Embedded laser flexible machining process simulating method

A flexible processing and process simulation technology, applied in the field of simulation, can solve problems such as no research reports, and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

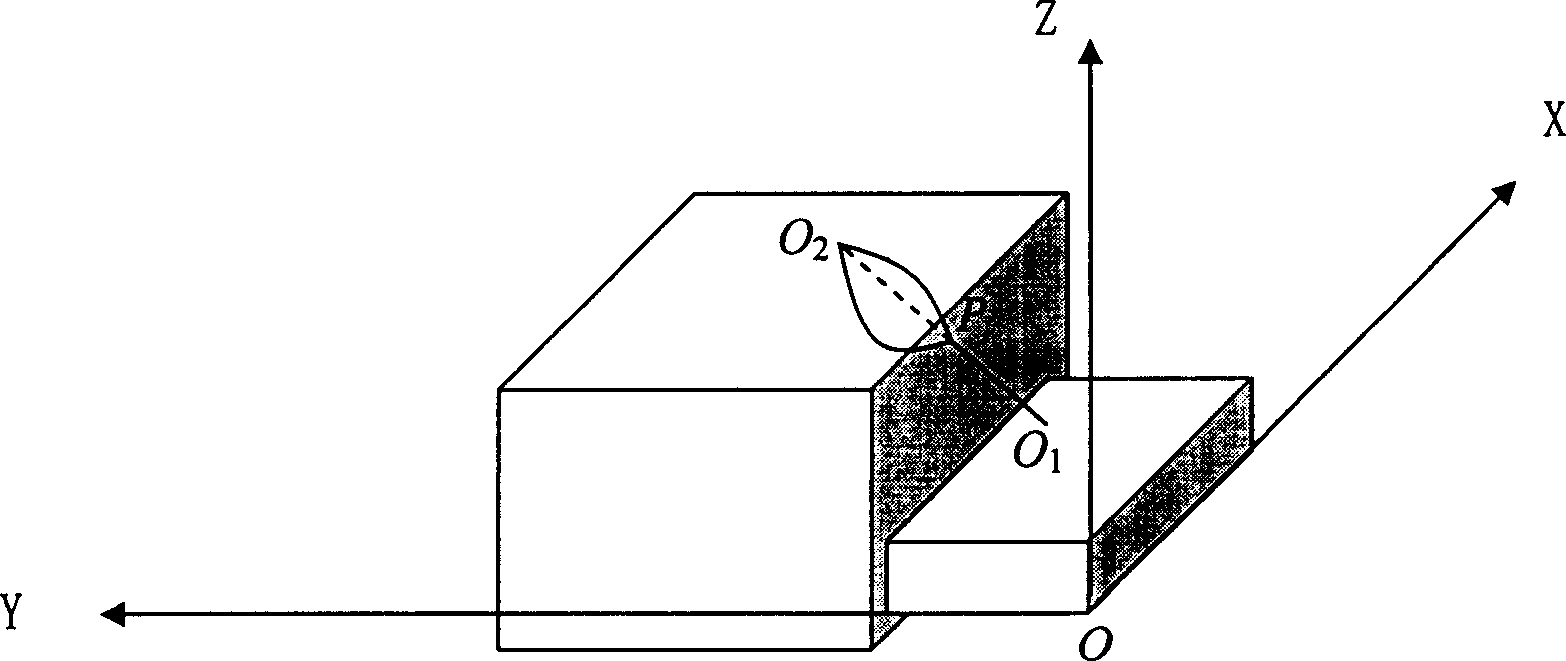

[0021] The method of the present invention mainly is the optimization algorithm and simulation model prediction of modeling and trajectory in the simulation process, and its concrete steps are as follows:

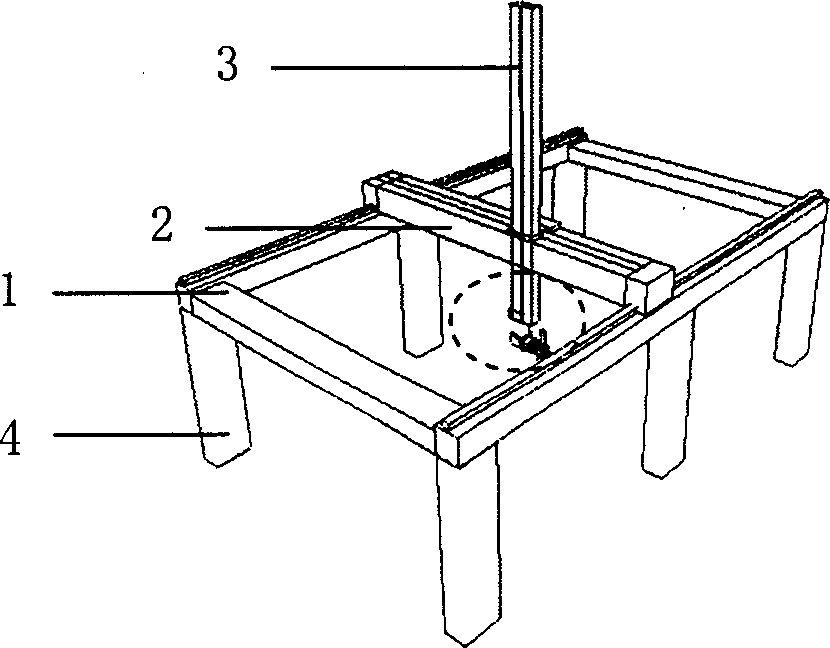

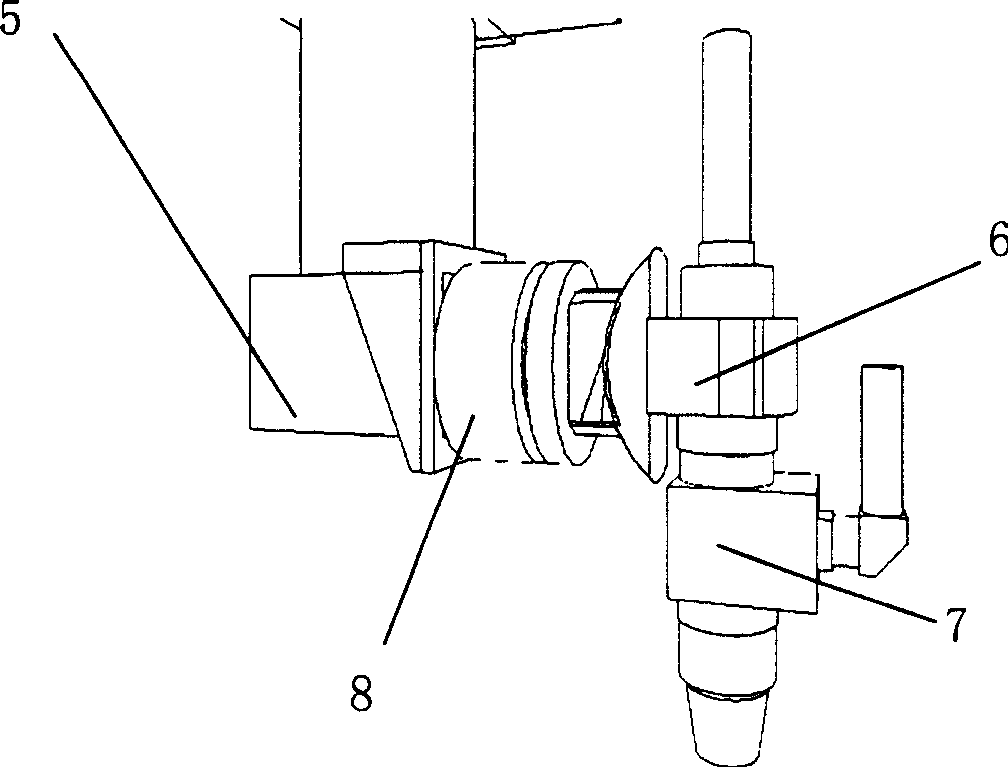

[0022] 1. Establish a virtual laser processing platform: the virtual platform is a processing platform for all laser processing, and the virtual laser processing equipment and virtual environment are required. This embodiment is aimed at "a laser processing device with flexible transmission and multi-axis linkage" developed by the Institute of Mechanics of the Chinese Academy of Sciences, the patent number is 98101217.5; its virtual environment is mainly the lighting, auxiliary facilities and layout of the processing room. The virtual processing equipment is mainly a virtual laser processing robot, including a robot geometric model and a robo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com