Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

62 results about "Virtual machining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Virtual machining is the practice of using computers to simulate and model the use of machine tools for part manufacturing. Such activity replicates the behavior and errors of a real environment in virtual reality systems. This can provide useful ways to manufacture products without physical testing on the shop floor. As a result, time and cost of part production can be decreased.

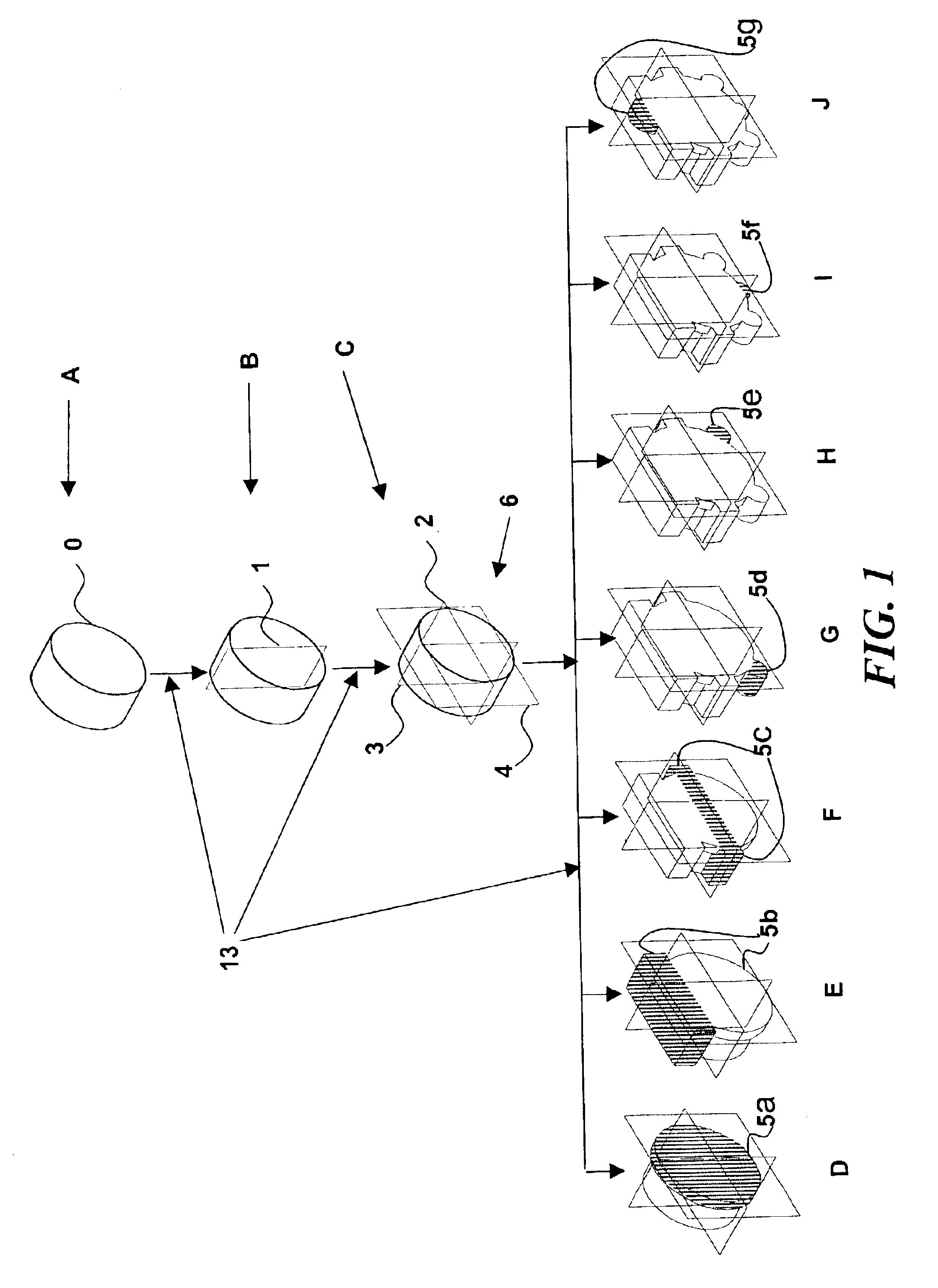

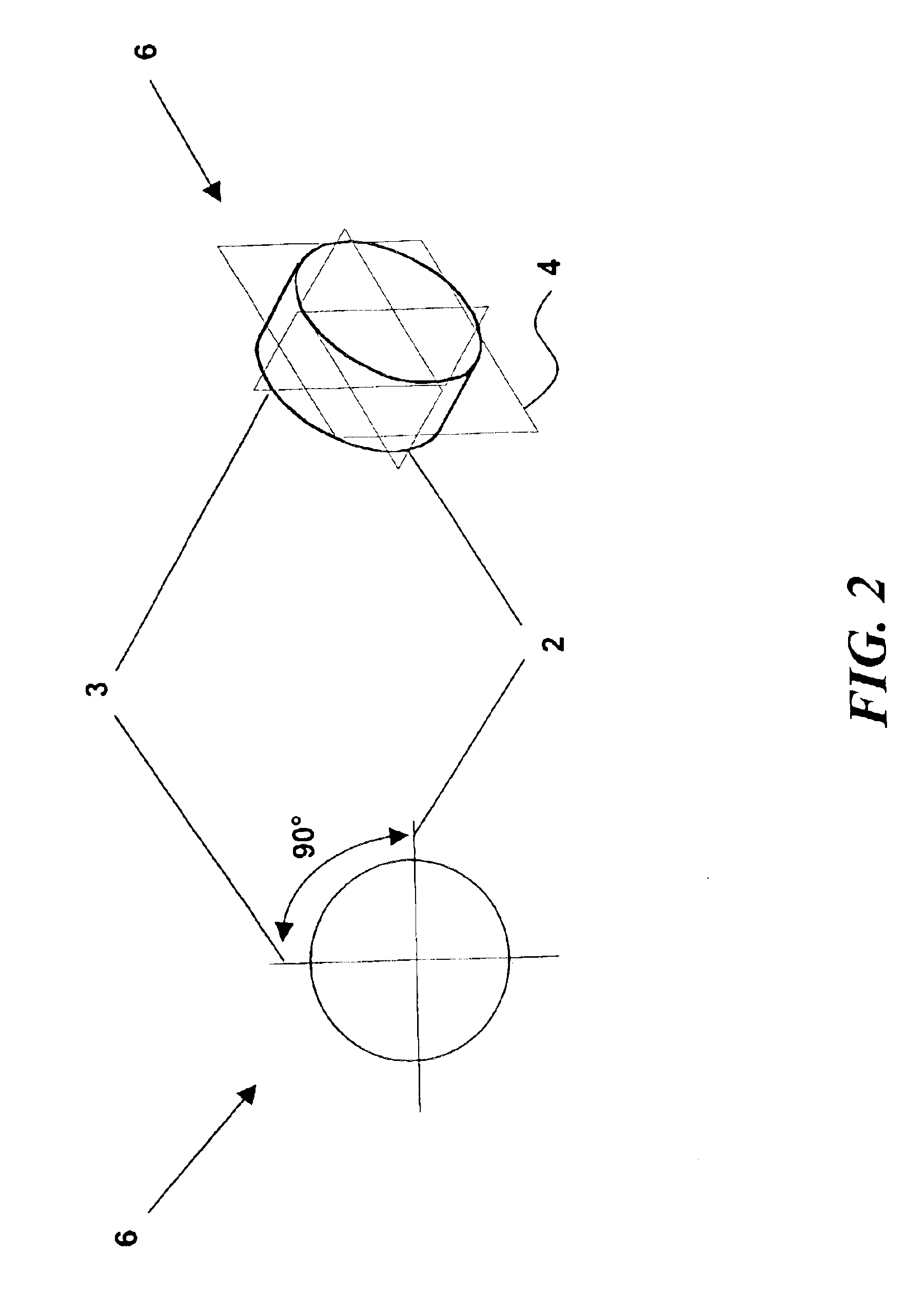

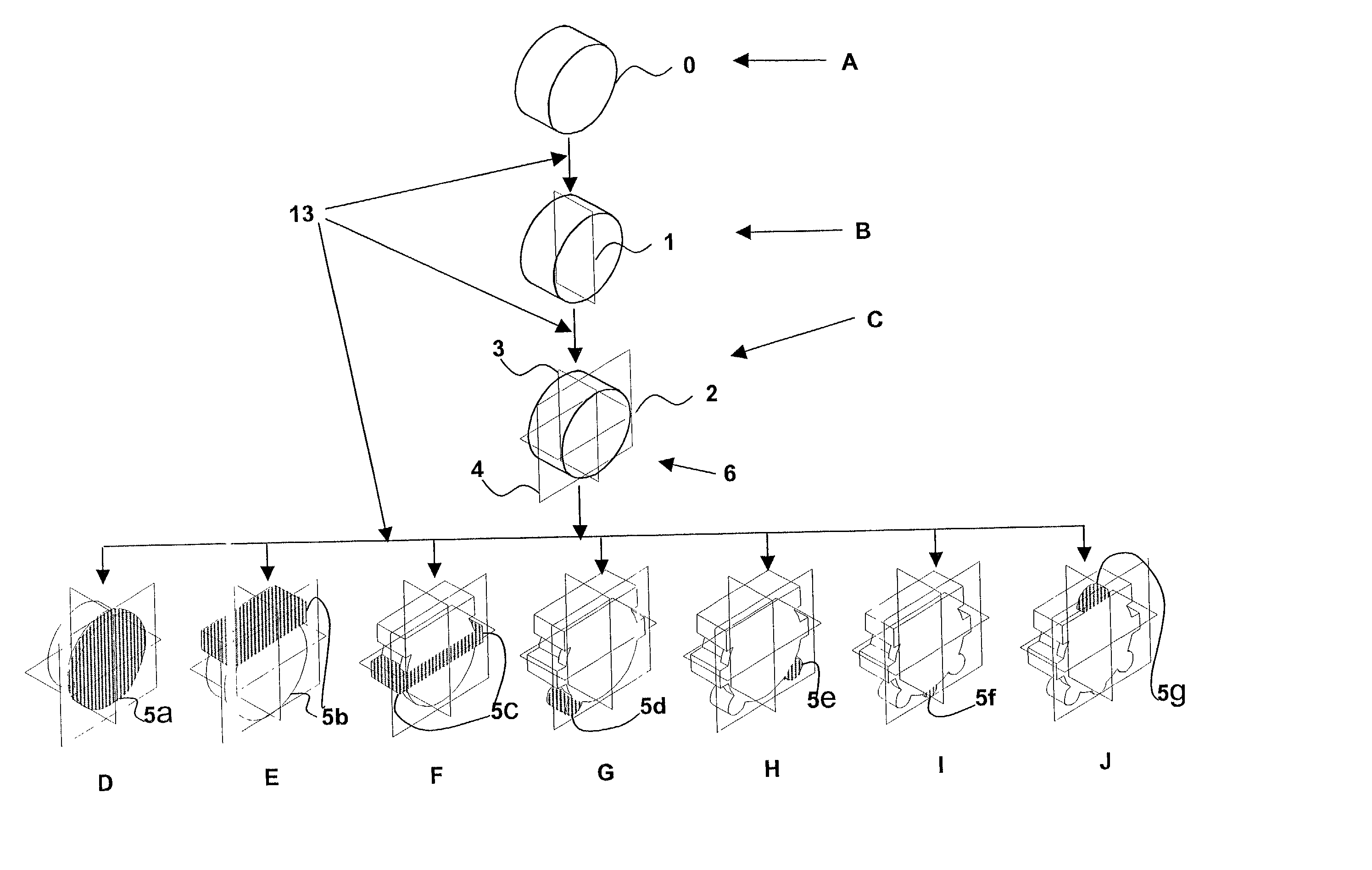

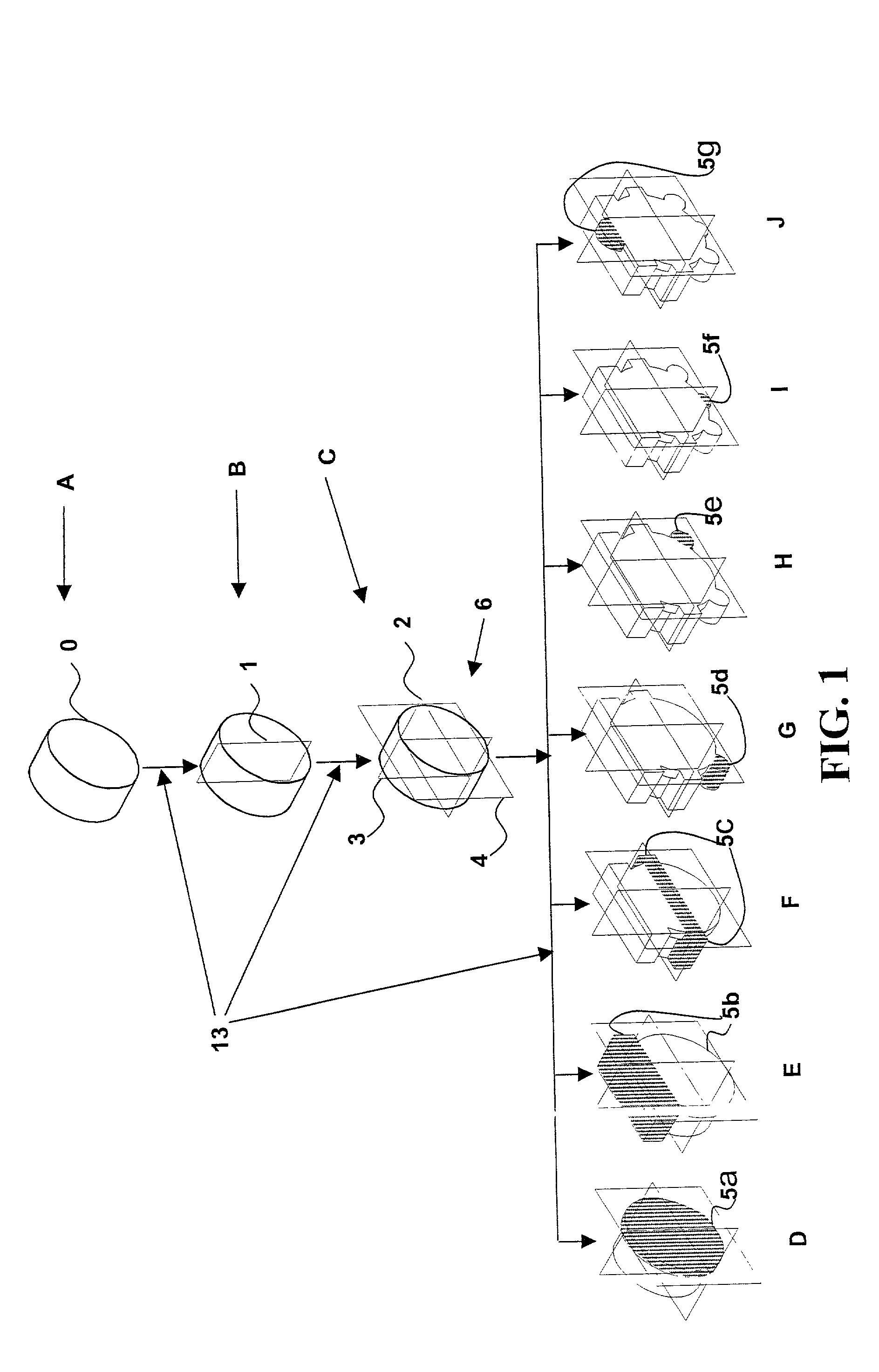

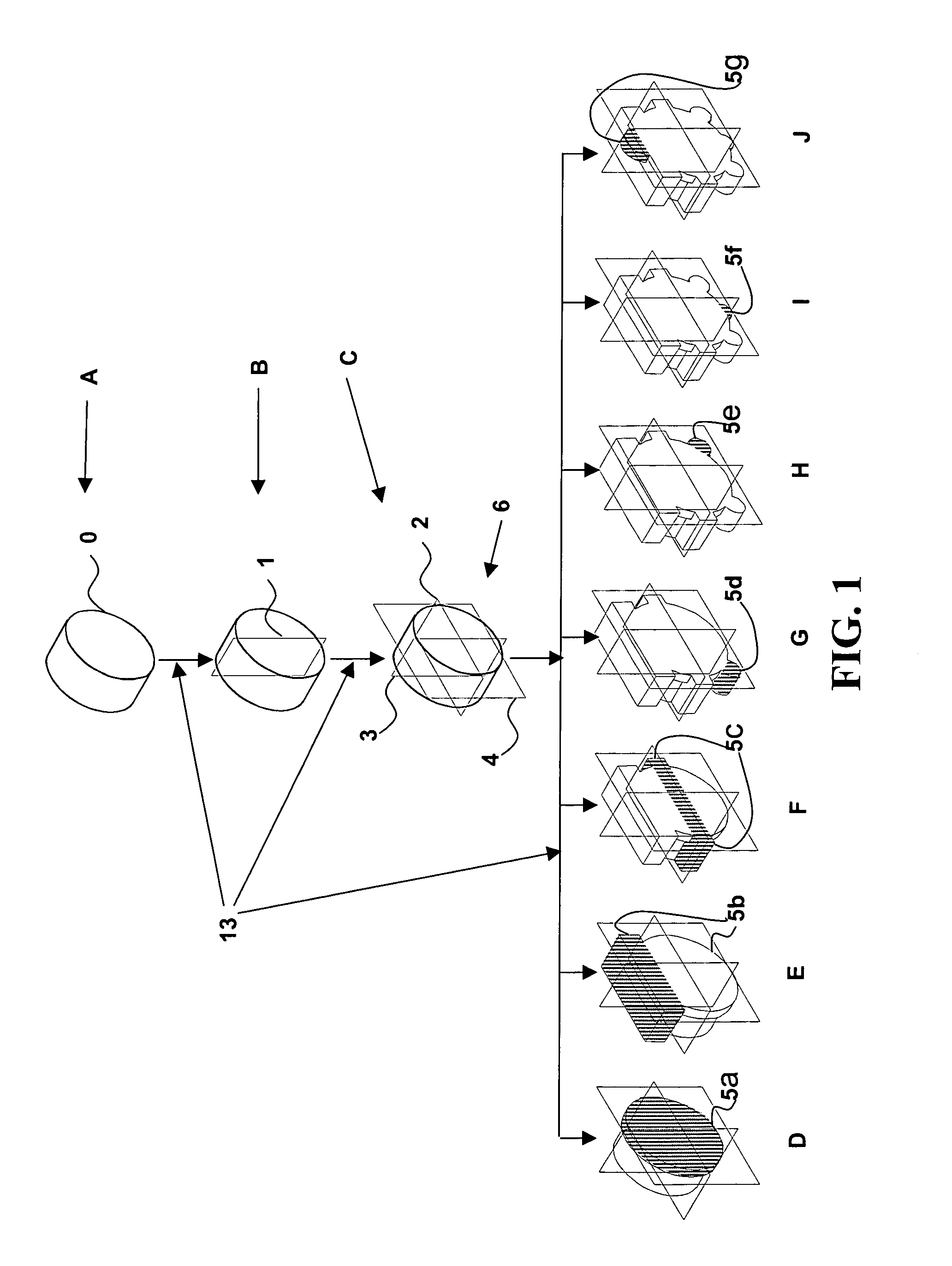

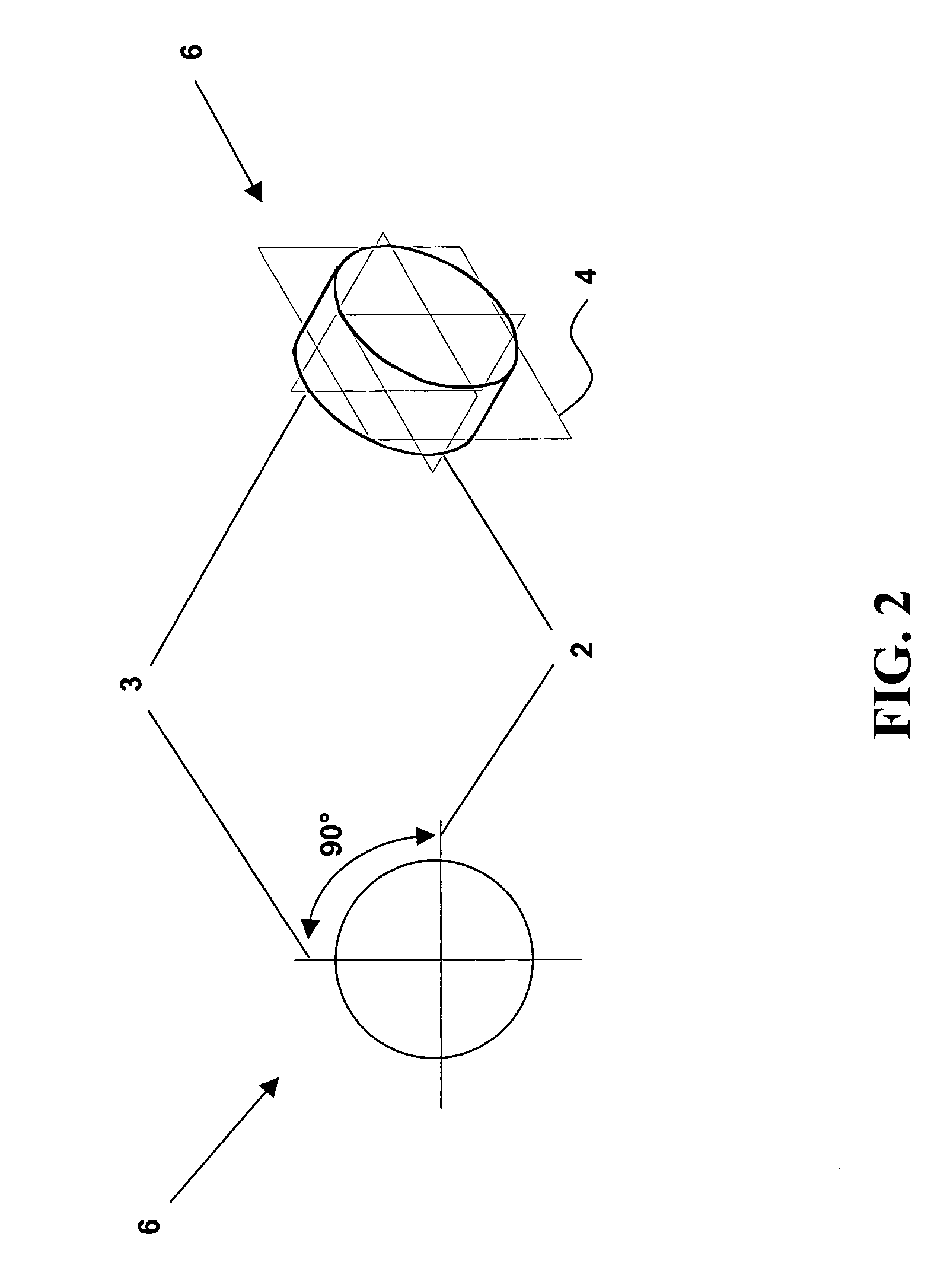

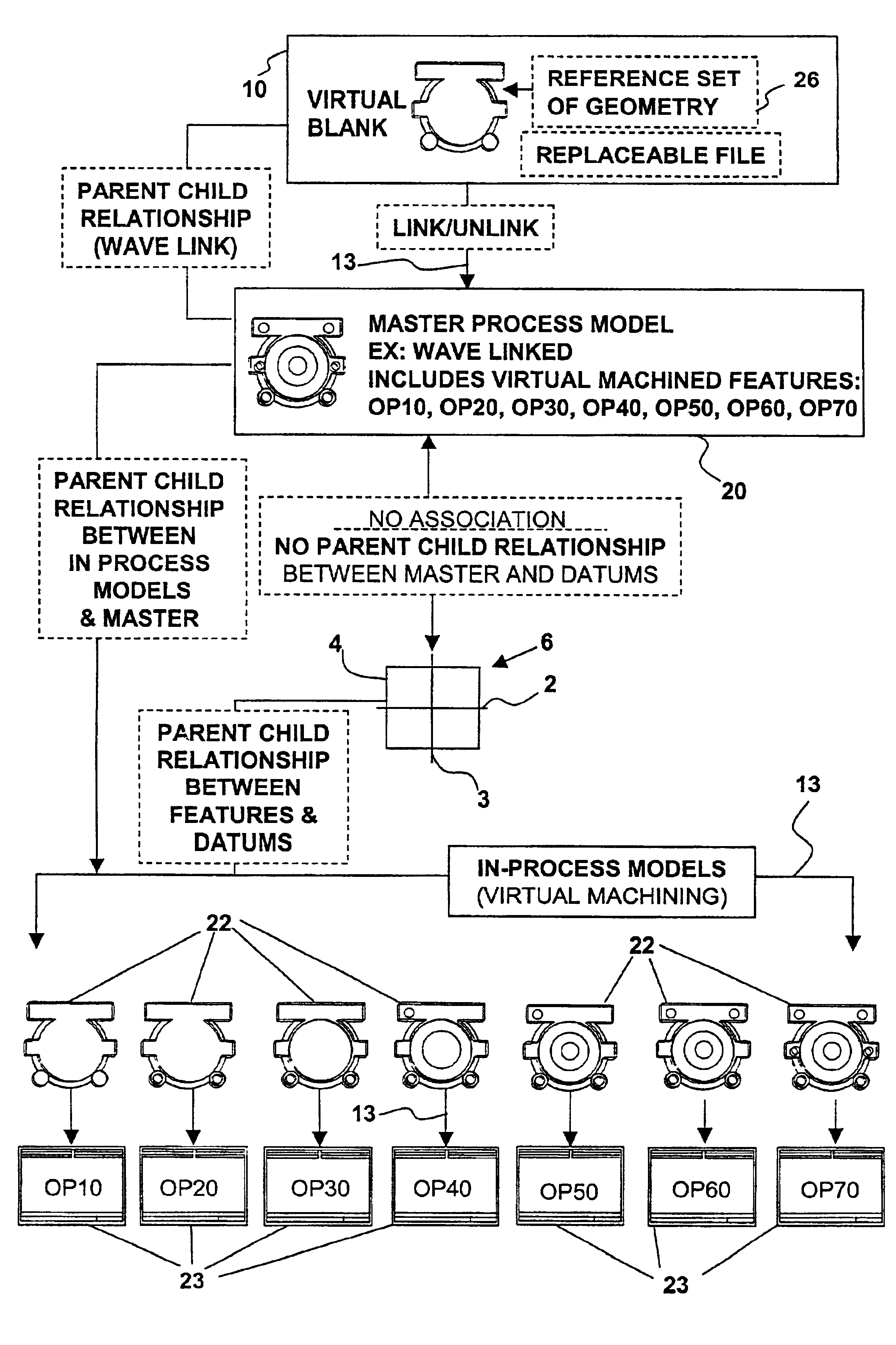

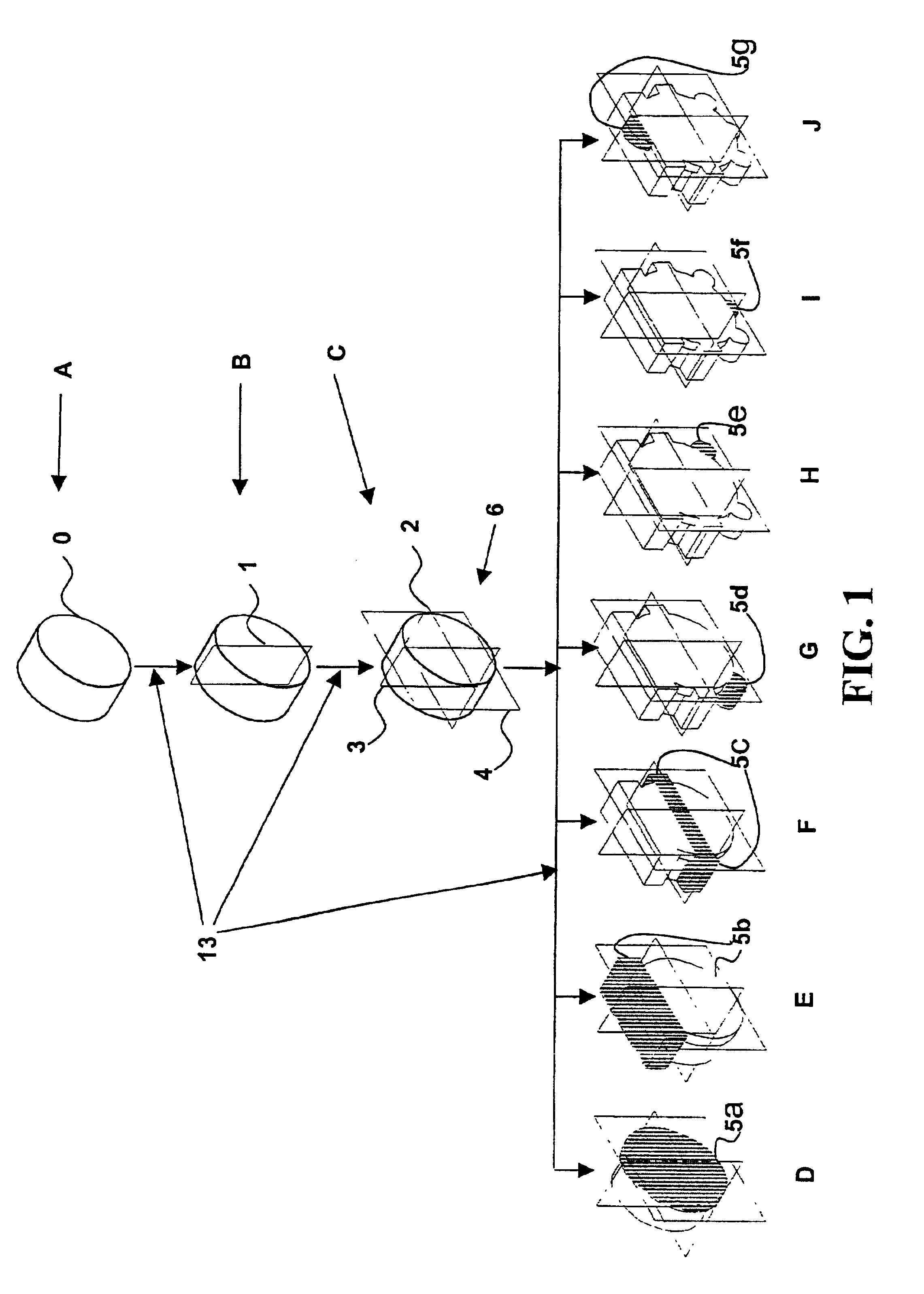

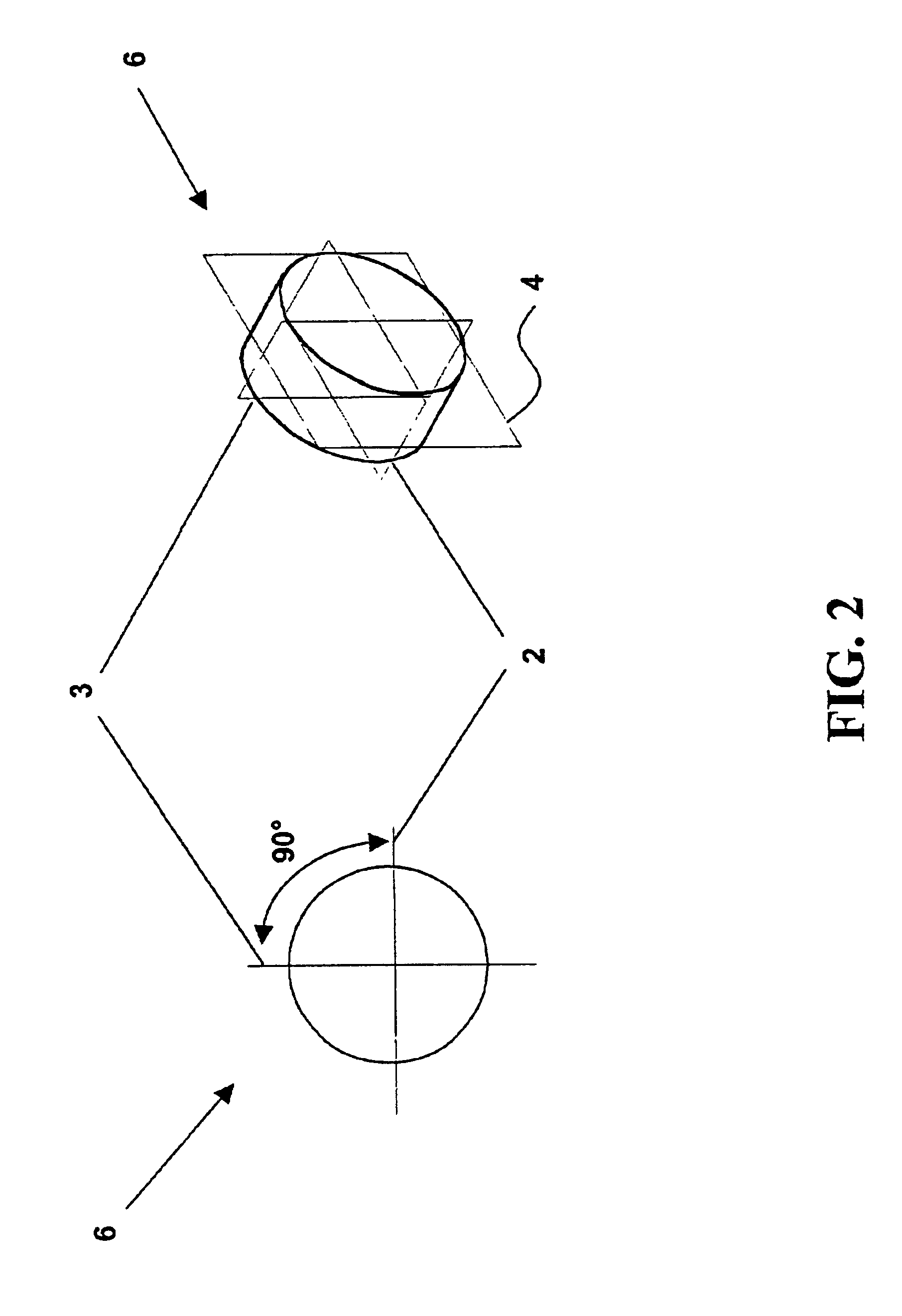

Horizontally-structured CAD/CAM modeling for virtual concurrent product and process design

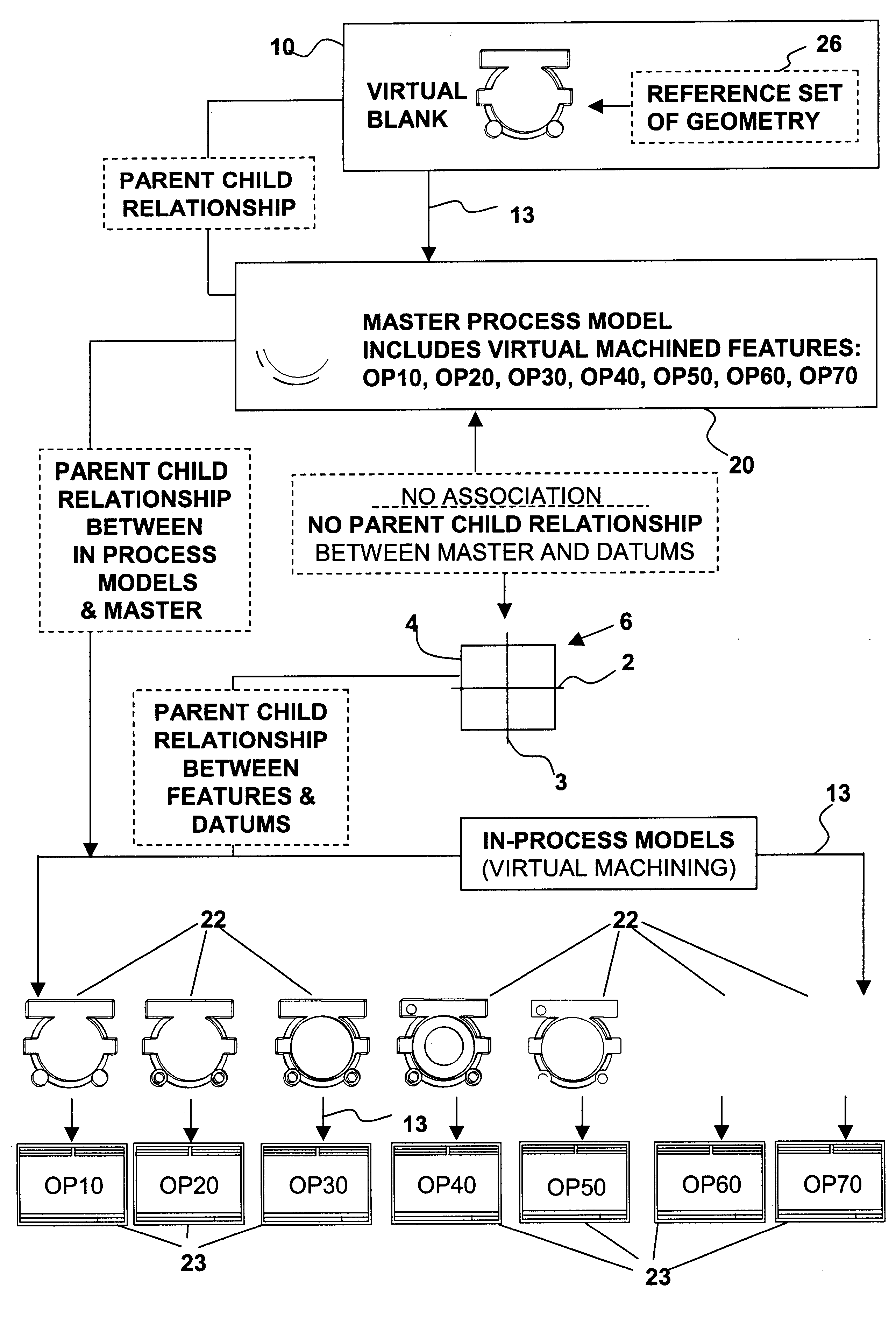

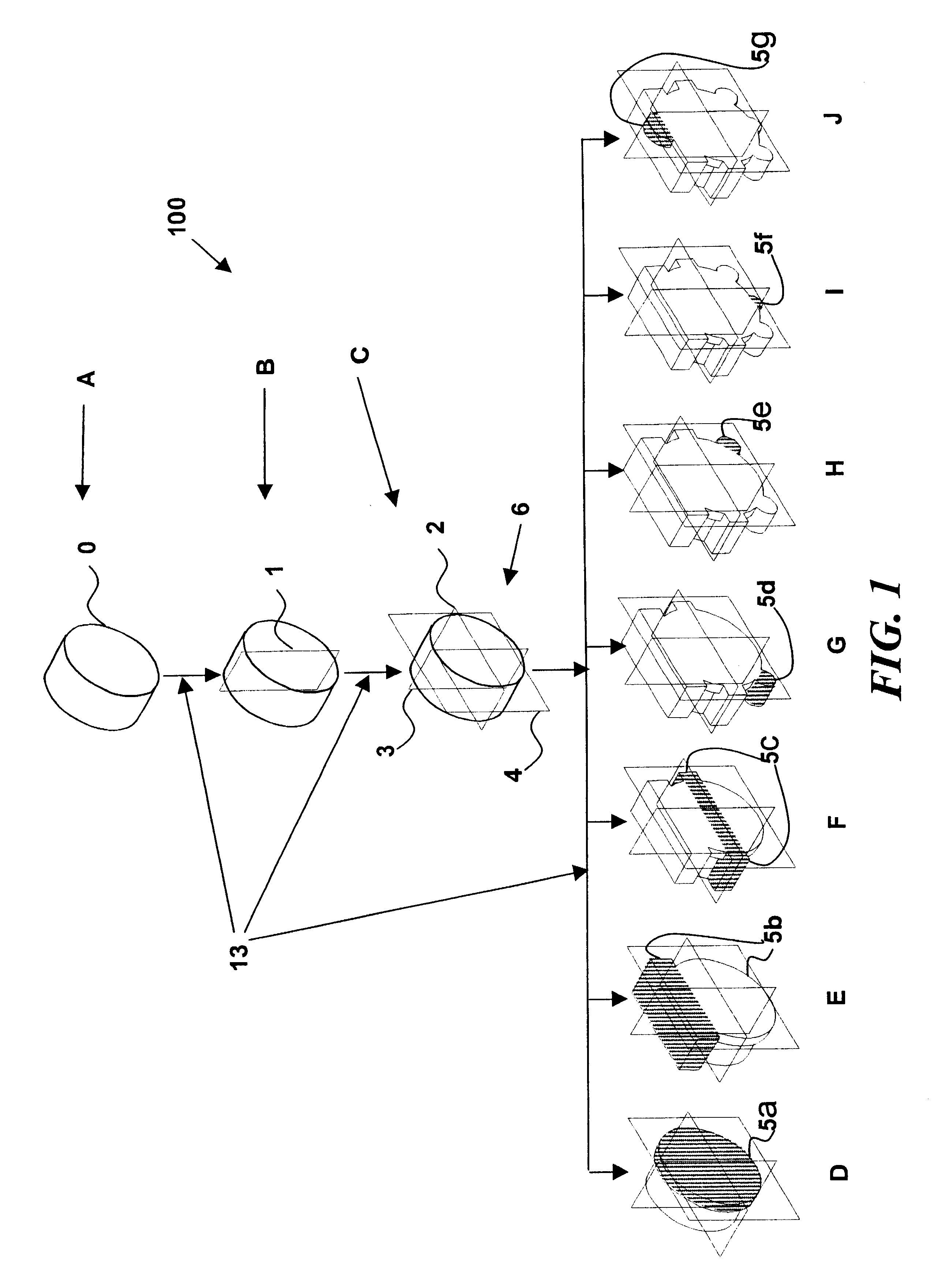

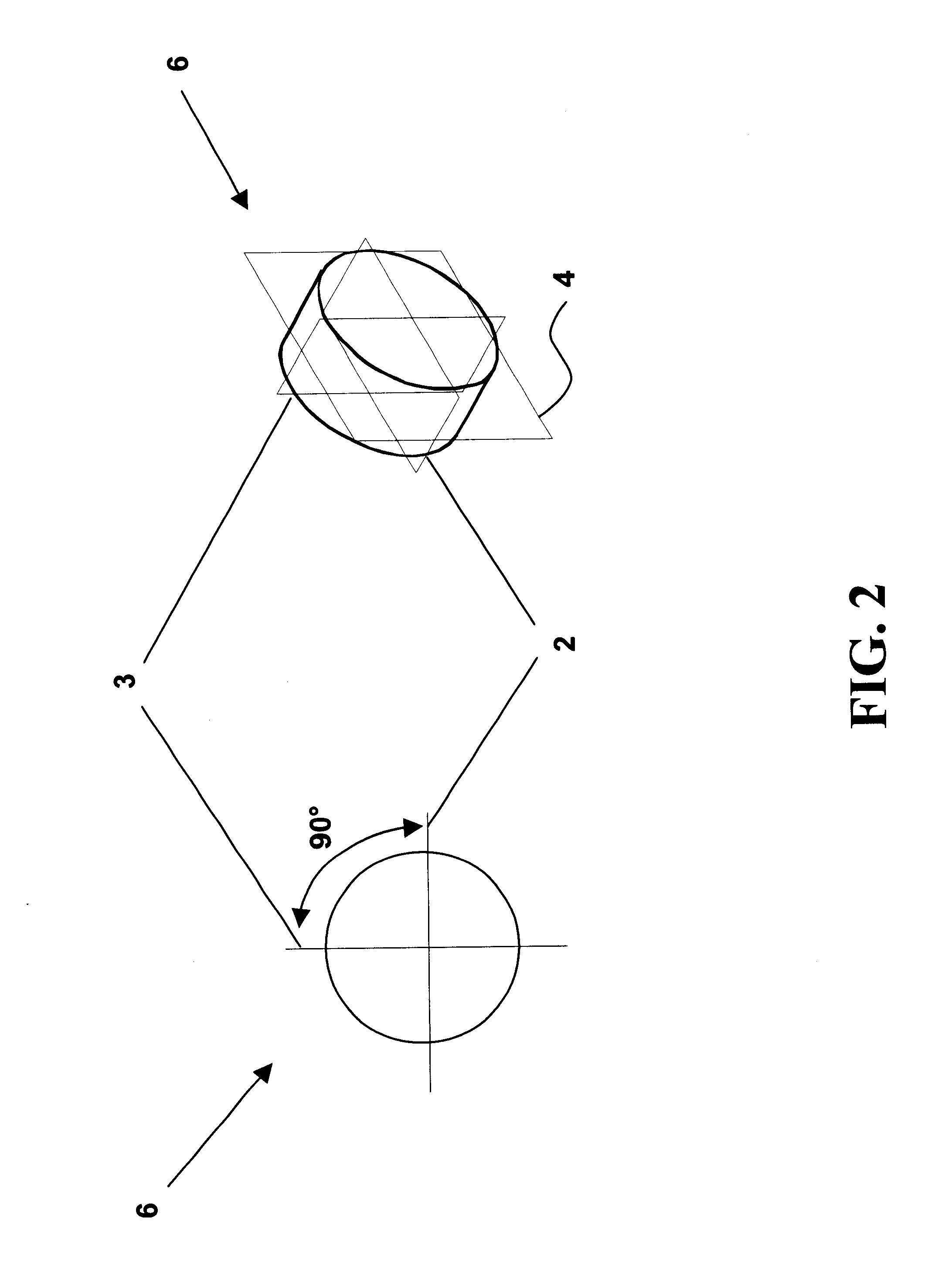

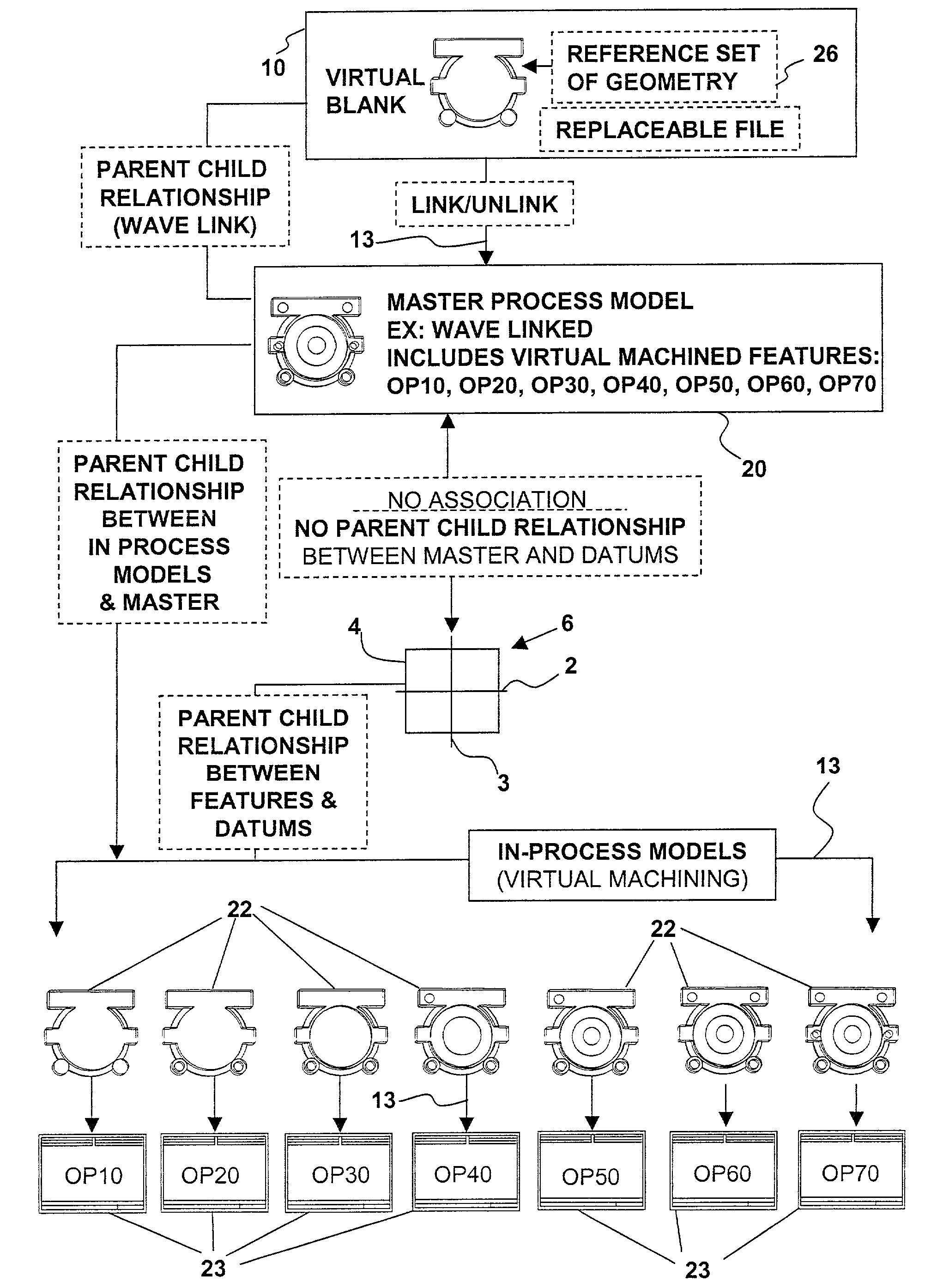

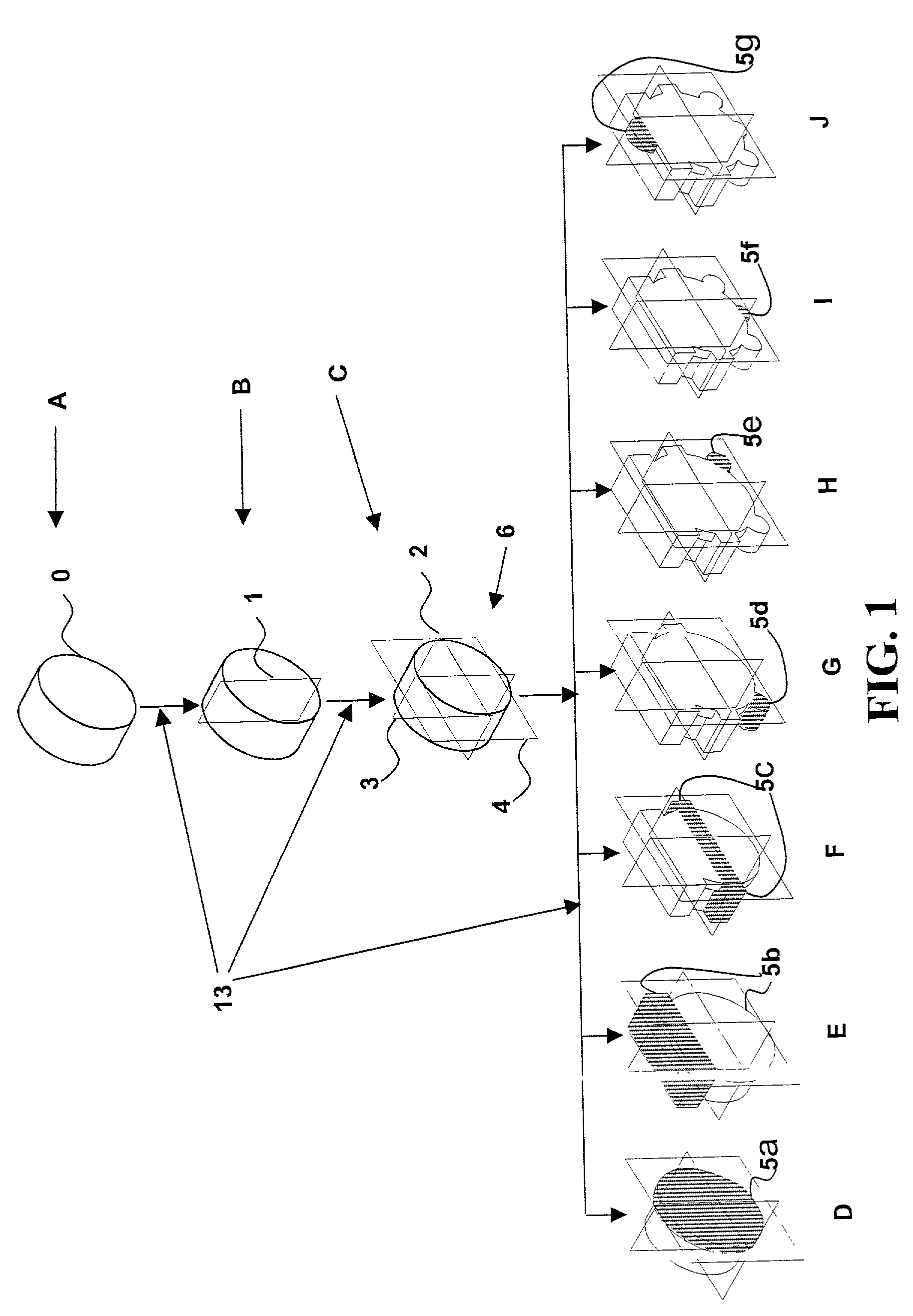

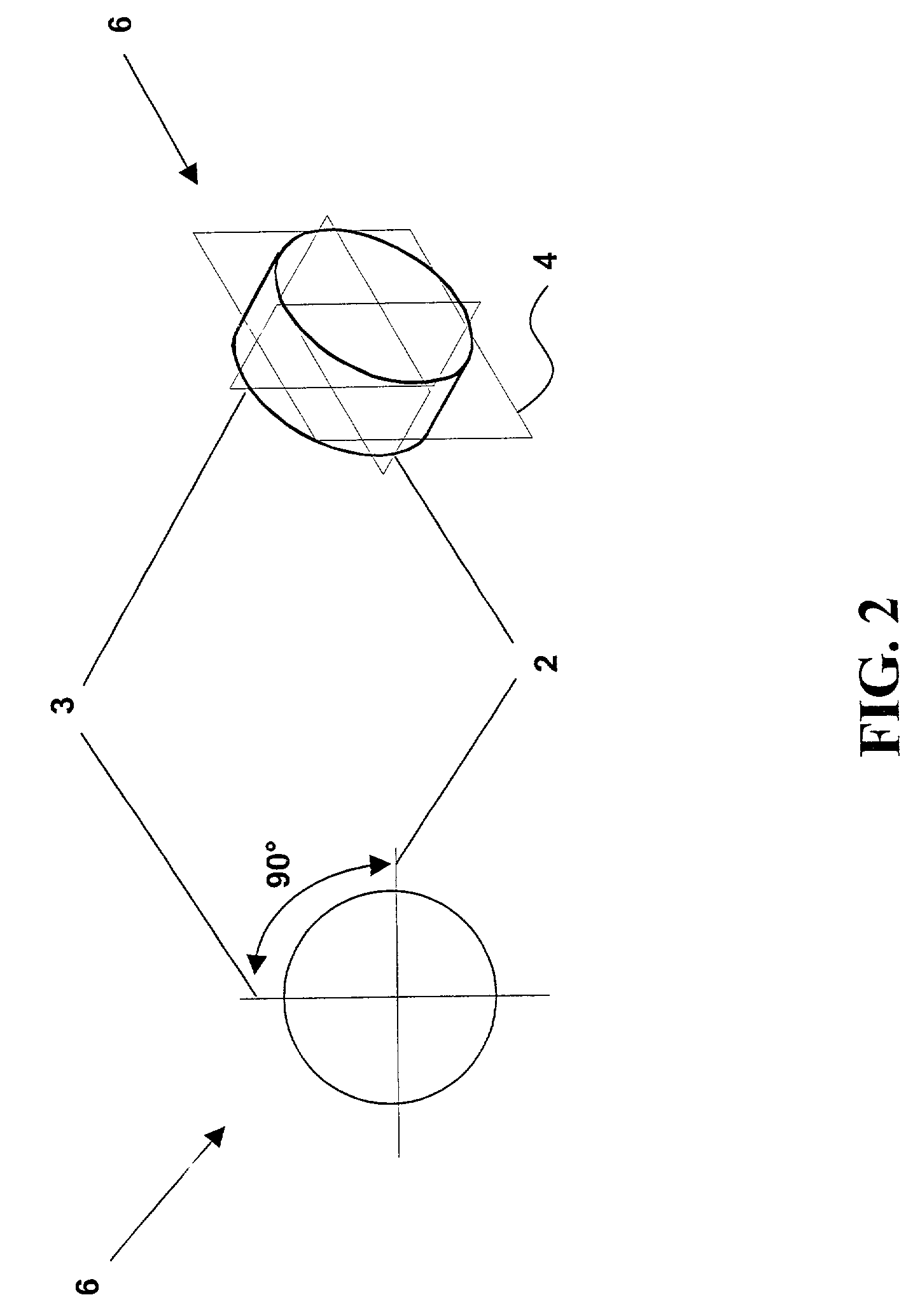

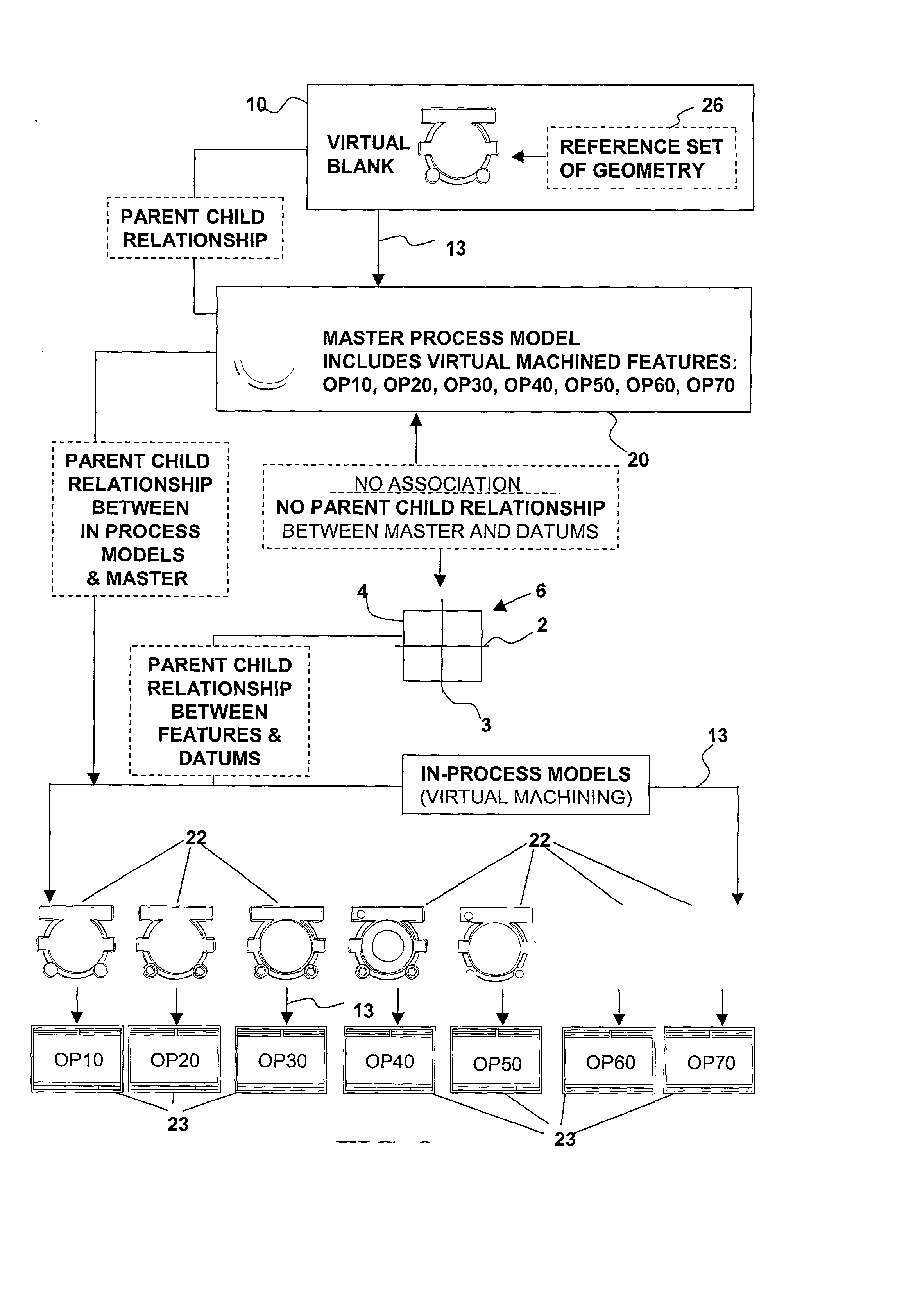

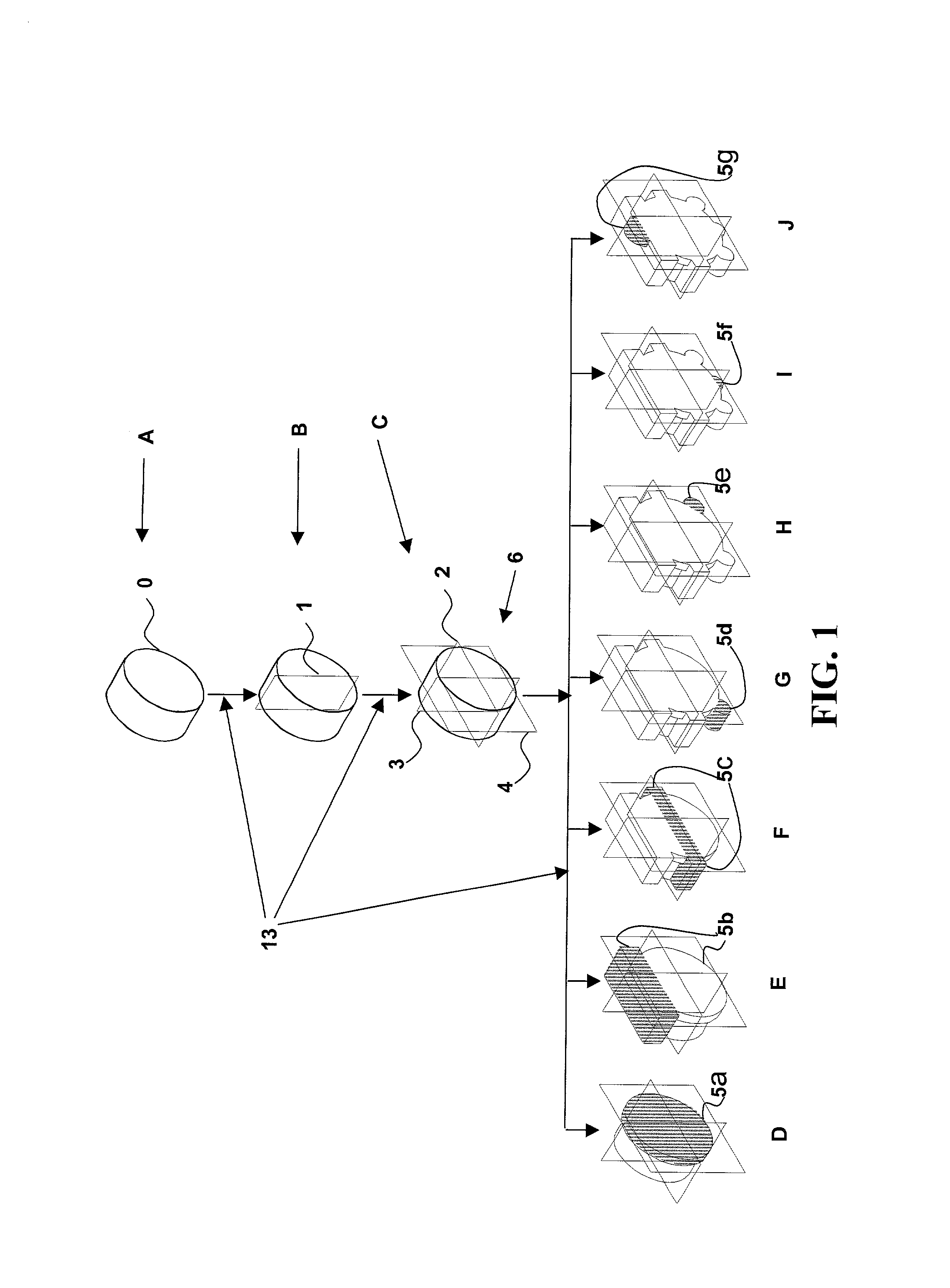

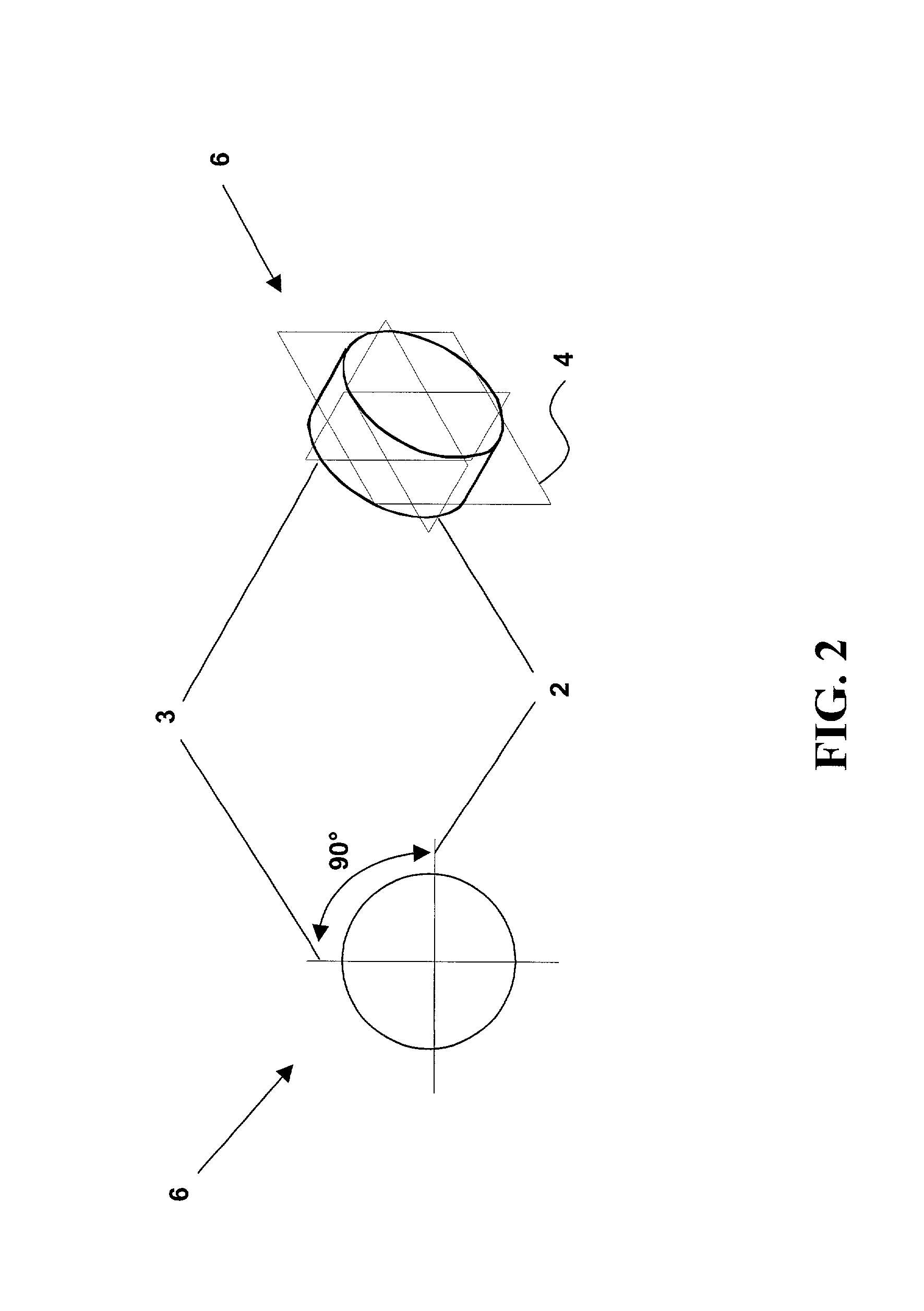

Disclosed herein is a method of horizontally structured CAD / CAM modeling and manufacturing for concurrent product and process design, comprising: selecting a blank for machining into an actual part establishing a coordinate system; and creating a master product and process concurrent model comprising: a virtual blank corresponding to the blank; a manufacturing feature; virtual machining of the manufacturing feature into the virtual blank; where the manufacturing feature exhibits an associative relationship with the coordinate system. The method also includes generating a product drawing of the actual part; and generating machining instructions to create the actual part by machining the manufacturing feature into the blank. Also disclosed herein is a horizontally structured CAD / CAM model for concurrent product and manufacturing processes comprising: a blank for machining into an actual part; a coordinate system; and a master product and process concurrent model comprising: a virtual blank corresponding to the blank; a manufacturing feature; the manufacturing feature virtual machined into the virtual blank; and the manufacturing feature exhibiting an associative relationship with the coordinate system. Further disclosed is a storage medium encoded with a machine-readable computer program code for horizontally structured CAD / CAM modeling. The storage medium including instructions for causing a computer to implement the method of horizontally structured CAD / CAM modeling and manufacturing for concurrent product and process design. Additionally disclosed is a computer data signal for horizontally structured CAD / CAM modeling. The computer data signal comprising code configured to cause a processor to implement a method of horizontally structured CAD / CAM modeling and manufacturing for concurrent product and process design.

Owner:STEERING SOLUTIONS IP HLDG +1

Simulation system

ActiveUS20070061037A1Easy to operateEasy to useProgramme controlSpecial data processing applicationsProgram managementVirtual machining

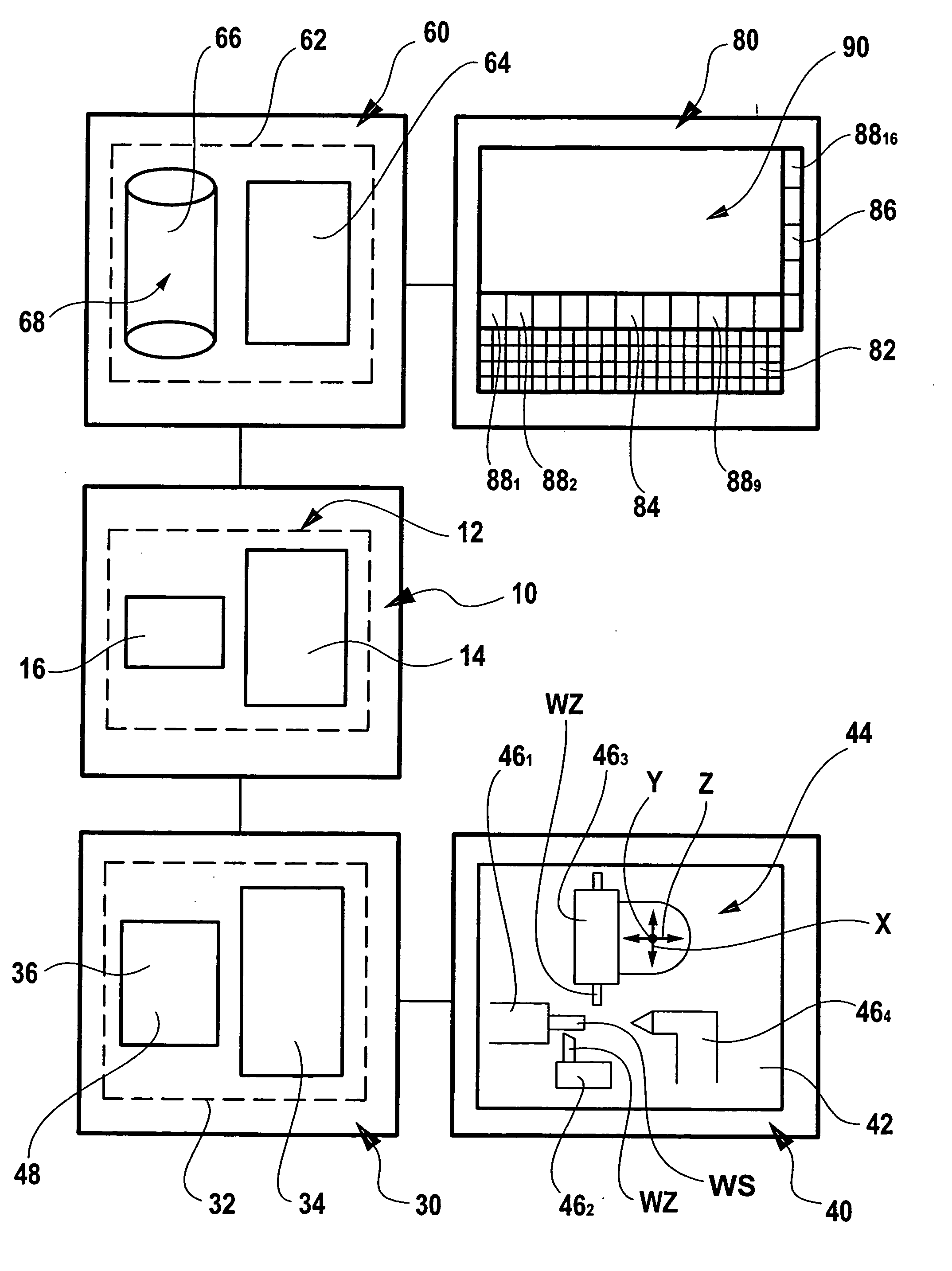

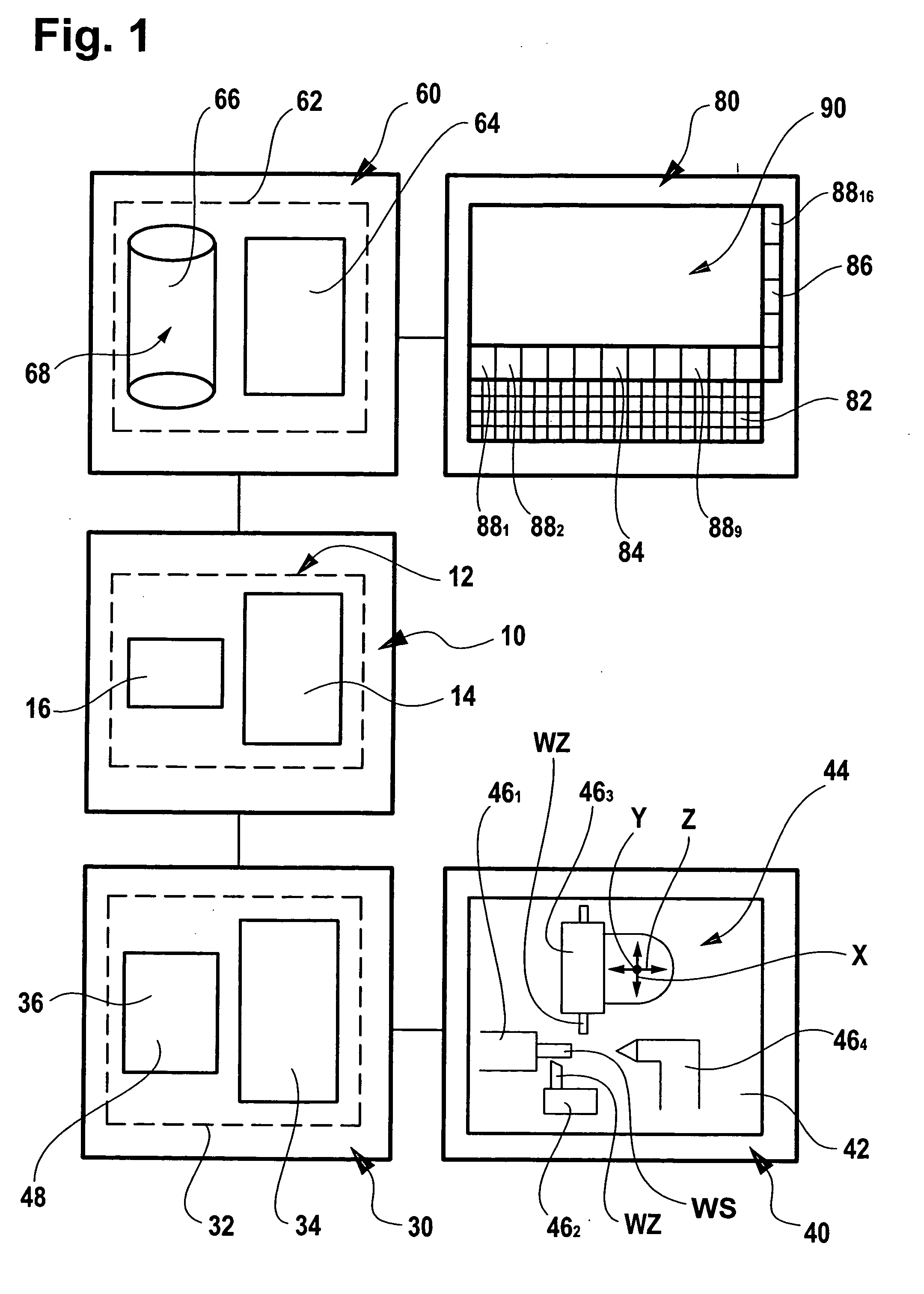

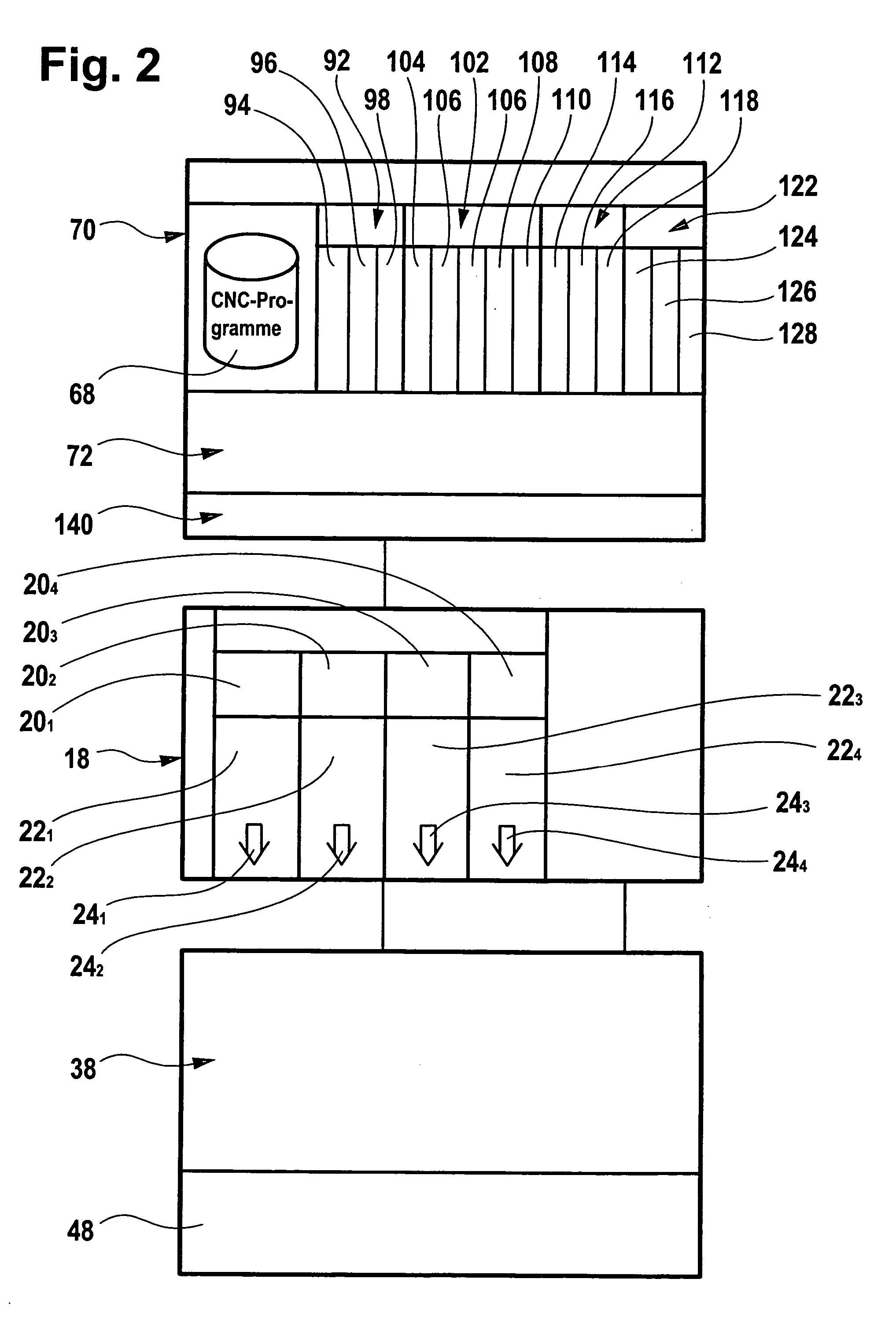

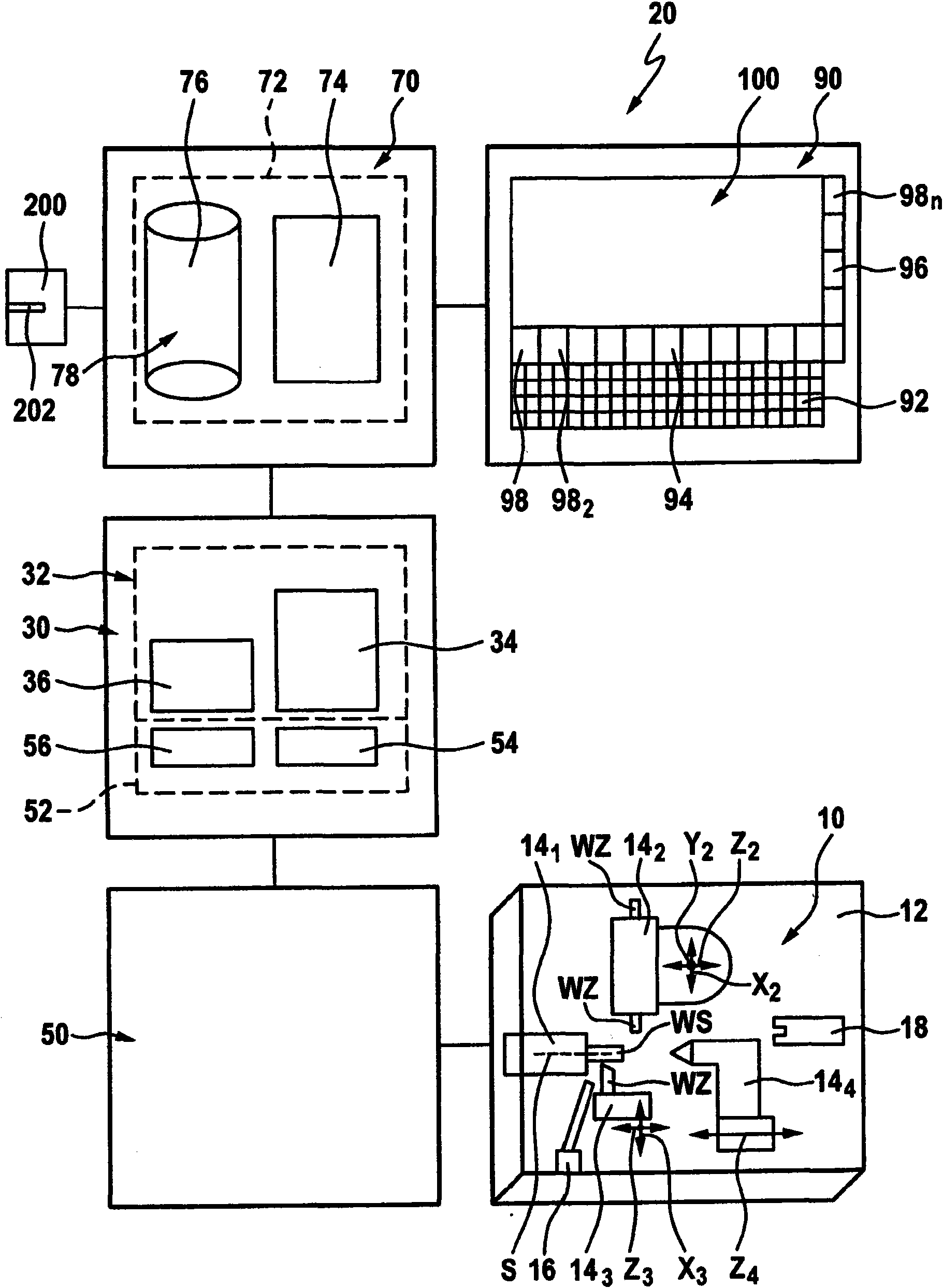

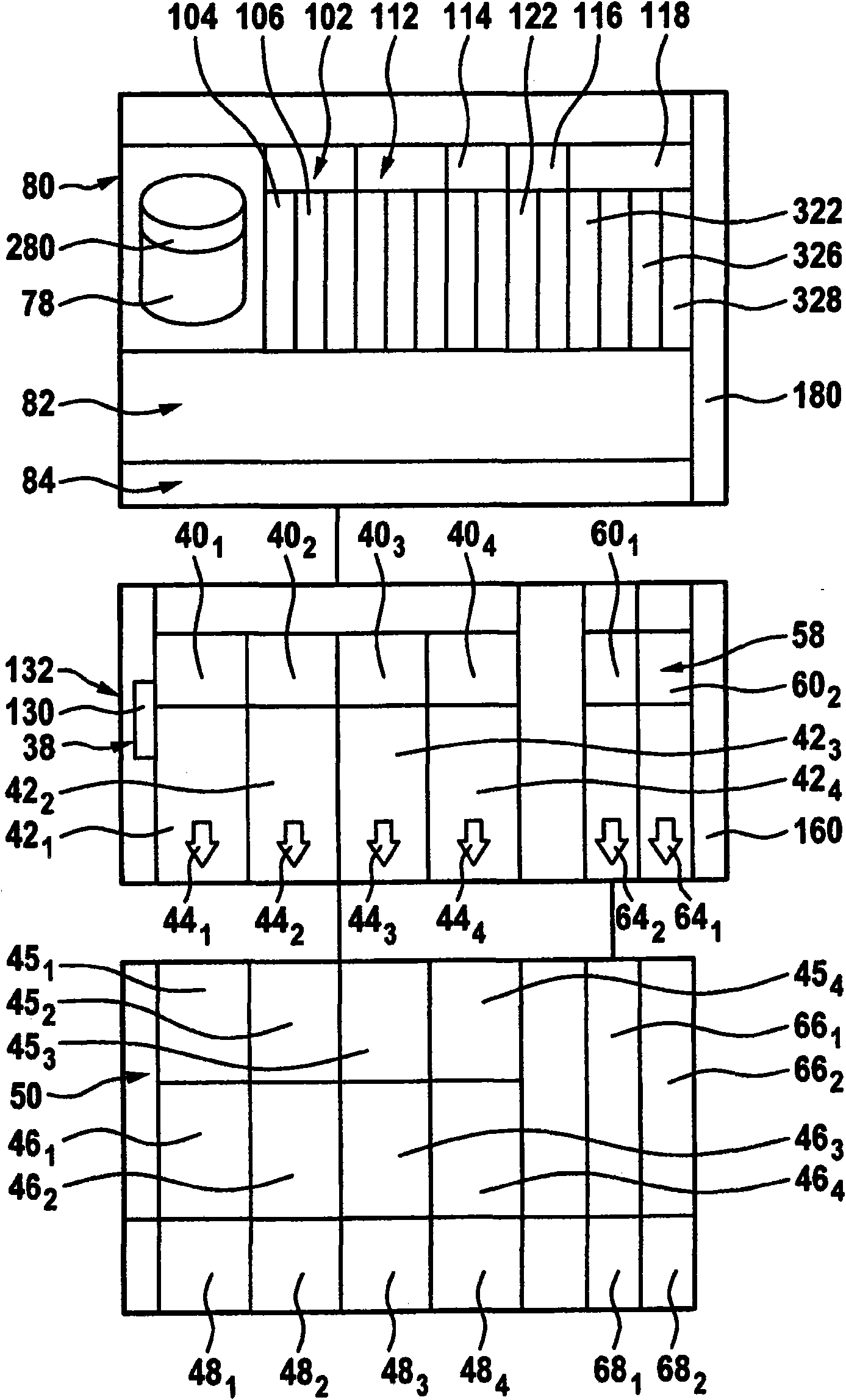

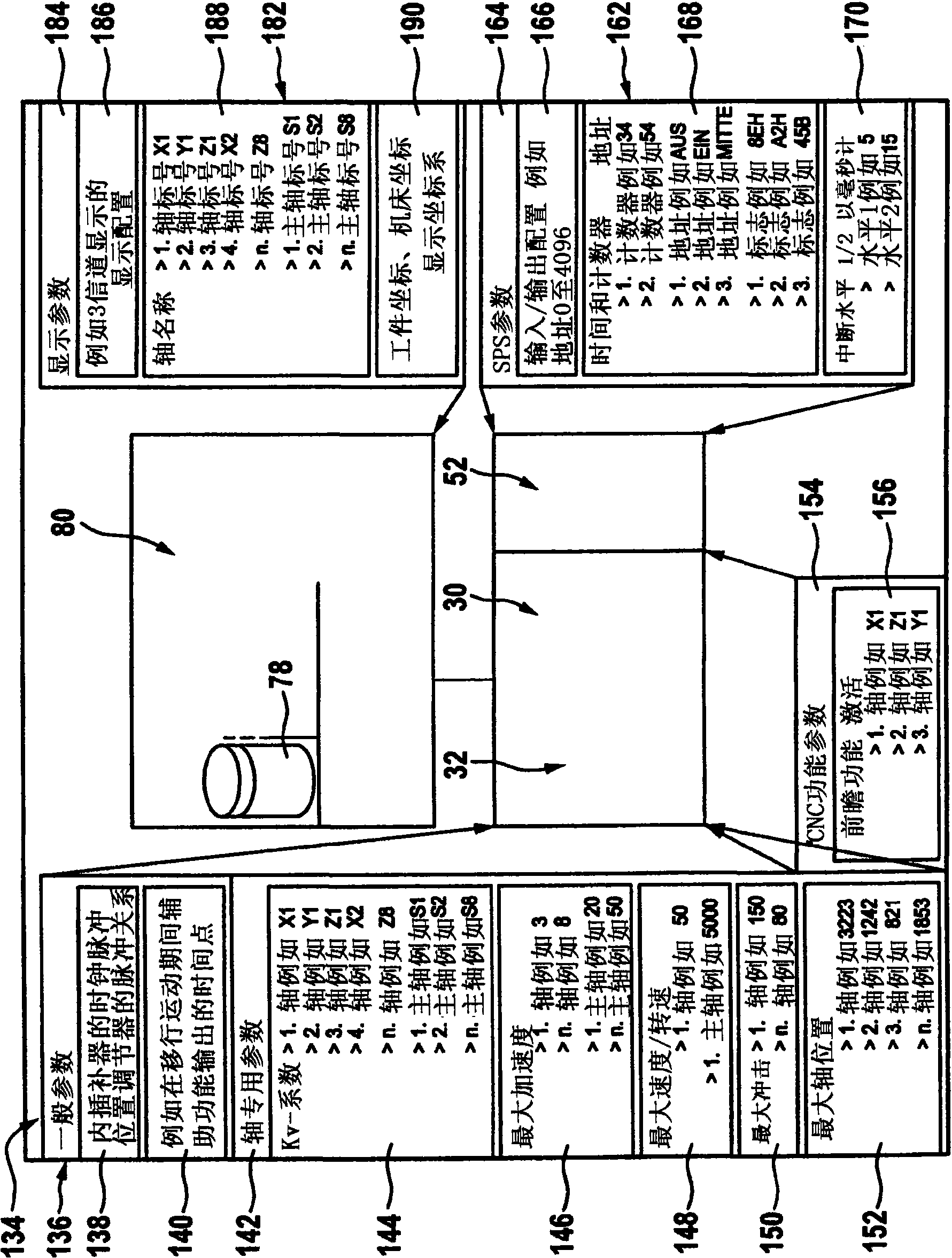

In order to improve a simulation system for representing actions of machining units of a machine tool, in particular actions in the machining of a workpiece, in accordance with a CNC machining program complex by means of at least one first visualization unit in the form of actions of virtual machining units of a virtual machine tool, comprising an action control, which has at least one first data processing unit, which establishes control commands for actions of the virtual machining units by a control program processing CNC blocks of the CNC machining program complex, and a visualization control, which has at least one second data processing unit, which represents actions of the virtual machining units on the first visualization unit by a visualization program on the basis of configuration data of a stored machine model and the control commands determined by the action control, in such a way that it can be operated more easily, it is proposed that the simulation system comprises an operating control with a third data processing unit, which operates the action control by an operating program, and that the operating program has a program management function, which transfers at least program parts of the CNC machining program complex in a workpiece-related manner from said CNC machining program complex stored in a memory of the third data processing unit to the action control for executing said program complex.

Owner:INDEX WERKE GMBH & CO KG HAHN & TESSKY

Intelligent machining workshop production planning and scheduling integration method

ActiveCN108009739AClosed loopTimely response to ordersResourcesLogisticsVirtual machiningProgram planning

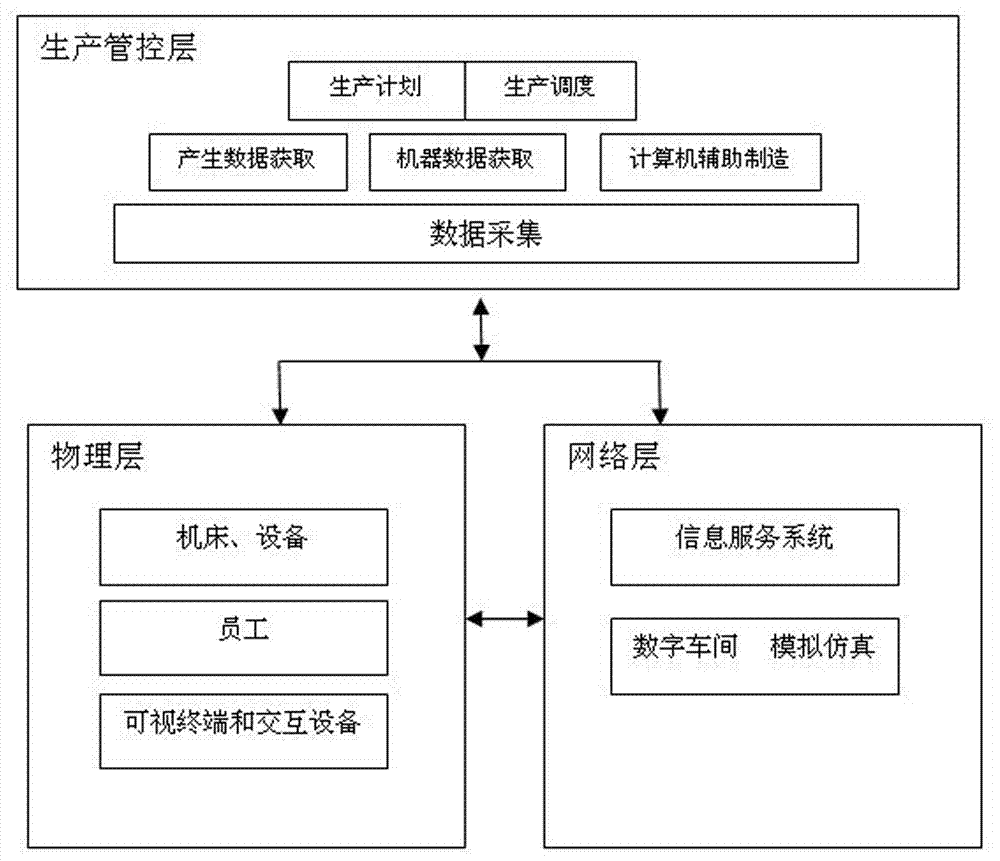

The invention discloses an intelligent machining workshop production planning and scheduling integration method, which belongs to the field of automated technical application. The method comprises thefollowing steps that: system modeling; data preparation; order form preparation; production planning and scheduling; virtual processing; dynamically monitoring; dynamically scheduling; revising a plan; and carrying out rolling optimization. Through production planning and scheduling integration under the support of an intelligent workshop network physical system, the closed loop of "production planning-production scheduling-production state information" under the dynamic environment of the workshop is realized, and the problem that an existing production planning and scheduling method is difficult in responding to various categories of dynamic events of environment (market) changes and workshop sites in time.

Owner:SHENYANG POLYTECHNIC UNIV

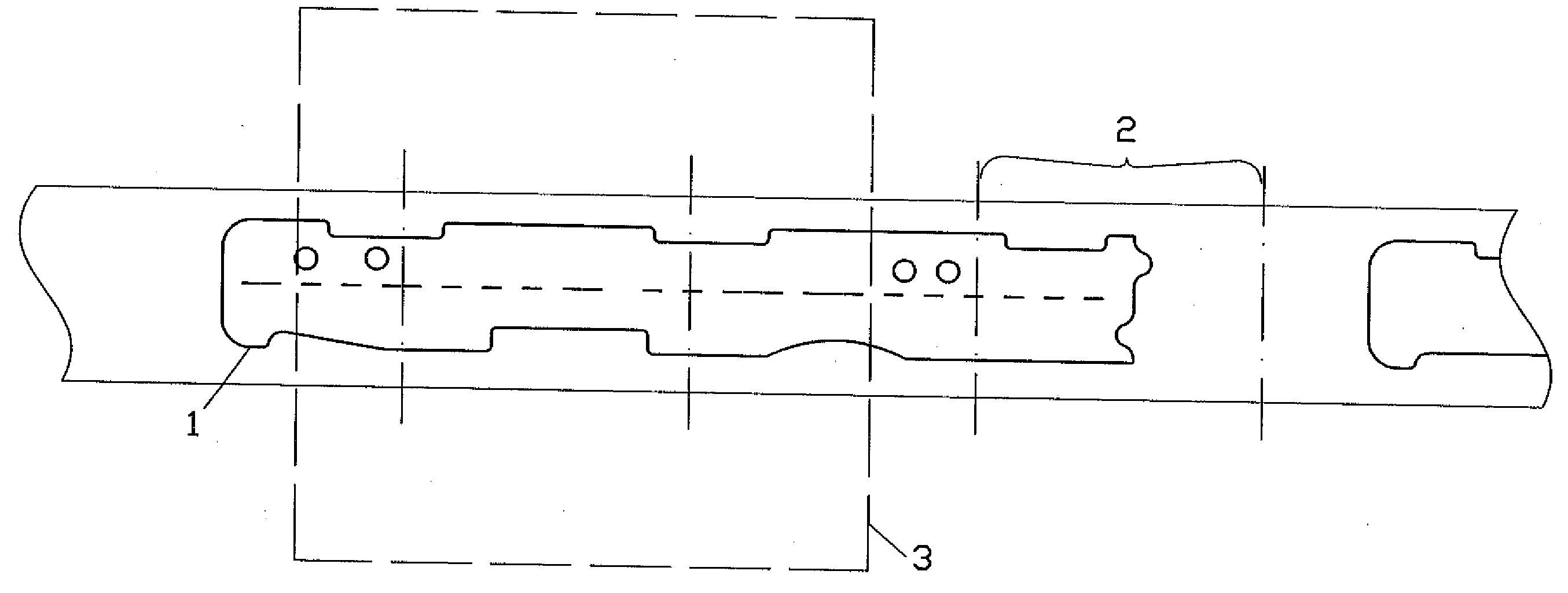

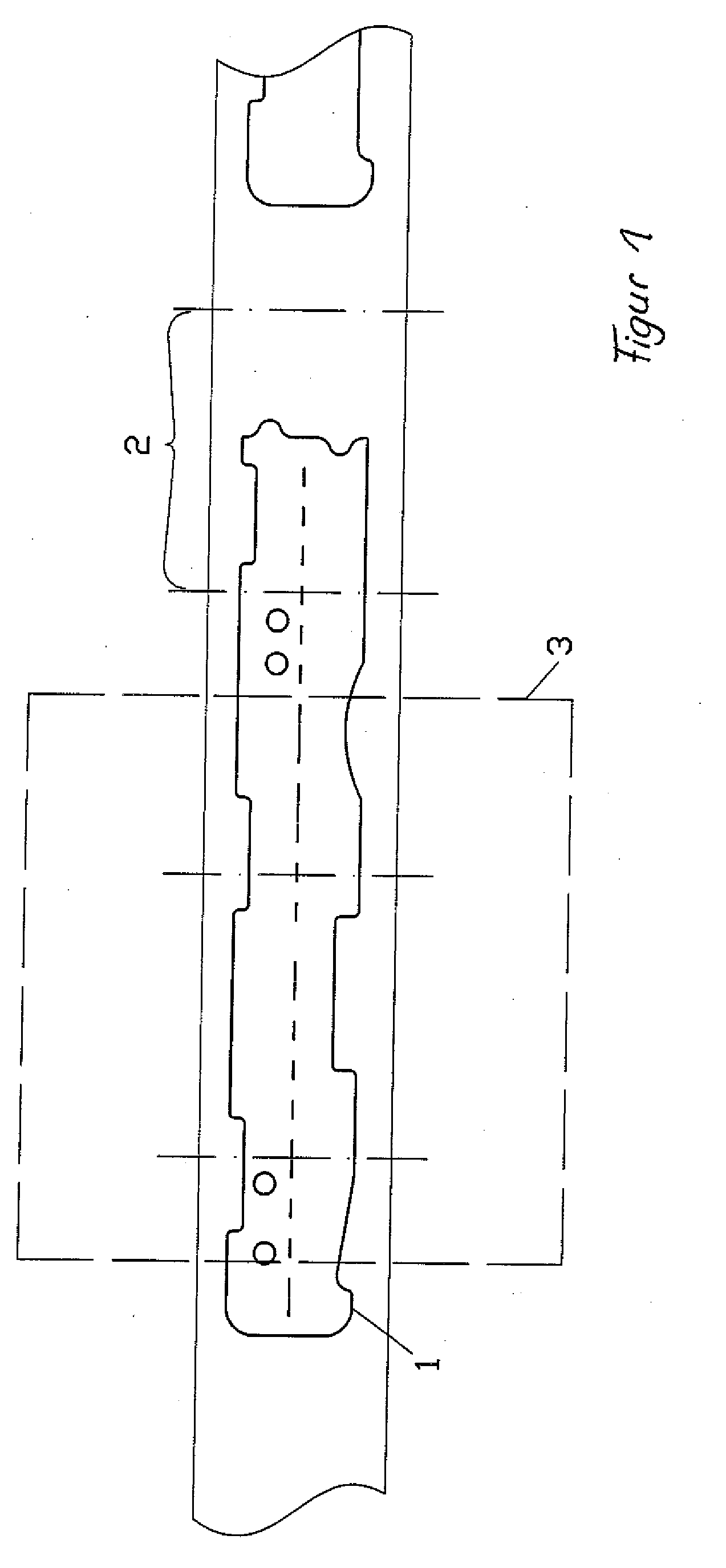

Horizontally-structured CAD/CAM modeling for virtual fixture and tooling processes

Disclosed herein is a method of horizontally structured CAD / CAM modeling and manufacturing process for fixtures and tooling comprising: selecting a contact area geometry; generating a tooling model corresponding to the contact area geometry; virtual machining the tooling model to generate the fixtures and tooling; and generating machining instructions to create the fixtures and tooling; where the tooling model exhibits an associative relationship with the contact area geometry. Also disclosed herein is a horizontally structured CAD / CAM model for fixtures and tooling, comprising: a selected contact area geometry; a tooling model that corresponds to the contact area geometry, generated from the selected contact area geometry; where the tooling model includes virtual machining operations to generate the fixtures and tooling; and the tooling model exhibits an associative relationship with the contact area geometry. Further disclosed is a storage medium encoded with a machine-readable computer program code for horizontally structured CAD / CAM modeling. The storage medium including instructions for causing a computer to implement the method of horizontally structured CAD / CAM modeling and manufacturing for fixtures and tooling. Additionally disclosed is a computer data signal for horizontally structured CAD / CAM modeling. The computer data signal comprising code configured to cause a processor to implement a method of horizontally structured CAD / CAM modeling and manufacturing for fixtures and tooling.

Owner:STEERING SOLUTIONS IP HLDG +1

Horizontally-structured CAD/CAM modeling for virtual concurrent product and process design

Disclosed herein is a method of horizontally structured CAD / CAM modeling and manufacturing for concurrent product and process design, comprising: selecting a blank for machining into an actual part establishing a coordinate system; and creating a master product and process concurrent model comprising: a virtual blank corresponding to the blank; a manufacturing feature; virtual machining of the manufacturing feature into the virtual blank; where the manufacturing feature exhibits an associative relationship with the coordinate system. The method also includes generating a product drawing of the actual part; and generating machining instructions to create the actual part by machining the manufacturing feature into the blank. Also disclosed herein is a horizontally structured CAD / CAM model for concurrent product and manufacturing processes comprising: a blank for machining into an actual part; a coordinate system; and a master product and process concurrent model comprising: a virtual blank corresponding to the blank; a manufacturing feature; the manufacturing feature virtual machined into the virtual blank; and the manufacturing feature exhibiting an associative relationship with the coordinate system. Further disclosed is a storage medium encoded with a machine-readable computer program code for horizontally structured CAD / CAM modeling. The storage medium including instructions for causing a computer to implement the method of horizontally structured CAD / CAM modeling and manufacturing for concurrent product and process design. Additionally disclosed is a computer data signal for horizontally structured CAD / CAM modeling. The computer data signal comprising code configured to cause a processor to implement a method of horizontally structured CAD / CAM modeling and manufacturing for concurrent product and process design.

Owner:STEERING SOLUTIONS IP HLDG +1

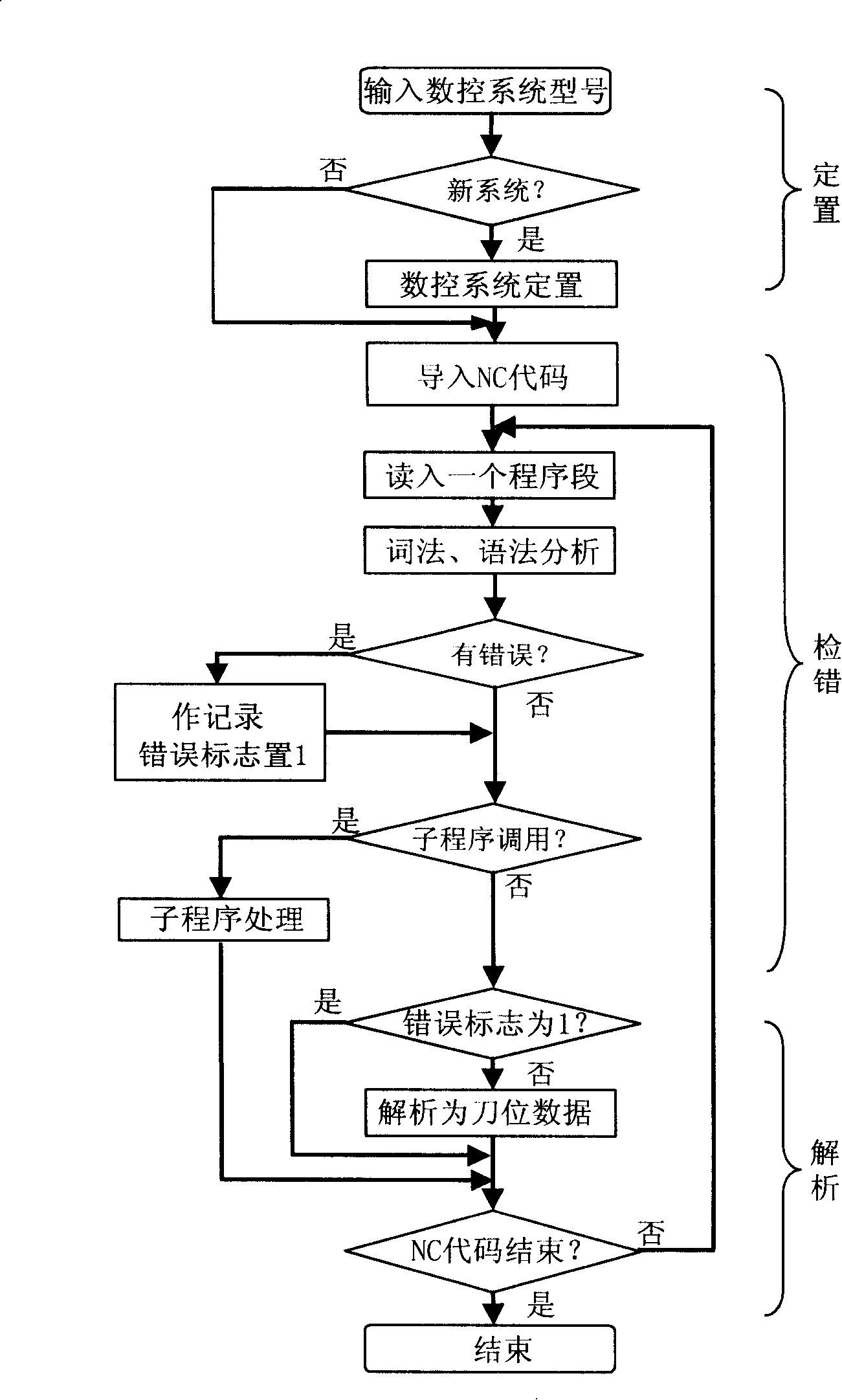

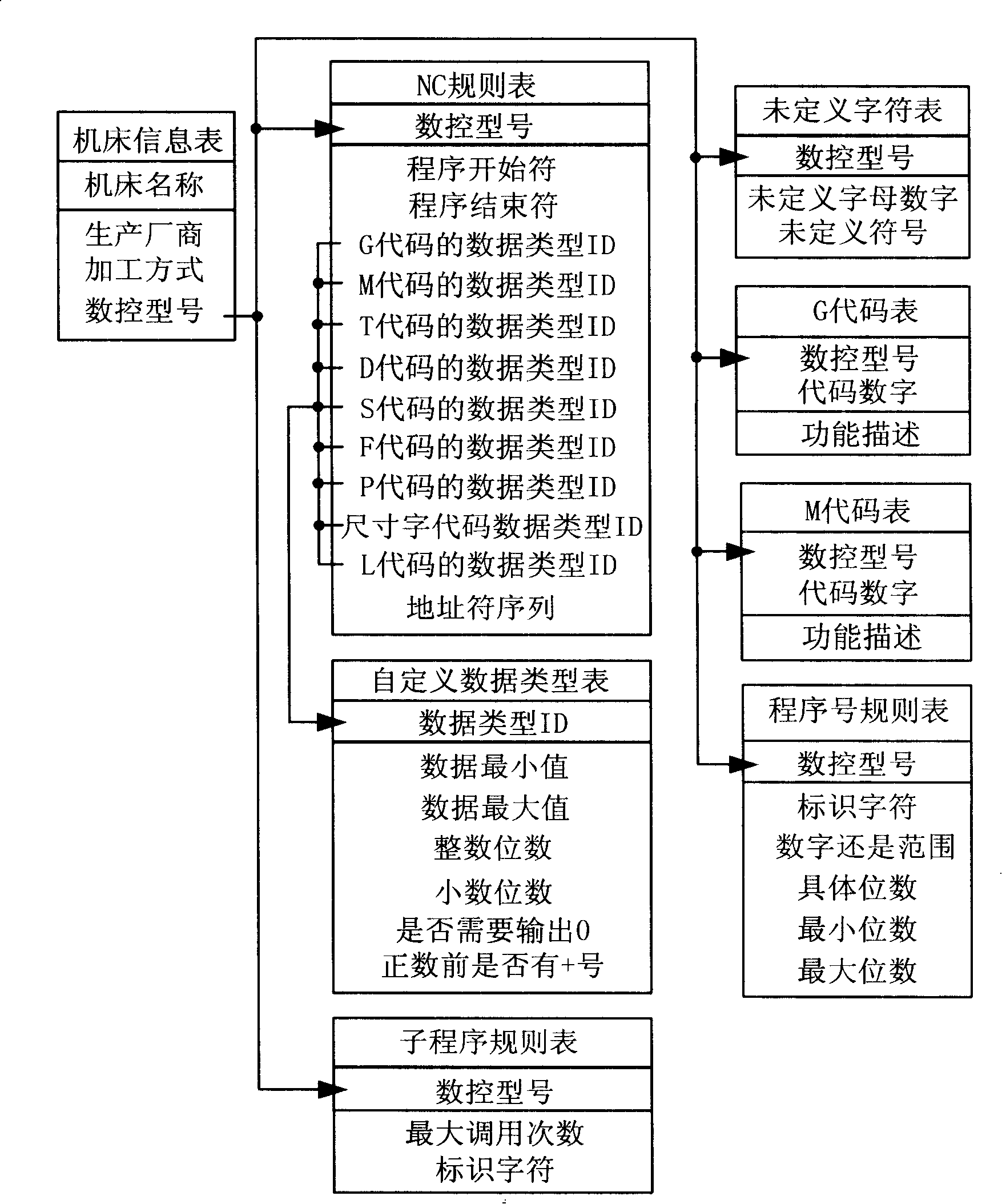

Universal numerical control code analysis method

InactiveCN101206467AVersatilityEasy to implementComputer controlSimulator controlVirtual machiningNumerical control system

The invention discloses a general numerical control code analytic method. The invention relates to an error detection and analytic method for NC codes and provides a customized means which is used for extending functions of a parser on the basis of the method. The invention analyzes morphology and grammar of the NC codes on the basis of a rule database; if errors exist, the parser can output an error report and indicate error types and positions; a user modifies the NC codes and then detects errors, and the process is repeated until no error exists in the codes; the NC codes are analyzed by adoption of a time slice discrete method, and tool position files are generated and used for driving virtual manufacturing processes; as for numerical control systems which are not supported by a system, the user arranges rules of a novel system in the rule database by three steps through a customized interface. The invention has commonality and openness, and can widen application fields of virtual processing systems and processing simulation softwares and then strengthens competitive power of enterprises in the market.

Owner:NANJING UNIV OF SCI & TECH

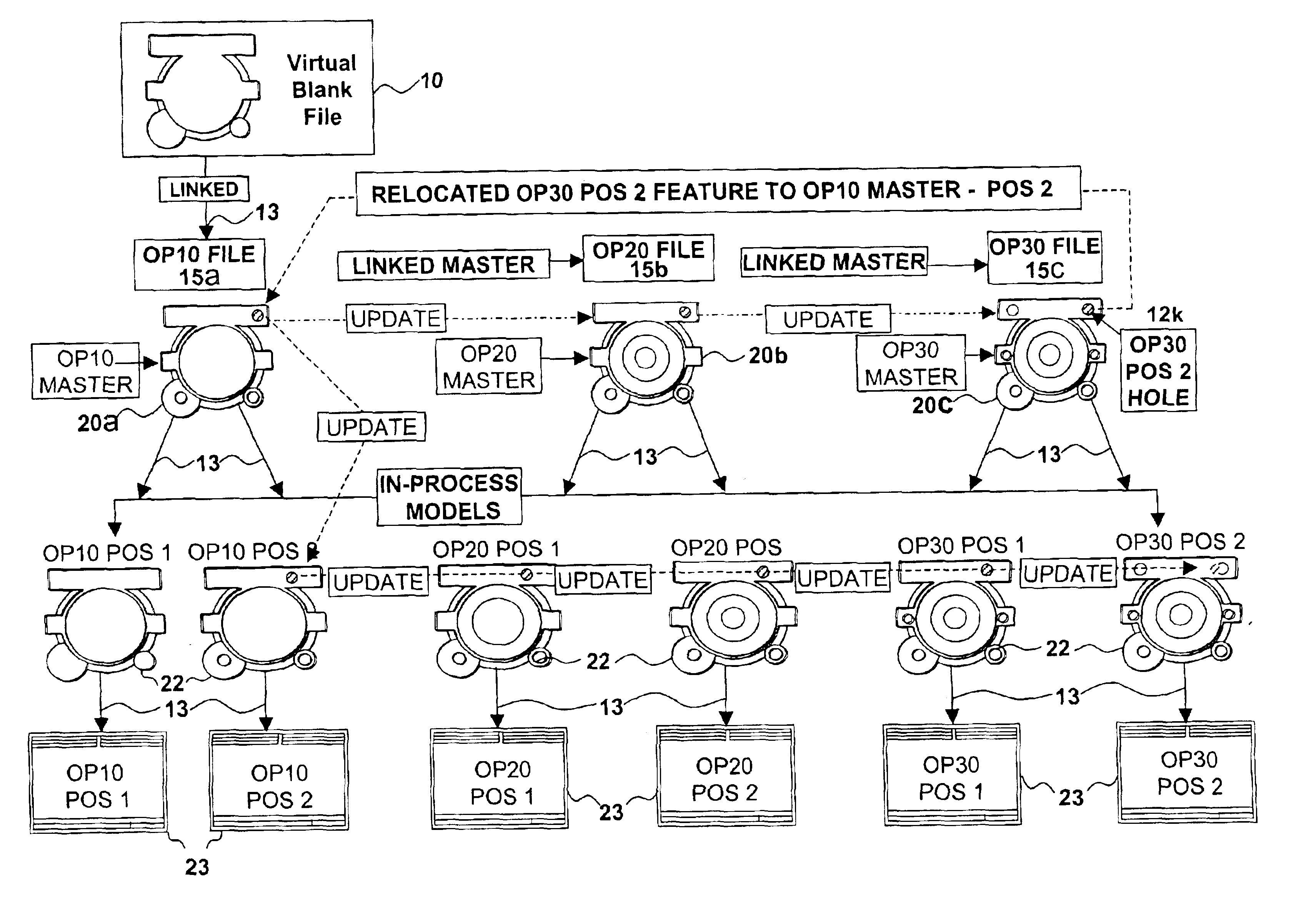

Horizontally structured manufacturing process modeling: across file feature operability

A method of manipulating manufacturing features in horizontally structured manufacturing process models for large parts, comprising: selecting a manufacturing feature from a plurality of manufacturing features; wherein the horizontally structured manufacturing process model includes a first master process model in a first file with an established coordinate system with an existing sequence of virtual machining each manufacturing feature of the plurality of manufacturing features into a virtual blank, and each manufacturing feature exhibiting an associative relationship with the coordinate system and the virtual blank. The method also includes relocating the selected manufacturing feature of another master process model; and re-sequencing the master process model to establish a new sequence for virtual machining each manufacturing feature of the plurality of manufacturing features into the virtual blank indicative of the relocating.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Horizontally-structured CAD/CAM modeling for virtual fixture and tooling processes

Disclosed herein is a method of horizontally structured CAD / CAM modeling and manufacturing process for fixtures and tooling comprising: selecting a contact area geometry; generating a tooling model corresponding to the contact area geometry; virtual machining the tooling model to generate the fixtures and tooling; and generating machining instructions to create the fixtures and tooling; where the tooling model exhibits an associative relationship with the contact area geometry. Also disclosed herein is a horizontally structured CAD / CAM model for fixtures and tooling, comprising: a selected contact area geometry; a tooling model that corresponds to the contact area geometry, generated from the selected contact area geometry; where the tooling model includes virtual machining operations to generate the fixtures and tooling; and the tooling model exhibits an associative relationship with the contact area geometry. Further disclosed is a storage medium encoded with a machine-readable computer program code for horizontally structured CAD / CAM modeling. The storage medium including instructions for causing a computer to implement the method of horizontally structured CAD / CAM modeling and manufacturing for fixtures and tooling. Additionally disclosed is a computer data signal for horizontally structured CAD / CAM modeling. The computer data signal comprising code configured to cause a processor to implement a method of horizontally structured CAD / CAM modeling and manufacturing for fixtures and tooling.

Owner:STEERING SOLUTIONS IP HLDG +1

Laser and blast compound forming method based prestress force

InactiveCN101288888AOvercome the disadvantage of damage or even destructionImprove plastic fluiditySpecial data processing applicationsThermal energyVirtual machining

The invention discloses a composite forming method of laser and shot peening on the basis of pre-stress, which is characterized in that virtual process is firstly carried out by a blank piece so as to gain all parameters in the machining process; during the processing, a temperature field is formed at a difficult-deformation area by the laser; when the laser is used for scanning, the local shot peening disposal leads the surface at the other side of the stiffener to generate tensile plastic deformation; when the method of the invention is adopted for forming, the thermal energy converted by the laser energy can reduce the deformation resistance of the material in the laser function area, and can lead the surface to generate larger plastic deformation and improve the forming quantity by raising the temperature of the whole processing of the blank piece little.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

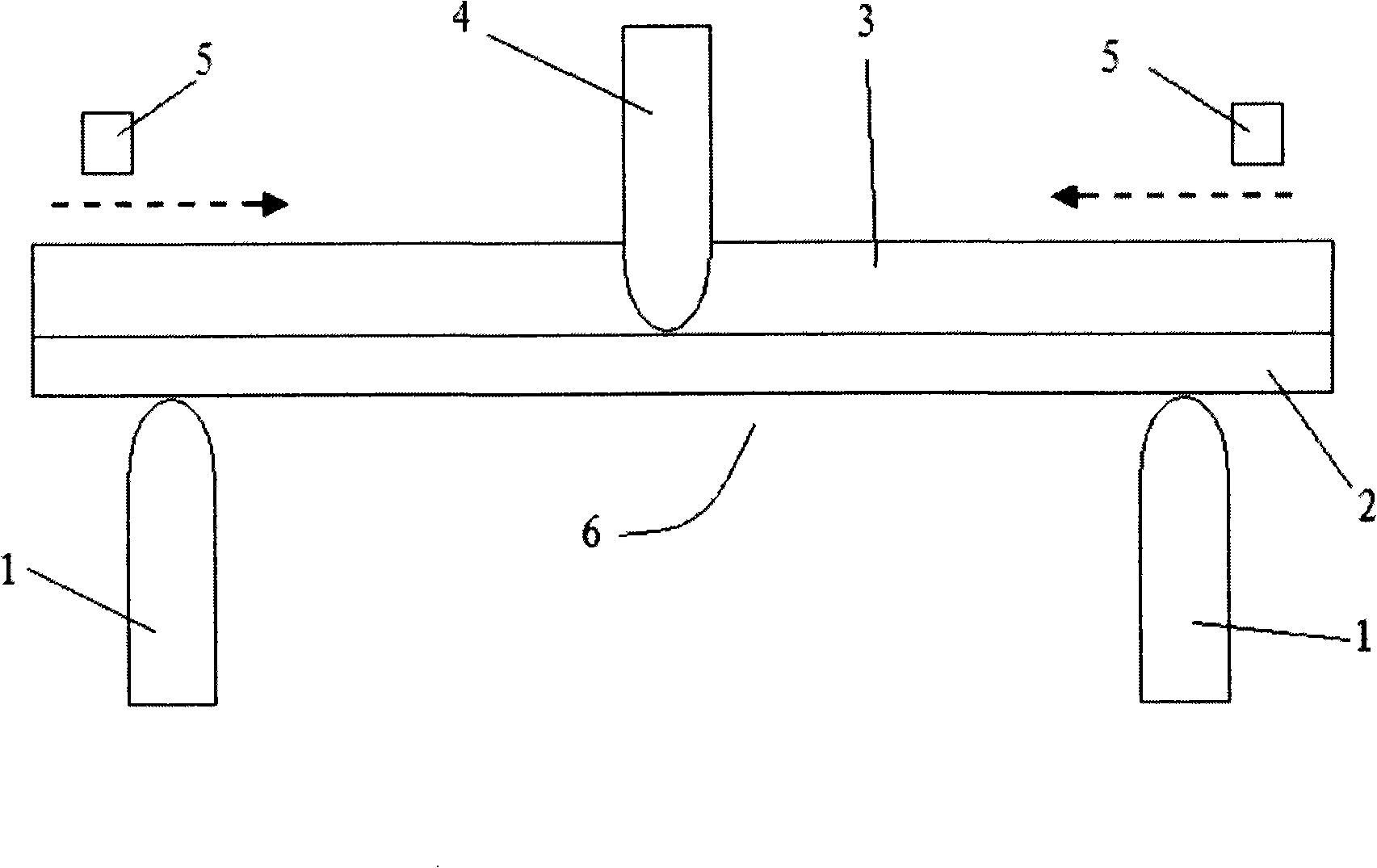

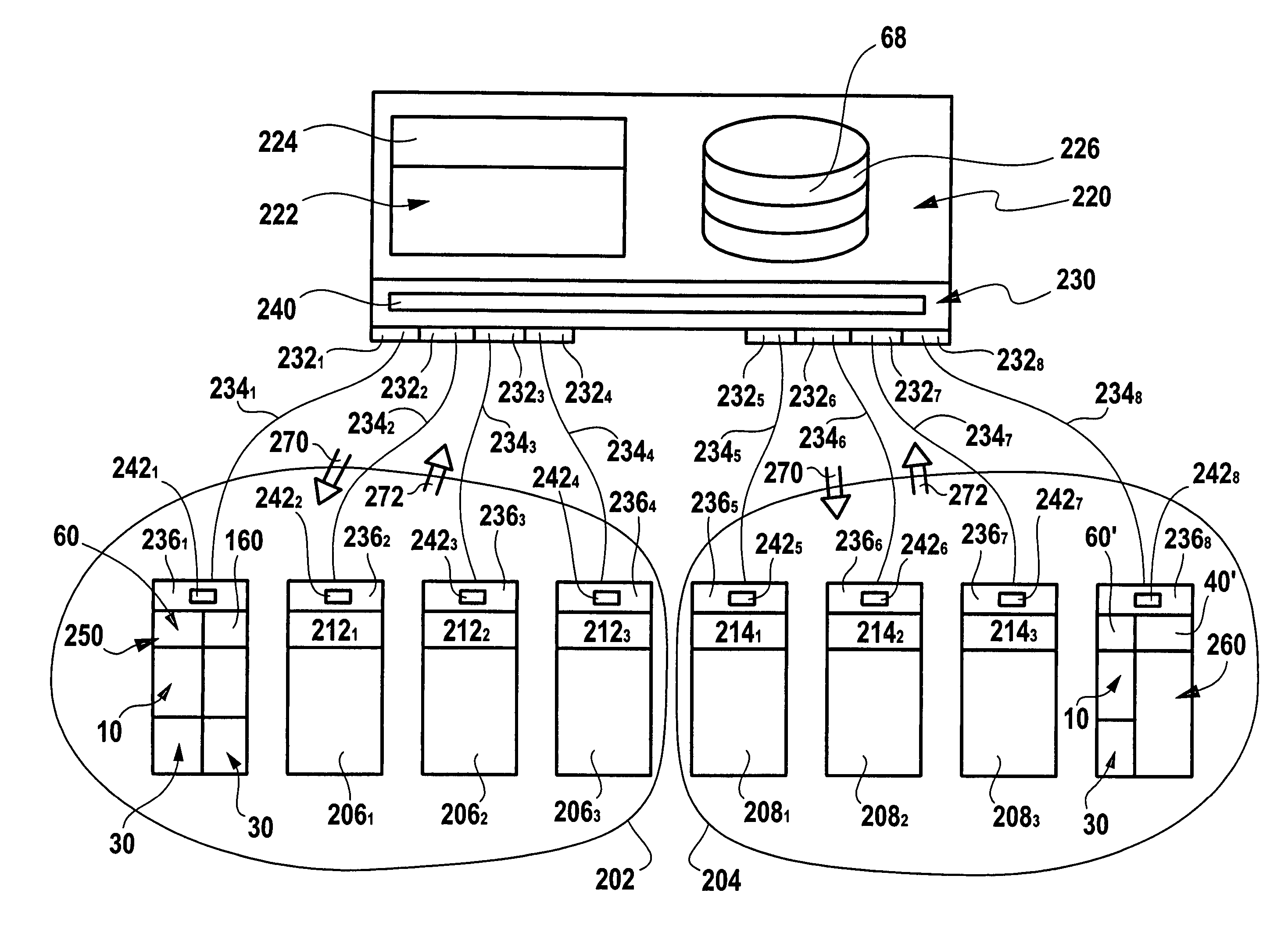

Method and system for simulating multisystem synchronous numerical-control processing

InactiveCN103236217ALearn about the training experienceSolve repair machining simulation problemsEducational modelsVirtual machiningControl system

The invention relates to a method and a system for simulating multisystem synchronous numerical-control processing, and belongs to the field of simulating training of numerical-control processing. The method comprises the following steps of customizing a virtual processing environment by a virtual processing system by an operator, and customizing a real processing environment by a real processing system; selecting a numerical-control system panel through a multisystem control platform to carry out numerical-control programming and controlling, encoding a numerical-control instruction, sending to a simulation controller, and enabling the simulation controller to simulate and calculate; on one hand, sending movement parameters of a cutter to the virtual processing system to complete virtual processing; and on the other hand, sending a processing macro instruction to the real processing system, so as to control a machine tool to complete the practical processing of blanks or repairing pieces. The method and the system have the advantages that the design concept is advanced, the function is practical, the cost is low, the deployment is convenient, the system compatibility is good, the group training method is flexible and variable, the processing process is visual and accurate, the human-computer interaction is good, the operation reality of a user is high, the user experience can be obviously changed, and the like.

Owner:PLA ARMORED FORCE TECH COLLEGE

Built-in type vision based inspection tool for autonomous setting of initial origin

ActiveUS20150094844A1Reduce shapingMinimize delayAutomatic control devicesImage analysisVirtual machiningVision based

The present invention relates to a vision based inspection tool for setting of an initial origin of an automation machine tool, and more particularly, to a built-in type of vision based inspection tool for setting of an initial origin capable of improving setting precision of a current automation machine tool that depends on initial setting and increasing productivity depending on individual automatic setting by automatically sensing a machining origin in order to perform initial machining and re-machining of an existing workpiece using an automation machine tool and compensating for the machining origin to eliminate a time required for setting machining origins for various shapes in a jog mode.

Owner:KOREA INST OF MACHINERY & MATERIALS

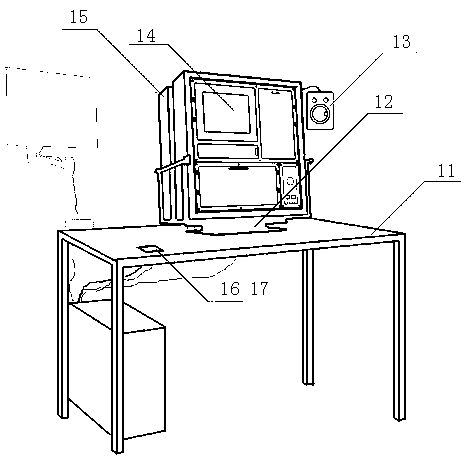

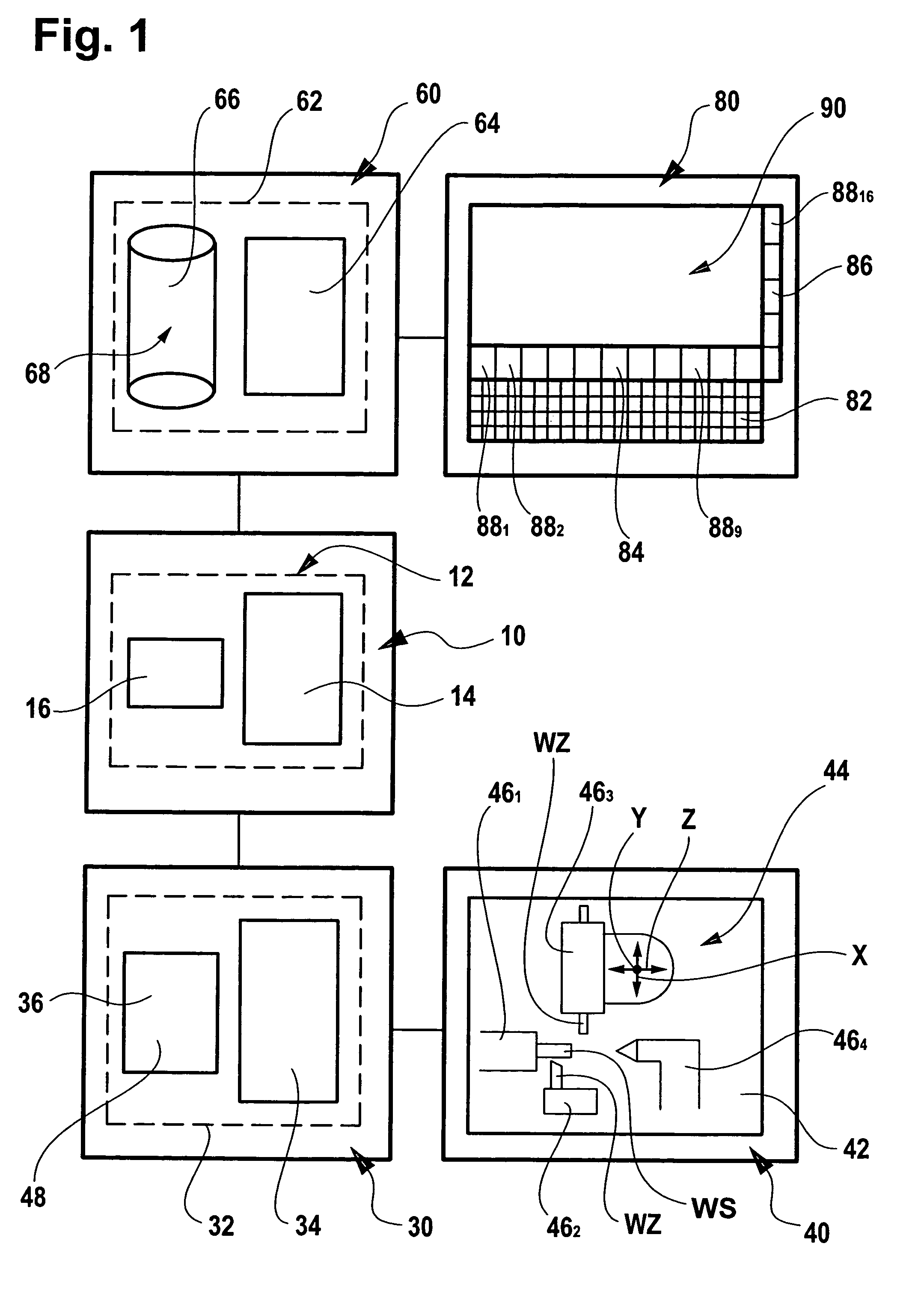

Virtual machine tool for representing operations of machining units of a real machine tool

ActiveCN101802734AChange sizeWear correctionProgramme controlComputer controlVirtual machiningTrue Case Status

The invention relates to a virtual machine tool for representing operations of machining units of the machine tool, especially operations during machining of a workpiece according to a CNC machining program package, using at least one first visualization unit, in the form of operations of virtual machining units. Said virtual machine tool comprises an operation control which has at least one first data processing unit that determines control commands for operations of the virtual machining units, using a control program processing CNC sets of the CNC machining program package, a visualizationcontrol comprising at least one second data processing unit that represents operations of the virtual machining units on the first visualization unit, using a visualization program and geometric configuration data of a stored machine model and the control commands determined by the operation control, and an operator control comprising a third data processing unit that operates the operation control, using an operator control program. The aim of the invention is to improve the virtual machine tool in such manner that the simulation of the machining of a virtual workpiece comes as close as possible to reality. The virtual machine tool according to the invention comprises a tool modeling system which allows the generation of tool configuration data for at least one virtual tool, using tool data and a tool model, and the supply thereof to the visualization program.

Owner:INDEX WERKE GMBH & CO KG HAHN & TESSKY

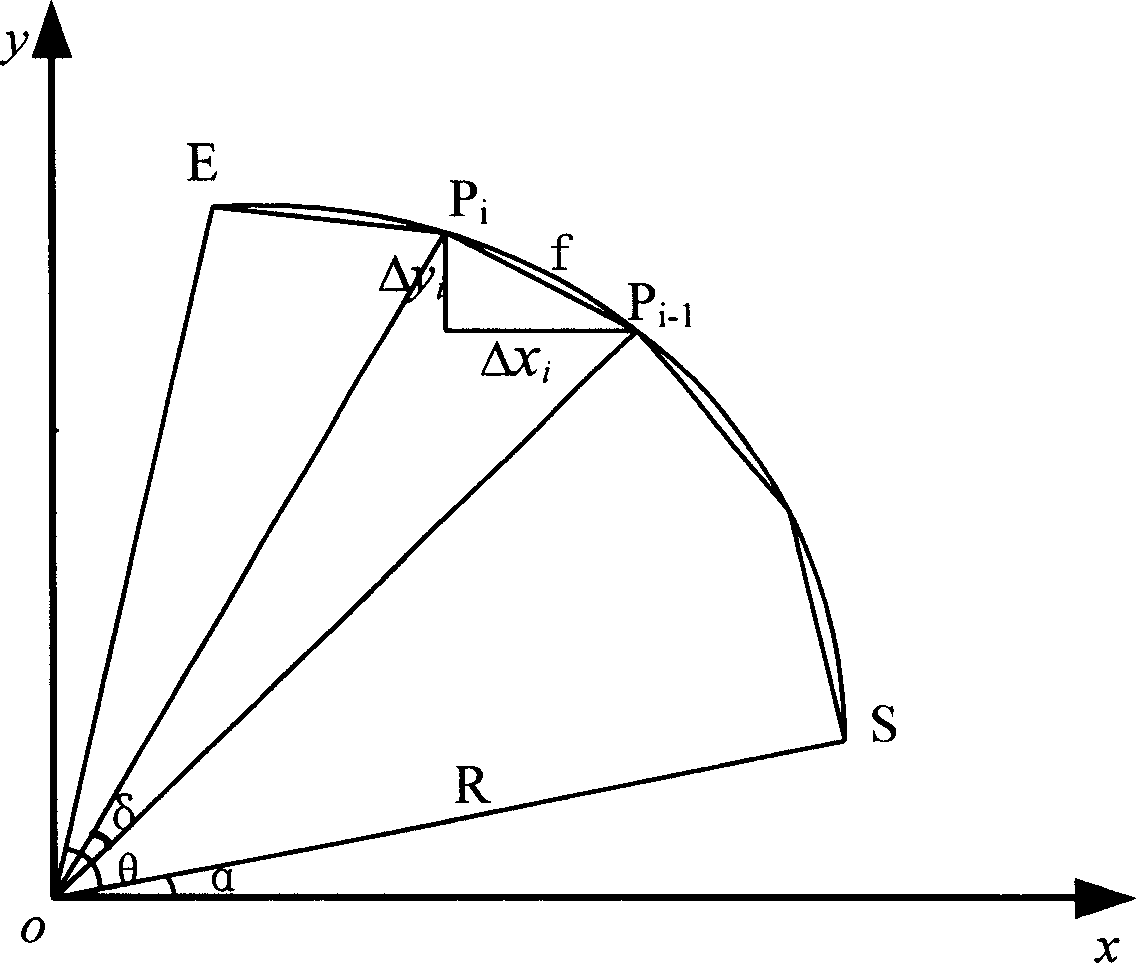

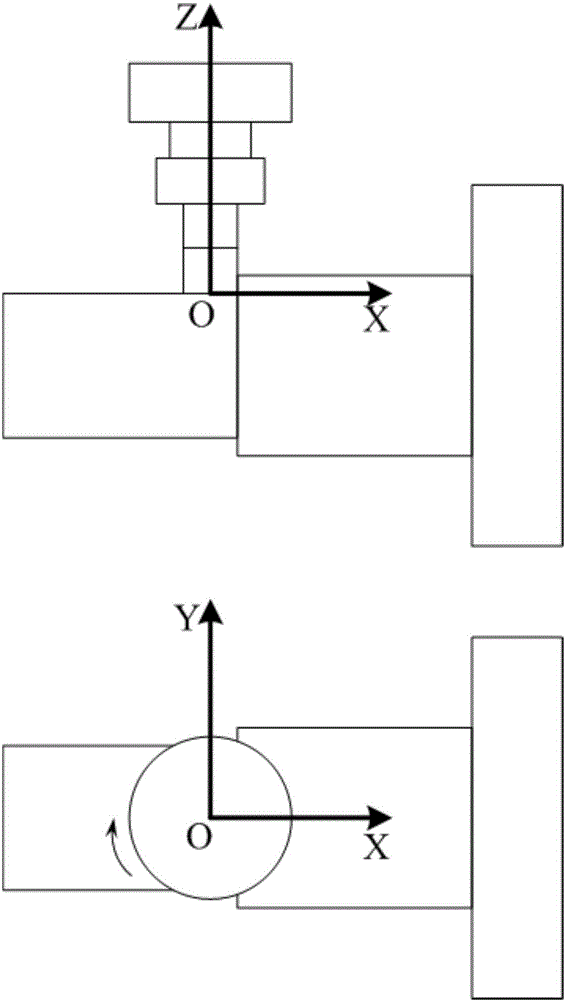

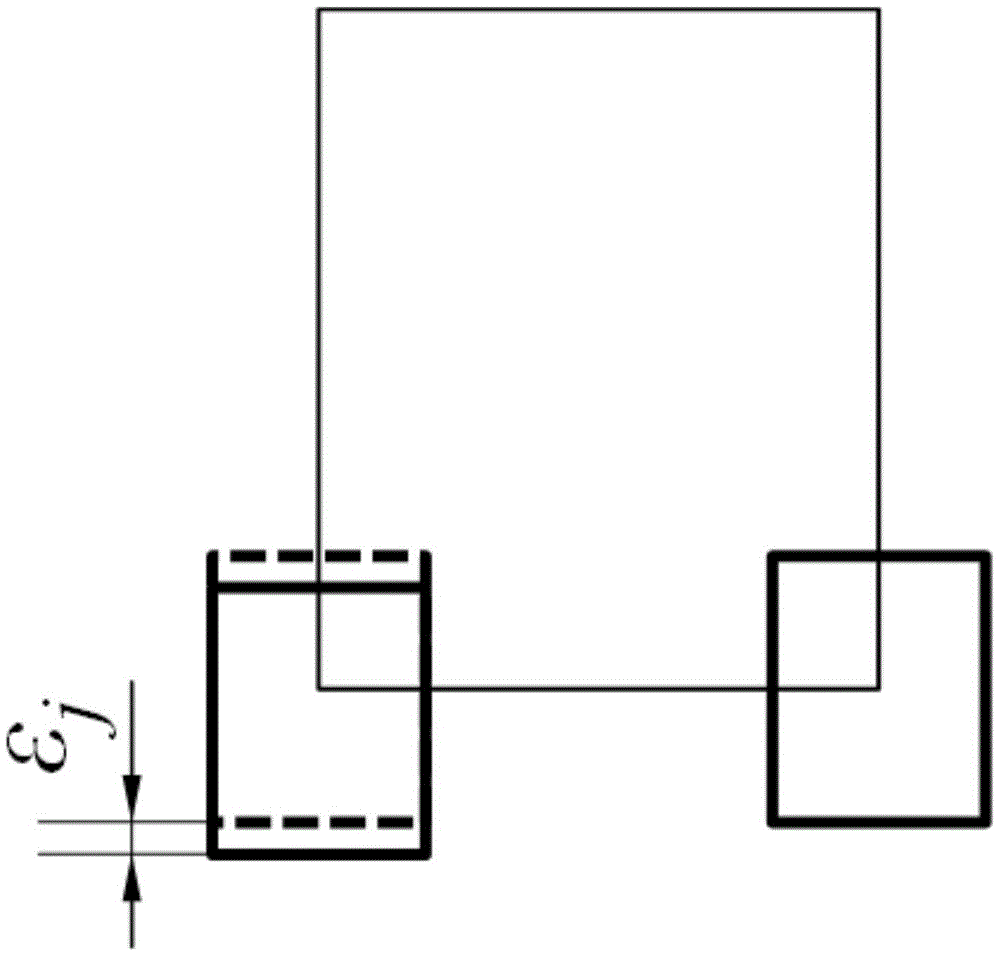

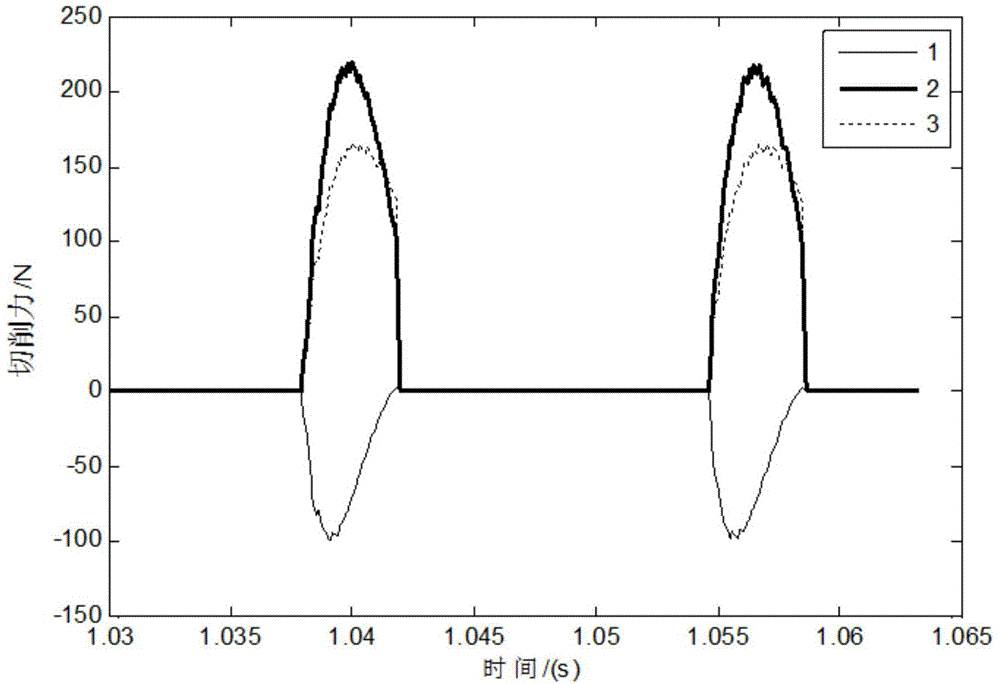

Modeling method for judging cutting force of orthogonal turn-milling machining end face on basis of boundary conditions

InactiveCN104794337AAccurately reflectHigh expressionSpecial data processing applicationsModel methodVirtual machining

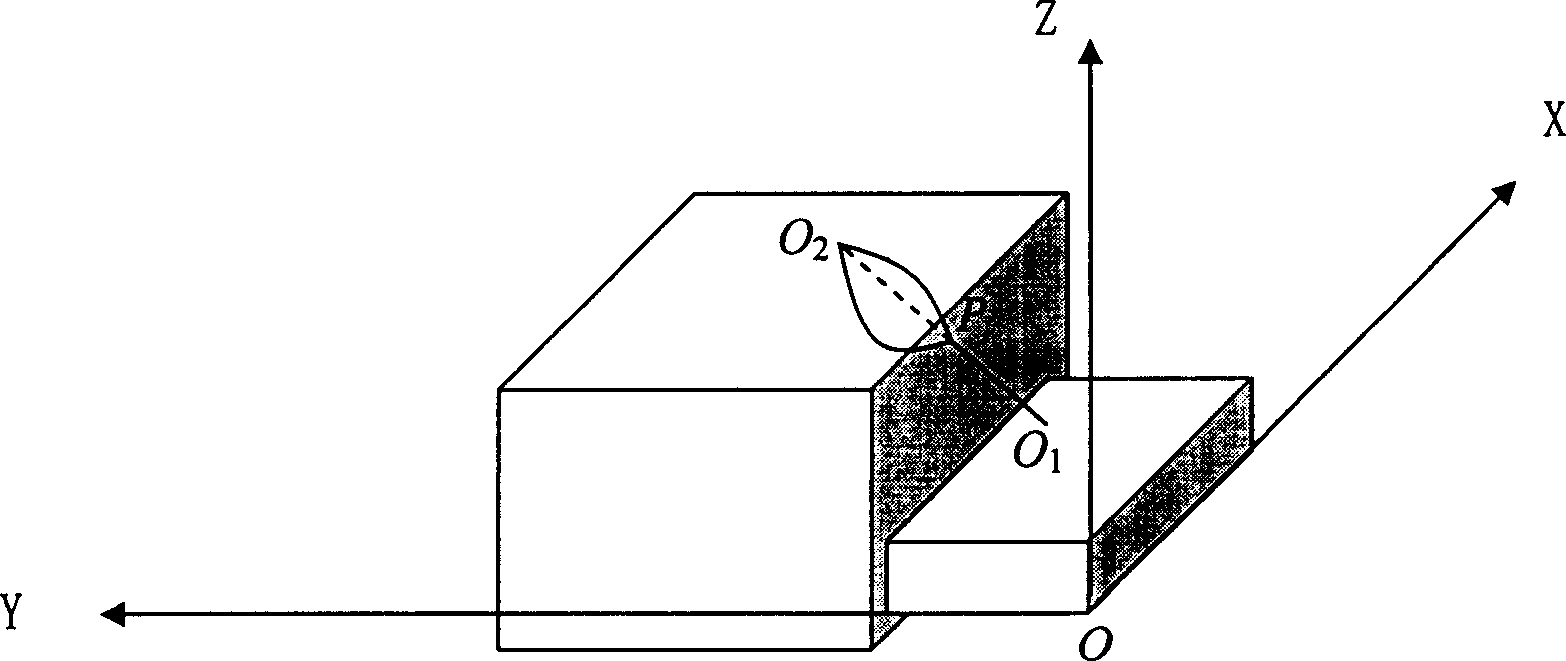

The invention discloses a modeling method for judging the cutting force of an orthogonal turn-milling machining end face on the basis of boundary conditions. The method includes the five steps of firstly, establishing a tool coordinate system; secondly, dividing the tool end face into a plurality of microelements in the radial direction; thirdly, judging whether the microelements participate in cutting or not through the boundary conditions; fourthly, obtaining thickness of cuttings, and calculating the microelement cutting force on the basis of the thickness; fifthly, adding the cutting force on all the microelements participating in cutting to obtain the total cutting force. By means of the method for judging the cutting state of the microelements through a united boundary condition equation, the disadvantage that in the prior art, when the orthogonal turn-milling machining end face blade cutting force is predicted, the cutting progress needs to be divided into multiple stages to be discussed is avoided; due to the fact that the influences of jumping are taken into consideration, the prediction effect is more accurate. The expression is simple and easy to understand, the complex characteristic angle calculation is omitted, and the modeling method is suitable for development of virtual machining simulation systems and has good application aspects.

Owner:BEIHANG UNIV

Embedded laser flexible machining process simulating method

InactiveCN1881204ASave human effortSave moneySpecial data processing applicationsAdaptive controlVirtual machiningPhysical model

The invention relates to a virtual laser flexible processing simulating method which can embed the physical models of different machining processes into the simulate system, wherein the method comprises: (1) building virtual machining platform; (2) optimizing the track; (3) building physical models; (4) checking the models; (5) simulating. The invention can watch each process in computer, to directly display the impact interference between the laser machining robot and other elements, to reflect the machining effect.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

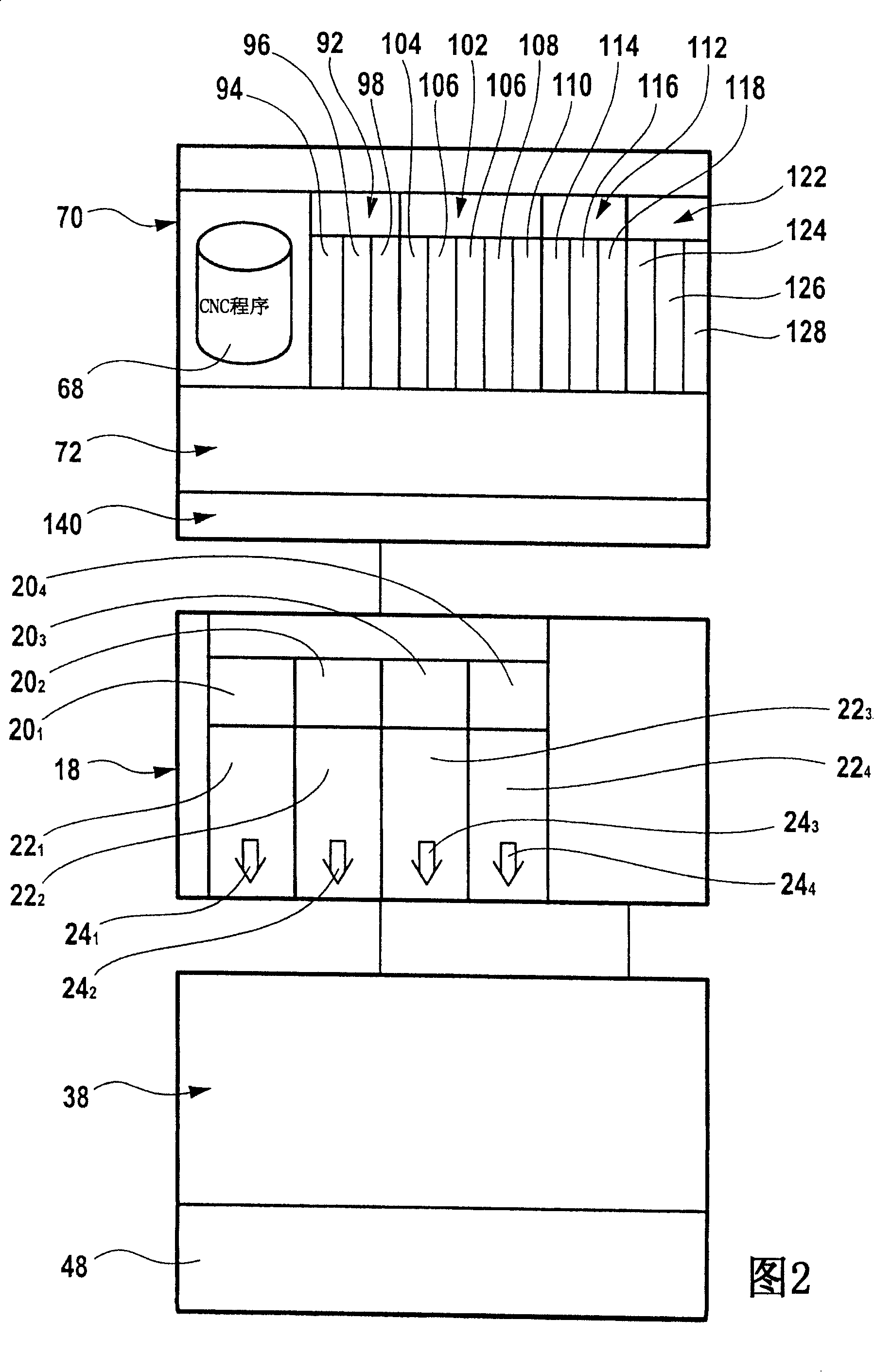

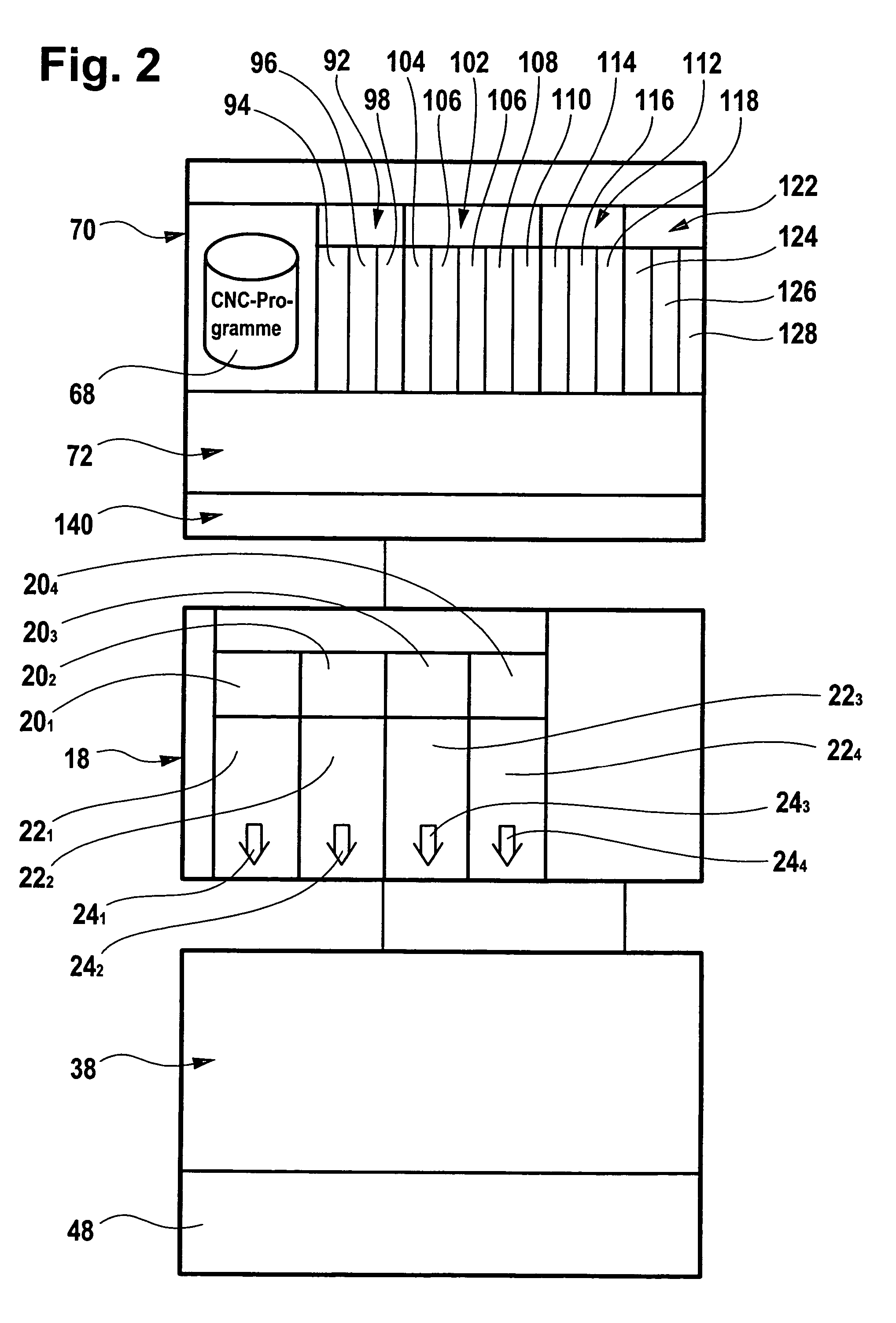

Emulation system

InactiveCN101187815ASuitable for requirementsSuitable for requirements in terms of ease of operationSimulator controlRecording and playback systemsProgram managementVirtual machining

The invention relates to an improvement simulation system, which is used on an actuation mode of a virtual processing unit of a virtual machine tool, and expresses action of the processing unit of the machine tool according to a CNC processing program complex by means of at least a first visualized unit. The invention comprises action control, and which comprises at least a first data handling unit. Action control command of the virtual processing unit and visualized control are established by controlling a procedure to handle a CNC block. And the invention comprises at least a second data handling unit, the determined control command is controlled by action according to layout data of a machine model which is stored, the action of the virtual processing unit is expressed on the first visualized unit on a visualized procedure, and the analog system is suggested to comprising operation control of a third data processing unit, the operation control is used for an operating procedure to control the action control, and the operating procedure has a program management function, at least a procedure of the CNC processing program complex is transferred to the action control for conveniently carrying out the program complex by the invention which is relative with workpieces.

Owner:INDEX WERKE GMBH & CO KG HAHN & TESSKY

Tool and technique for machining long and narrow skin part

ActiveCN107309658AHigh quality and efficient processingFast locationFuselage bulkheadsOther manufacturing equipments/toolsPosition toleranceVirtual machining

The invention provides a technique for machining a long and narrow skin part. The machining scheme of a long and narrow skin is optimized on the aspects such as the clamping and cutting parameters and the technical scheme by adopting the technical method that roll bending and pit machining are conducted successively, the purposes of clamping of the dual-side-concave long and narrow skin and butt joint of the front side and the back side are achieved, the machining thickness tolerance and the position tolerance of the narrow and long skin are ensured, and the situation that concave areas crack as pit machining is conducted before roll bending is avoided. According to the technique for machining the long and narrow skin part, by adoption of the technical machining method that roll bending formation and vacuum adsorption unfolding are conducted successively, the adsorption stability in the machining process of the dual-side long and narrow skin is ensured; by designing the length and width standards of the front side and the back side, the location degrees of the part outline and the pit during machining of the front side and the back side can be quickly met, and high-quality and high-efficiency machining of the long and narrow skin is achieved.

Owner:JIANGXI HONGDU AVIATION IND GRP

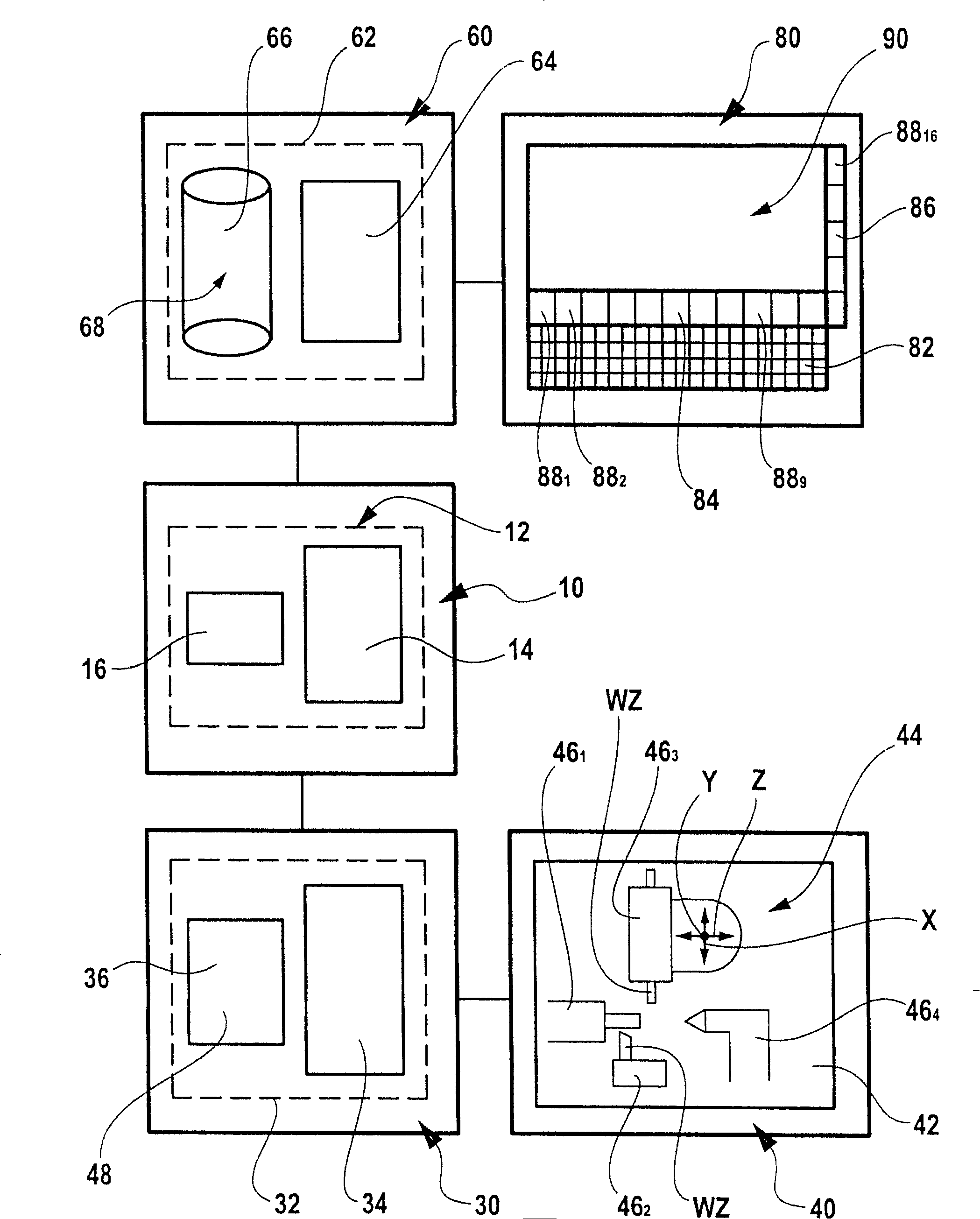

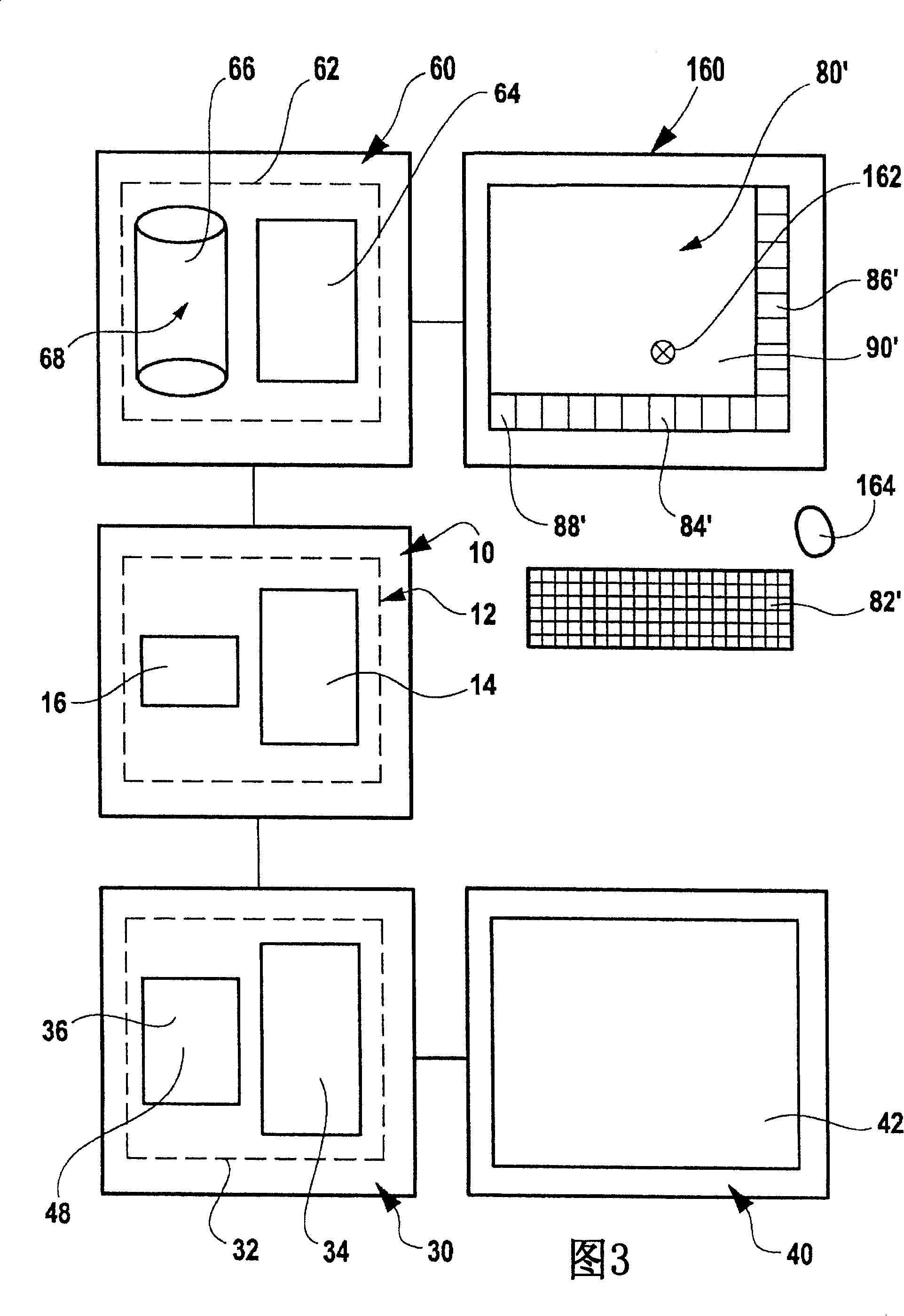

Simulation system

ActiveUS7684890B2Improve operational convenienceEasy to handleProgramme controlSpecial data processing applicationsMain processing unitProgram management

In order to improve a simulation system for representing actions of machining units of a machine tool, in particular actions in the machining of a workpiece, in accordance with a CNC machining program complex by means of at least one first visualization unit in the form of actions of virtual machining units of a virtual machine tool, comprising an action control, which has at least one first data processing unit, which establishes control commands for actions of the virtual machining units by a control program processing CNC blocks of the CNC machining program complex, and a visualization control, which has at least one second data processing unit, which represents actions of the virtual machining units on the first visualization unit by a visualization program on the basis of configuration data of a stored machine model and the control commands determined by the action control, in such a way that it can be operated more easily, it is proposed that the simulation system comprises an operating control with a third data processing unit, which operates the action control by an operating program, and that the operating program has a program management function, which transfers at least program parts of the CNC machining program complex in a workpiece-related manner from said CNC machining program complex stored in a memory of the third data processing unit to the action control for executing said program complex.

Owner:INDEX WERKE GMBH & CO KG HAHN & TESSKY

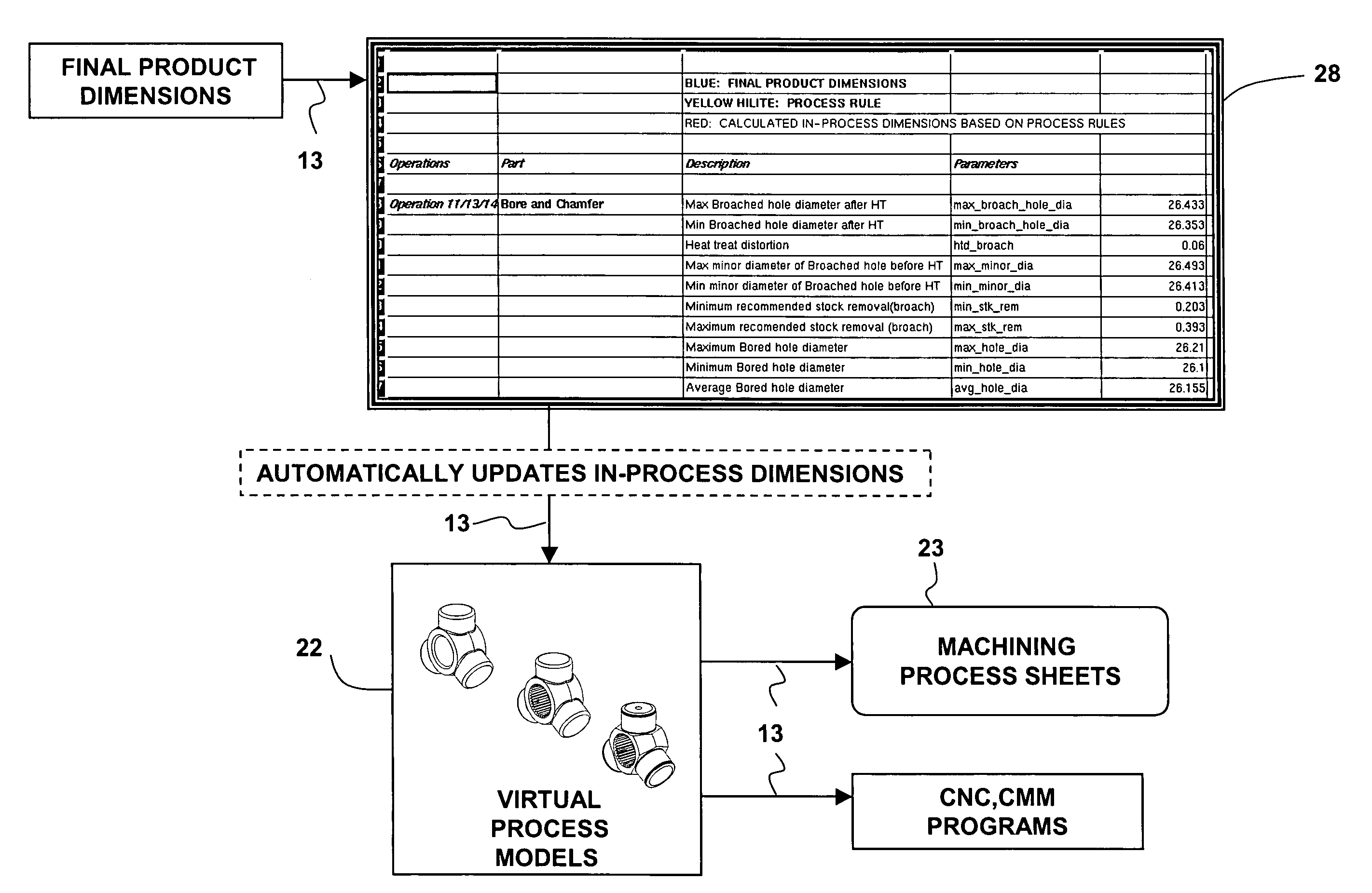

Automated horizontally structured manufacturing process design modeling

Disclosed is a method of horizontally structured automated CAD / CAM manufacturing process, comprising: selecting a blank for machining into an actual part; establishing a coordinate system; creating a master process model comprising: virtual blank corresponding to the blank; a manufacturing feature; virtual machining of the manufacturing feature into the virtual blank, the manufacturing feature exhibiting an associative relationship with the coordinate system; and generating machining instructions to create the actual part by machining the manufacturing feature into the blank; capturing manufacturing process rules in a spread sheet; and the spread sheet exhibiting an associative relationship with the master process model. Also disclosed is a manufactured part created by a method of horizontally structured automated CAD / CAM manufacturing process. Also disclosed is a storage medium and computer data signal encoded with a machine-readable computer program code for horizontally structured automated CAD / CAM manufacturing.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

Horizontally structured manufacturing process modeling for fixtures and tooling

Disclosed is a method of horizontally structured CAD / CAM manufacturing for fixtures and tooling comprising: selecting a contact area geometry; creating extracts from a master process model; generating a tooling model corresponding to the contact area geometry; virtual machining the tooling model to generate the fixtures and tooling; and generating machining instructions and drawings to create the fixtures and tooling; where the tooling model exhibits an associative relationship with the contact area geometry. Also disclosed is a manufactured part created by a method of horizontally structured CAD / CAM manufacturing for fixtures and tooling comprising: a contact area geometry selected from a master process model for tooling or fixture modeling; extracts created from the master process model; a tooling model corresponding to the contact area geometry including virtual machining the tooling model to generate the fixtures and tooling; where the fixtures and tooling are created by machining in accordance with a machining instruction; and the tooling model exhibits an associative relationship with the contact area geometry. Also disclosed is a storage medium encoded with a machine-readable computer program code for horizontally structured CAD / CAM manufacturing. The storage medium including instructions for causing a computer to implement the method of horizontally structured CAD / CAM modeling and manufacturing for fixtures and tooling. Additionally disclosed is a computer data signal for horizontally structured CAD / CAM manufacturing. The computer data signal comprising code configured to cause a processor to implement a method of horizontally structured CAD / CAM modeling and manufacturing for fixtures and tooling.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

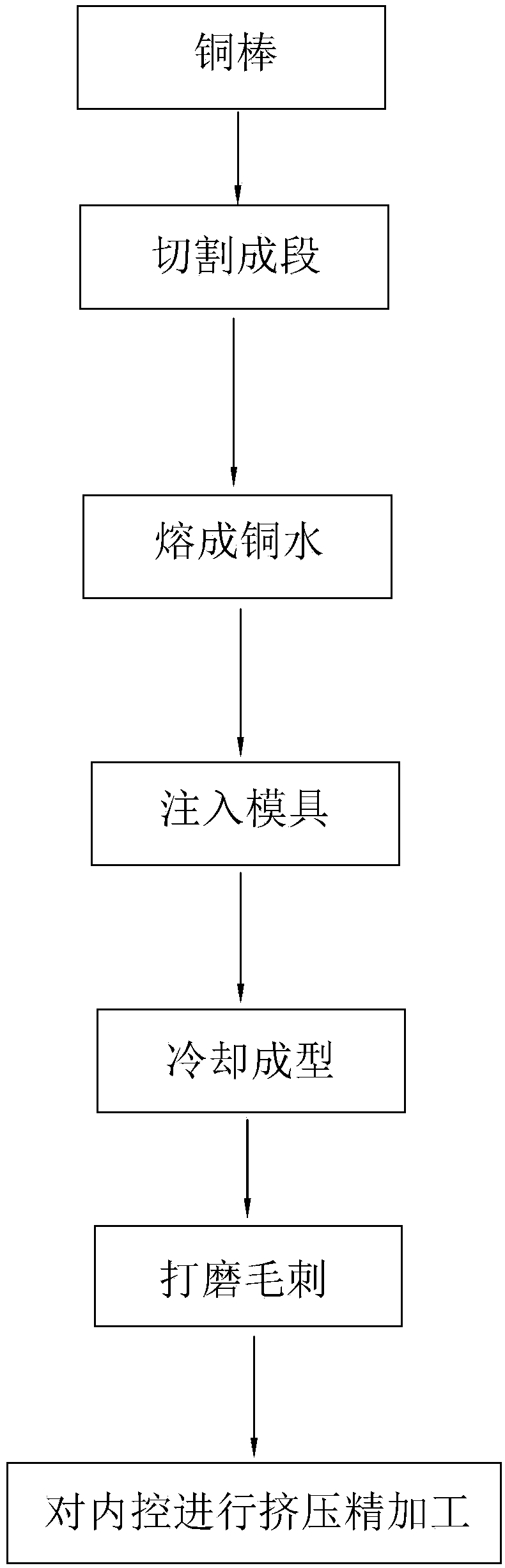

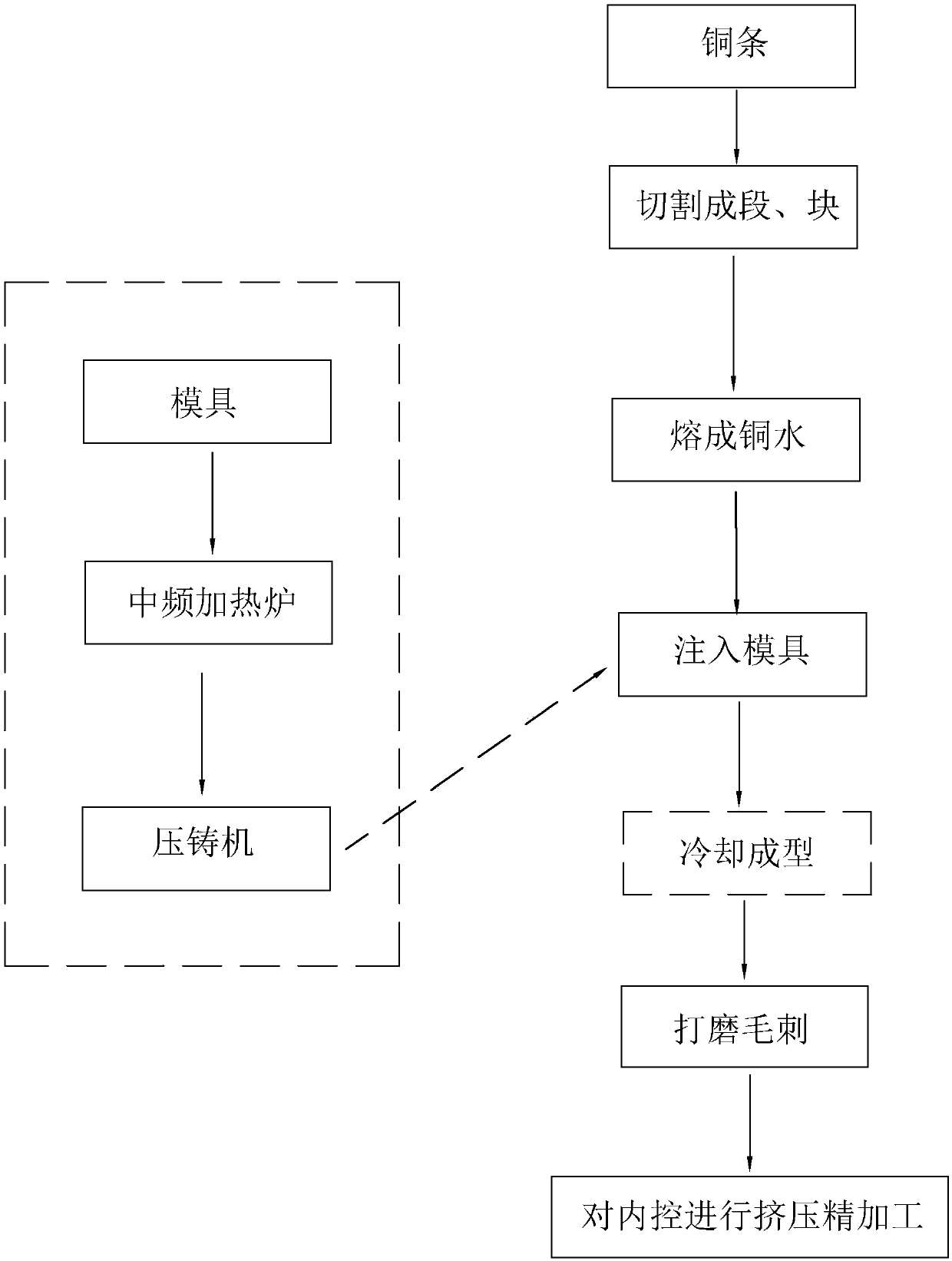

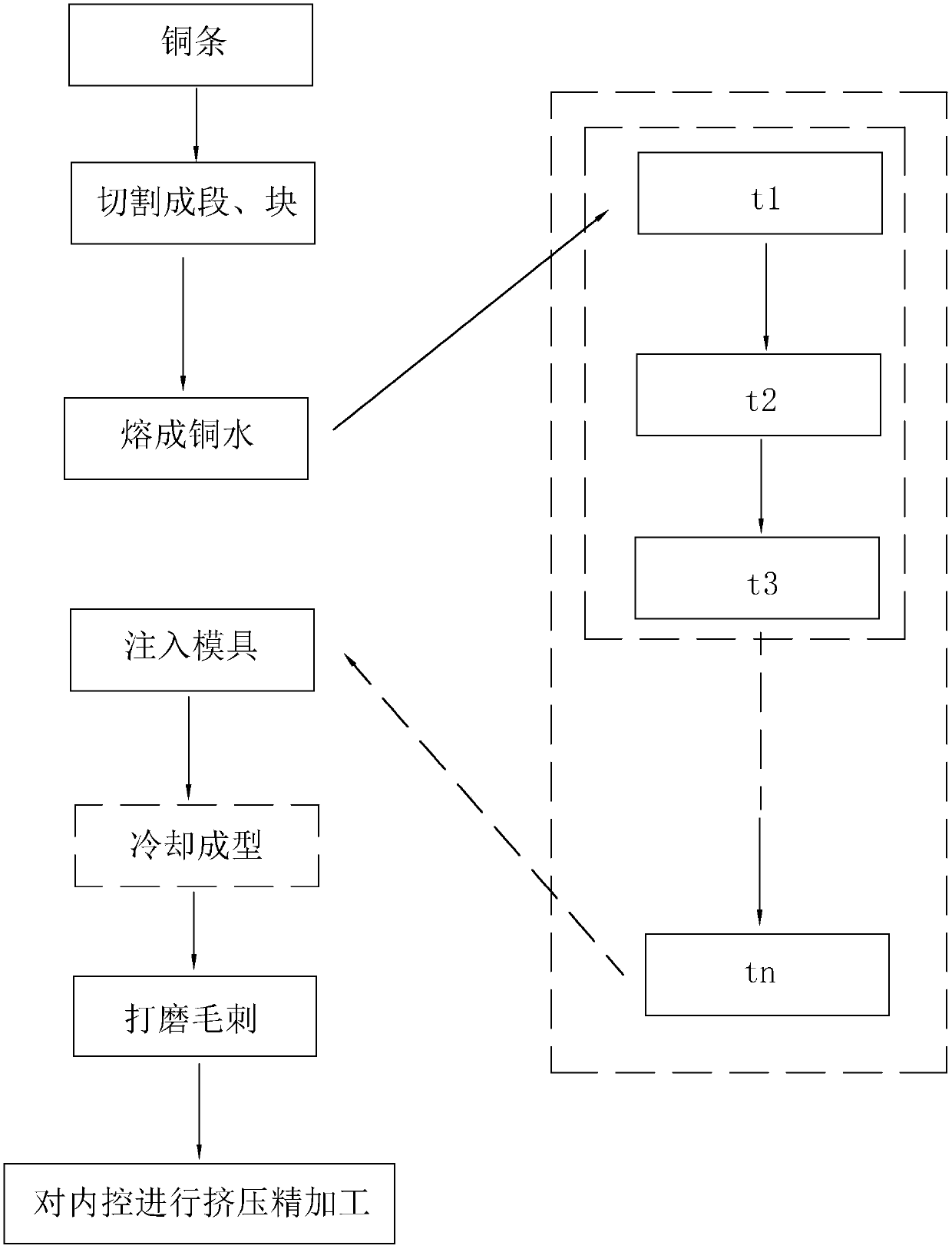

Valve machining technology

InactiveCN107838636ASlow down the speed of the conjunctivaSmall temperature differenceManufacturing technologyVirtual machining

The invention discloses a valve machining technology, and relates to the technical field of valve machining and manufacturing. The valve machining technology specifically comprises the steps that S1,metal raw materials are cut, and segment-shaped or blocky metal is obtained and thrown into a melting furnace to be heated and melted into liquid metal water; S2, a die is thrown into a medium-frequency heating furnace to be heated to the temperature ranging from 200 DEG C to 300 DEG C; S3, the die is taken out of the medium-frequency heating furnace and is installed on a die casting machine; S4,the metal water is pressed and injected into the die through the die casting machine; S5, the die is taken out and cooled, and a preliminarily-formed blank is obtained; S6, the blank is subjected to deburring treatment; S7, an inner hole of the blank is subjected to extrusion finish machining, and a finished valve body is obtained; S8, the valve body is subjected to metal flaw detection and otherdetection; and S9, the valve body and related components are assembled, and packaging and delivery are conducted after sampling inspection. According to the machining technology, the metal water is not prone to film formation in advance before the die is filled with the metal water.

Owner:ZHENJIANG YIBAO ELECTRICAL TECH CO LTD

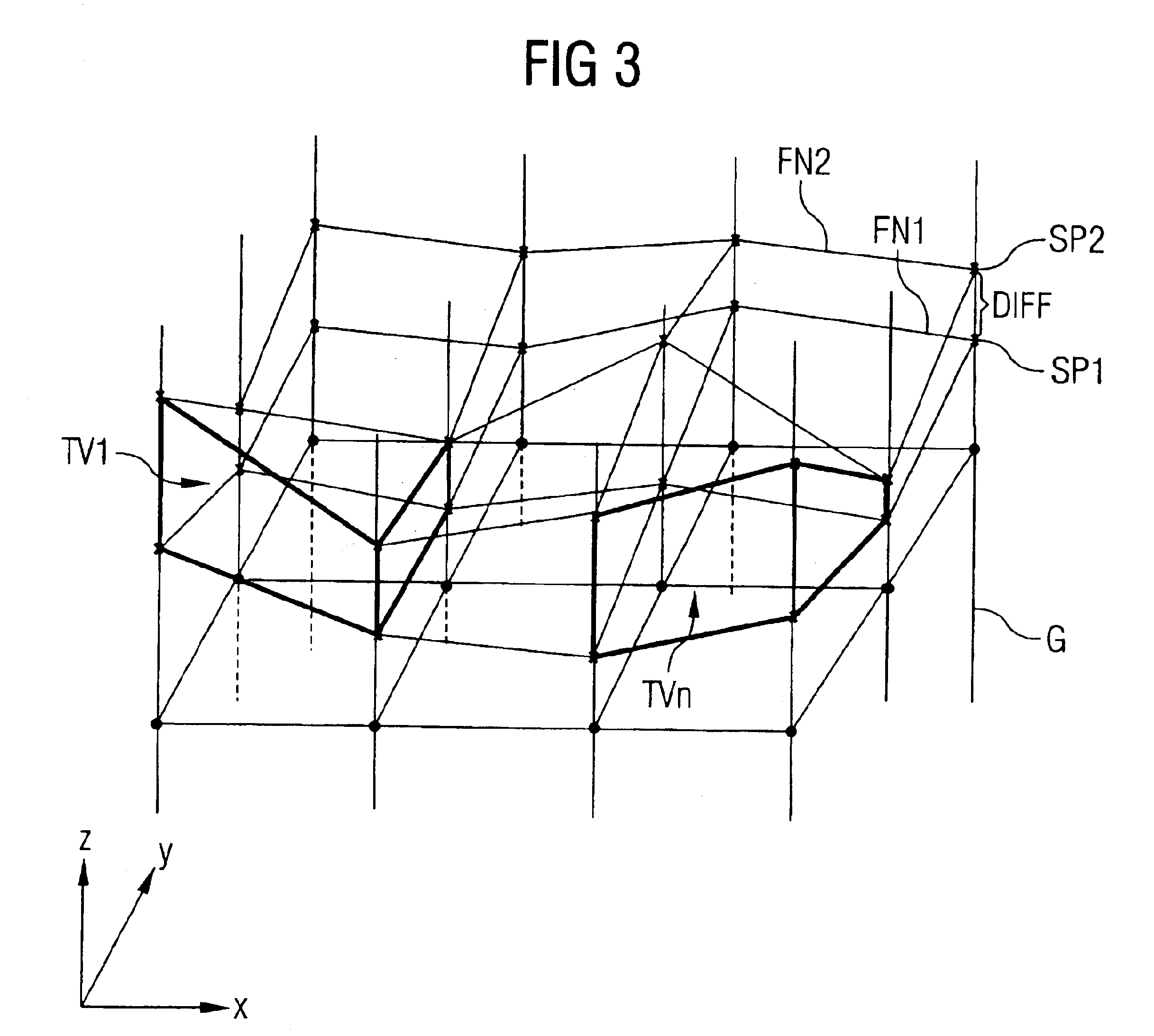

Differential visualization of countoured surfaces

InactiveUS6956567B2Reduce complexityConveniently producedDrawing from basic elementsCharacter and pattern recognitionGraphicsVirtual machining

A method and a system for visualizing differences of three-dimensional contour surfaces, in particular of three-dimensional contour surfaces produced by virtually machining a workpiece, are described. The method determines a first and second surface and spatial and / or volume differences between the contours of these surfaces. One of the surfaces together with the determined spatial and / or volume differences between the contours of the surfaces can be graphically rendered, wherein the differences are rendered as an additional attribute of the one surface, for example, in a different color.

Owner:SIEMENS AG

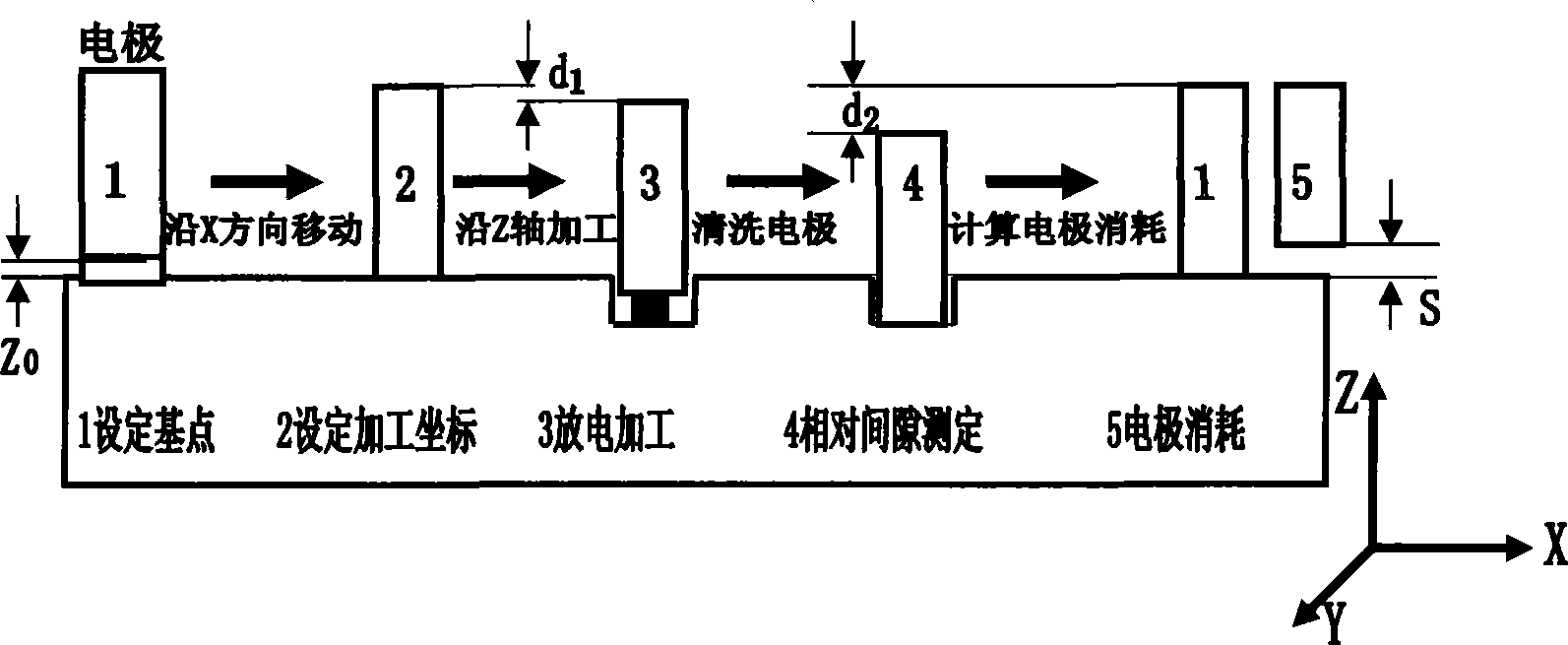

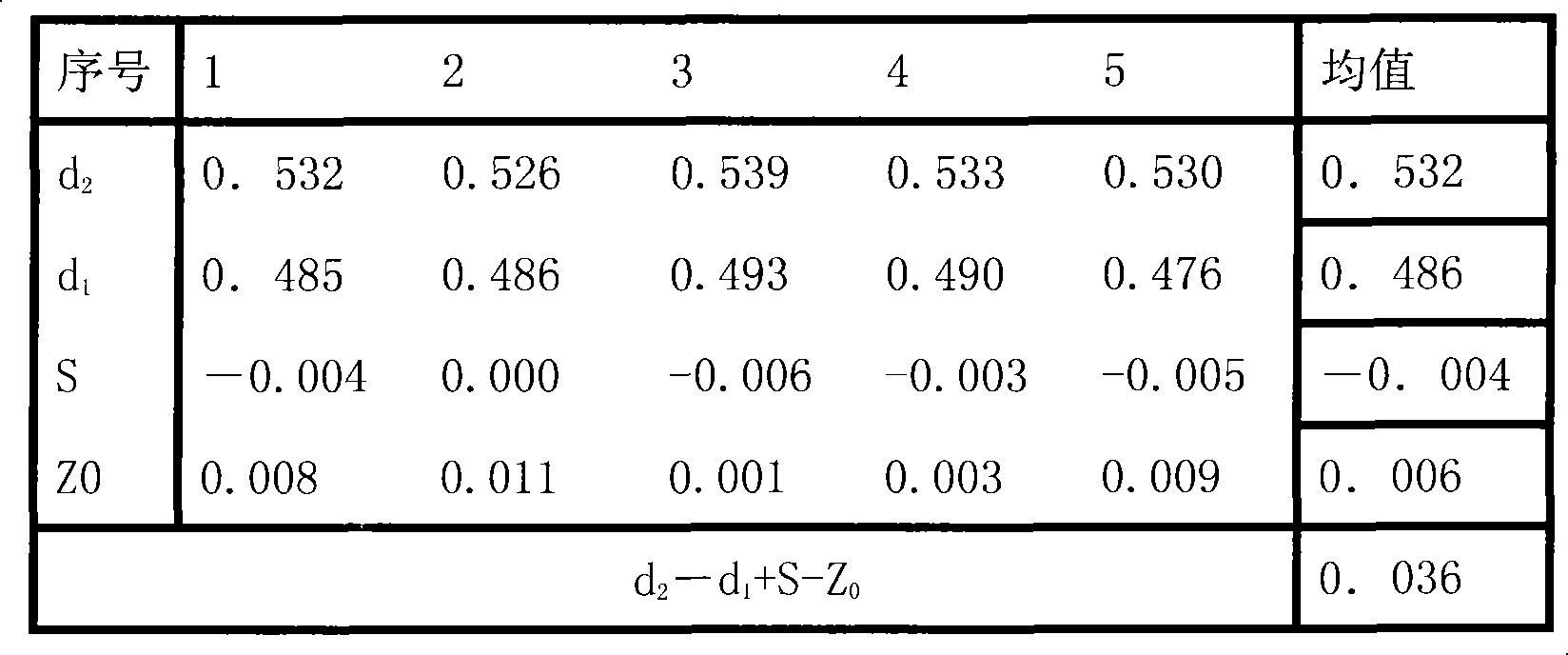

Measurement method of electro discharge machining gapping place

InactiveCN101249617ALow costEasy to operateMechanical clearance measurementsMeasurement/indication equipmentsVirtual machiningCoordinate difference

The invention relates to a measuring method for discharge machining gap in special machining technology field. The steps are as follows: an electrode and a workpiece are contact-sensed alone Z axis using the contact-sensing function of the machine tool, and the point is set to a base point. After the electrode moves along the direction of X or Y axis, the electrode and the workpiece surface are contact-sensed again, and the coordinate difference value of the base point relative to the contact point is recorded, and the coordinate of the point is set to zero; the machining is carried out along Z axis, and when the machining is over, the electricity is forbidden to cut off, and the electrode is stopped at the discharge position, and the machining depth of the electrode at the moment is recorded; after the electrode and workpiece surface are washed directly, the electrode is fallen down along the direction of Z axis to the position contacted with the machining surface to measure the virtual machining depth in the direction of Z axis; the electrode is moved again to the coordinate position of the base point to be contact-sensed with the base point, and the difference between the coordinate value of Z axis at the moment and the formerly recorded coordinate value of the base point is recorded, and the loss of the electrode after machining is measured, and then the discharge machining gap can be achieved. The method is simple, easy to apply, reliable and accurate.

Owner:SHANGHAI JIAO TONG UNIV

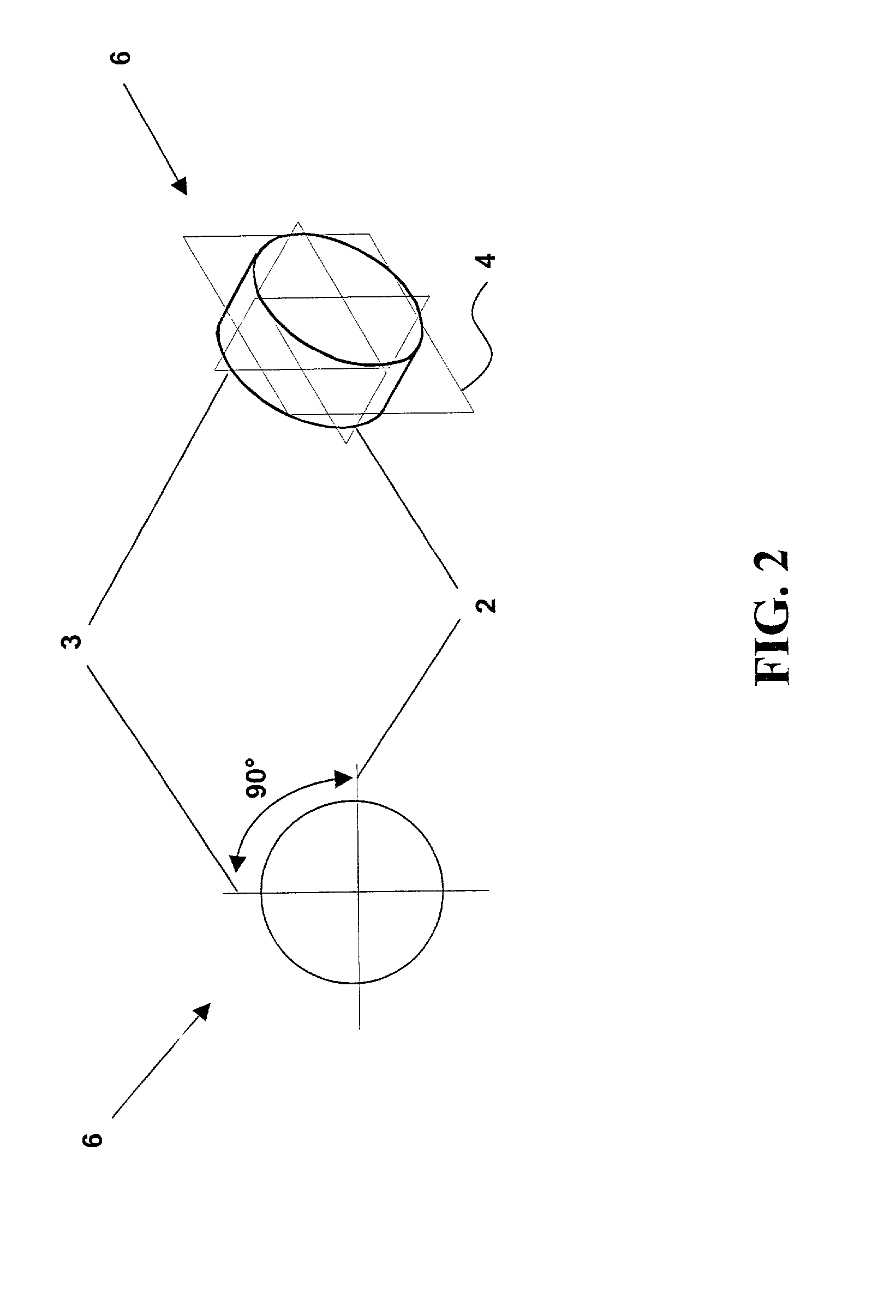

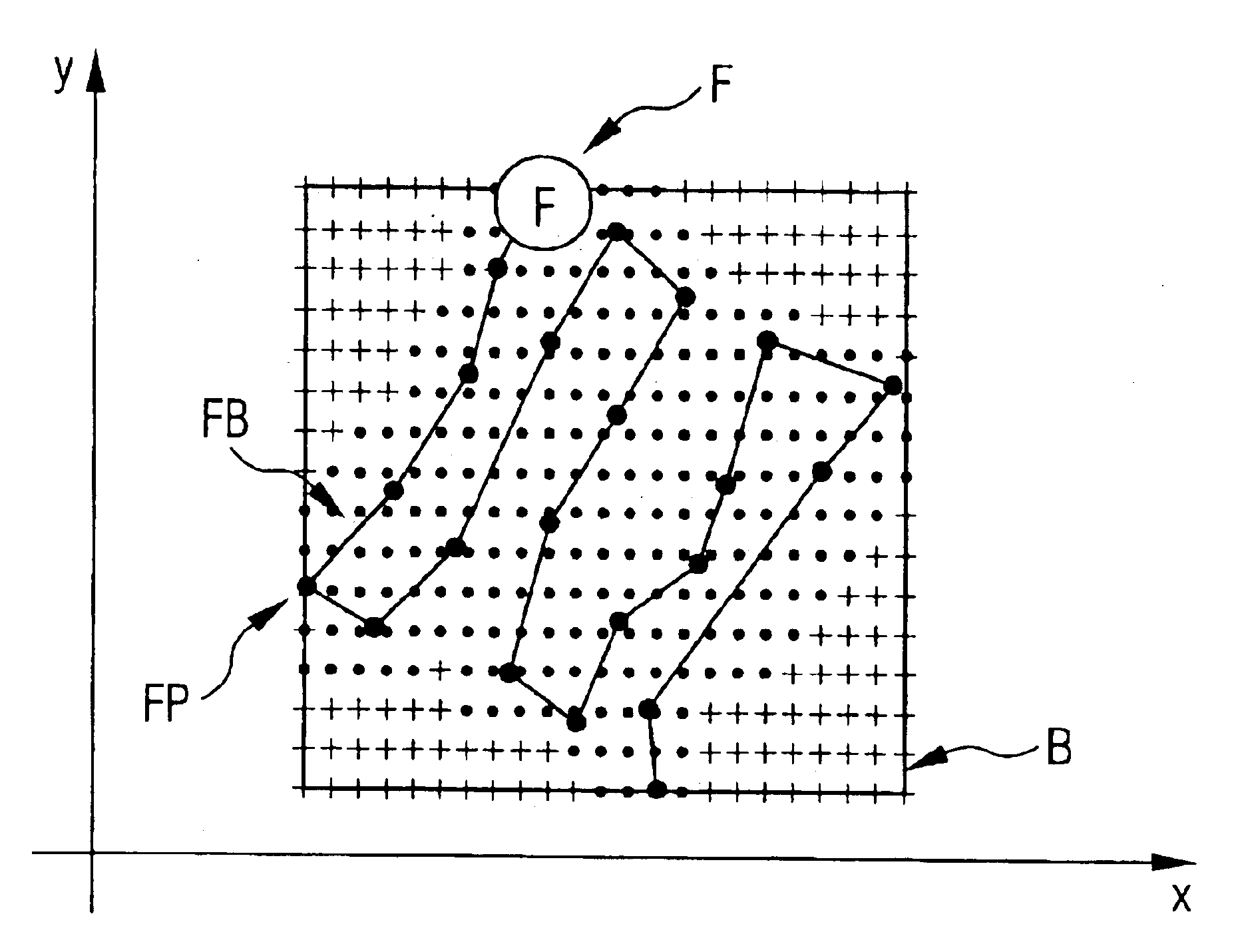

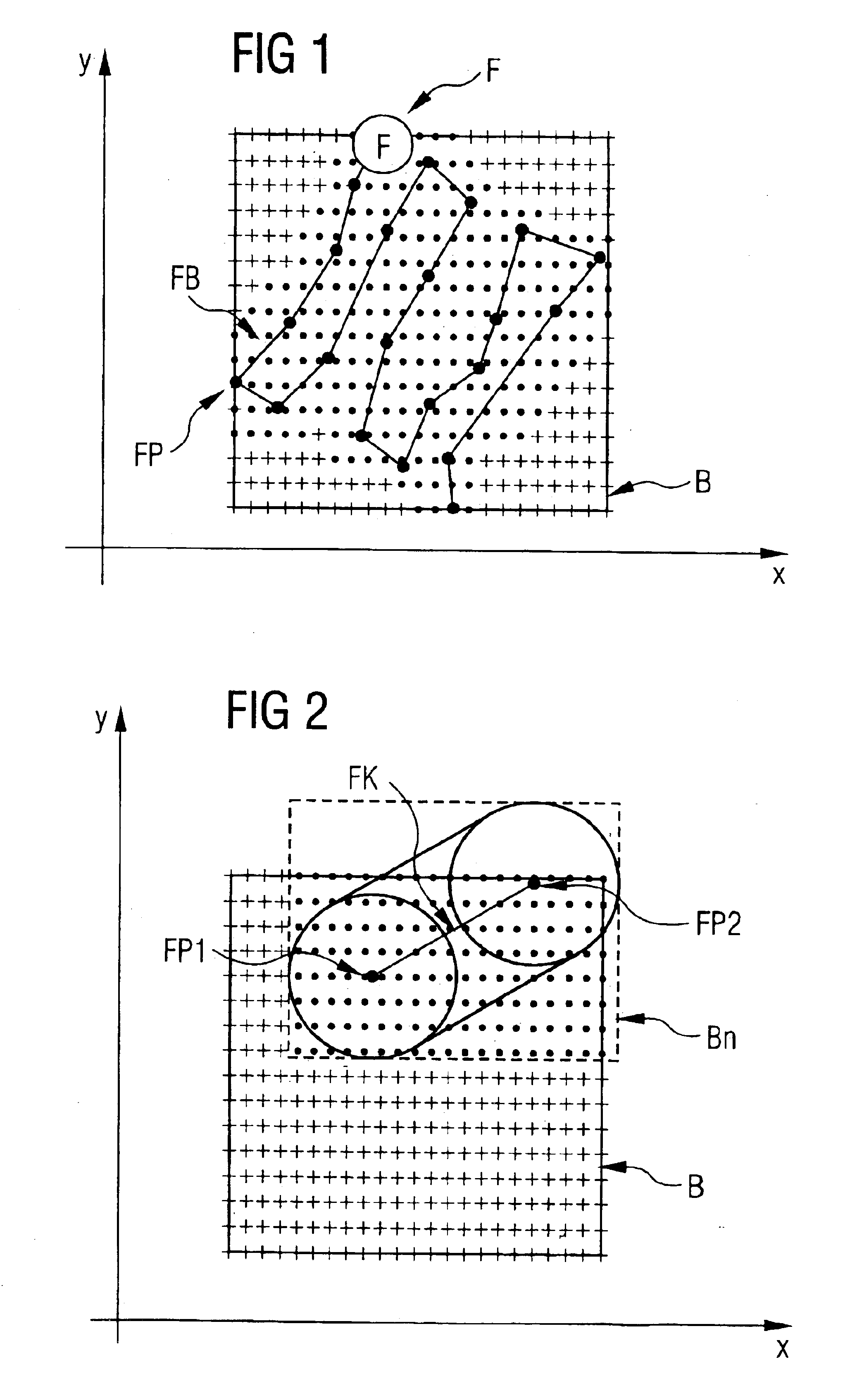

Method For Machining Workpieces By Using Laser Radiation

InactiveUS20080190903A1Increase machine speedImprove accuracyWelding/soldering/cutting articlesMetal working apparatusVirtual machiningLight beam

The invention relates to a method for machining workpieces by using laser radiation, wherein the workpieces to be machined are moved during the machining and at least one laser beam is deflected with respect to two axes aligned orthogonally to one another. It is therefore the object of the invention to form large-area machining contours with as high a machining speed and as great an accuracy as possible. In the method in accordance with the invention, a procedure is followed that a laser beam is deflected within a working field with respect to two axes aligned orthogonally to one another. Positional coordinates of the respective machining contour are moreover associated in an electronic evaluation and control unit with virtual machining segments in which the machining is carried out sequentially. The borders of individual machining segments are predetermined so that the maximum spacing of mutually oppositely disposed borders of the respective machining segments does not exceed 50% of the maximum length of the working field for the laser beam in the feed direction of the moved workpiece.

Owner:FRAUNHOFER GESELLSCHAFT ZUR FOERDERUNG DER ANGEWANDTEN FORSCHUNG EV

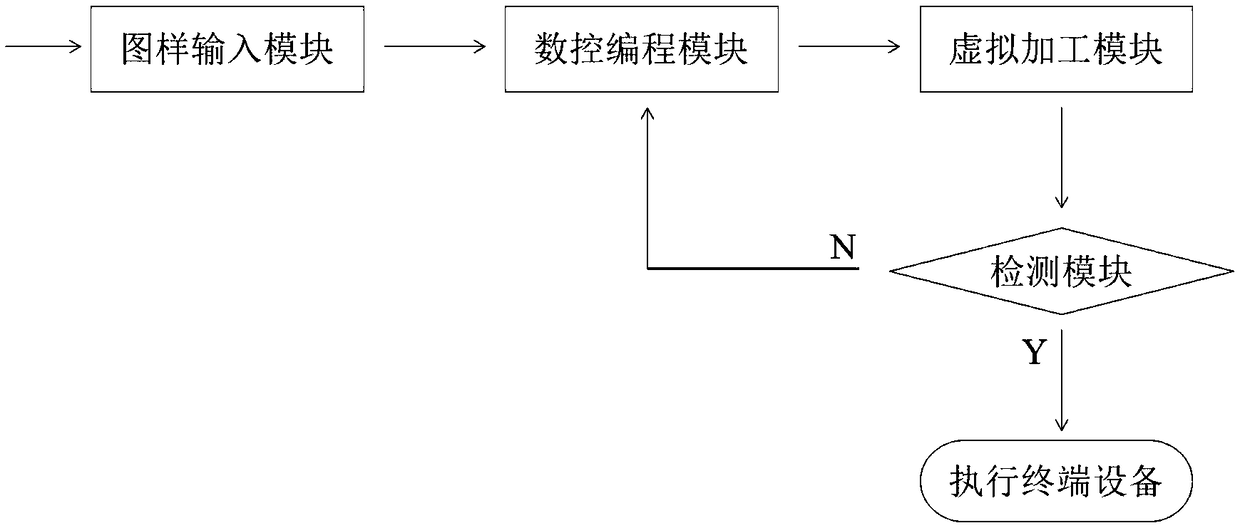

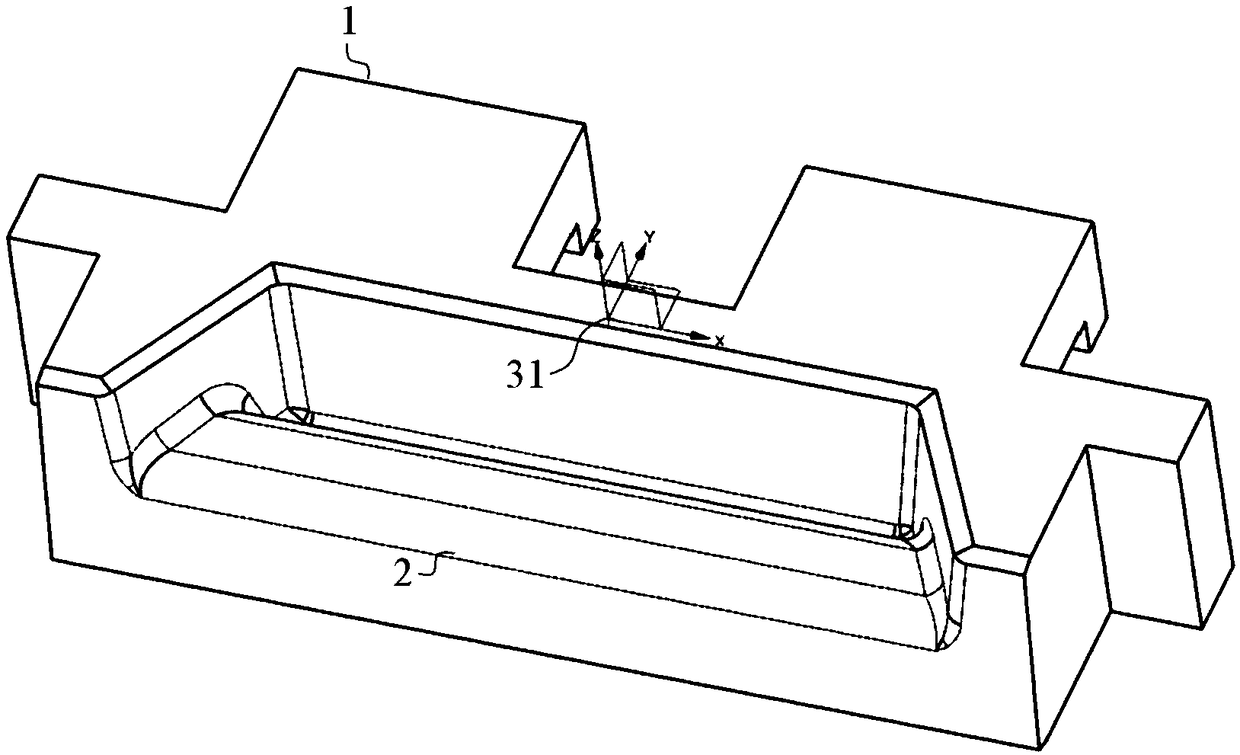

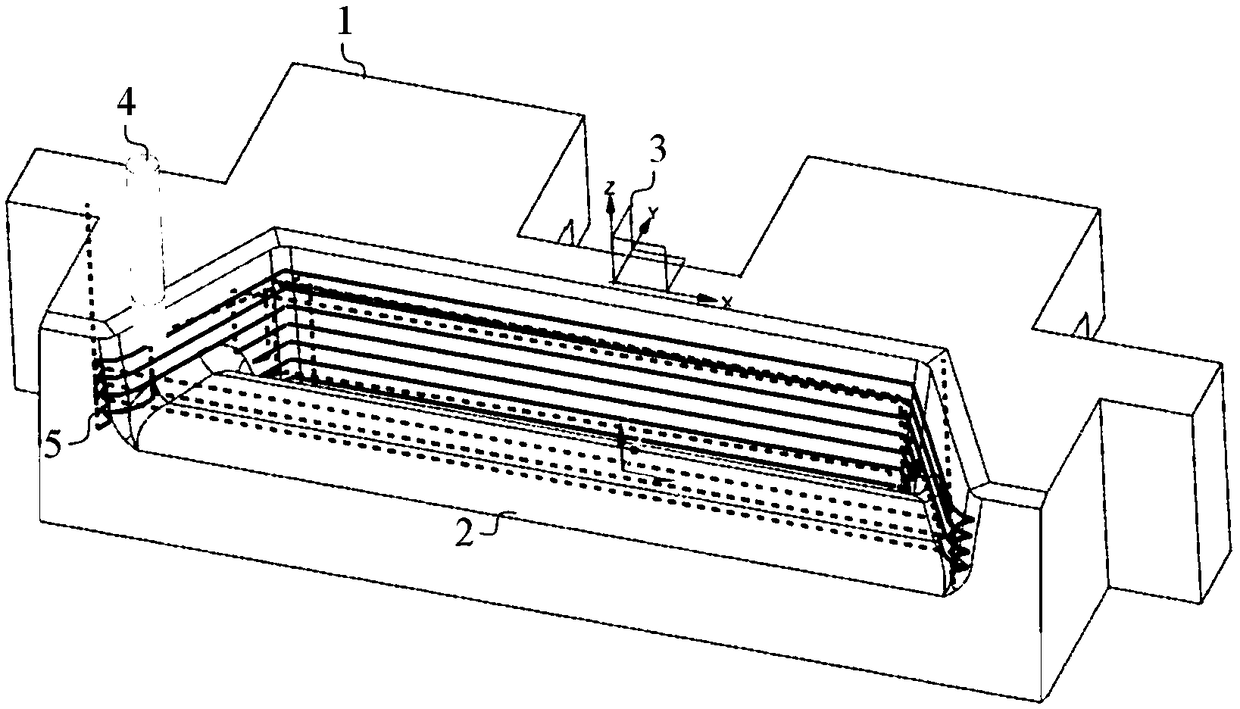

Dummy bar head machining system and machining method

ActiveCN109062144AWide applicabilityReduce stepsProgramme controlComputer controlVirtual machiningCutter location

The invention discloses a dummy bar head machining system and method, and belongs to the field of dummy bar head machining. The dummy bar head machining system comprises a pattern input module used for reading / outputting pattern information, a numerical control programming module used for carrying out machining cutter location programming on a to-be-machined curved surface structure of the dummy bar head, a virtual processing module used for simulating a numerical control program, and a detection module used for detecting whether the numerical control program is qualified or not; according tothe dummy bar head machining method, a to-be-machined dummy bar head three-dimensional model is input into the pattern input module; the numerical control programming module programs the machining cutter location; and finally, the debugged and qualified numerical control program is transmitted to execution terminal equipment to carry out entity production under the cooperation of the virtual processing module and the detection module. The system disclosed by the invention is simple to use and easy to learn, and the dummy bar head machining method disclosed by the invention adopts the system ofthe invention, so that the machining efficiency of the curved surface structure of the dummy bar head can be greatly improved, the machining quality is guaranteed, and the material cost and the laborcost are lowered.

Owner:ANHUI MAGANG HEAVY MASCH MFG CO LTD

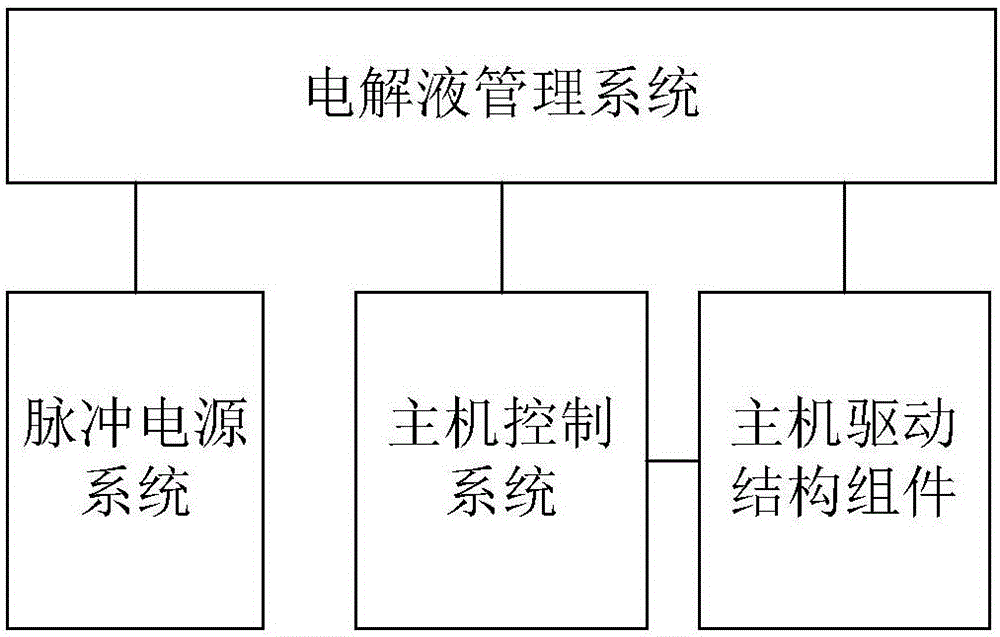

Operation control method for precise electrolytic machining

ActiveCN107175376AMachining electric circuitsElectric circuitsElectrochemical responseAutomatic control

The invention provides an operation control method for precise electrolytic machining. By identifying and controlling basic parameters of an electrolyte, calculating parameters of various machining states, and precisely controlling a machining voltage, a pulse duty factor and a feeding speed, electricity demand corresponding to machining intervals is met, so that steady-state electrochemical reaction is realized. According to the operation control method for precise electrolytic machining, the parameters of the electrolytic machining states are calculated, and a pulse power is precisely controlled, so that the machining intervals and the corresponding machining voltage, electric current density and feeding speed are controlled; the automatic control method for the machining intervals is completely solved; stable constant-interval machining is maintained; and various machining precision requirements of different materials are finally realized.

Owner:张玉炜 +1

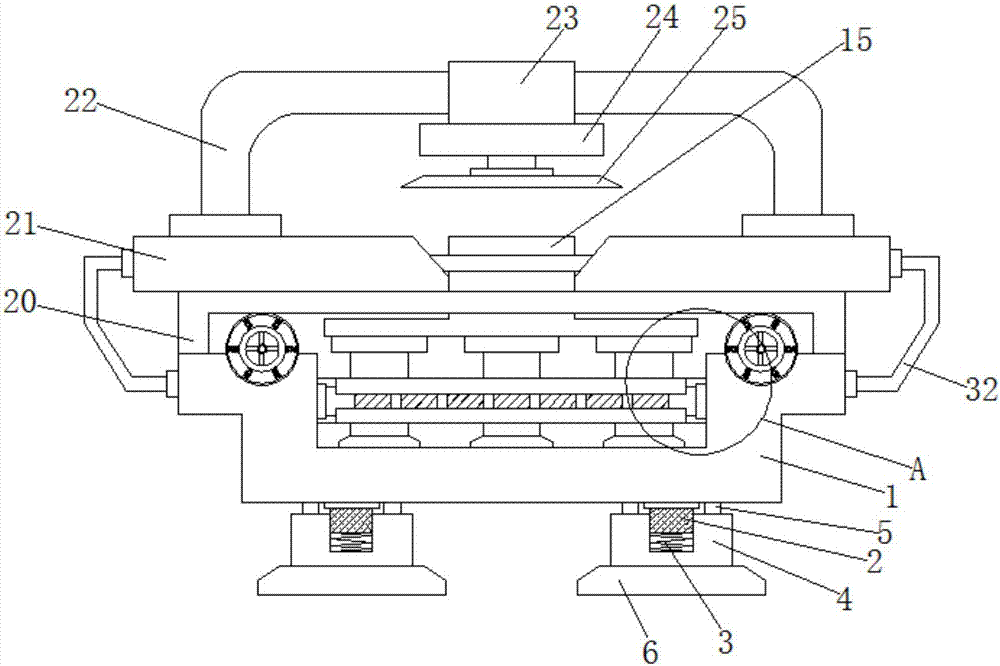

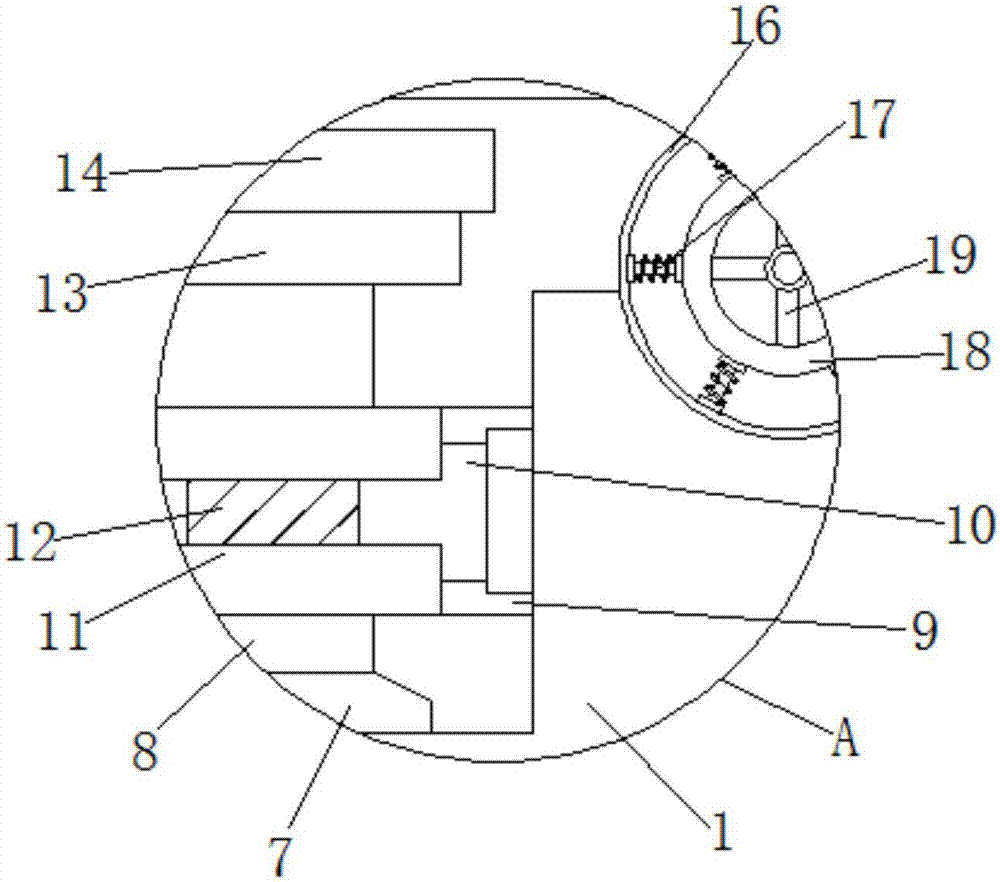

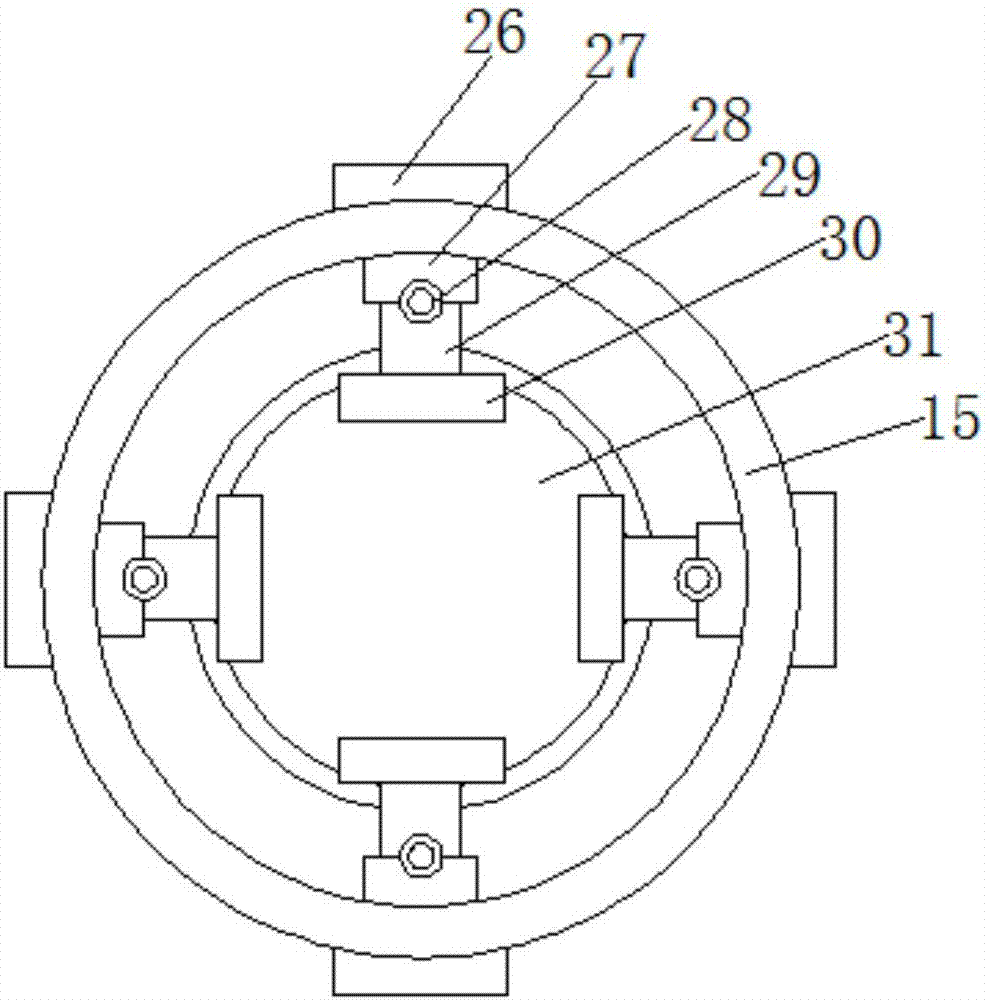

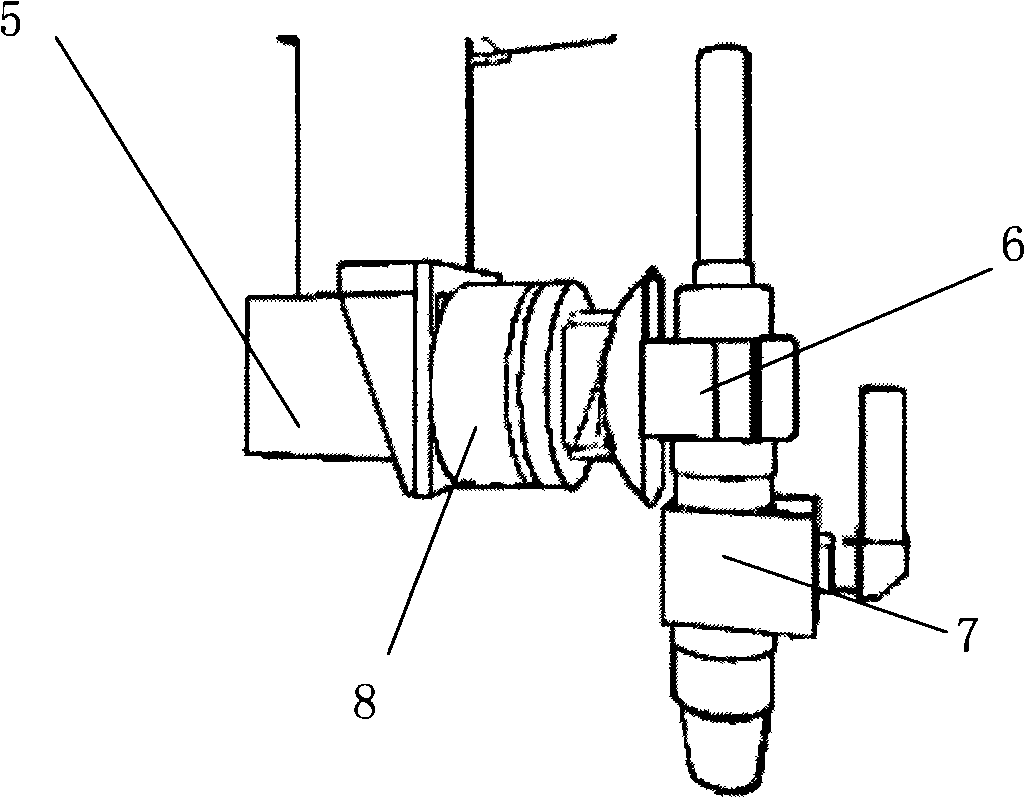

Valve machining method stable to use

The invention relates to the technical field of valve machining, and discloses a valve machining method stable to use. A workbench is involved. A positioning plate, a positioning block, a hinge ball,an adjusting rod and a clamping plate are arranged to be used in cooperation, a clamping effect is achieved on a valve in the using process, the problem that displacement is caused in the machining process and affects the machining quality of the valve in the machining process is avoided, a user can conveniently adjust the adjusting rod through the hinge ball, and practicability is effectively improved. A fixing base, a fixing column, a connection plate and a limiting base are arranged to be used in cooperation, a buffer effect can be achieved when a placing stable is subjected to force, acting force to the workbench and the placing table is reduced, the machining quality of the valve is prevented from being affected, the valve machining efficiency is ensured, and the practicability is greatly improved.

Owner:楼浩伟

Dummy laser processing procedure geometric simulation method

InactiveCN101308523ASave human effortSave moneySpecial data processing applicationsProcess optimizationLaser processing

The invention discloses a geometric simulation method in the virtual laser flexible processing course. The method comprises the establishment of a virtual processing platform, the trajectory planning based on CAD data, the trajectory optimization, the triangular simplification algorithm based on processing head effect, and a collision detection model. The invention can help observe the processing movement course in the computer visualization environment, visually display the collision interference and unreasonable processing trajectory in processing robots and other equipment as well as workpieces by laser, and forecast the processing defects in an early stage, so as to provide an effect basis for process parameter adjustment and process optimization, so as to save manpower, material resources, time and cost.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

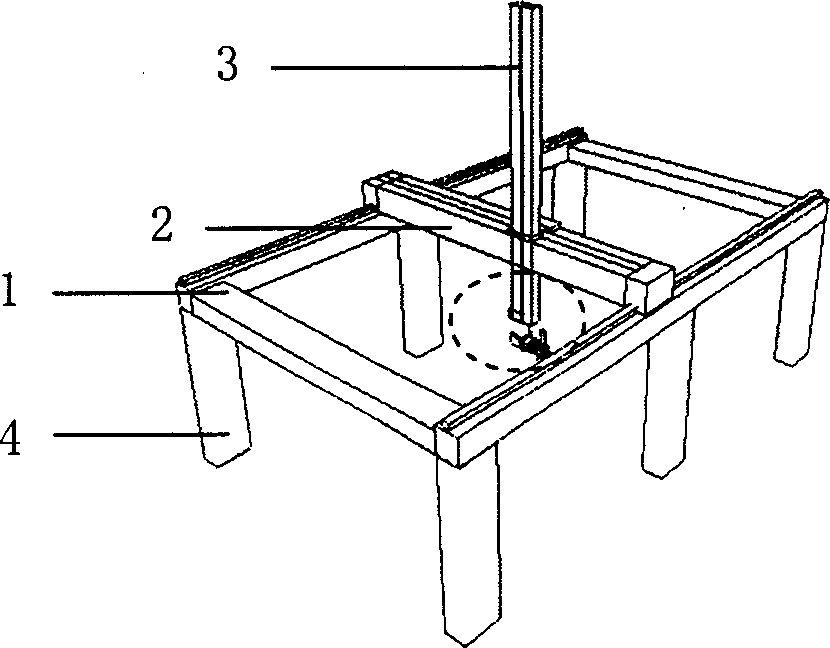

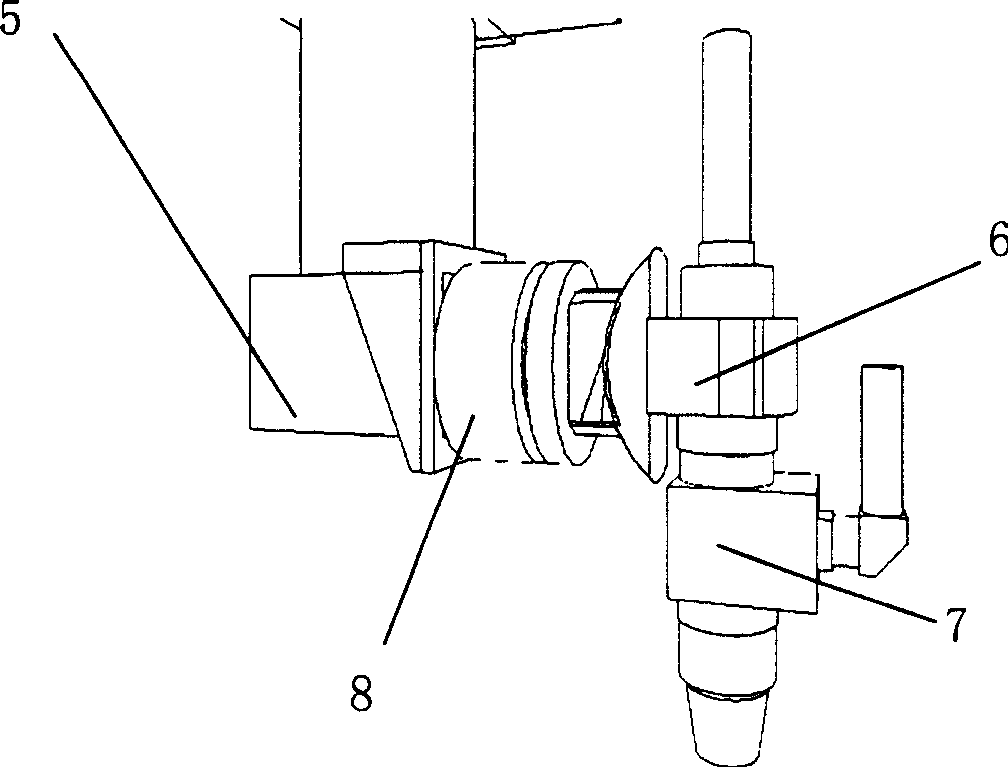

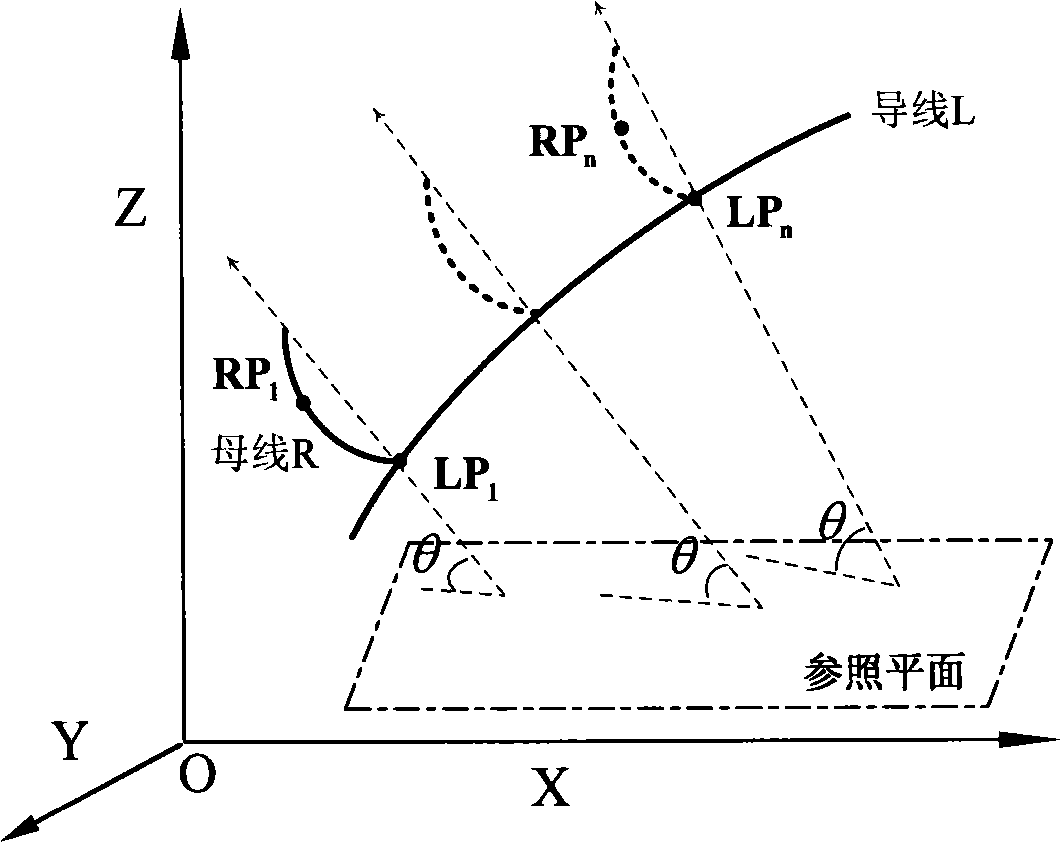

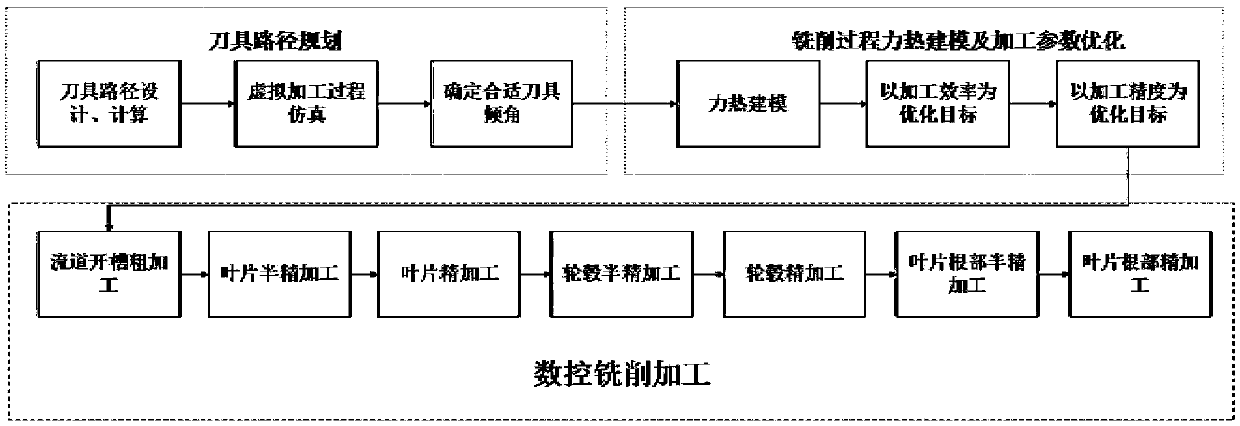

Machining technology method for miniature integrated impeller

ActiveCN109597356ASolve processabilitySolve efficiency problemsProgramme controlComputer controlAviationNumerical control

The invention discloses a machining technology method for a miniature integrated impeller. A proper cutter dip angle is determined through cutter path design and virtual machining process simulation,then, a milling process is subjected to force thermal modeling to optimize machining parameters, and finally, the optimized parameters are used for carrying out numerical control milling and machiningon the miniature integrated impeller through a five-axis numerical control machine tool. By use of the method, while machining quality is guaranteed, machining efficiency is improved, the localization of the manufacture technology of the integrated impeller of the type of difficult-to-machine materials is realized, and the manufacture technology level of Chine in the field of aircraft engines isimproved.

Owner:SHANGHAI JIAO TONG UNIV

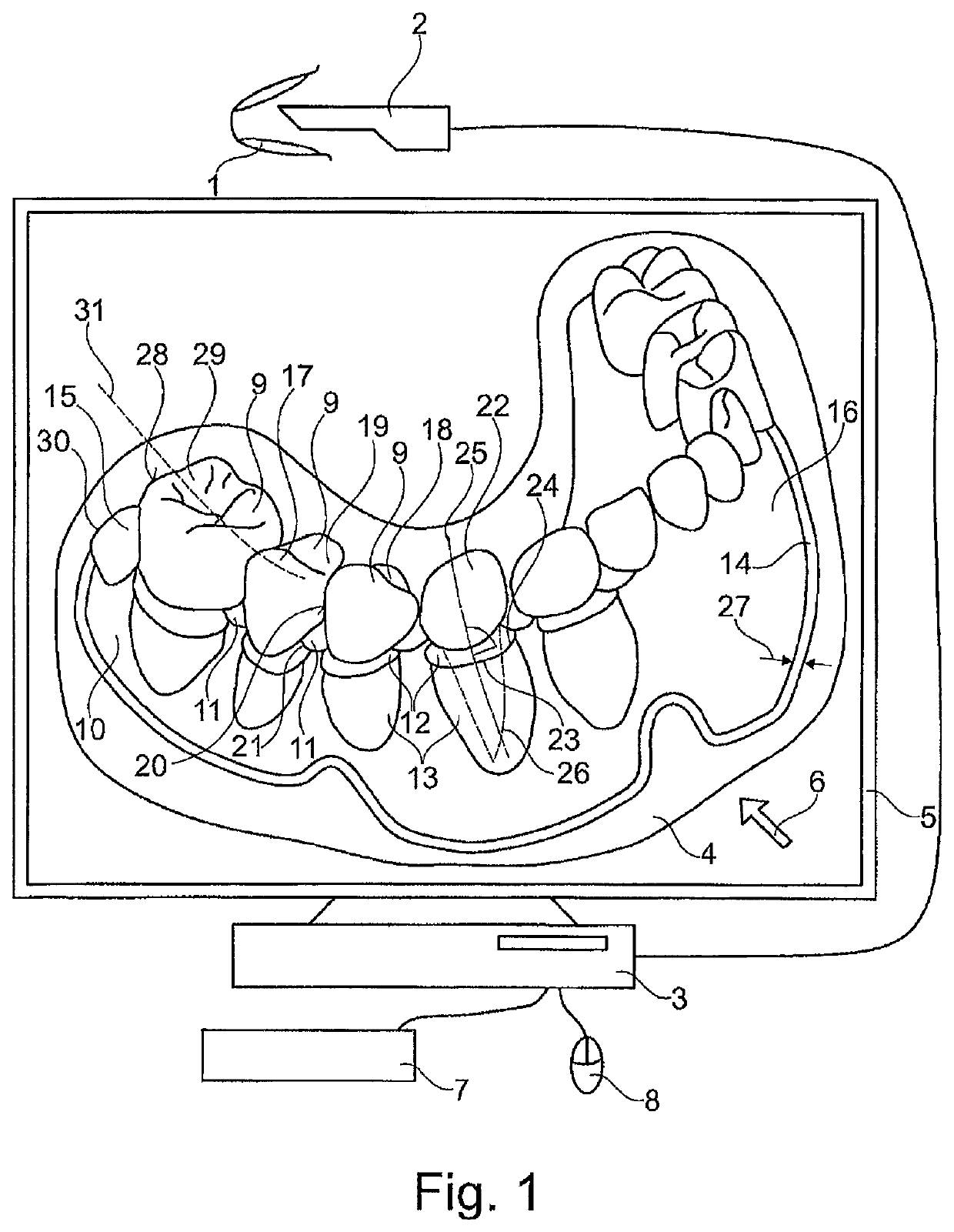

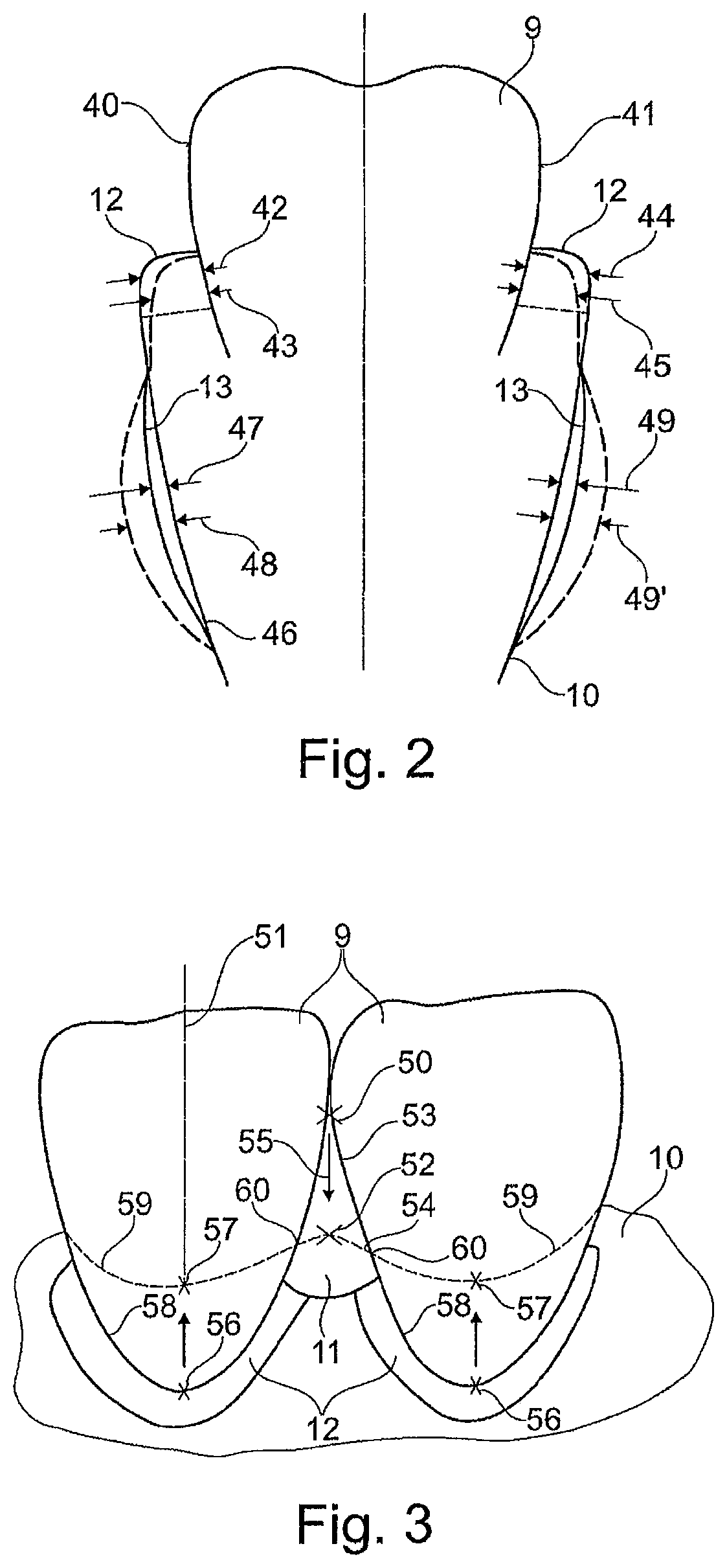

Method for the virtual secondary machining of a gingiva model

ActiveUS10729522B2The implementation process is simpleThickness is increased and reduced3D-image renderingDental prostheticsVirtual machiningDentistry

The invention relates to a method for the virtual secondary machining of a virtual three-dimensional gingiva model, said model having been created during the planning of an artificial gingiva. Here, the virtual gingiva model is virtually machined by at least one defined three-dimensional surface structure of the gingiva model being modified by means of a virtual tool using a computer.

Owner:DENTSPLY SIRONA INC

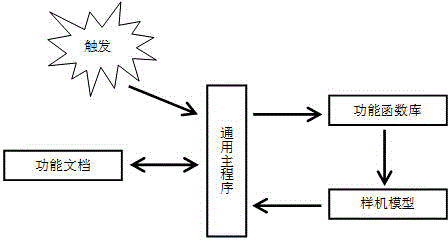

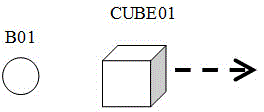

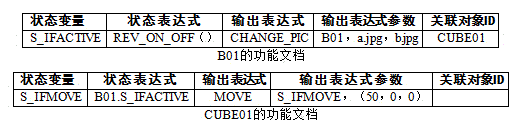

Virtual prototype based on editable text driving and method therefor

InactiveCN104866376AImprove reliabilityLower the thresholdSoftware simulation/interpretation/emulationNumerical controlVirtual machining

The invention discloses a virtual prototype based on editable text driving and a method therefor. The virtual prototype based on the editable text driving comprises a general main program, a functional document, a functional function library and a prototype model. The general main program is used for constantly monitoring a trigger signal, immediately searching and interpreting function description related to the trigger signal in the functional function document when detecting the trigger signal, then transferring a related function in the functional function library, and driving the prototype module to act in accordance with functionally described intentions. Specific functions of various kinds of virtual prototypes are separated from the main program and placed in the extensible functional function library, so that the main program is unrelated to specific varieties of virtual prototypes (e.g. virtual numerical control machines, virtual processing centers and the like), becomes a general execution program of the virtual prototype and can be developed and maintained by specially-assigned persons, and the reliability of the virtual prototype is remarkably improved.

Owner:单岩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com