Modeling method for judging cutting force of orthogonal turn-milling machining end face on basis of boundary conditions

A technology of orthogonal turning and milling and boundary conditions, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve unfavorable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

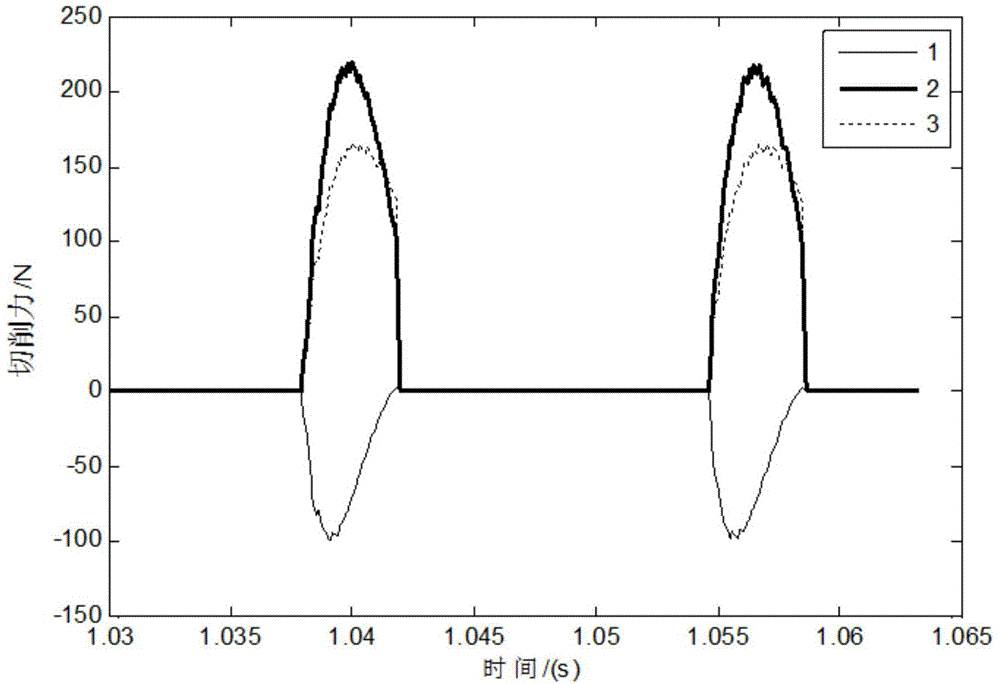

[0059] Orthogonal turning and milling of aluminum alloy 7050 round bars. The diameter of the workpiece is 40mm, and the rotation speed is 10rpm; the diameter of the tool is 16mm, 2 teeth, the rotation speed during processing is 1800rpm, the feed speed along the axial direction of the workpiece is 20mm / min, the processing method is no eccentricity, down milling, and the depth of cut is 2.5mm , taking No. 1 tooth as a reference, the runout of the tooth is 0mm and 0.008mm respectively.

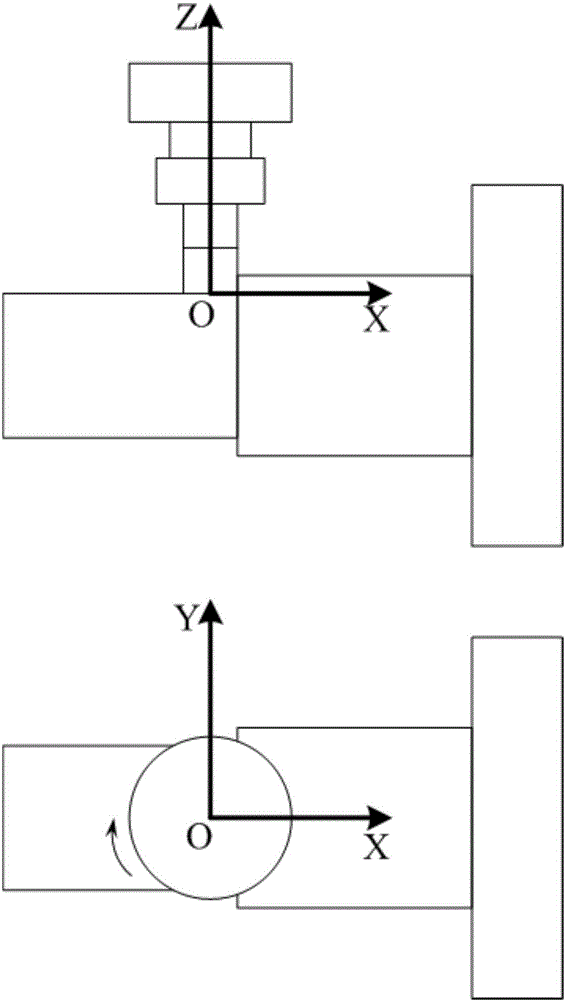

[0060] Step 1: Take the center of the bottom surface of the tool as the origin, take the direction parallel to the workpiece axis as the X-axis, and take the direction of the tool axis as the Z-axis to establish a Cartesian coordinate system, that is, the tool coordinate system, such as figure 1 shown.

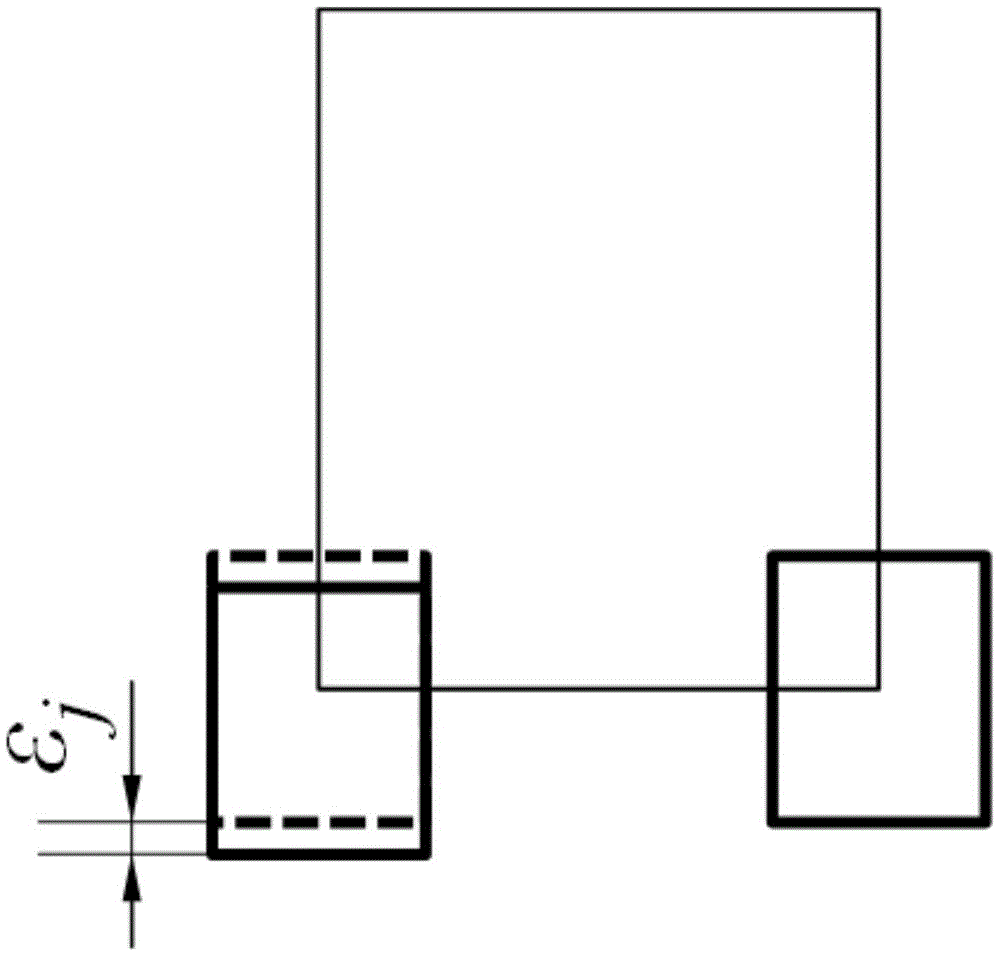

[0061] Step 2: Carry out discretization processing on the tool end face edge at an interval of 0.1mm along the radial direction. It can be seen from the cutting parameters that the discretizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com