve operational convenienceInput/output for user-computer interactionGraph readingTouchscreenElectronic equipment

A method for selecting functional icons is provided for use with an electronic device having a touch screen. A plurality of functional icons are shown on the touch screen, in which each functional icon represents an executable function of the electronic device. The method comprises the steps of: when the touch screen is touched, selecting a functional icon corresponding to the touched position, and showing an enlarged image corresponding to that selected functional icon; if the touched position is moved, selecting a new functional icon according to the vector of movement of the touched position, and showing an enlarged image corresponding to the newly selected functional icon; and if the touched position is relieved, activating the executable function represented by the functional icon corresponding to the enlarged image shown on the touch screen.

Owner:TELEPAQ TECH

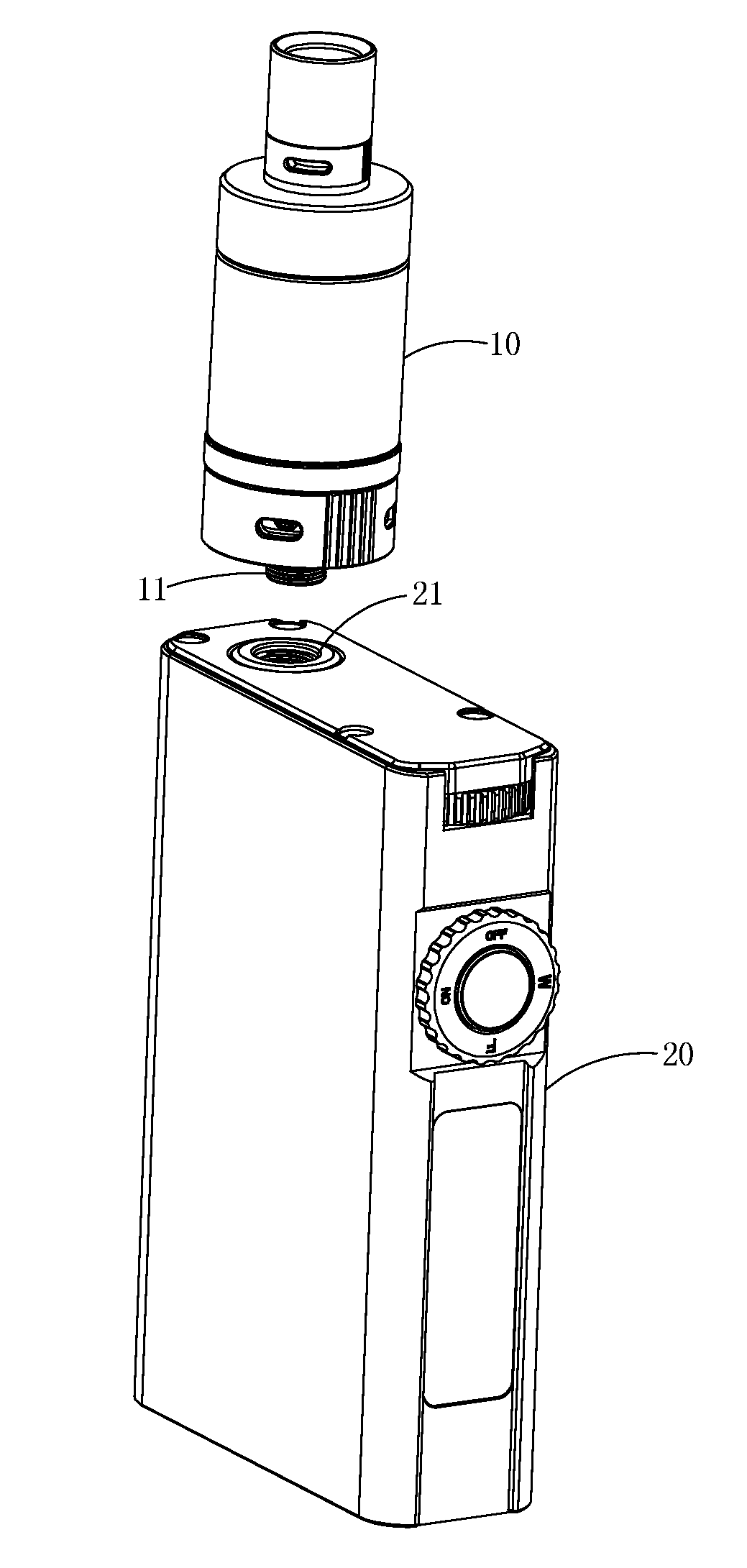

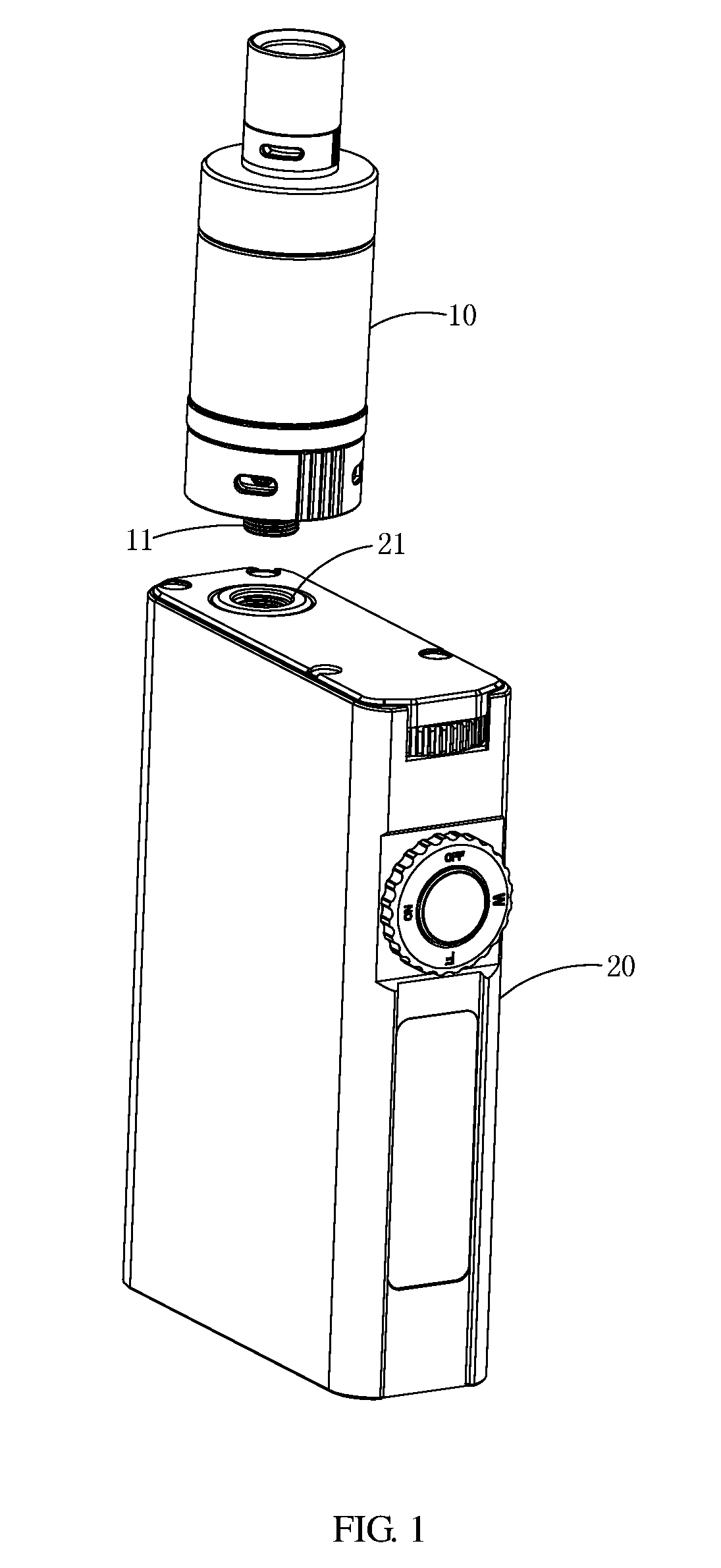

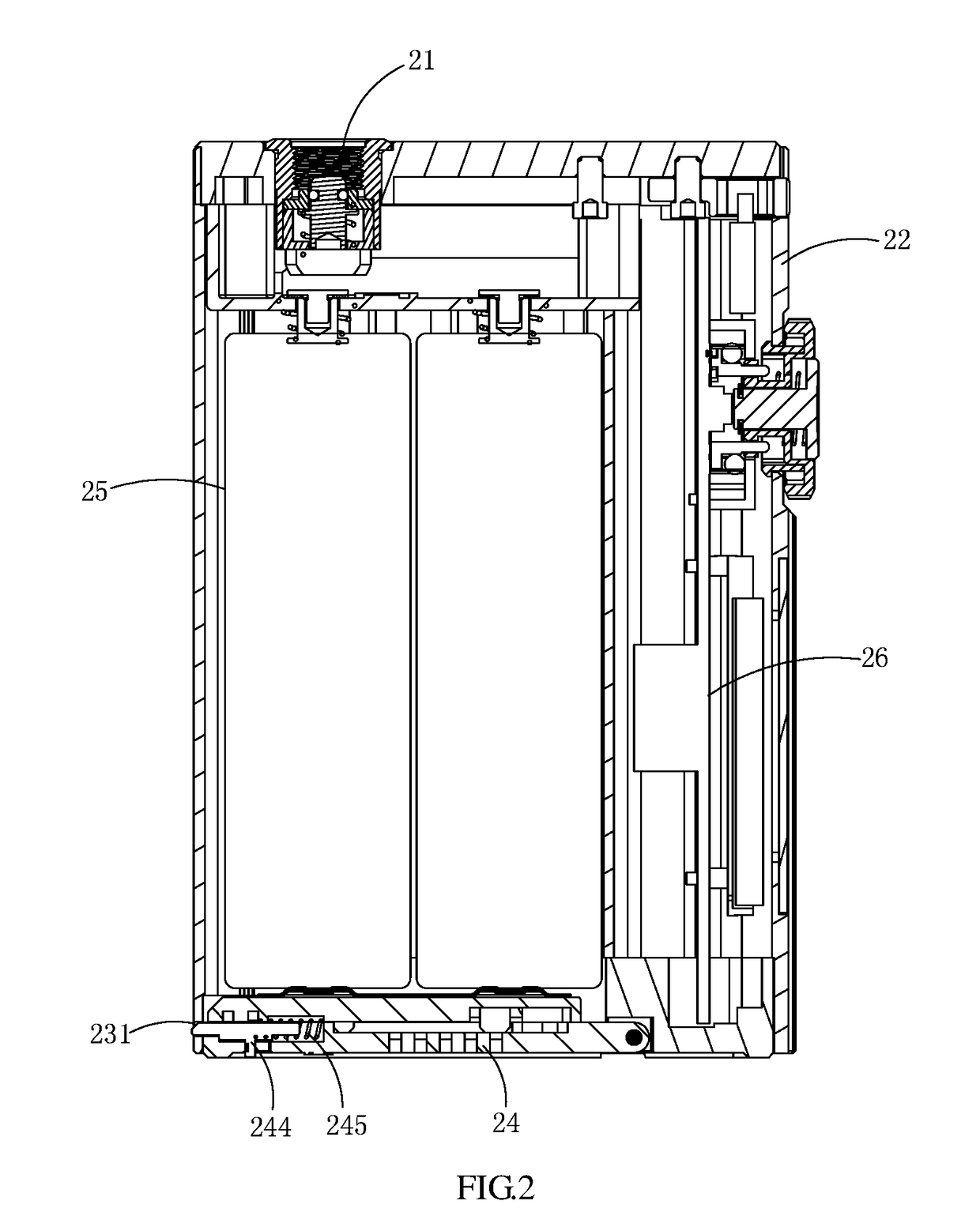

Power supply device for electronic atomizer

InactiveUS20170079327A1Improve technical effectImprove operational convenienceElectric heatingTobacco devicesMicrocontrollerElectricity

Disclosed is a power supply device for electronic atomizer, which includes a housing having a battery compartment formed therein, at least a battery installed in the battery compartment and a control circuit having an input side electrically connected with the battery and an output side electrically connected with an output electrode terminal. The control circuit includes a microcontroller unit, a mode selection module connected with the microcontroller unit for selecting working mode of the electronic atomizer, a regulation module connected with the microcontroller unit for regulating working parameter of the electronic atomizer and a start button connected with the microcontroller unit for controlling whether the electronic atomizer starts up. The mode selection module is a multi-position switch and the microcontroller unit is able to being triggered to start corresponding working modes by switching the multi-position switch to be different positions. The present invention has the advantage of convenient to use.

Owner:SHENZHEN JIESHIBO TECH

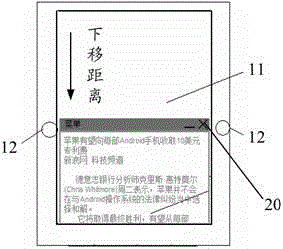

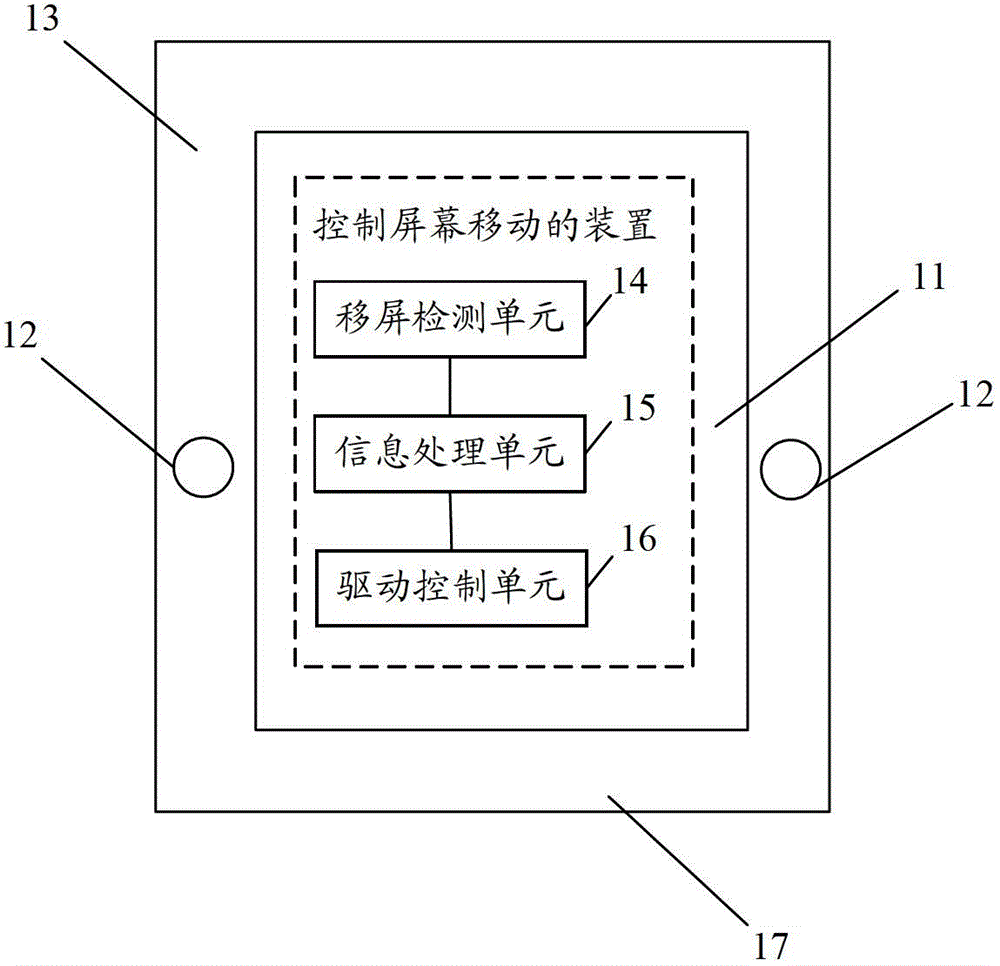

Method and device for controlling screen movement, and terminal

ActiveCN102722280AImprove operational convenienceEasy to touchInput/output processes for data processingSize increaseComputer graphics (images)

The invention provides a method and a device for controlling screen movement and a terminal. The method comprises the steps of: acquiring user screen movement instructions, adjusting display coordinate information of a terminal application on a display screen to move a corresponding display position of the display coordinate information into a contactable region according to the screen movement instructions, making the terminal application be displayed at a corresponding display position of the display coordinate information after adjustment, and adjusting touch induction coordinate information of a corresponding contactable region of the display coordinate information based on the screen mobile instructions to make the contactable region after movement and a display coordinate have a same position, wherein the display coordinate locates on the one hand held display screen in a finger contactable region. According to the invention, one hand operation convenience of the terminal touch screen is improved greatly after terminal touch screen size increases.

Owner:BEIJING ZHIGU TECH SERVICE

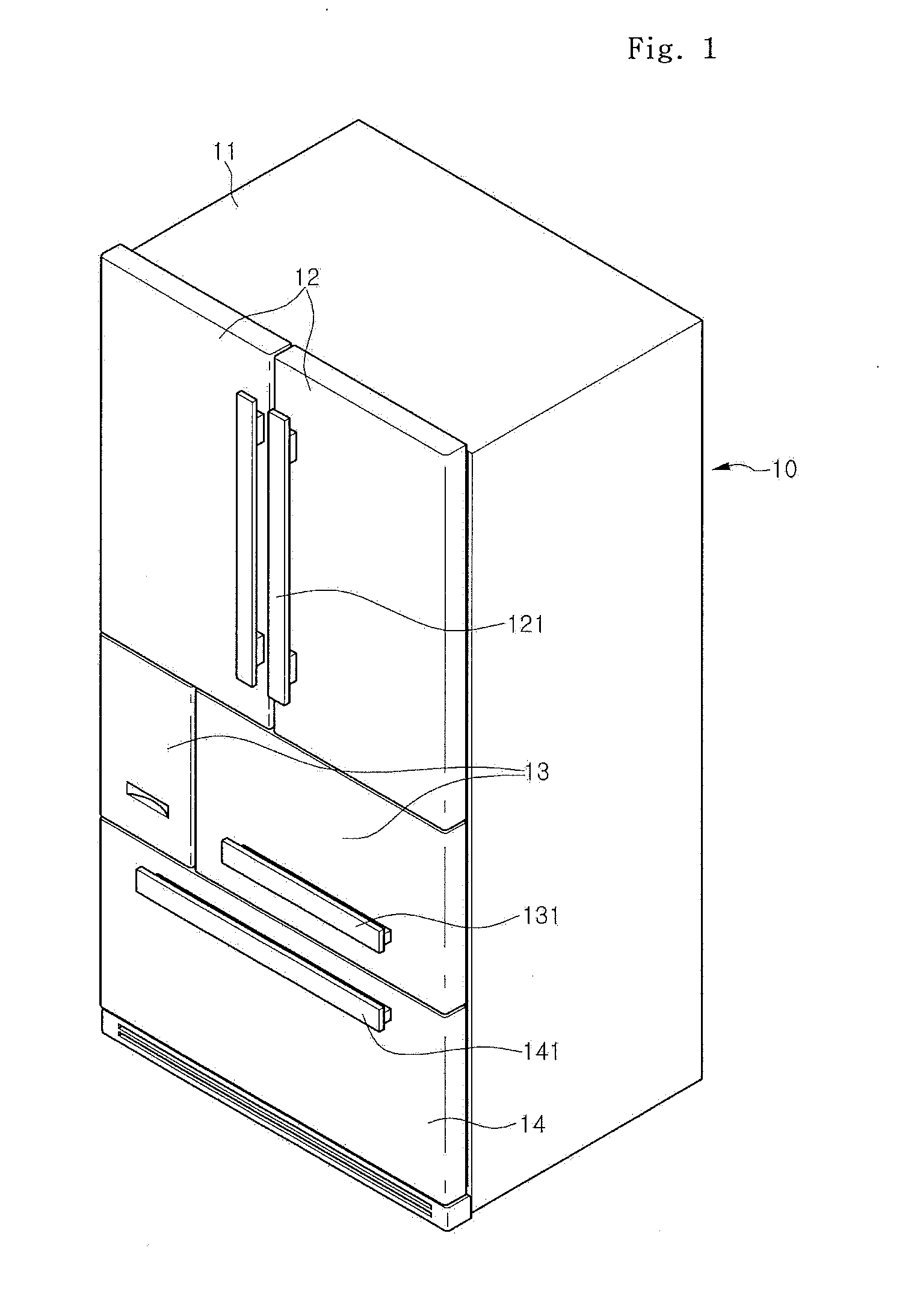

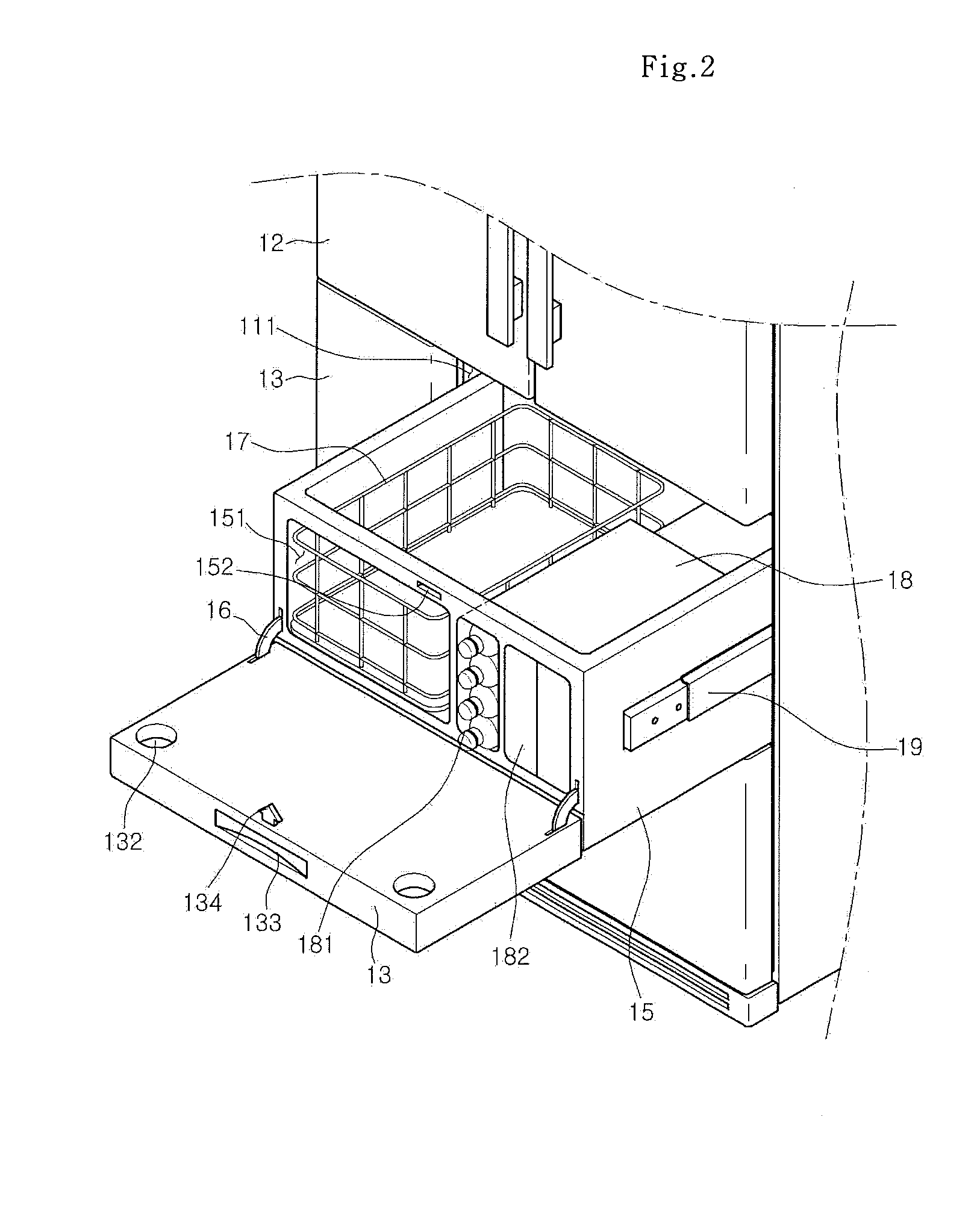

Refrigerator

ActiveUS20120060544A1Easily draw outImprove ease of useLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

Owner:LG ELECTRONICS INC

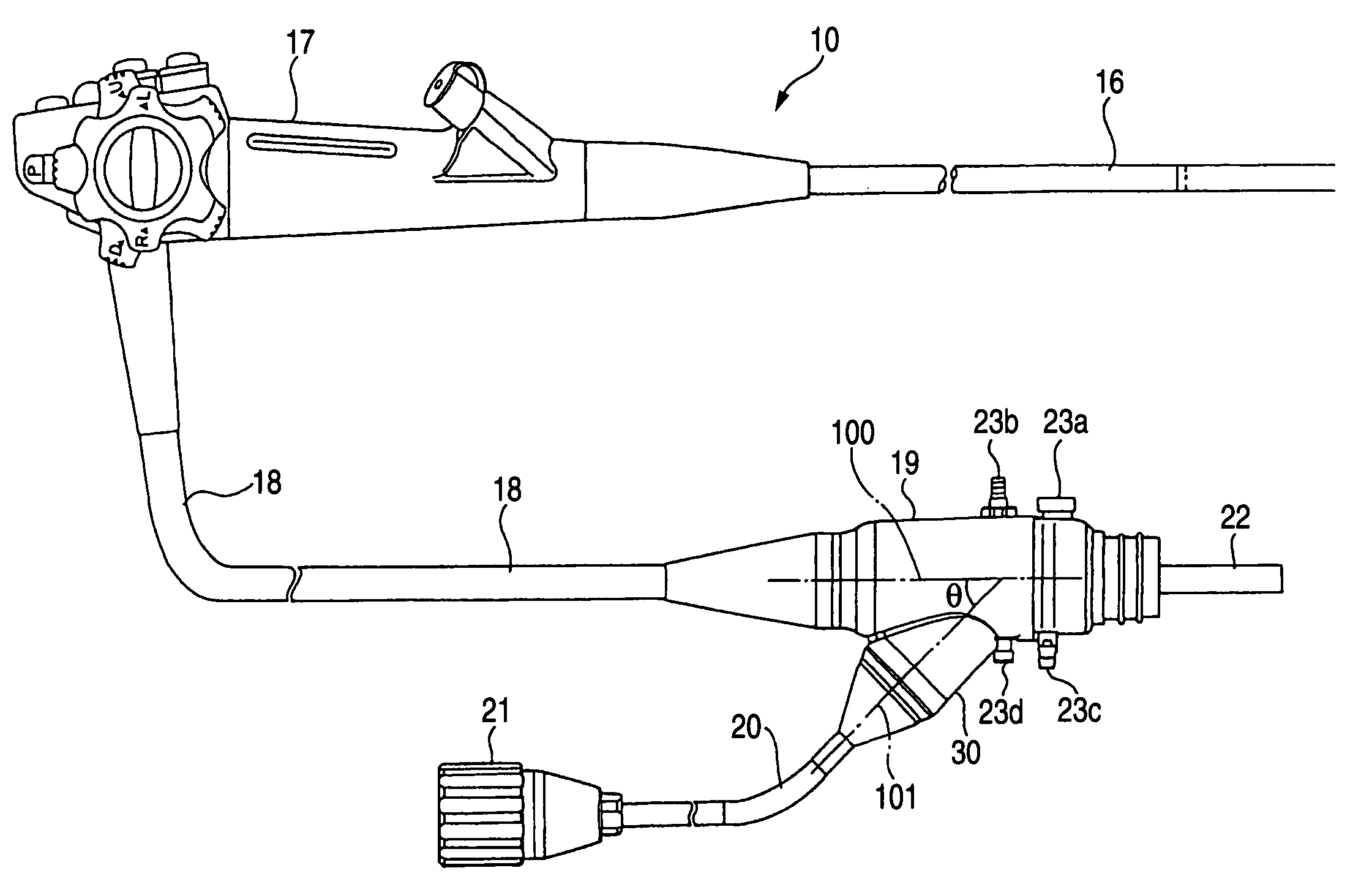

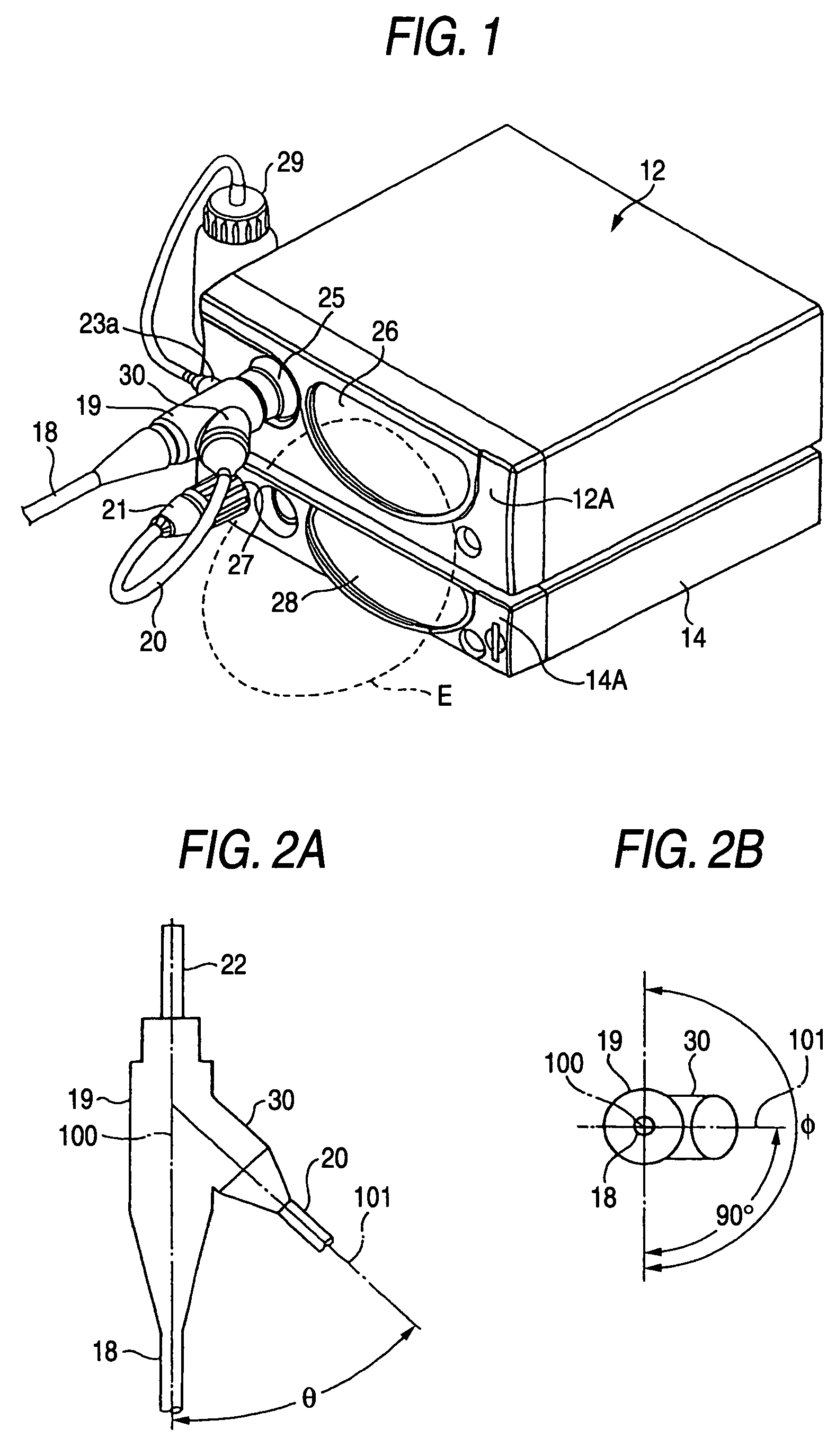

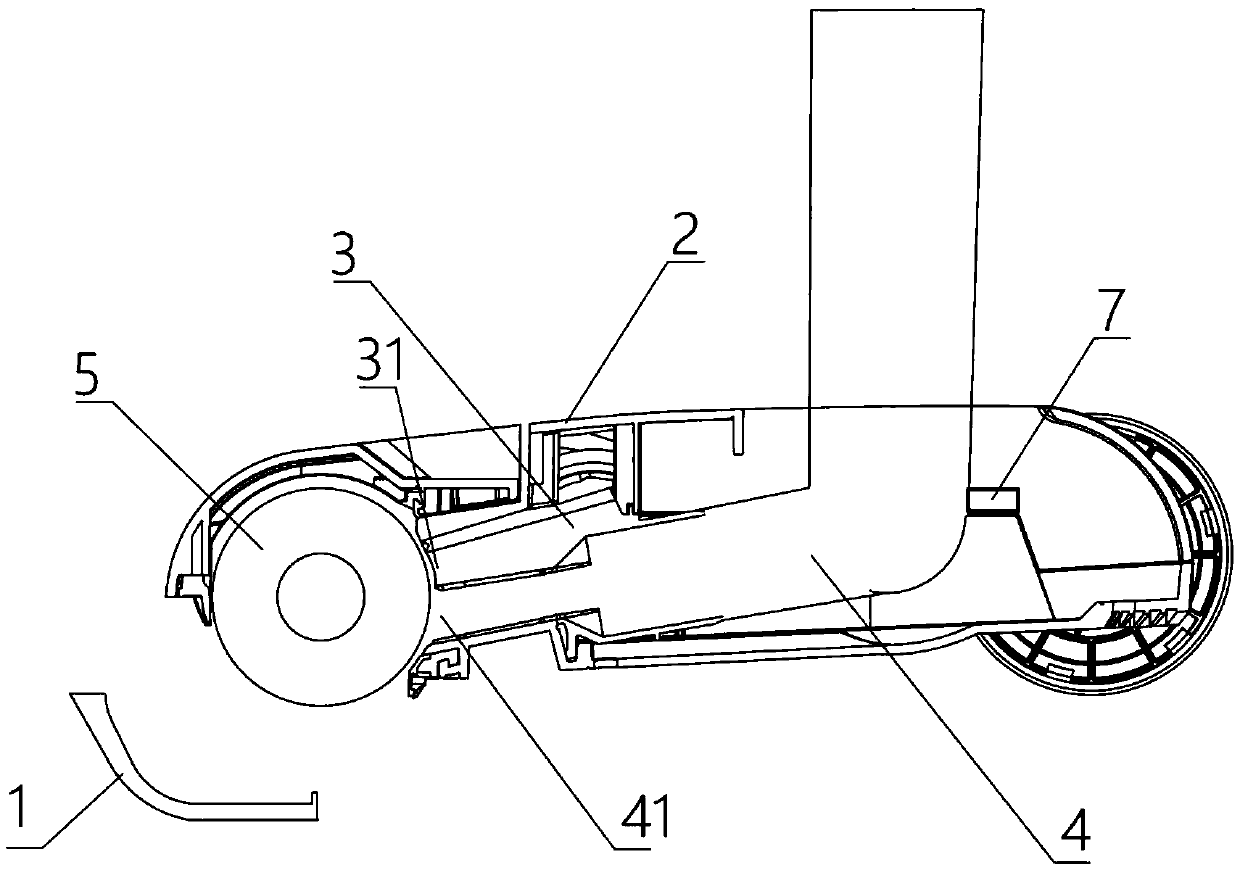

Endoscope connector device, endoscope cable lead-out unit and endoscope device

InactiveUS7695429B2Easy to useImprove operational convenienceCoupling device detailsSurgeryLight guideEngineering

An endoscope connector device comprises: a first cable of an endoscope, including a light guide for supplying illumination light and an electric wire for obtaining video signals from an image pickup device; a light guide connector connected to the first cable; and a second cable of the endoscope, including the electric wire led out of the light guide connector, wherein the second cable is attached diagonally from the light guide connector at an angle θ within a range of 0°<θ<90° from a first cable side of an axial direction of the first cable.

Owner:FUJI PHOTO OPTICAL CO LTD

Biaxially oriented polypropylene film

InactiveUS20040053064A1Low heat shrinkageGood dimensional stabilityFixed capacitor dielectricSynthetic resin layered productsFiberHigh stiffness

A biaxially stretched polypropylene film of the present invention has high stiffness in the film longitudinal direction and can be manufactured by a conventional longitudinal-transverse sequential biaxial stretching method, since the biaxially stretched polypropylene film comprises a polypropylene which comprises a polypropylene having controlled specific values of a melt strength (MS) and a melt flow rate (MFR) at 230° C. or consists of a polypropylene having controlled specific values of a melt strength (MS) and a melt flow rate (MFR) at 230° C. and / or a Trouton ratio of the polypropylene is controlled at a specific value, moreover, the biaxially stretched polypropylene film contains regulated longitudinal fibrils.

Owner:TORAY IND INC

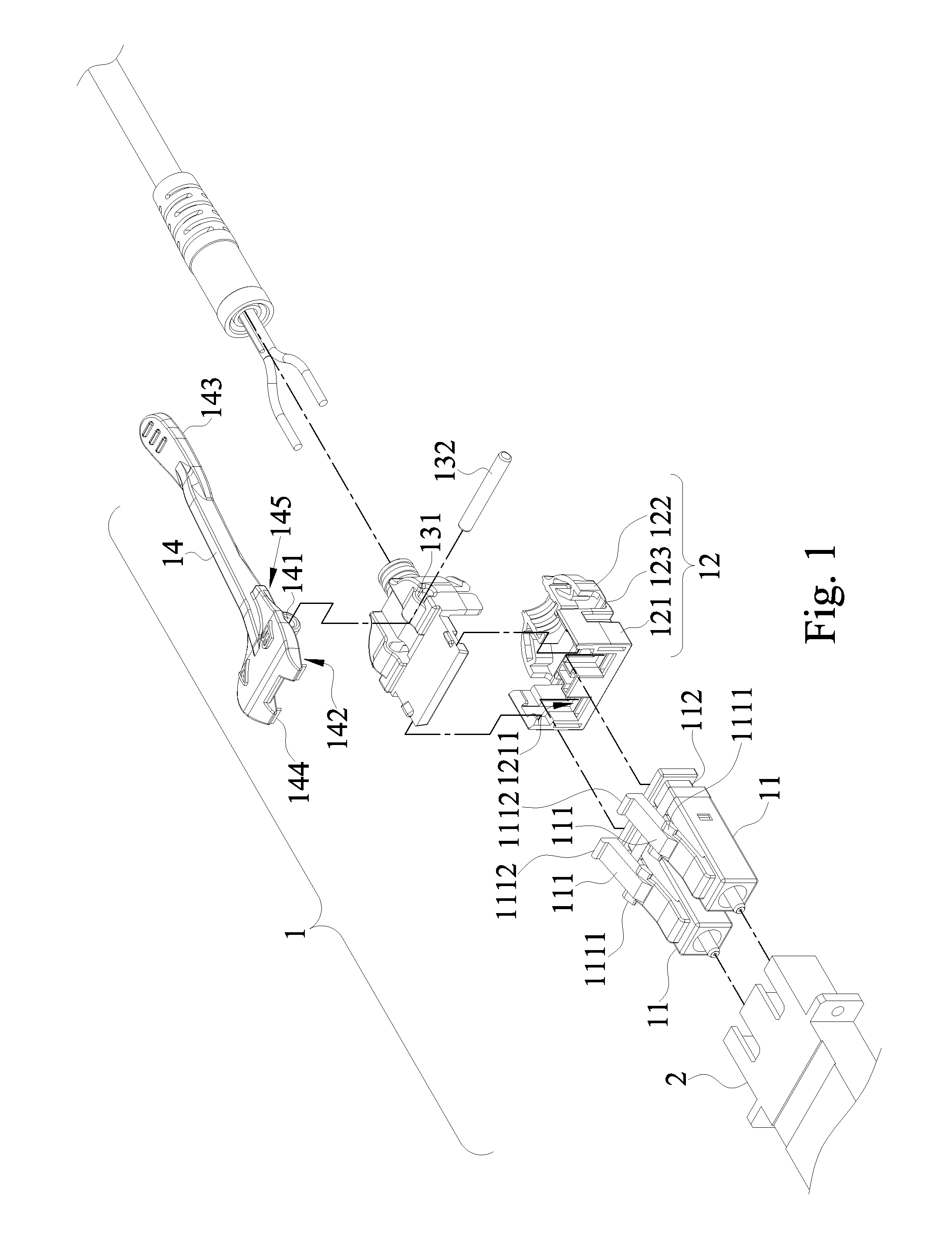

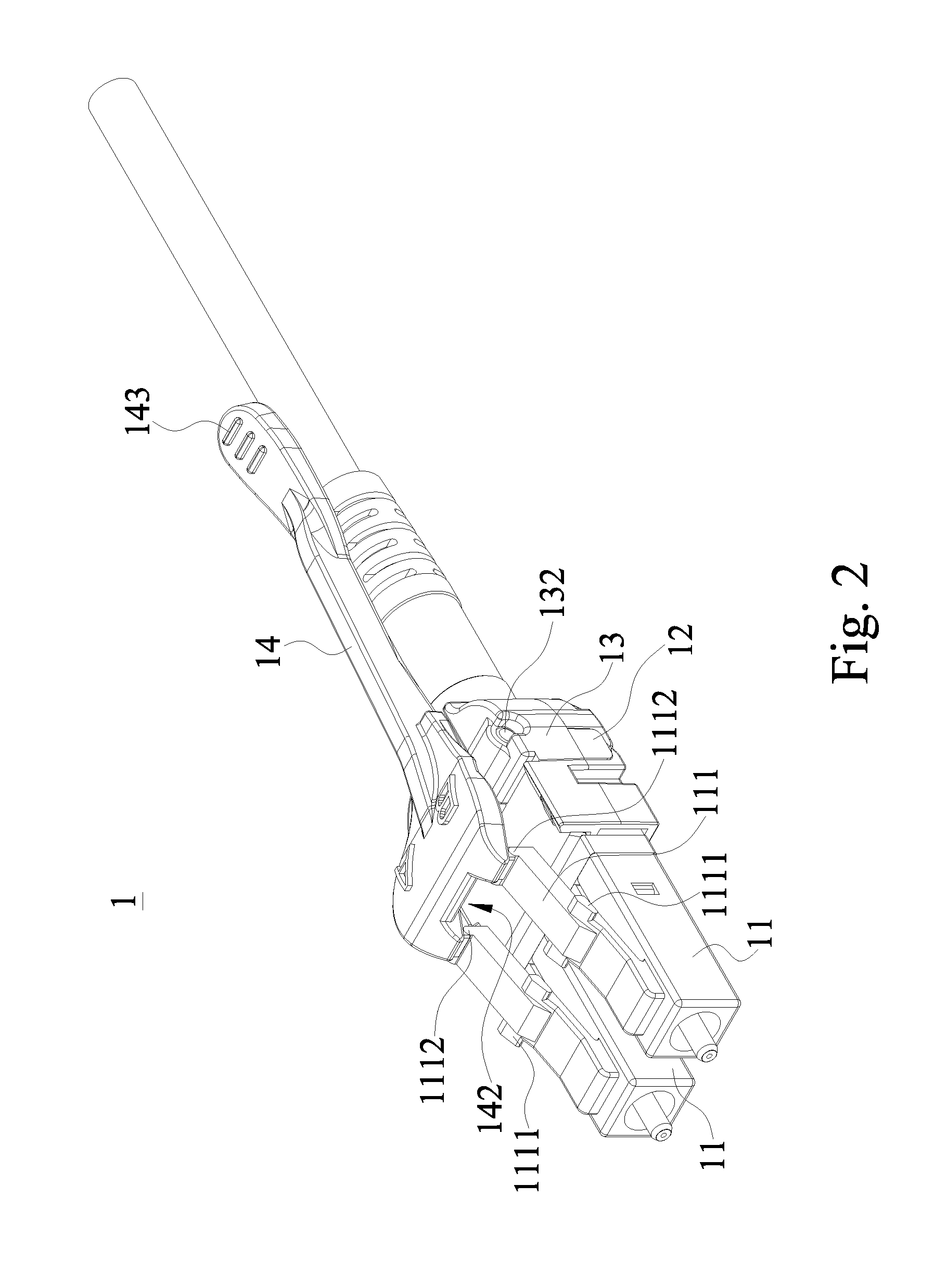

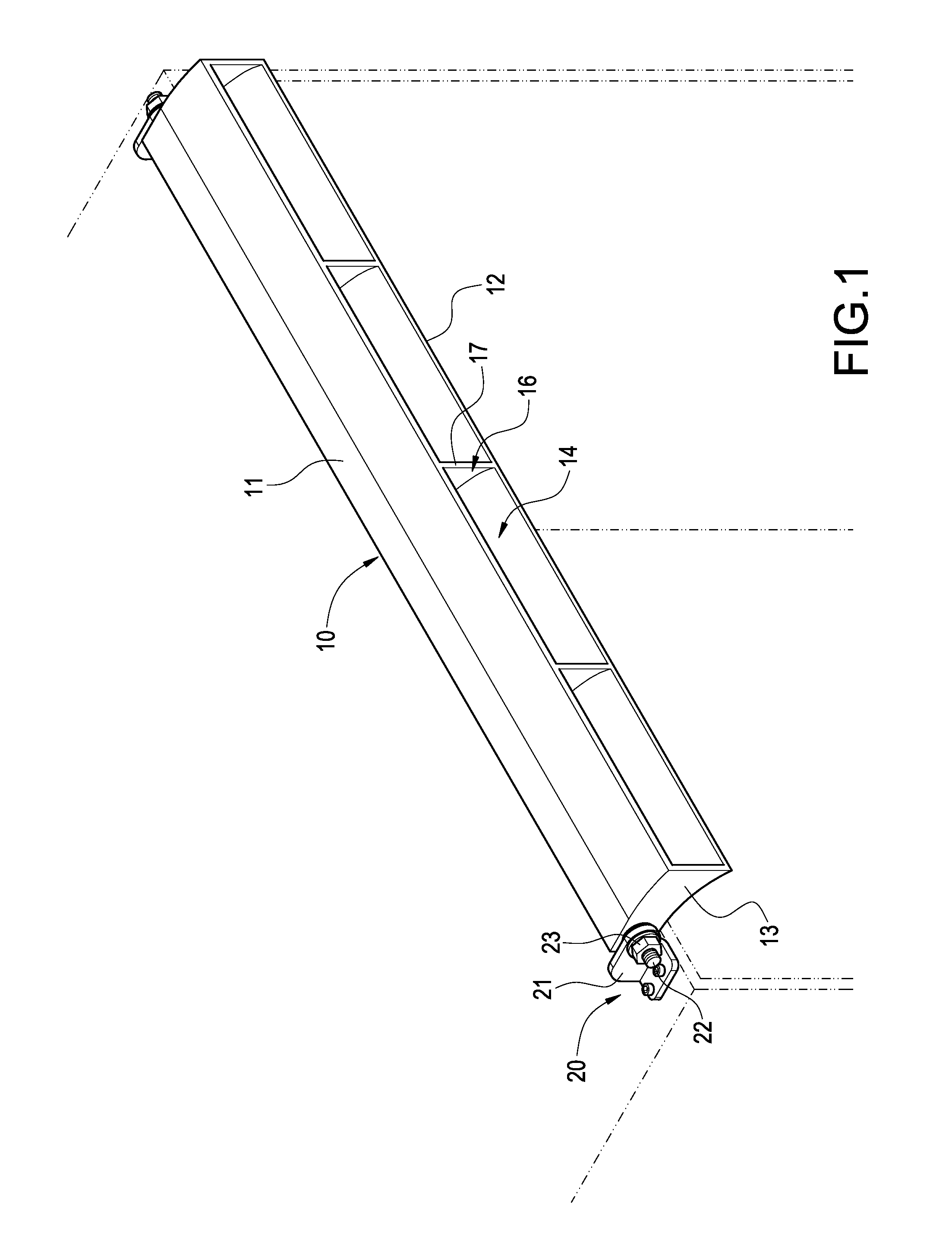

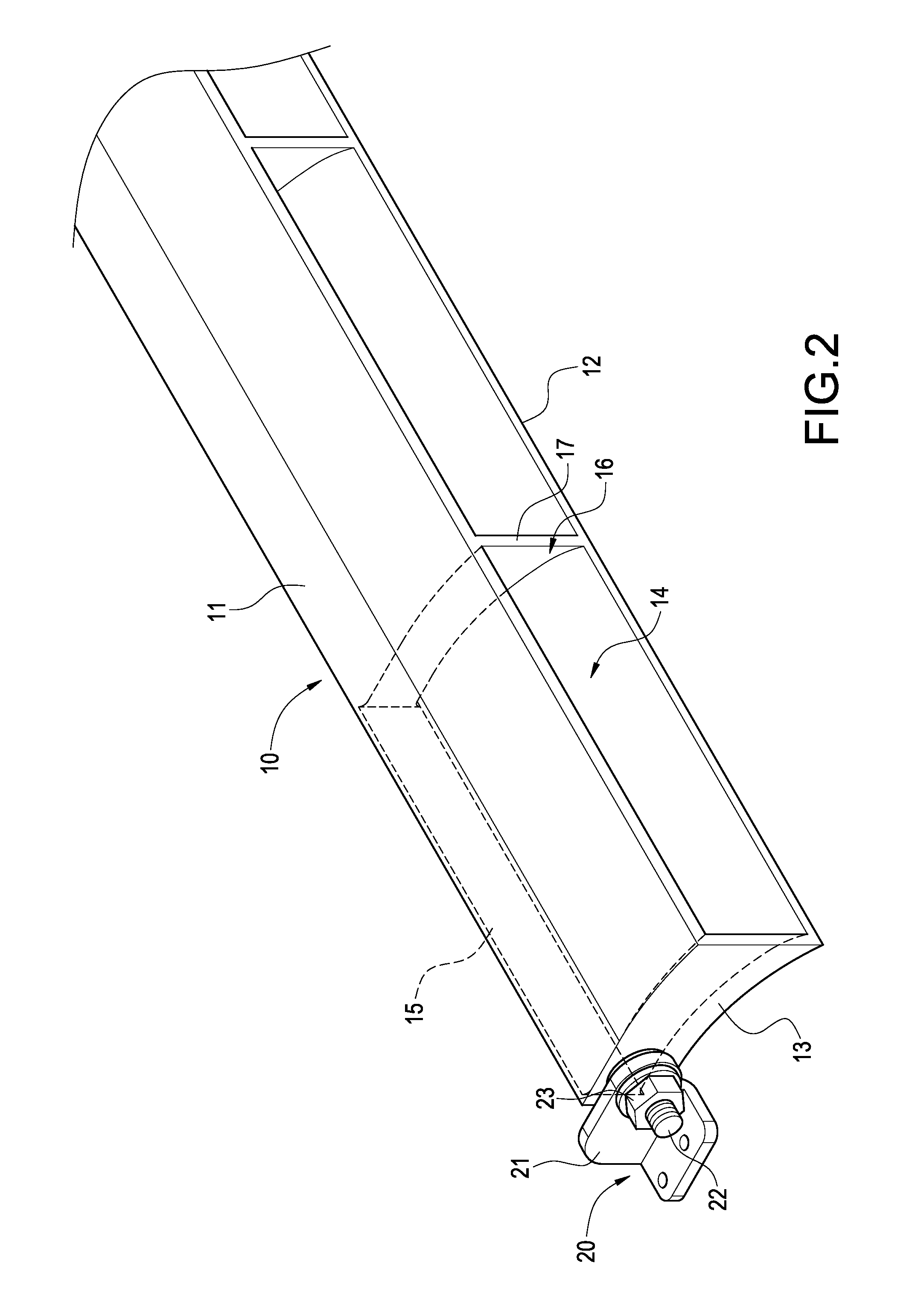

Duplex fiber optic connector plug

InactiveUS20150212282A1Improve operational convenienceEasy to operateCoupling light guidesFiberEngineering

A duplex fiber optic connector plug includes at least one fiber optic connector, a first casing, a second casing and a release lever. The release lever is axially coupled to a surface of the first casing and has an end coupled to a release bracket of the fiber optic connector to form a seesaw design. During operation, the release lever is compressed by the force of the finger, so that an end of the release lever is elevated, and the other end compresses the release bracket downward to release from a fiber optic socket, so as to provide an intuitively convenient operation and improve the convenience of use.

Owner:JYH ENG TECH

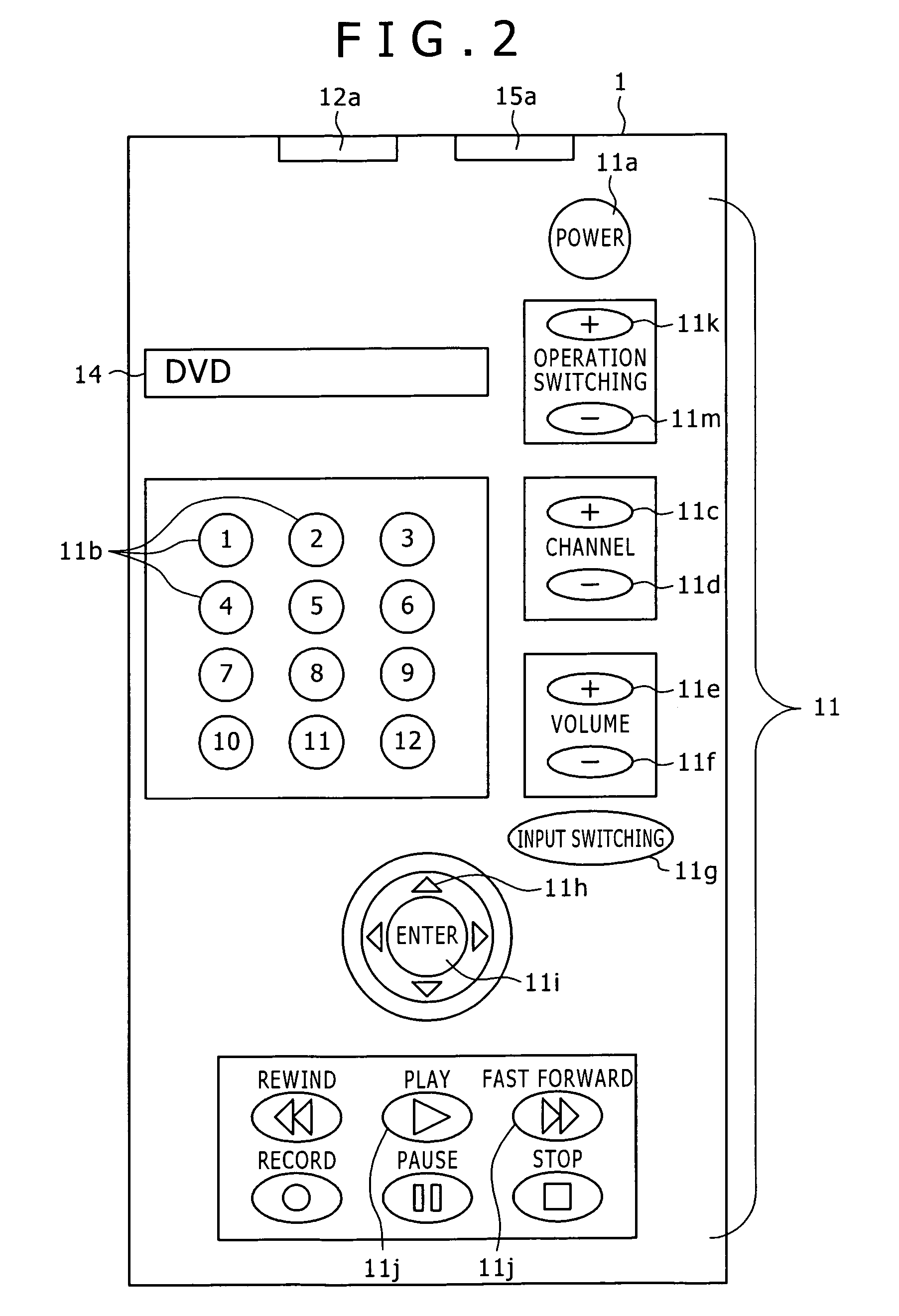

Remote controller, equipment operation system, and remote control method

InactiveUS20060267726A1Improve operational convenienceTelevision system detailsElectric signal transmission systemsOperational systemControl objective

A remote controller having a plurality of keys arranged thereon, sending a remote control signal allocated to each of the keys upon being operated to thereby remotely control control-target equipment. The remote controller can send a remote control signal corresponded to each of the control-target equipment by mode switching and allows a remote control of selection in which specific equipment out of the control-target equipment can select a signal from the other control-target equipment. The remote controller includes an input selection key for directing the selection on the one specific equipment; a receiver receiving a connected equipment signal; a controller generating and sending a remote control signal corresponding to an operation of the key, and effecting the mode switching based on the connected equipment signal, thereby selecting control-target equipment; a transmitter sending the remote control signal; and a display displaying information of the selected control-target equipment.

Owner:SONY CORP

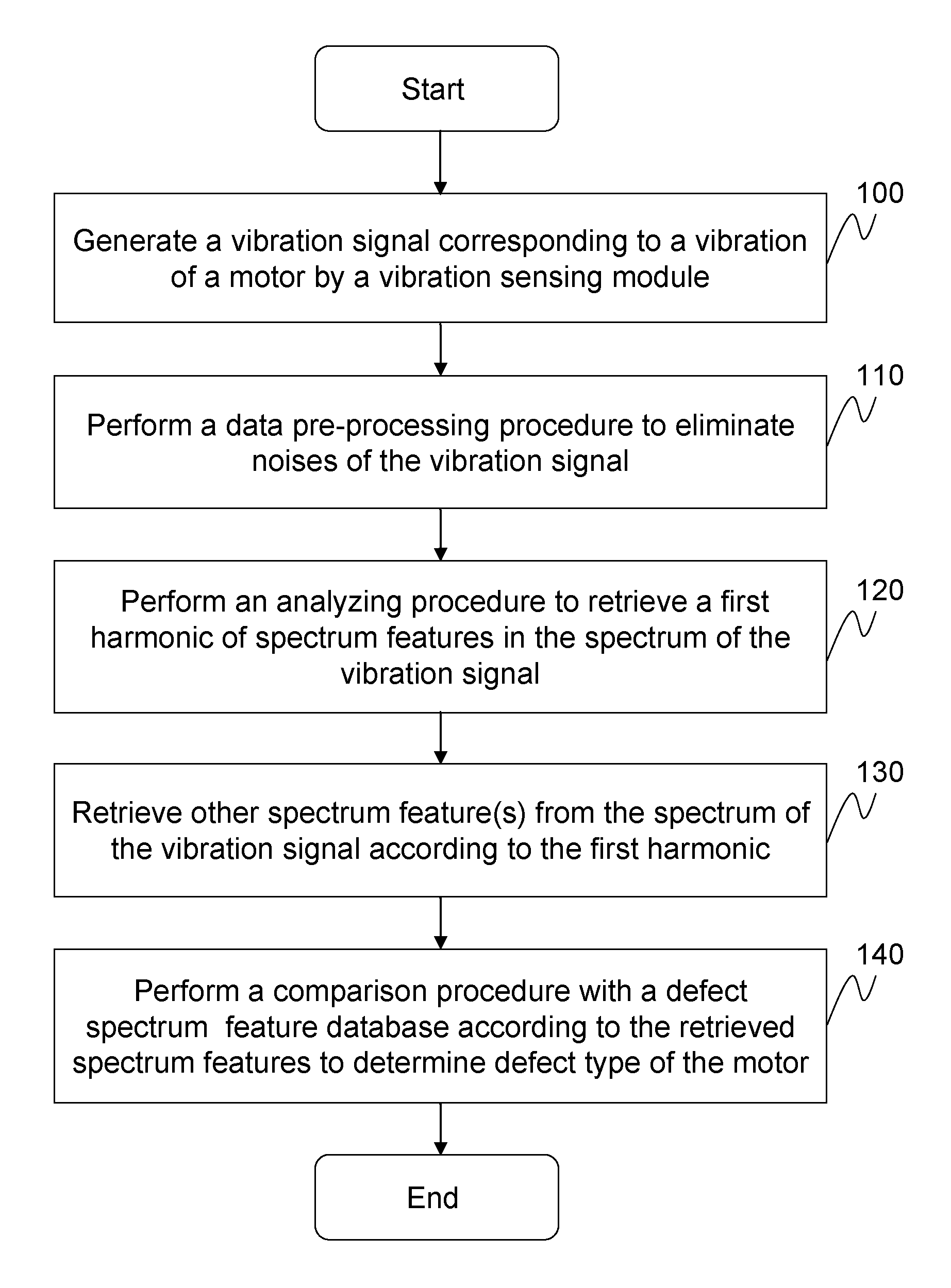

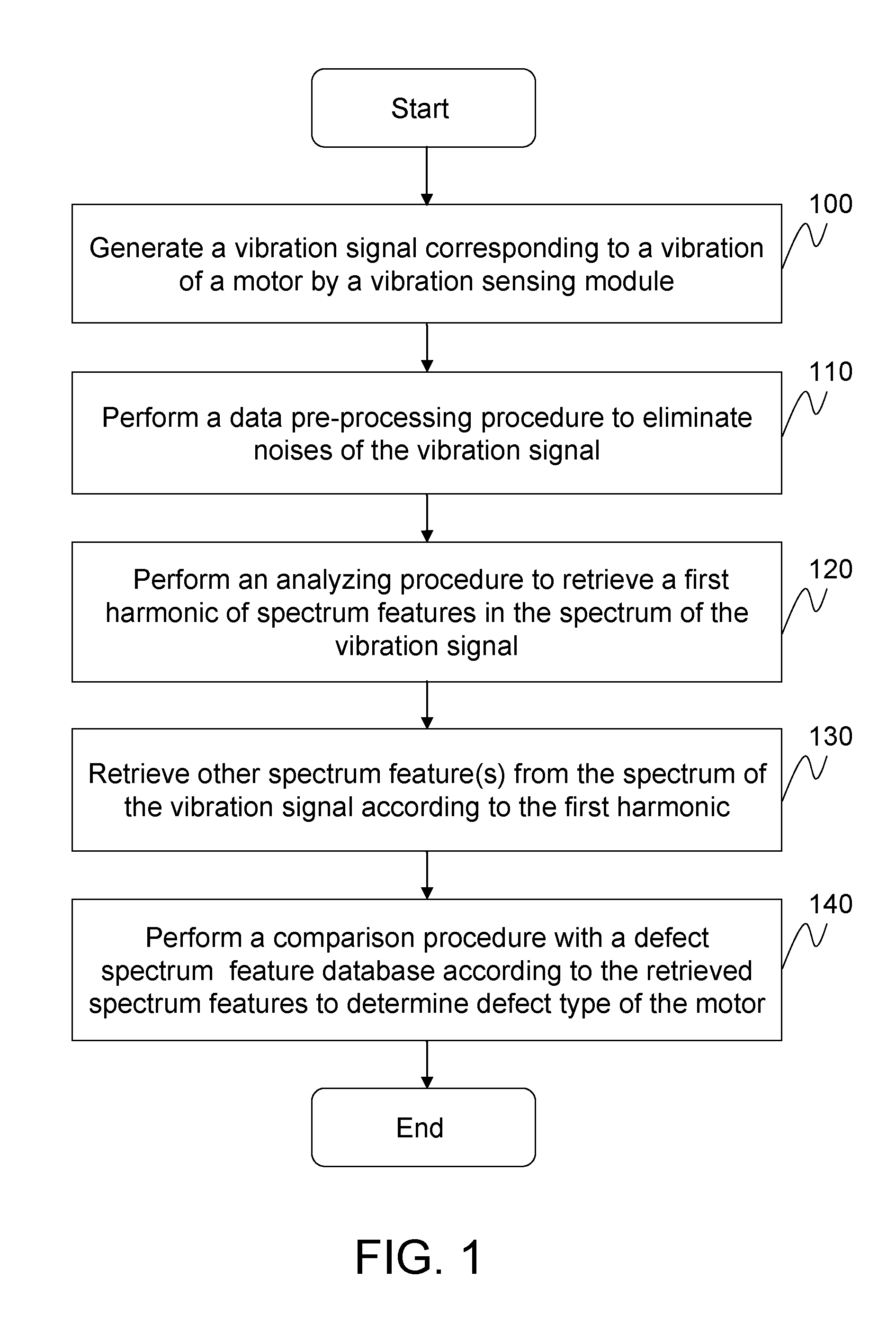

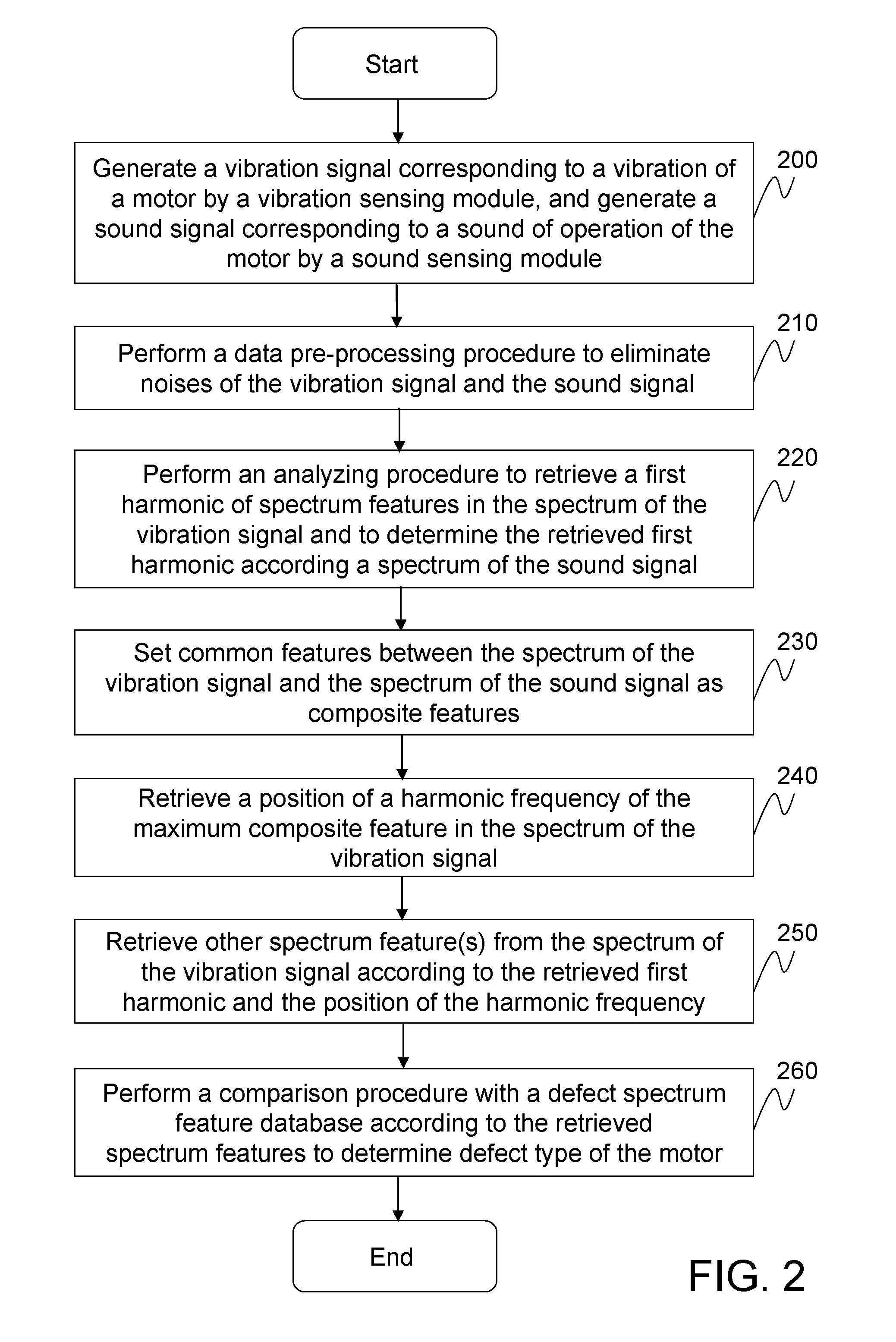

Diagnosis method of defects in a motor and diagnosis device thereof

ActiveUS20100145639A1High diagnosis speedLow costVibration measurement in solidsMaterial analysis using sonic/ultrasonic/infrasonic wavesEngineeringLight spectrum

A diagnosis method of defects in a motor and a diagnosis device thereof are described. A vibration sensing module can generate a vibration signal corresponding to a vibration of a motor during operation of the motor. Then, a data pre-processing procedure is performed to eliminate noises of the vibration signal. After the data pre-processing procedure, an analyzing procedure is performed to determine a first harmonic of spectrum features in the spectrum of the pre-processed vibration signal. And, other spectrum feature(s) is( / are) retrieved from the spectrum of the pre-processed vibration signal according to the first harmonic. Finally, a comparison procedure is performed with a defect spectrum feature database according to the retrieved spectrum features, so as to determine a defect type of the motor.

Owner:IND TECH RES INST

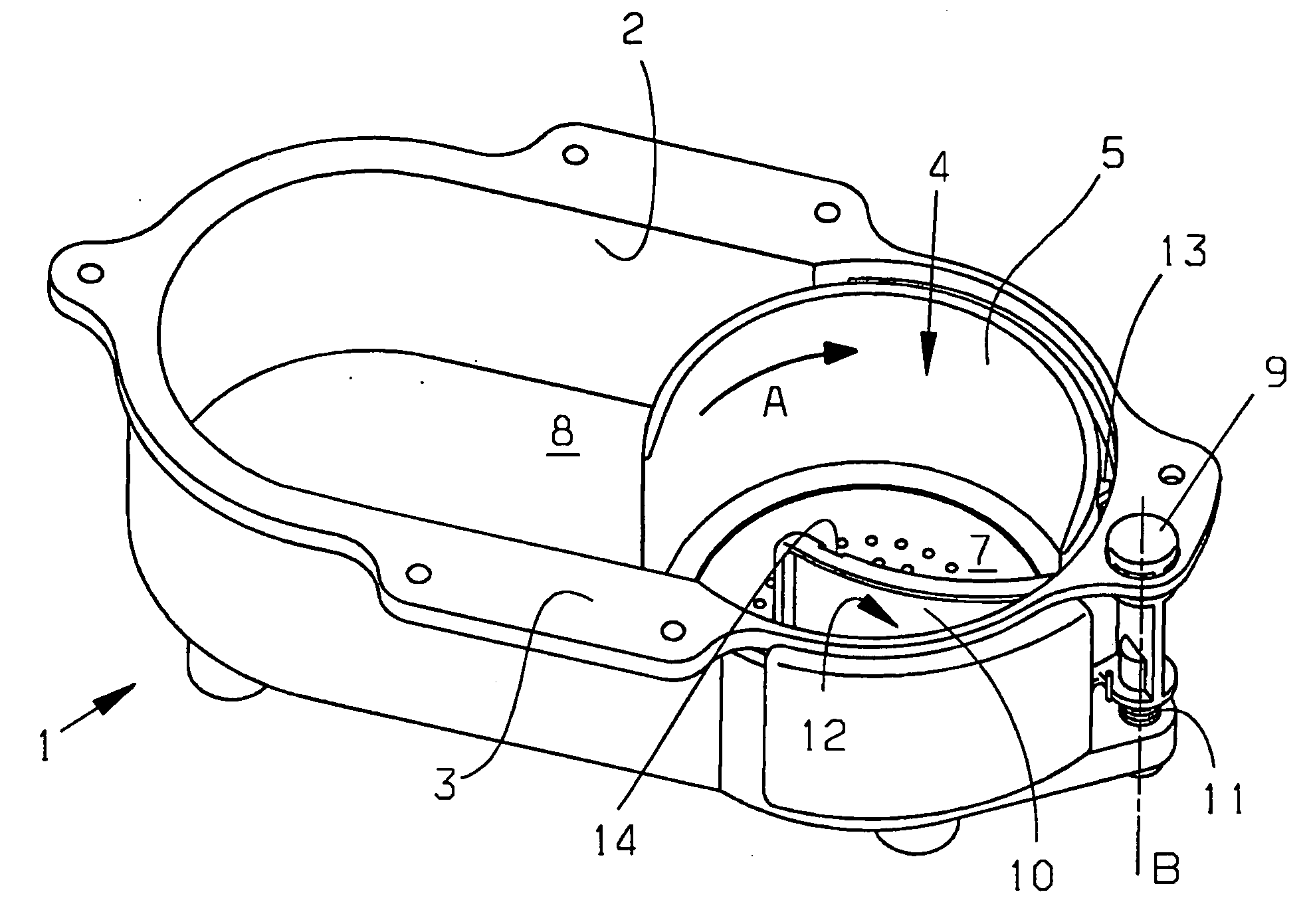

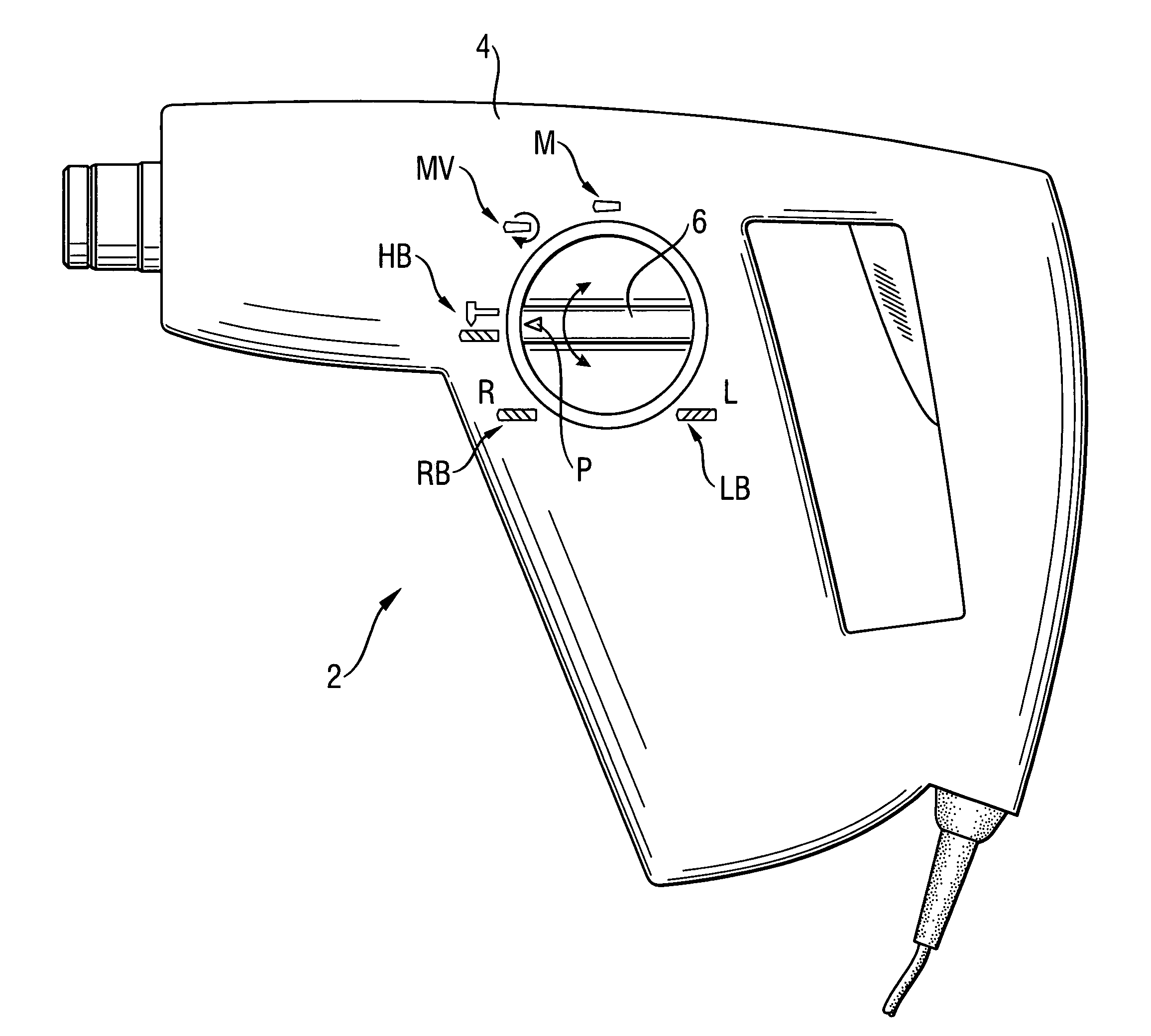

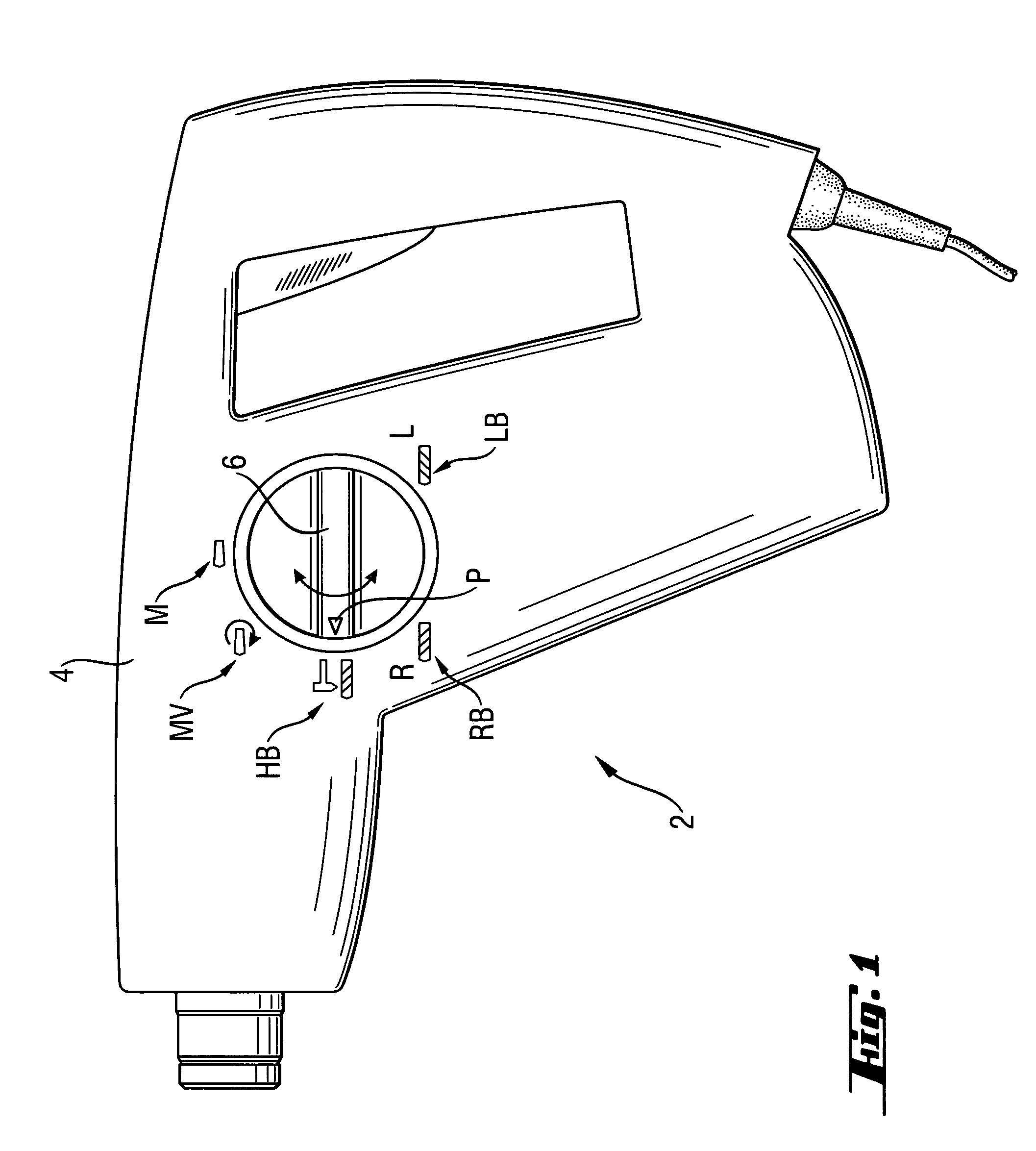

Hammer drill

ActiveUS20050224242A1Easy constructionReduce manufacturing costStapling toolsMechanical apparatusPinionClockwise

A hammer drill (2) includes a clockwise and counterclockwise driven tool spindle (28), a drive pinion (70) operatively connectable with the tool spindle (28) for transmitting a torque thereto, a separate control handle (6) for selecting one of the hammer drill functions including a pure drilling operation, a pure percussion operation, and a rotary-percussion operation), and a switching device (8) which is adjustable in accordance with a position of the control handle (6) and which is shiftable by the control handle (6) in a clockwise rotation position for effecting a pure drilling operation in a clockwise direction and in a counterclockwise rotation position for effecting a pure drilling operation in a counterclockwise direction.

Owner:HILTI AG

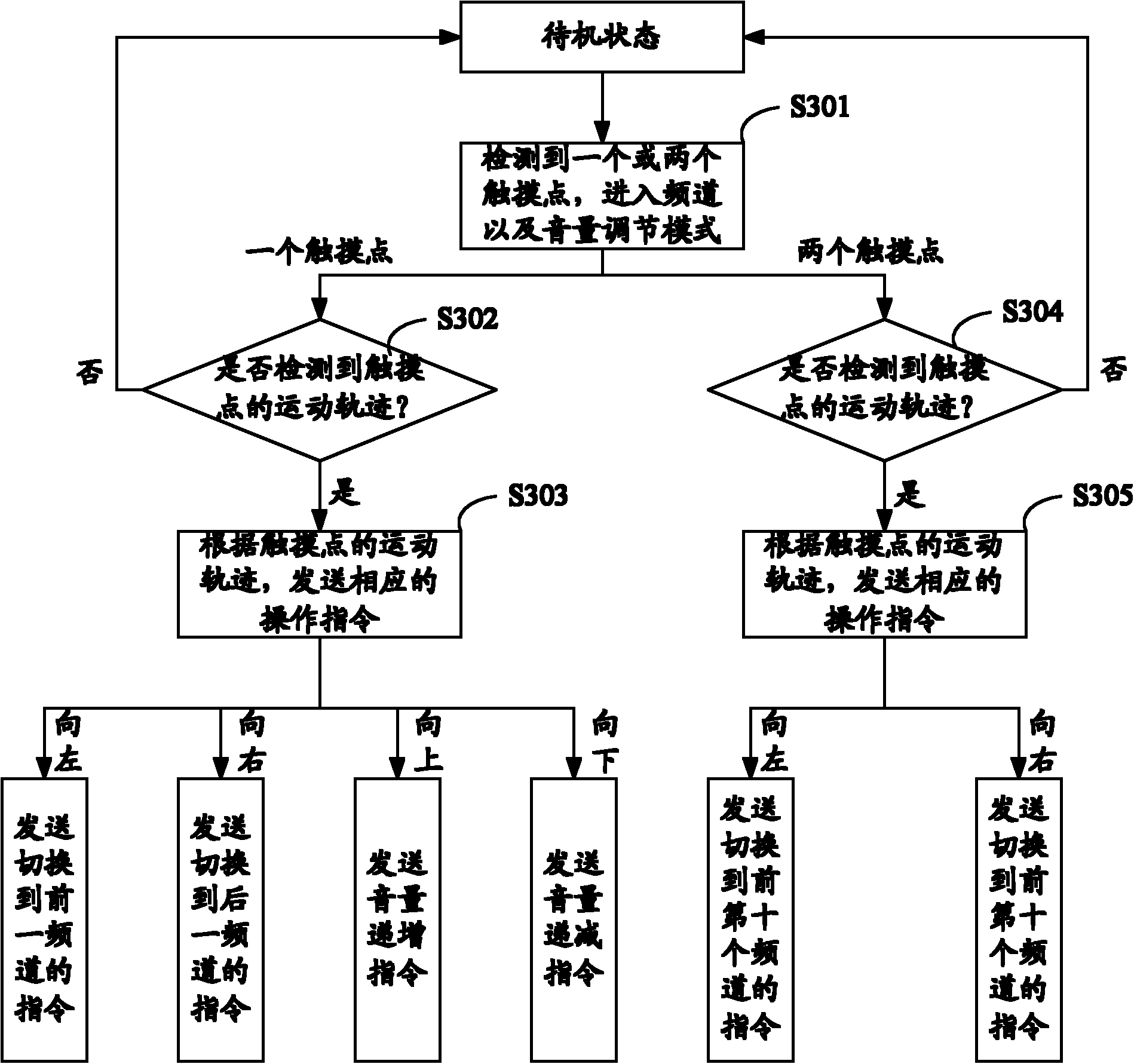

Television remote control method, device and system based on touchpad remote control

InactiveCN102279665AImprove experienceEasy to operateTelevision system detailsColor television detailsRemote controlTouchpad

The invention is applicable to the field of remote control technology, and provides a television remote control method, device and system based on touchpad remote control. The method comprises the following steps: detecting the number of touch points, and turning into a corresponding operation mode; in the current operation mode, detecting the motion track of the touch points; and sending a corresponding operation instruction to the television according to the motion track of the touch points. According to the invention, remote control on various functions of the television is realized by detecting the user operation on the touchpad based on a touchpad remote control adopting multi-point touch technology; compared with the traditional method for realizing remote control on television by use of different keys of the remote control, the method provided by the invention remarkably simplifies the operation steps, improves the operation convenience and enhances the user experience.

Owner:TCL CORPORATION

Display method and device for application icons and equipment

InactiveCN105718148AImprove experienceImprove operational convenienceInput/output processes for data processingTime efficientTerminal equipment

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

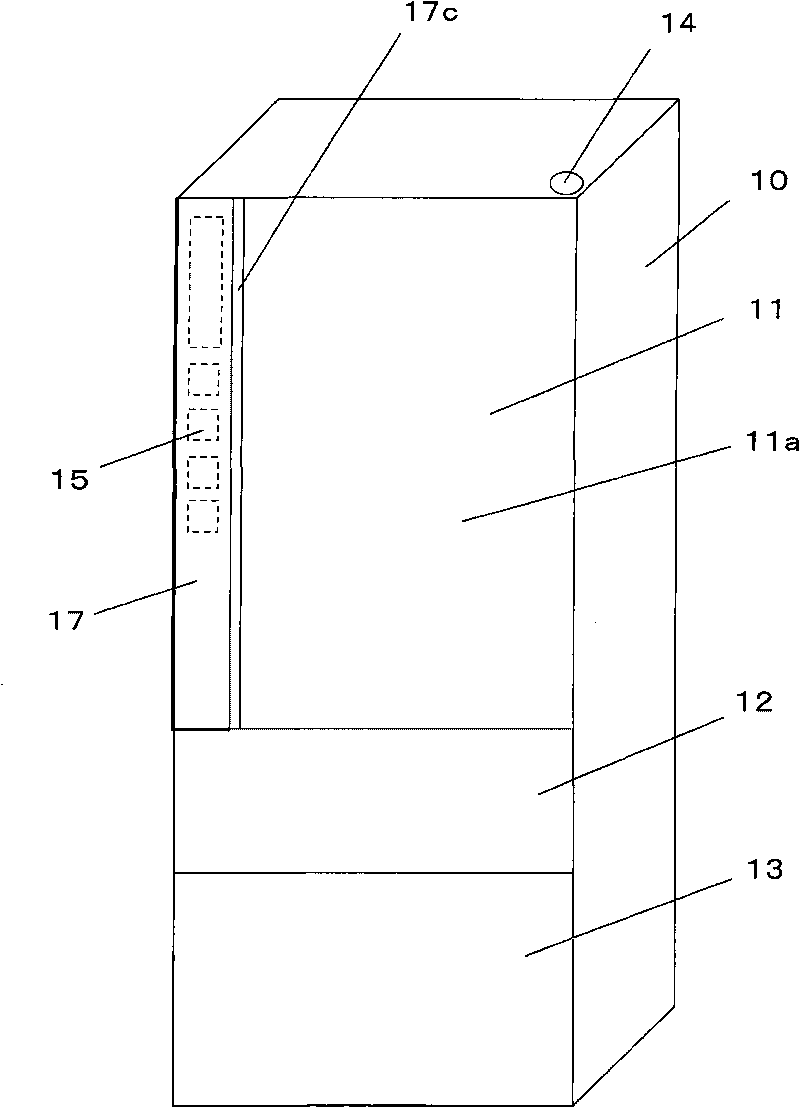

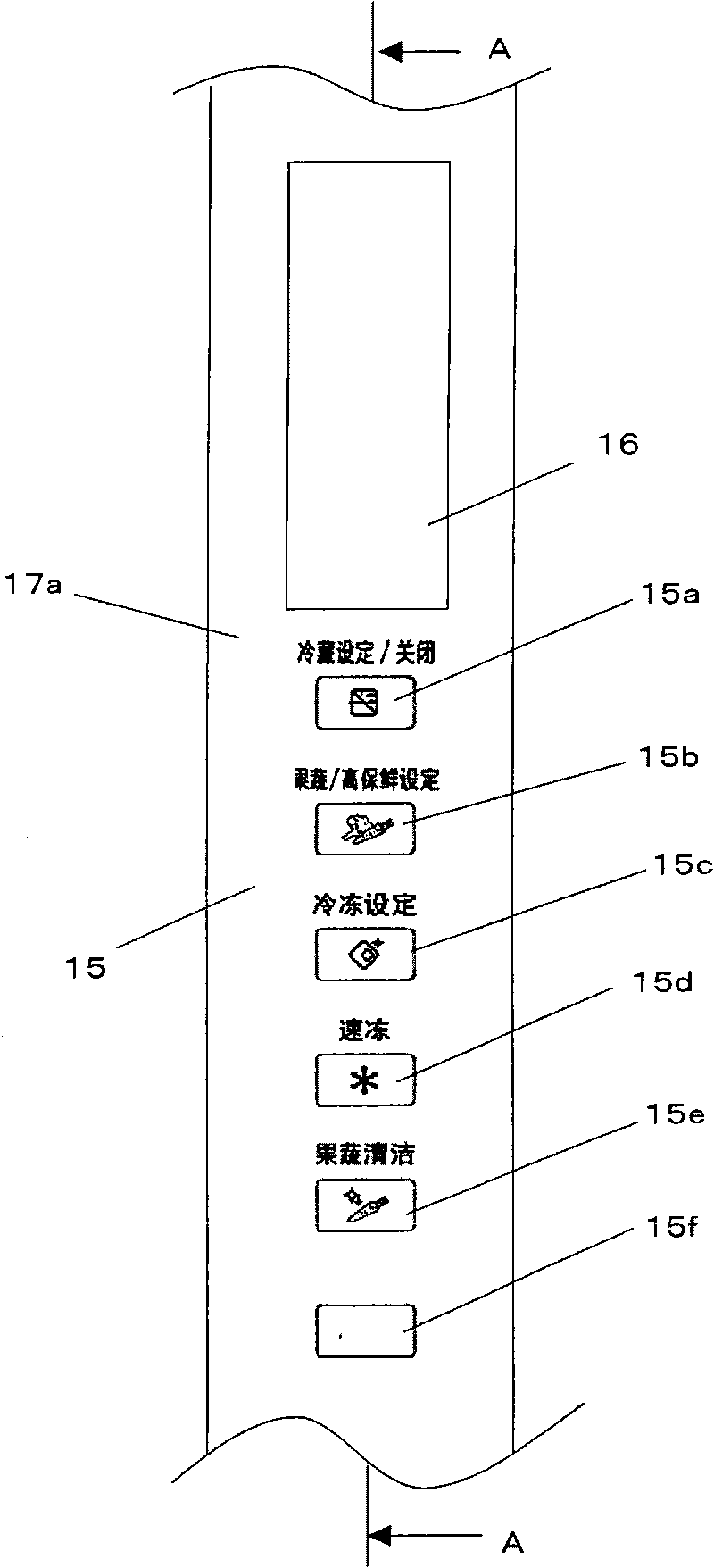

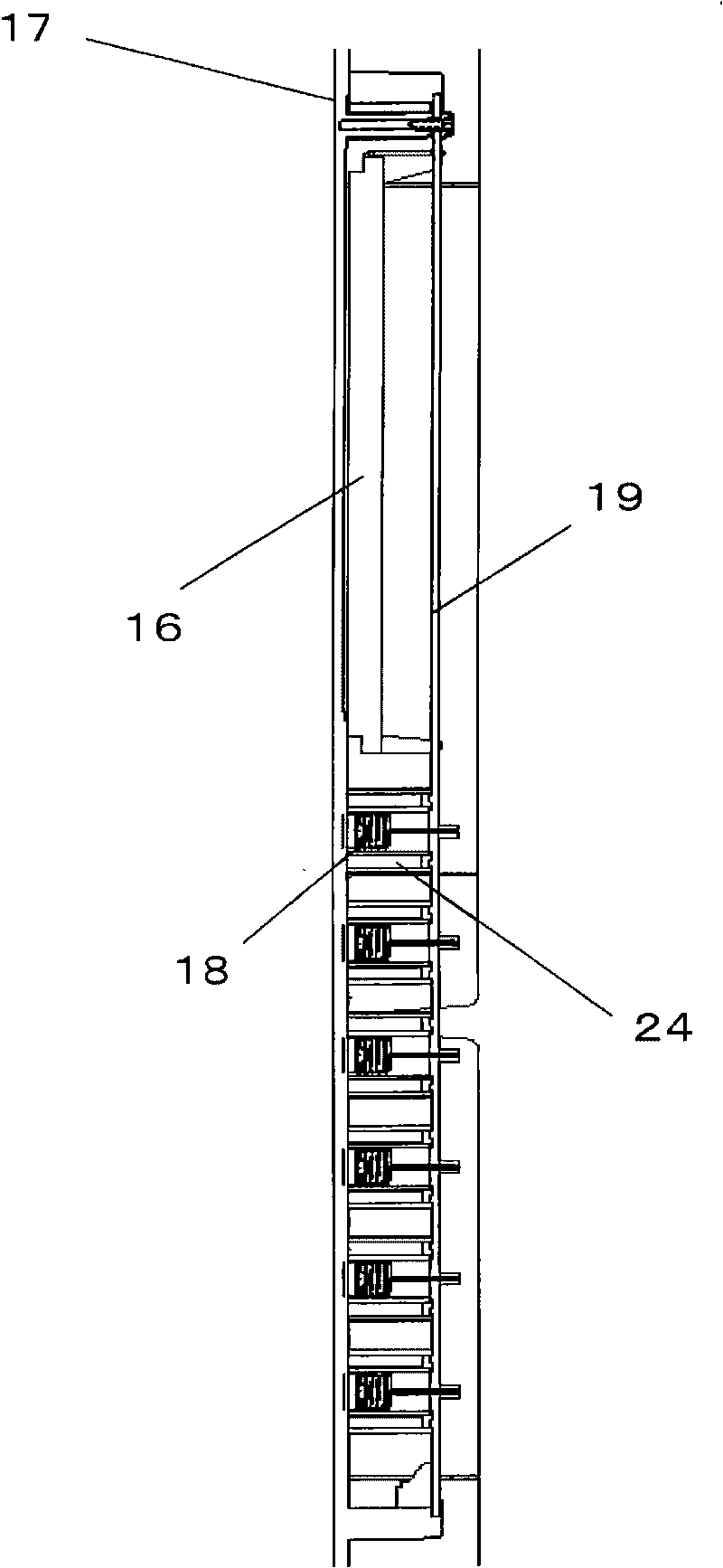

Touch switch

ActiveCN101741371AImprove reliabilityEasy to fixLighting and heating apparatusDomestic refrigeratorsEngineeringOperational stability

The invention provides a touch switch which can improve the operation stability and the reliability per se and also can ensure the operation convenience, the reliability and the appearance beauty of machinery equipment provided with the touch switch. The touch switch is internally provided with a box body (24) covering the periphery of an induction part (18), the induction part is connected with a connecting part (21) under a state that the upper surface (18a) of the induction part is higher than the upper surface (24c) of the box body, and the connecting part is an elastic part. After the box body is fixed on a printed substrate, the induction part after being connected with the connecting part is easy to be fixed on the printed substrate, and the difference of assembly operation also can be reduced. Because the induction part is arranged at the position protruding over the upper surface of the box body, tight attaching type fixation can be realized between a part arranged on the upper surface of the induction part and supplied for people to touch and the induction part, and the detection deviation of an electrostatic capacity can be lowered.

Owner:无锡松下冷机有限公司 +1

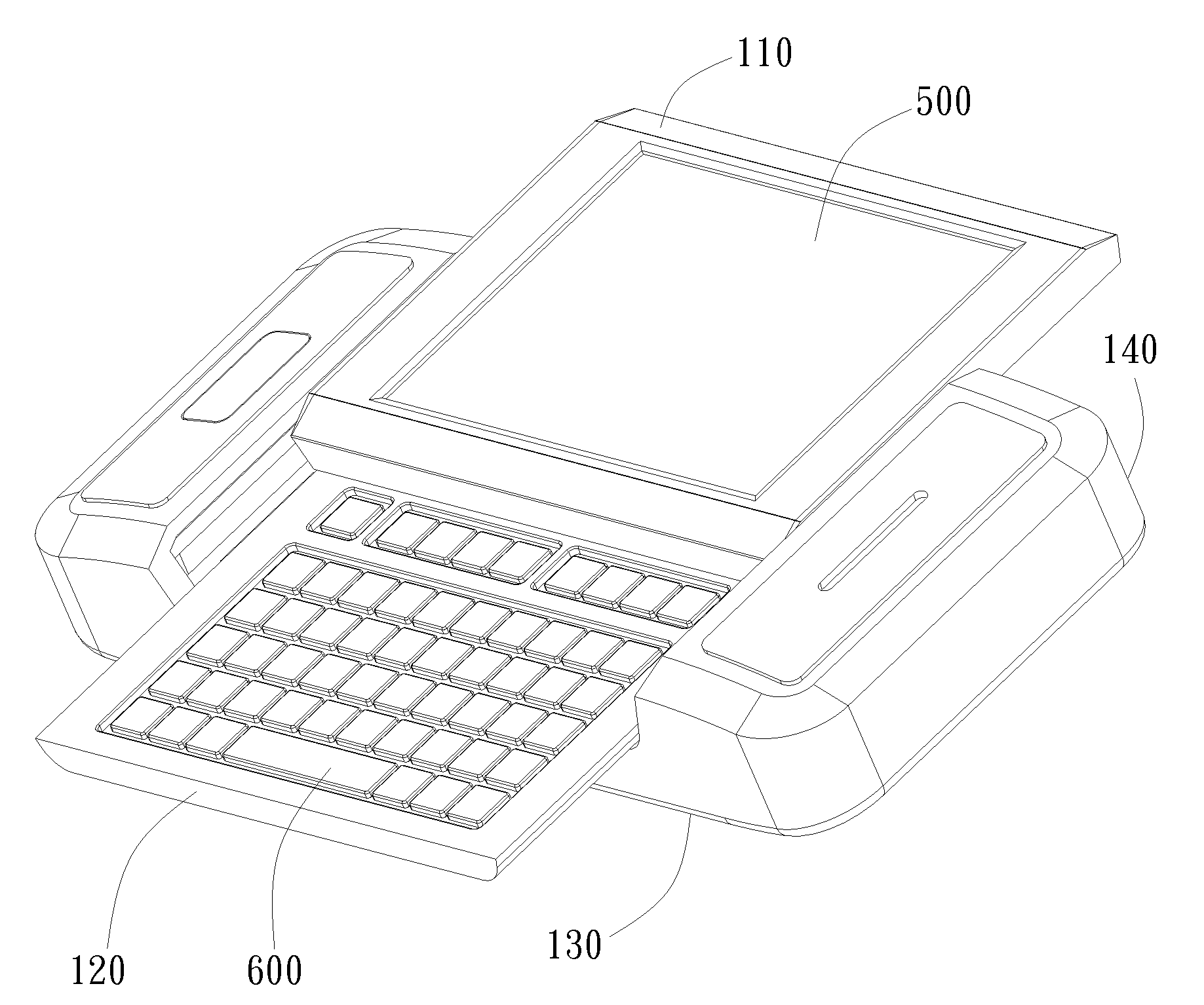

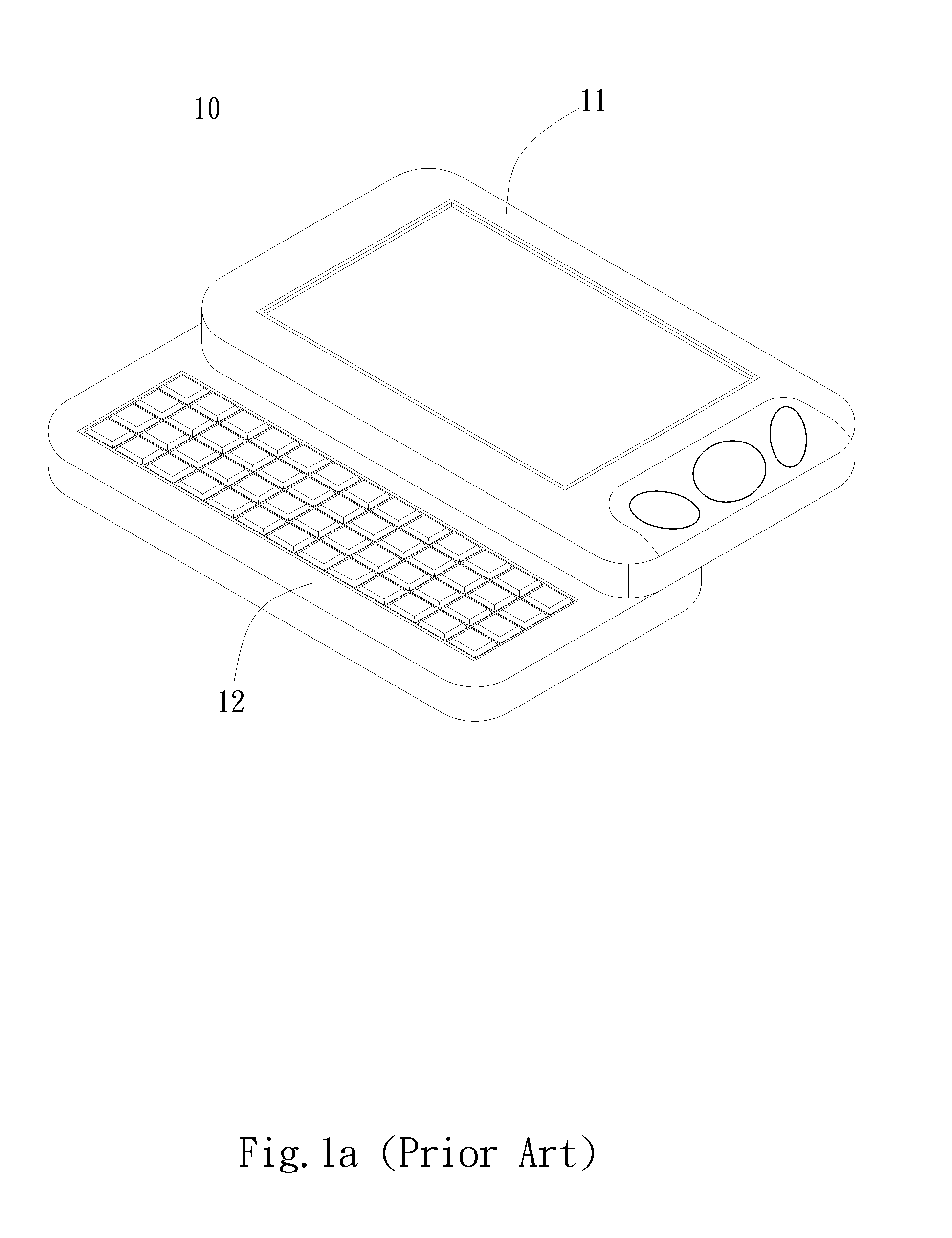

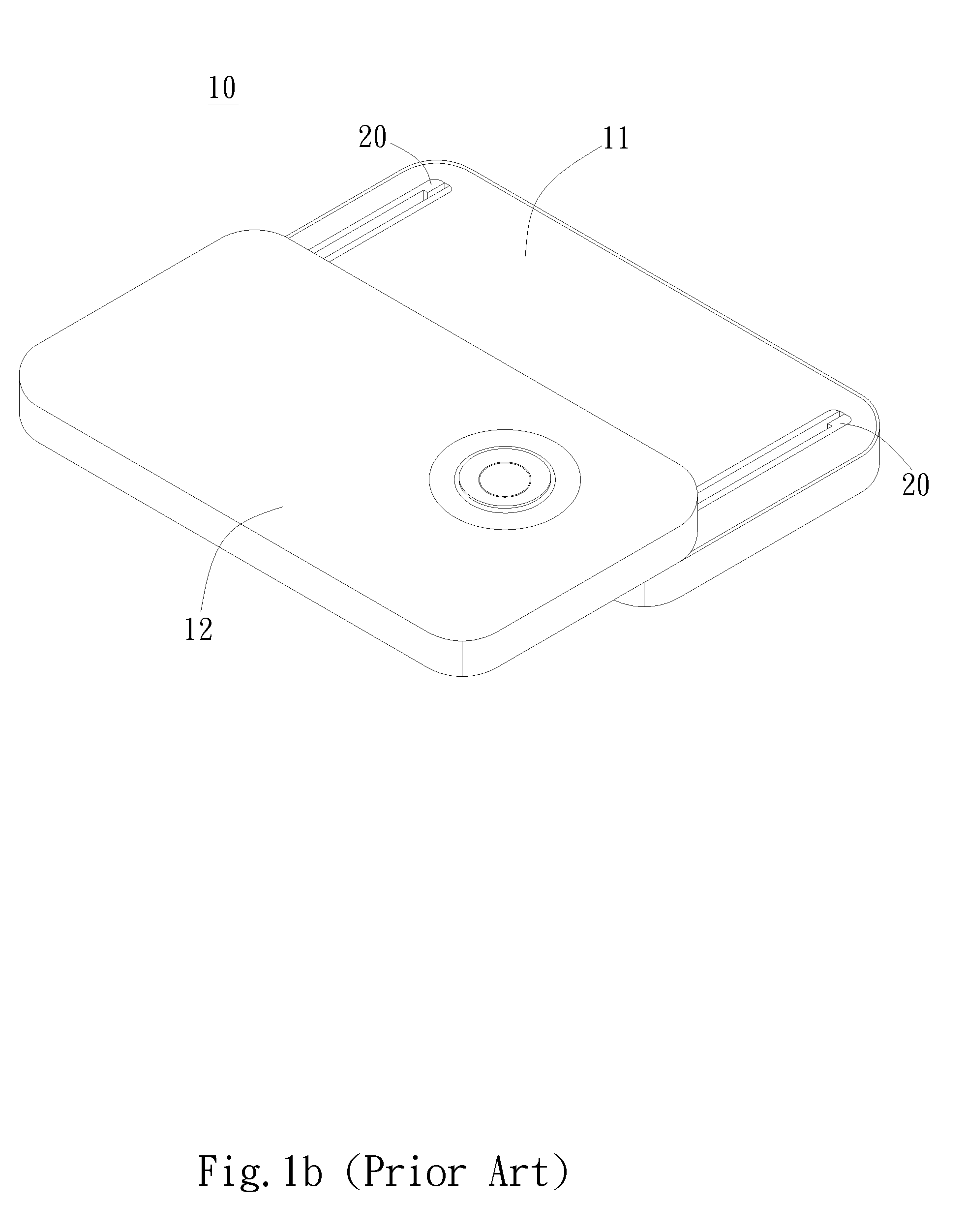

Bilateral sliding module and the electronic device using the same

InactiveUS20090093285A1More roomImprove convenienceSubstation equipmentElectrical and Electronics engineeringElectronic equipment

Owner:BENQ CORP

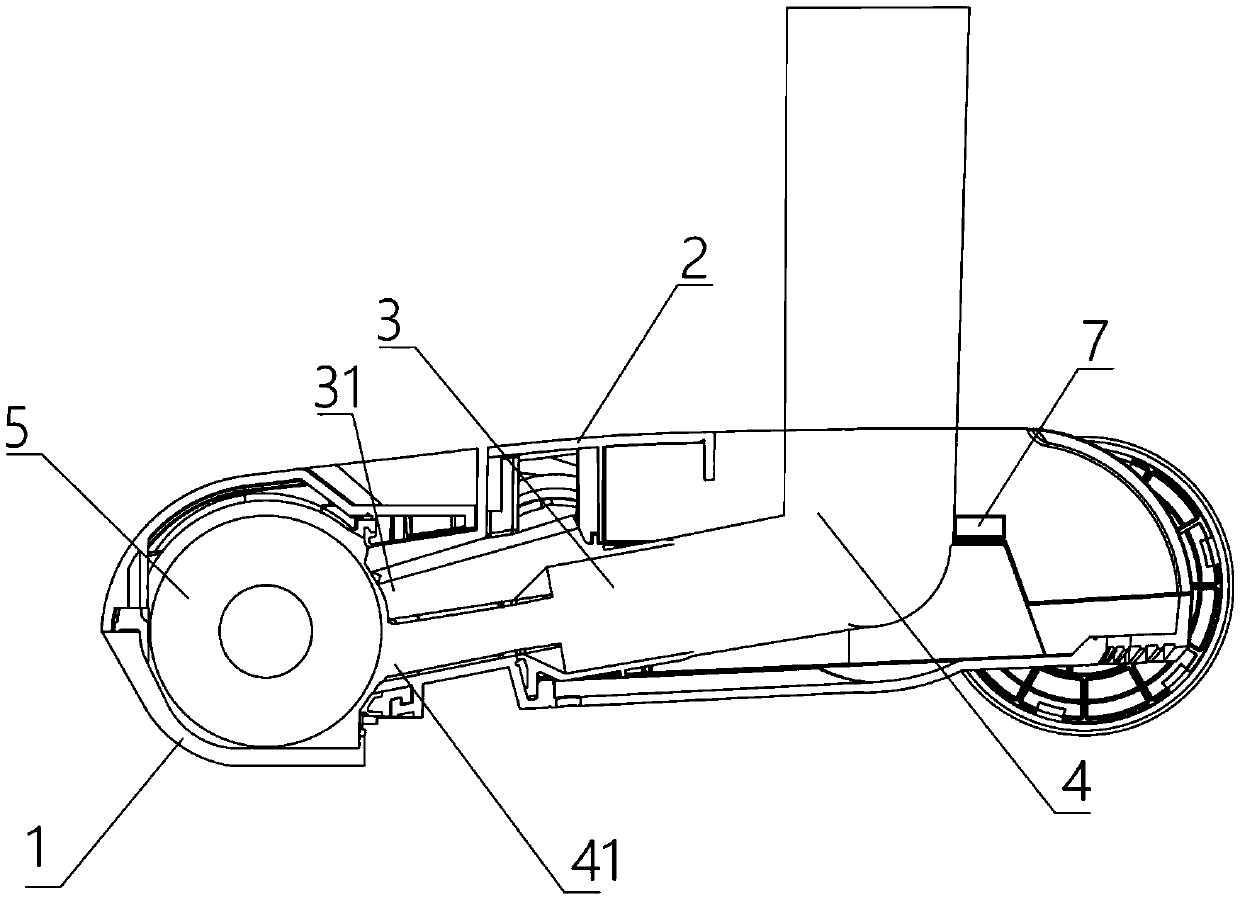

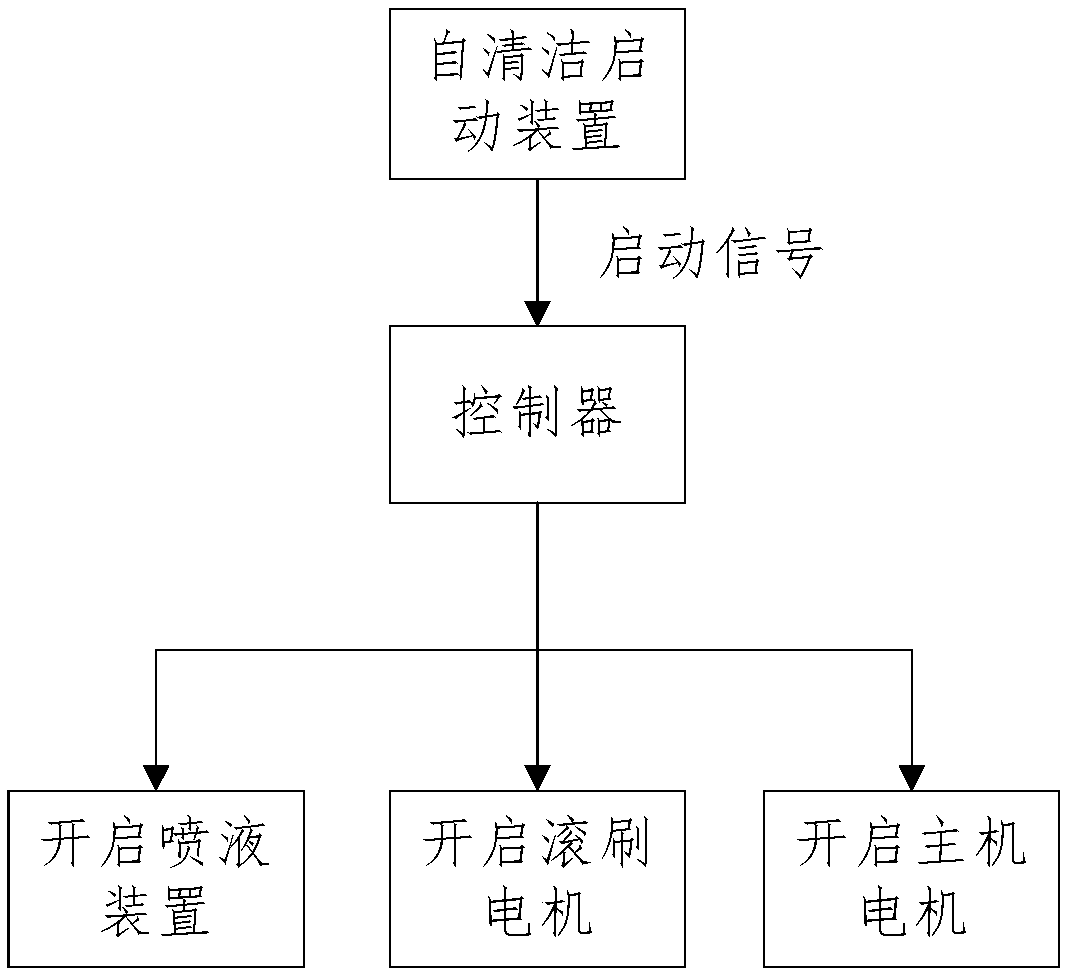

Surface cleaning machine and surface cleaning machine self-cleaning method

ActiveCN110946524AImprove experienceImprove operational convenienceCarpet cleanersFloor cleanersSurface cleaningControl engineering

The invention provides a surface cleaning machine and a self-cleaning method thereof. The surface cleaning machine comprises a controller, a liquid spraying device, a rolling brush, a rolling brush motor used for controlling the rolling brush, a suction device and a main machine motor used for controlling the suction device. The liquid spraying device, the rolling brush motor and the host motor are respectively connected with the controller; the controller starts a first cleaning mode according to a received starting signal, and in the first cleaning mode, the liquid spraying device is in a starting state and sprays liquid to the rolling brush, the rolling brush motor is in a starting state, the rolling brush rotates, the main machine motor is in the starting state, and liquid flowing through the rolling brush is sucked into the liquid suction pipeline. According to the surface cleaning machine, the convenience can be significantly improved, the cleaning effect is improved, and the user experience is improved.

Owner:TIANKE INTELLIGENT TECH CO LTD

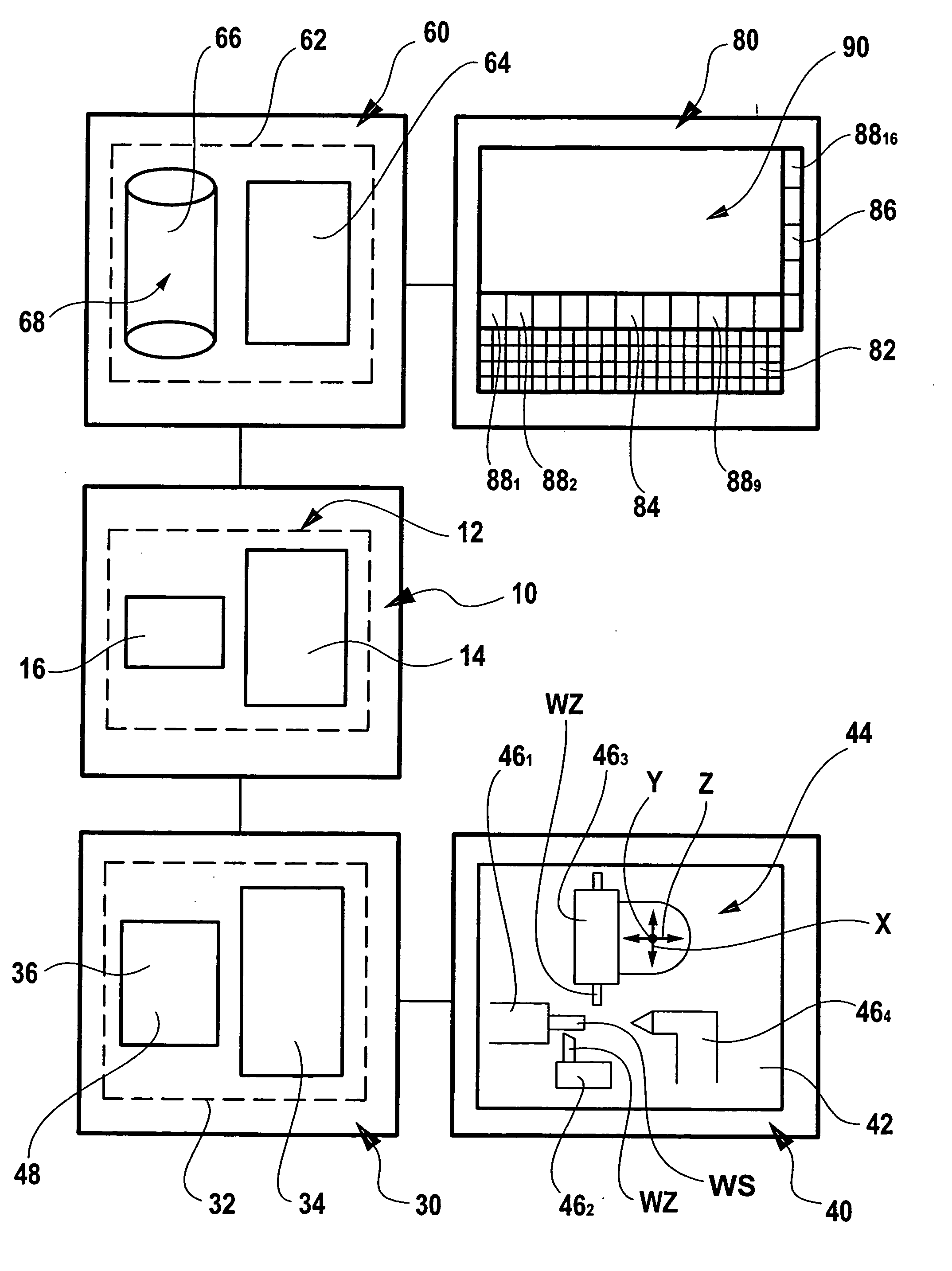

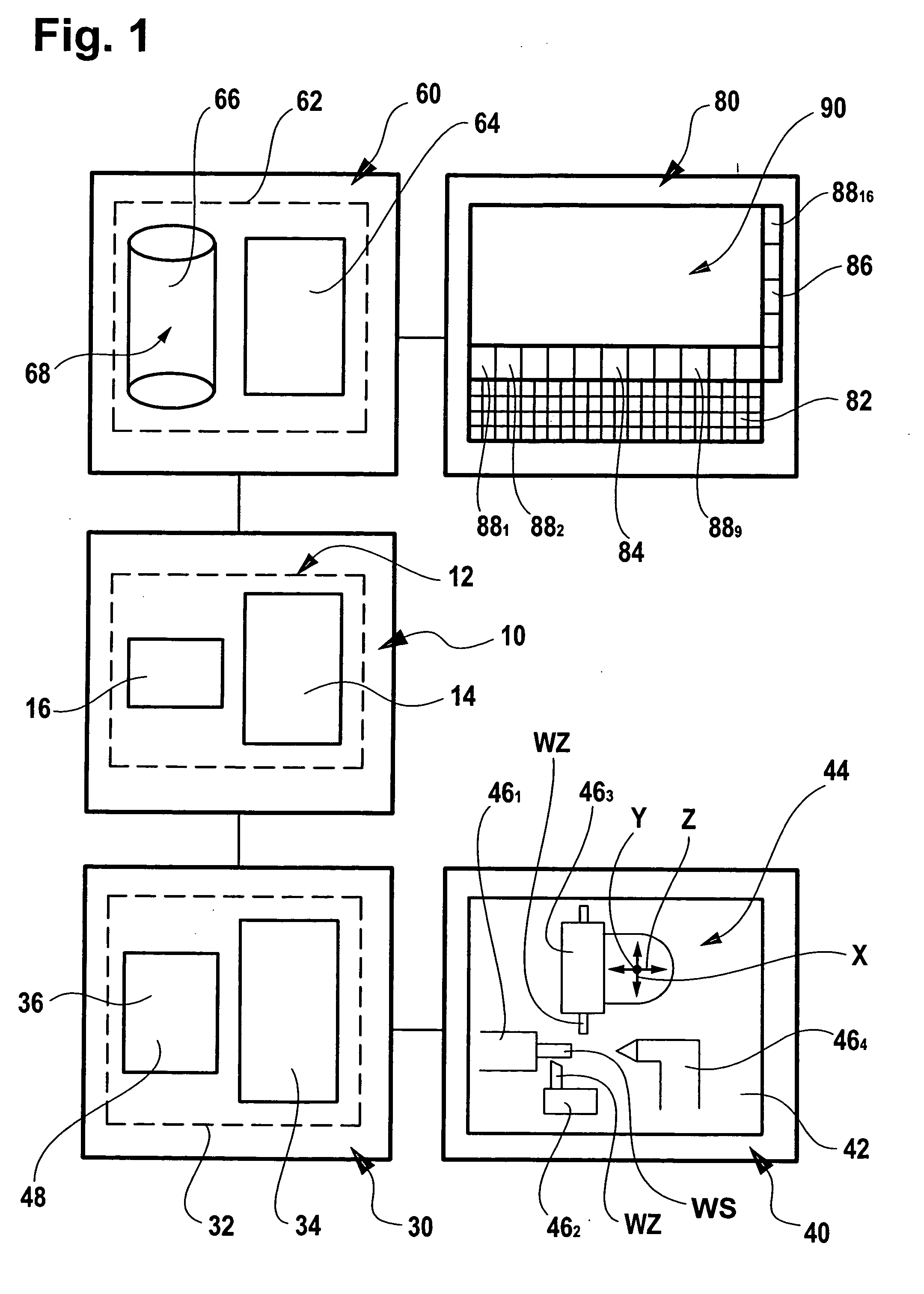

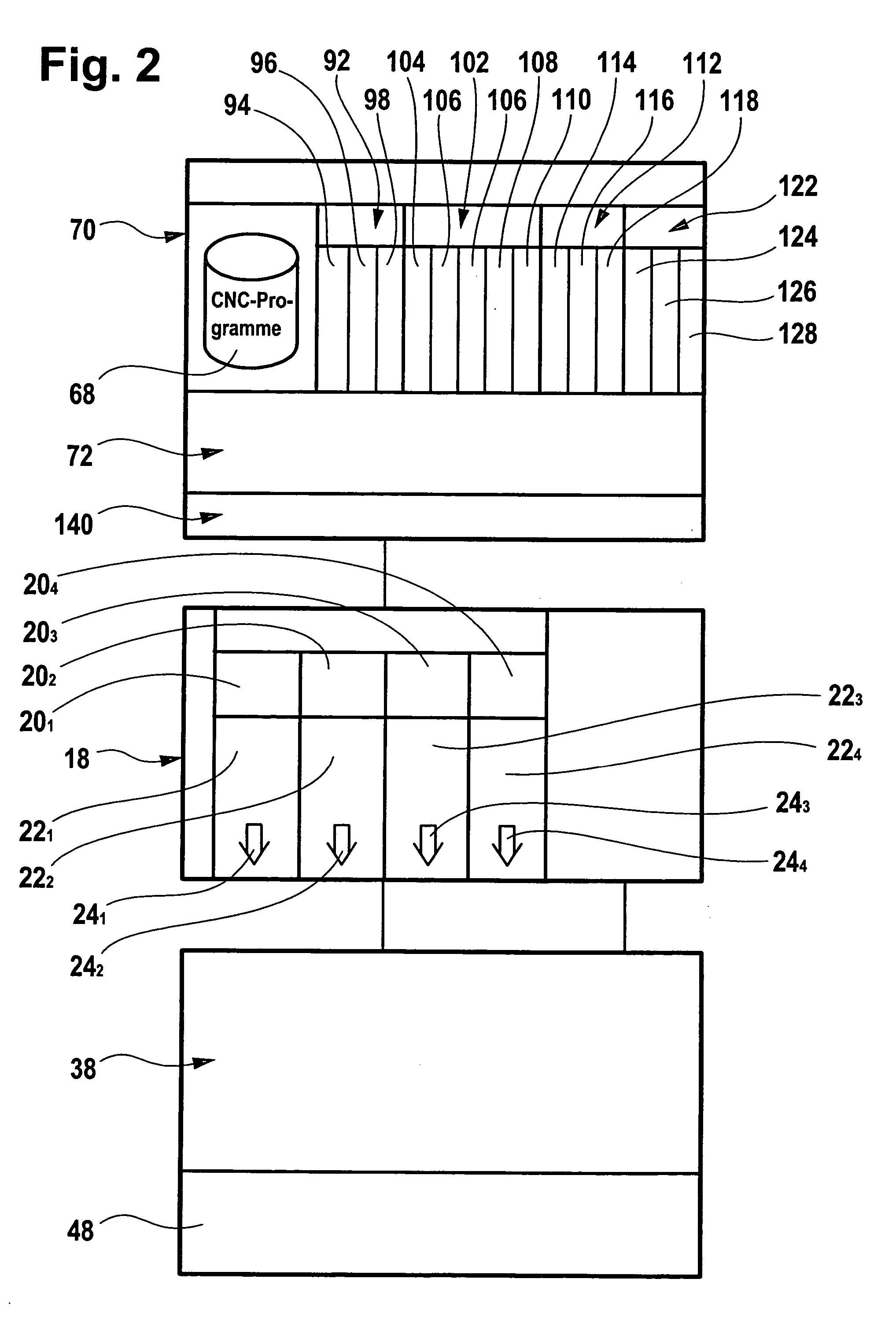

Simulation system

ActiveUS20070061037A1Easy to operateEasy to useProgramme controlSpecial data processing applicationsProgram managementVirtual machining

In order to improve a simulation system for representing actions of machining units of a machine tool, in particular actions in the machining of a workpiece, in accordance with a CNC machining program complex by means of at least one first visualization unit in the form of actions of virtual machining units of a virtual machine tool, comprising an action control, which has at least one first data processing unit, which establishes control commands for actions of the virtual machining units by a control program processing CNC blocks of the CNC machining program complex, and a visualization control, which has at least one second data processing unit, which represents actions of the virtual machining units on the first visualization unit by a visualization program on the basis of configuration data of a stored machine model and the control commands determined by the action control, in such a way that it can be operated more easily, it is proposed that the simulation system comprises an operating control with a third data processing unit, which operates the action control by an operating program, and that the operating program has a program management function, which transfers at least program parts of the CNC machining program complex in a workpiece-related manner from said CNC machining program complex stored in a memory of the third data processing unit to the action control for executing said program complex.

Owner:INDEX WERKE GMBH & CO KG HAHN & TESSKY

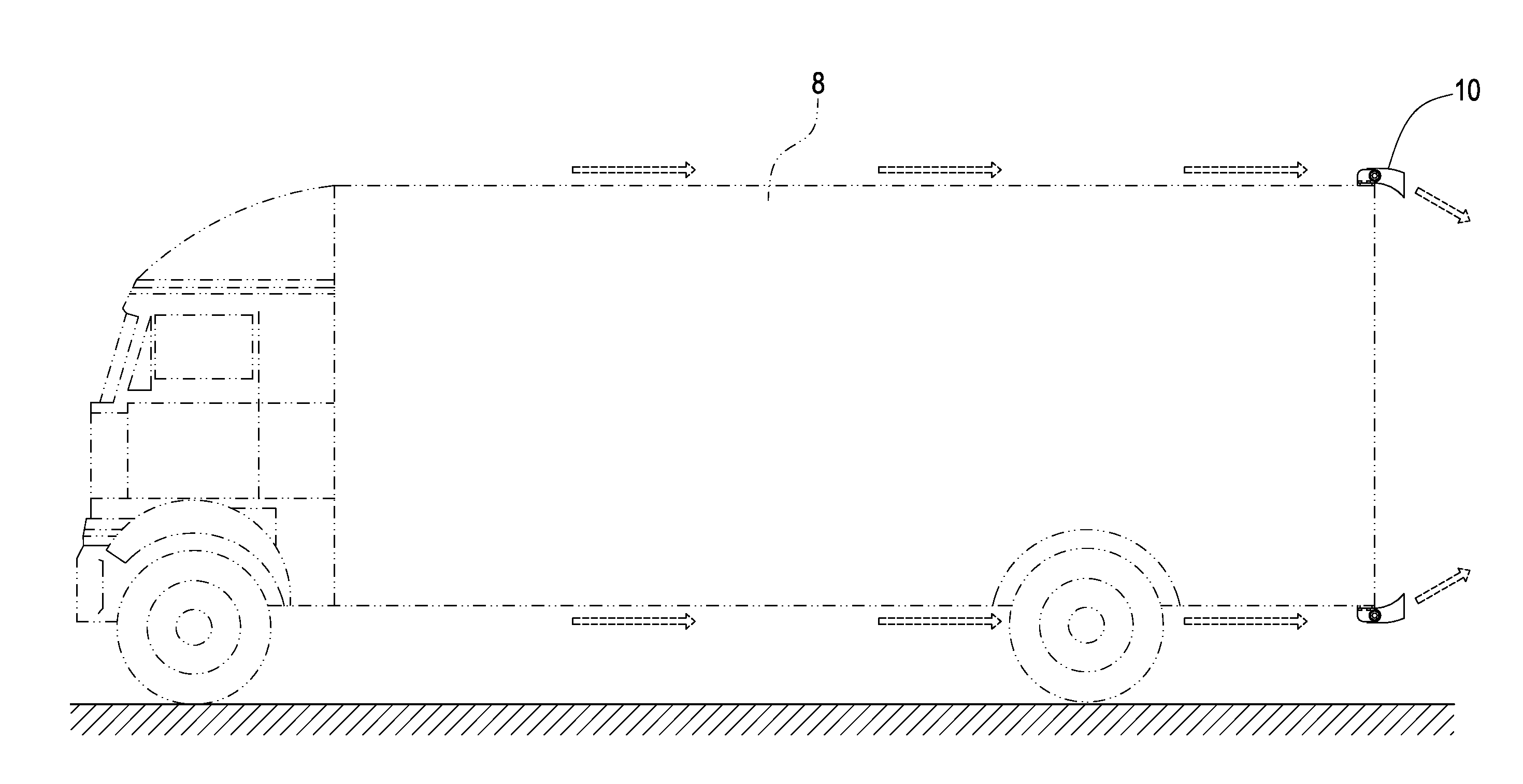

Nozzle-typed drag-reducing structure for vehicle

A nozzle-typed drag-reducing structure for vehicle is arranged at the tail end of a vehicle, including a frame body comprised of a combination of a plurality of deflectors, between two of which an airflow channel is formed; and an air inlet and an air outlet respectively formed at two sides of the frame body, and the area comprised by surrounding the air outlet is larger than the area comprised by surrounding the air inlet. Thereby, whenever the vehicle is driven in high speed or low speed, it is all possible to boost the running efficiency and increase the driving stability.

Owner:SMART ENERGY

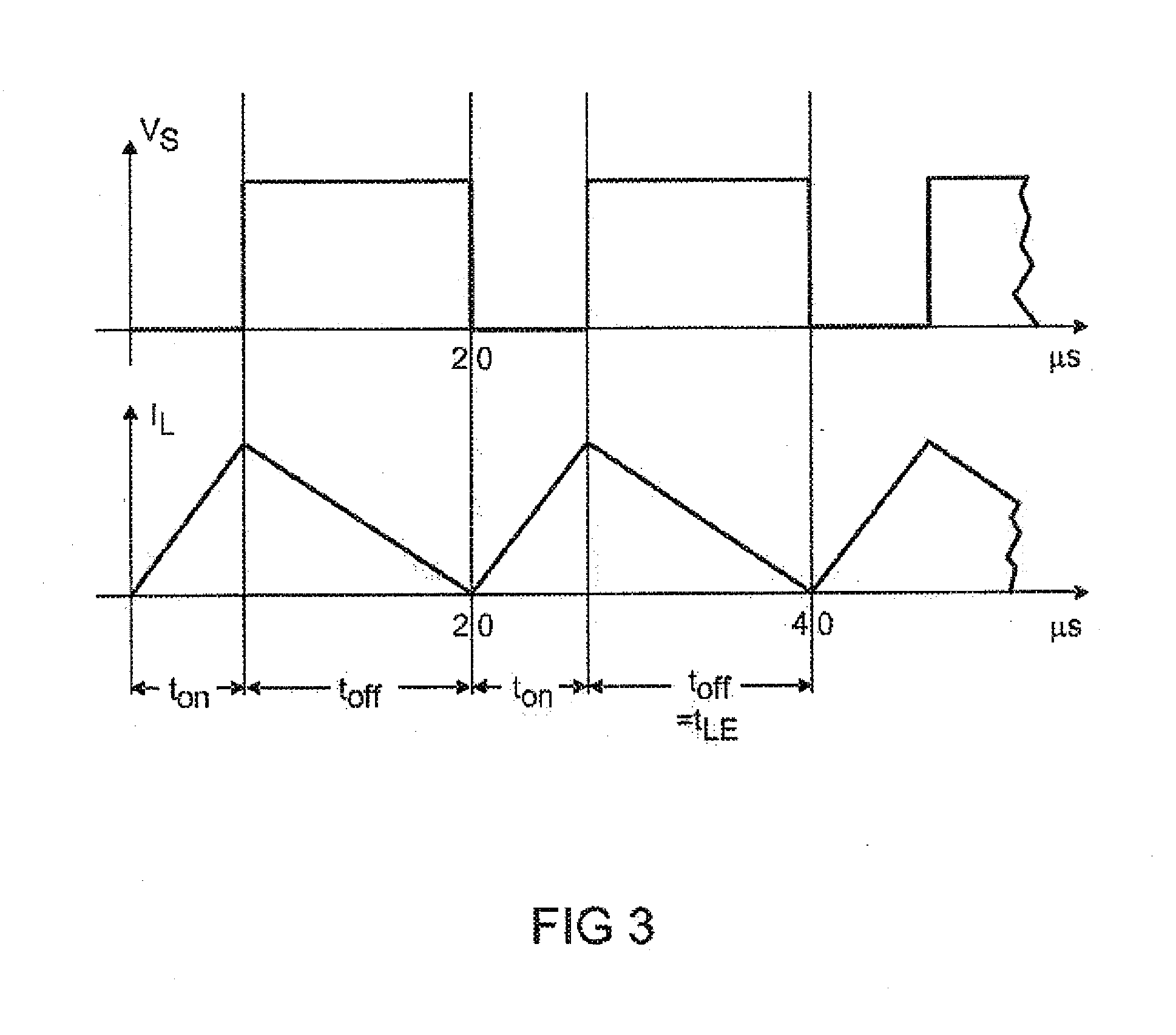

Method for Controlling a Voltage Transformer for Overvoltage Protection, Voltage Transformer and Operating Device having a Voltage Transformer

InactiveUS20120139435A1Easy to detectExtended service lifeEfficient power electronics conversionEmergency protective circuit arrangementsOvervoltageTransformer

A method for controlling a voltage transformer for operating a switchable load having at least one inductance and a switch, which is activated by a digital control device. When the switch is closed, a magnetizing current flows through the inductance. When the switch is open, a demagnetizing current flows through the inductance. The method comprises the steps of measuring the demagnetizing time of the inductance and, when a maximum value of the demagnetizing time of the inductance is exceeded, storing such an ocurrence as a fault. The load is disconnected by the control device when a predetermined maximum frequency of faults is exceeded.

Owner:OSRAM GMBH

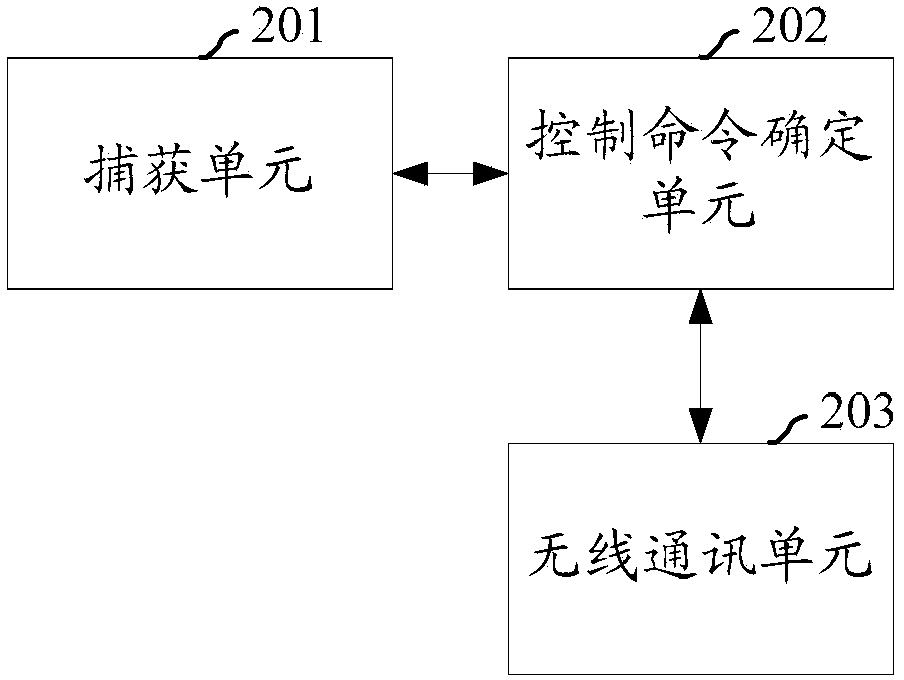

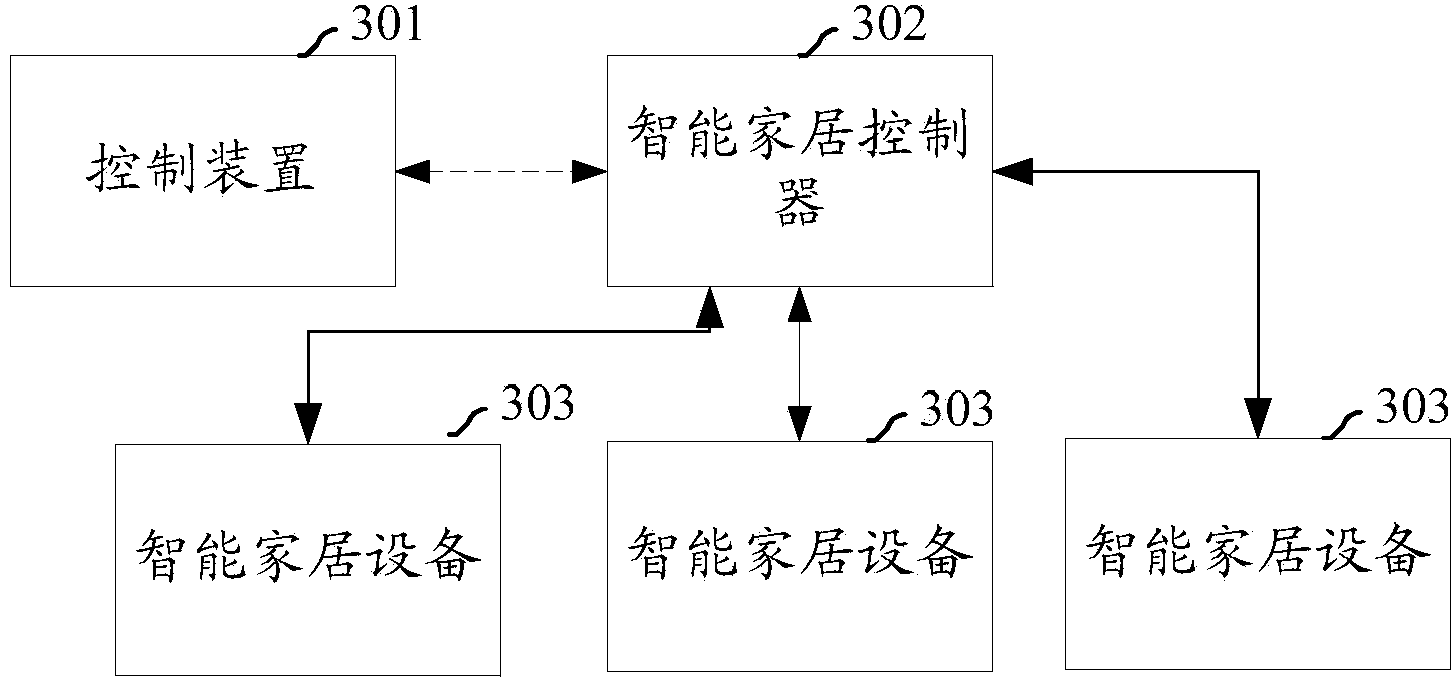

Smart home control method, device and system

ActiveCN103529778ARealize spatial movement controlImprove operational convenienceProgramme total factory controlEmbedded systemControl equipment

The execution mode of the invention provides a smart home control method, a smart home control device and a smart home control system. The smart home control method comprises the following steps of capturing a user limb space movement through a mobile terminal camera, and determining a smart home control command corresponding to the user limb space movement; sending the smart home control command to a smart home controller in a wireless communication manner; controlling smart home equipment through the smart home controller based on the smart home control command. A user only needs to hold mobile terminal equipment instead of being limited in an appointed region of a controller camera to realize remote control operation for the smart home control equipment under a condition that a mobile terminal and the smart home control equipment keep effective wireless network connection, so that the human-machine interaction mode of the smart home control equipment is expanded, and the usability of smart home operation is improved.

Owner:FUJIAN STAR NET COMM

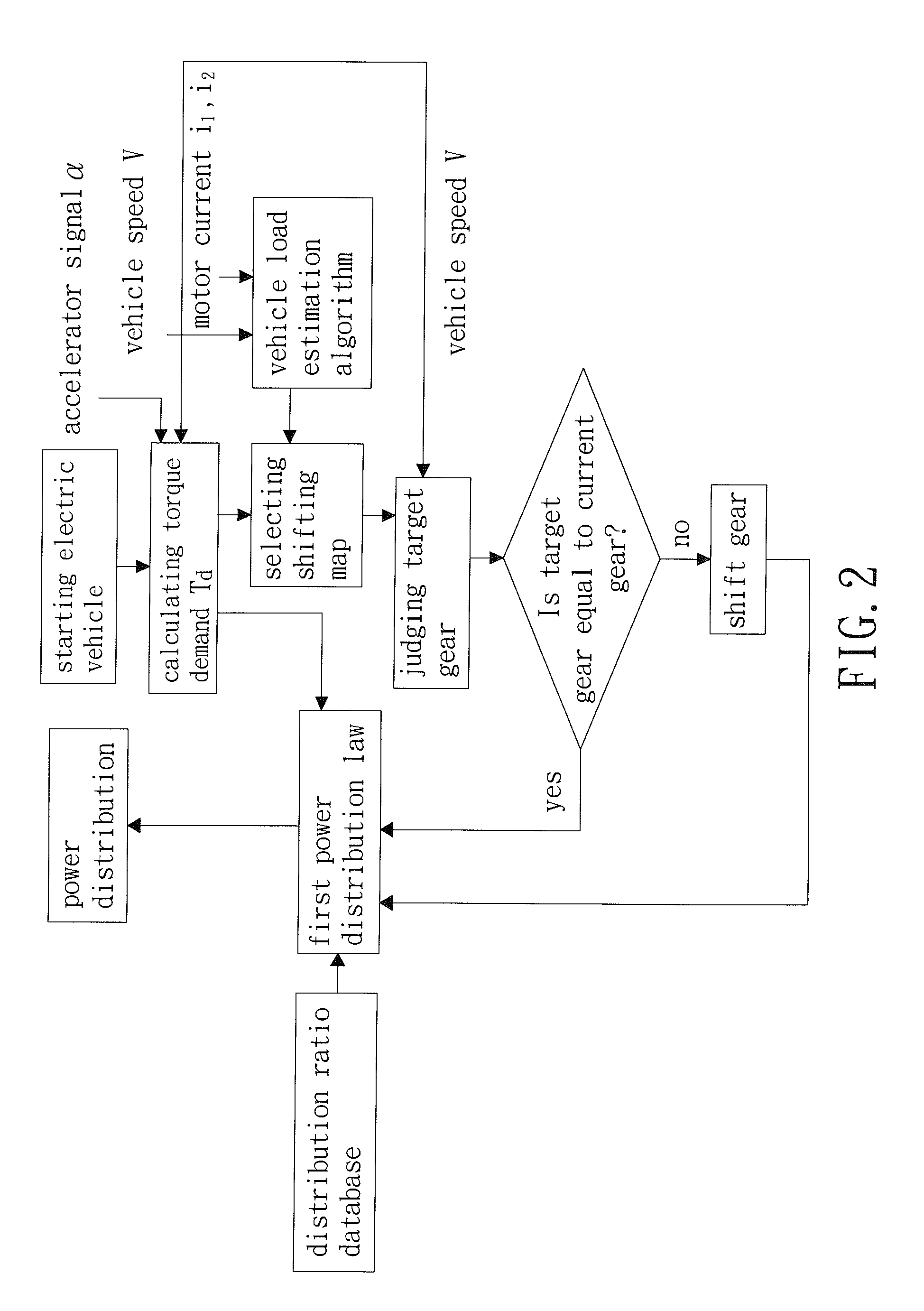

Power Distribution Method for Electric Vehicle Driven by Two Power Sources

InactiveUS20150057866A1Operation efficiency can be improvedReduce energy consumptionDigital data processing detailsElectric propulsion mountingDistribution methodOperation point

A power distribution method for electric vehicle driven by two power sources includes executing a first power distribution law by a vehicle control unit, wherein the first power distribution law sets a distribution ratio according to a vehicle speed of the electric vehicle, a torque demand, and a current gear of a transmission. The powers outputted by first and second motors are adjusted according to the distribution ratio such that the first and second motors can operate at the most efficient operation points to increase the operational efficiency of the electric vehicle driven by two power sources.

Owner:NAT PINGTUNG UNIV OF SCI & TECH

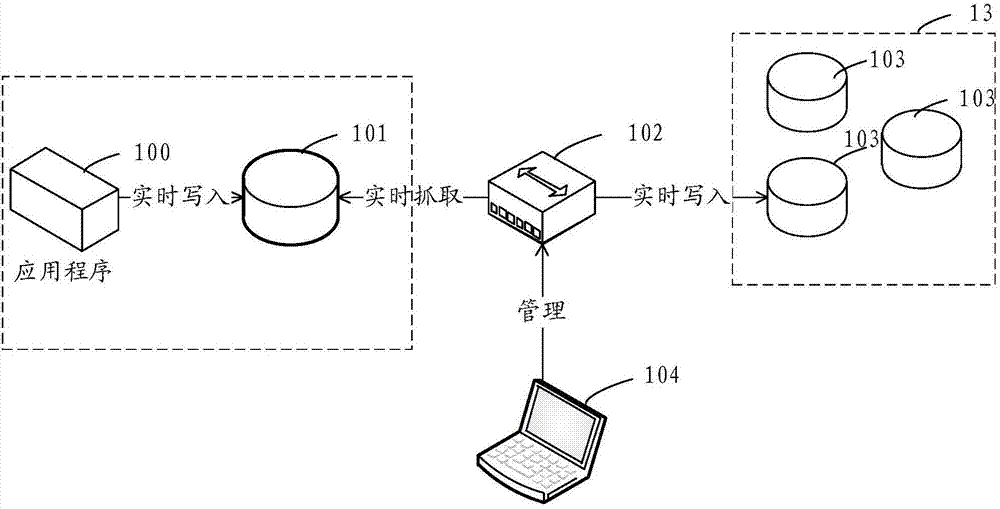

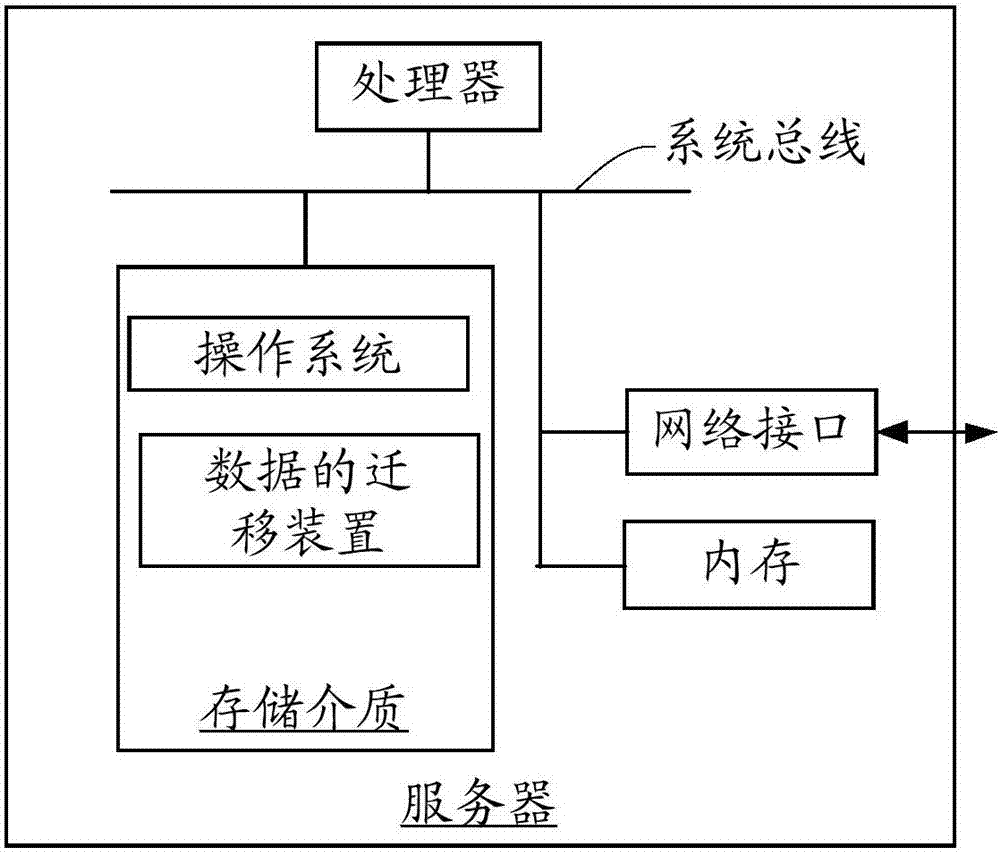

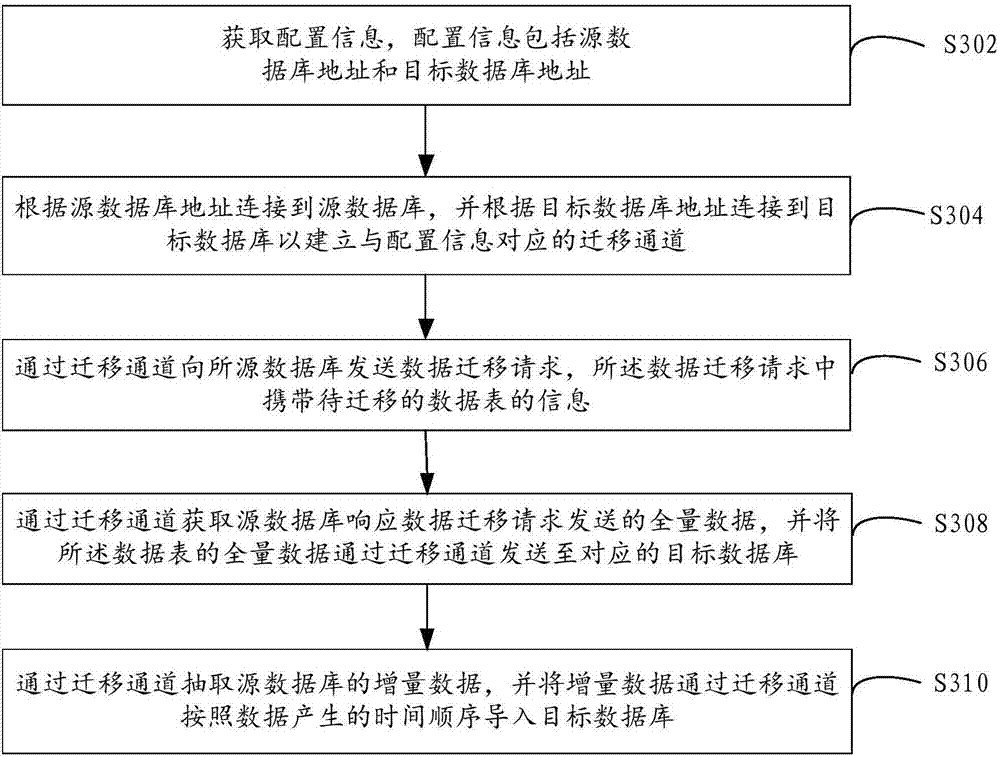

Data migration method and device

ActiveCN106874389ARealize online migrationEnsure data consistencyDatabase distribution/replicationDigital data authenticationChronological timeTarget database

The invention provides a data migration method and a data migration device. The method comprises the steps of obtaining configuration information, wherein the configuration information contains a source database address and a target database address; connecting to a source database according to the source database address, connecting to a target database according to the target database address to build a migration channel corresponding to the configuration information; transmitting a data migration request to the source database through the migration channel; obtaining total data transmitted by the source database in response to the data migration request through the migration channel and transmitting the total data to the corresponding target database through the migration channel; extracting incremental data of the source database through the migration channel and introducing the incremental data into the corresponding target database through the migration channel according to the time sequence of data generation. According to the method, the convenience of migration operation of the data can be improved.

Owner:TENCENT CLOUD COMPUTING BEIJING CO LTD

Holder for a beverage container

InactiveUS20050001127A1Easy to operateStable positionVehicle arrangementsWash-standsEngineeringTorsion spring

A holder for a beverage container has a storage compartment, a divider which is movably guided on the storage compartment with a substantially vertically arranged rotary bearing as a guide, from the non-use position in which the divider does not divide the storage compartment, in the position of use in which the divider divides off an insertion region for the beverage container from a remainder of the storage compartment, and back again, a diameter-compensating flap which is moved out of the storage compartment as the divider moves into the non-use position, the divider having a torsion spring system and being lockable by a locking device.

Owner:FISCHER AUTOMOTIVE SYST

Hammer drill

A hammer drill (2) includes a clockwise and counterclockwise driven tool spindle (28), a drive pinion (70) operatively connectable with the tool spindle (28) for transmitting a torque thereto, a separate control handle (6) for selecting one of the hammer drill functions including a pure drilling operation, a pure percussion operation, and a rotary-percussion operation), and a switching device (8) which is adjustable in accordance with a position of the control handle (6) and which is shiftable by the control handle (6) in a clockwise rotation position for effecting a pure drilling operation in a clockwise direction and in a counterclockwise rotation position for effecting a pure drilling operation in a counterclockwise direction.

Owner:HILTI AG

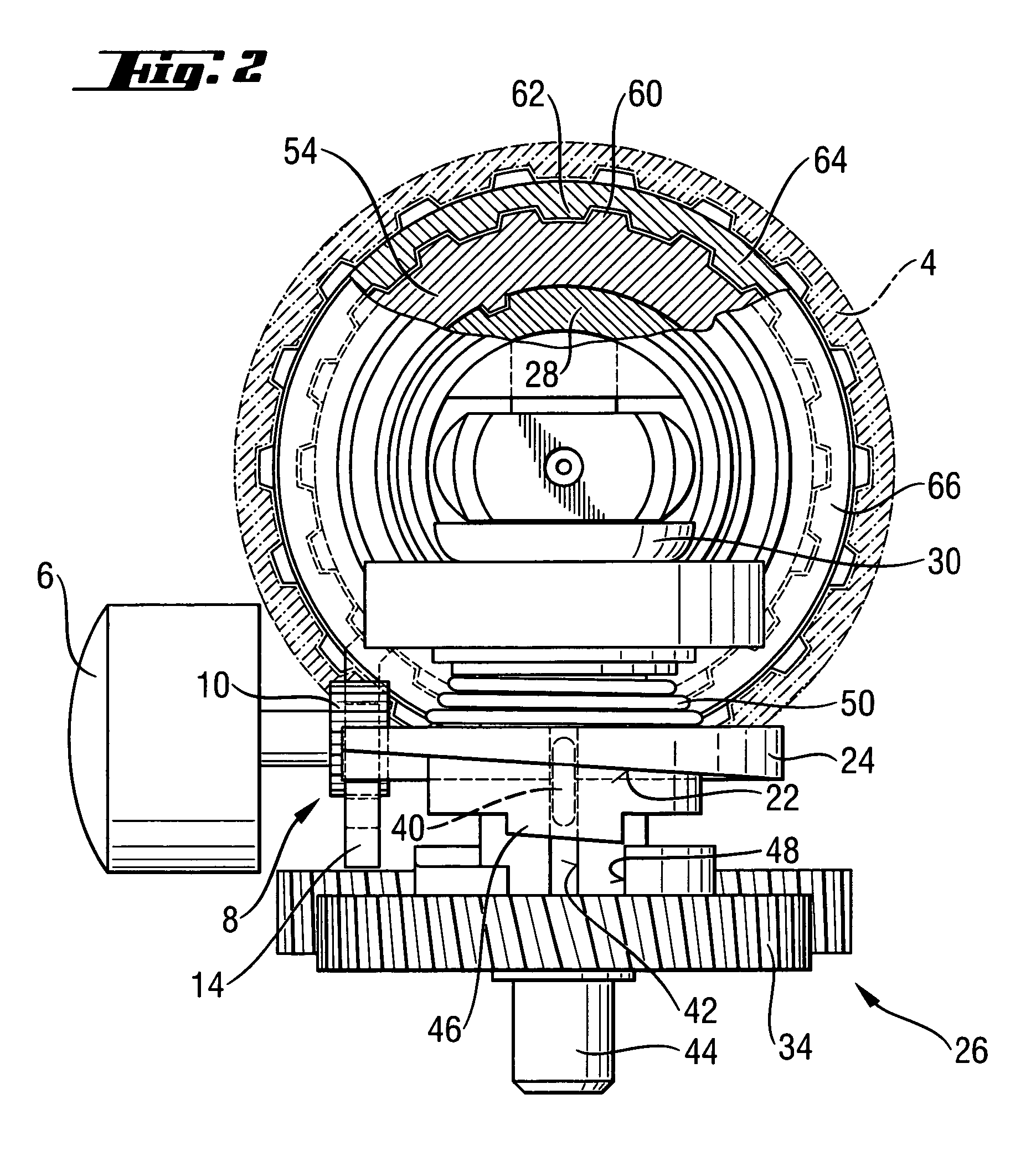

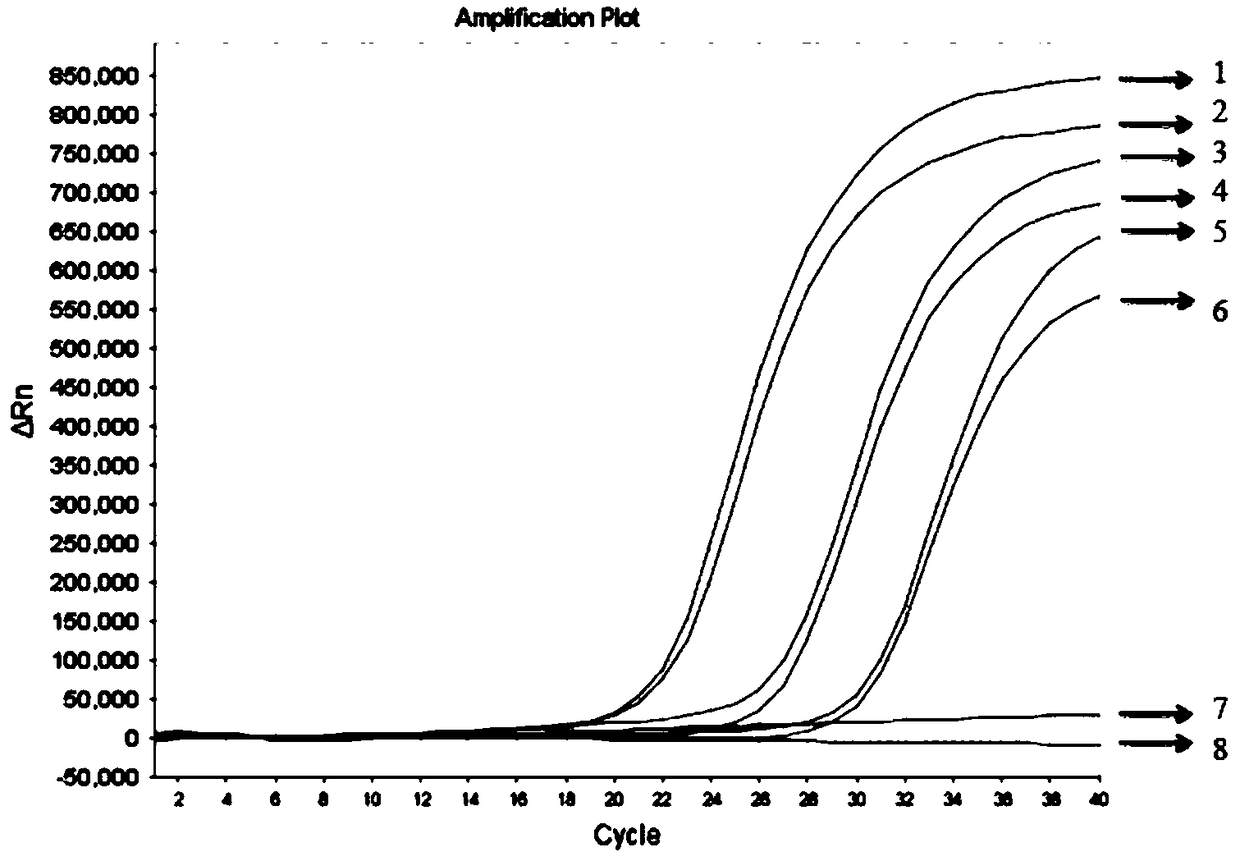

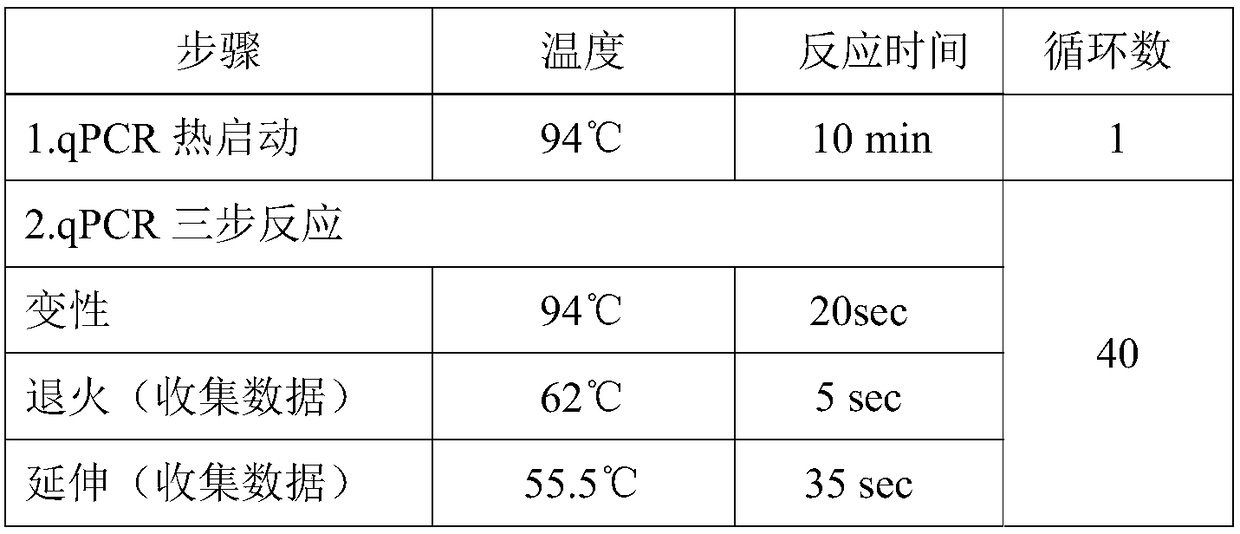

Magnetic bead process nucleic acid extraction and transformation kit, and using method thereof

InactiveCN109022417AAvoid wastingHigh purityMicrobiological testing/measurementDNA preparationLysisMagnetic bead

The invention provides a magnetic bead process nucleic acid extraction and transformation kit, and a using method thereof. The kit includes a lysate, a protease K, a magnetic bead solution, a transforamtion reagent, a nucleic acid protection agent, a binding solution, a washing solution I, a washing solution II and an eluent. The using method of the kit includes the following steps: (1) lysis; (2)transformation; (3) layering; (4) binding; (5) primary washing; (6) secondary washing; (7) drying; and 8) elution. The kit and the using method thereby can complete the transformation while achievingautomatic extraction of nucleic acid from a sample. The sample is lysed, releases the nucleic acid, and then begins to transform, the nucleic acid is separated from proteins by the binding solution after the transformation is completed, the methylated nucleic acid is purified by a magnetic bead process, and a pre-denaturation step in subsequent qPCR detection of the sample is used to replace a previously omitted sulfo group removal step, so a purification process in the original nucleic acid extraction step is omitted in the entire extraction and transformation process.

Owner:SUREXAM BIO TECH

server

ActiveUS20130063894A1Improve efficiencyEasy to operateServersDigital data processing detailsElectric power transmissionElectricity

A server includes a rack, at least one server unit, at least one communication exchange unit, at least one rack control unit and an electric power transmission unit. The rack has a plurality of shelving spaces. The server unit, the communication exchange unit, and the rack control unit are moved into or moved out of a corresponding shelving space along a horizontal axis, respectively. The server unit is communicatively connected to the communication exchange unit, and communicates with the rack control unit through the communication exchange unit. The electric power transmission unit is disposed in the rack and runs adjacent to the shelving spaces along a vertical axis. After the server unit, the communication exchange unit and the rack control unit are moved into corresponding shelving spaces, the server unit, the communication exchange unit and the rack control unit are electrically connected to the electric power transmission unit.

Owner:INVENTEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com