Valve machining technology

A processing technology and valve technology, which is applied in the field of valve processing technology, can solve the problems of valve body forming influence, copper water obstruction, large temperature difference, etc., and achieve the effect of slow condensation speed, preventing cracks, and slowing down the heat dissipation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

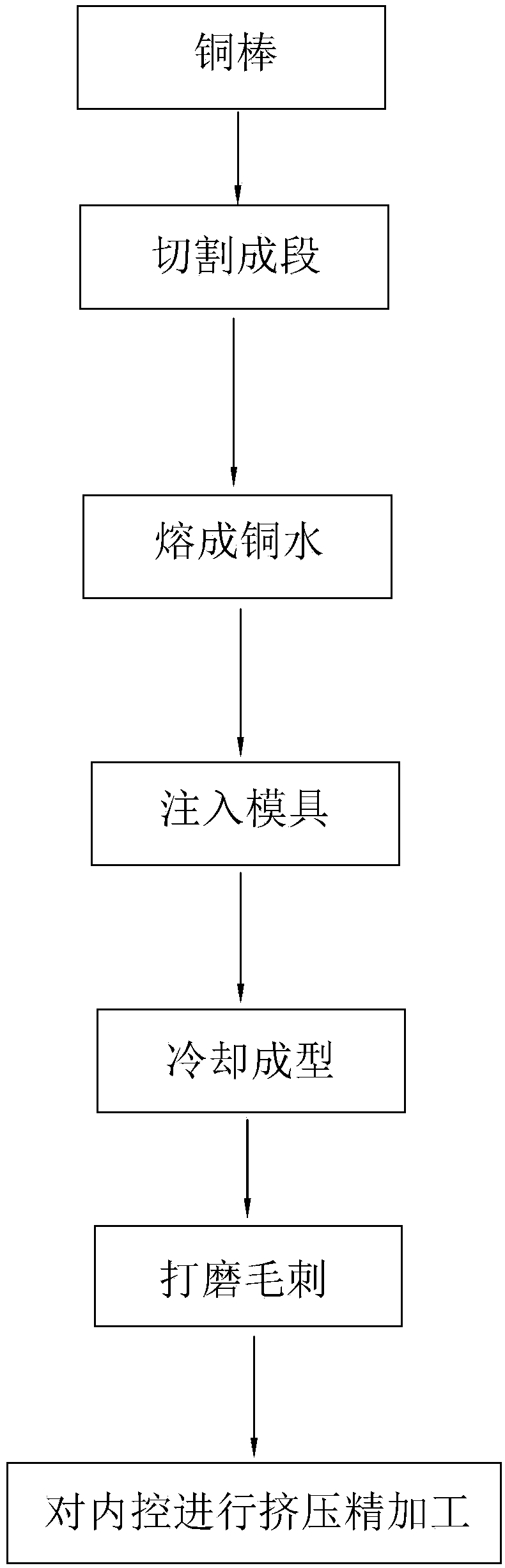

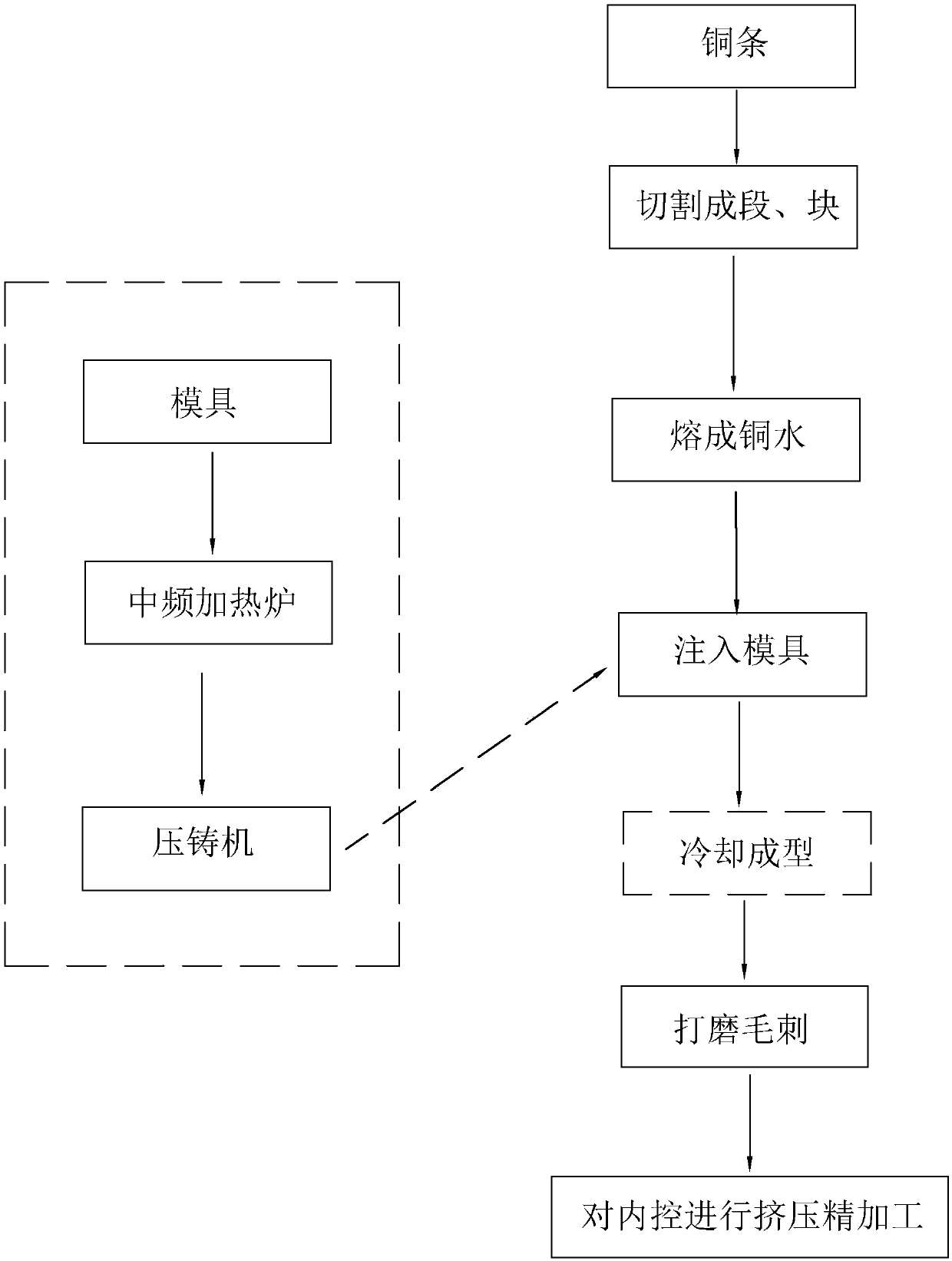

[0042] The processing technology for producing copper globe valve includes the following steps:

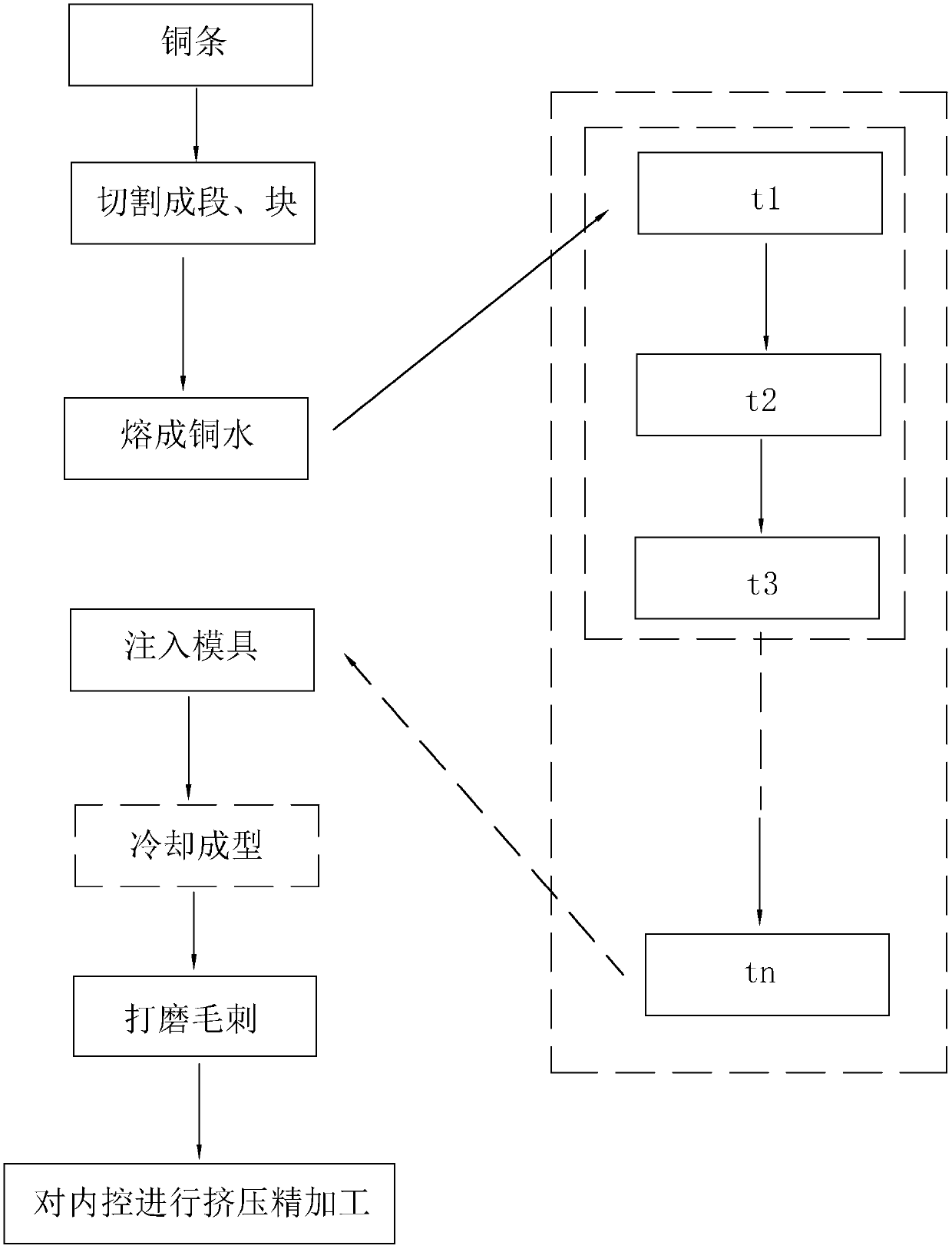

[0043] S1. Copper raw materials are cut to obtain segmented or massive copper, which is put into a furnace and heated to above 700°C to melt into liquid copper water. Inject copper water into the holding furnace for heat preservation treatment. The heat preservation process:

[0044] t1: 750°C constant temperature heat preservation, the heat preservation time is 9 to 11 minutes, and the pressure of the casting is raised to 2 to 3 times the atmospheric pressure during the heat preservation process;

[0045] t2: 700° constant temperature and heat preservation, the heat preservation time is 14 to 16 minutes, and the pressure reaches 4 times the atmospheric pressure 10 minutes before this stage;

[0046] t3: keep the temperature at 750°C for 10 to 15 minutes, and reach 5 to 7 times the atmospheric pressure before the end of this stage.

[0047] Wherein, in step t3, keep the temperat...

Embodiment 2

[0063] The processing technology for producing aluminum butterfly valves includes the following steps:

[0064] S1. Aluminum ingots are cut to obtain segmented or massive aluminum, which is put into a furnace and heated to 750°C to 800°C to melt into liquid aluminum water. Inject aluminum water into the holding furnace for heat preservation treatment. The heat preservation process:

[0065] t1: 750°C constant temperature heat preservation, the heat preservation time is 9 to 11 minutes, and the pressure of the casting is raised to 2 to 3 times the atmospheric pressure during the heat preservation process;

[0066] t2: 700° constant temperature and heat preservation, the heat preservation time is 14 to 16 minutes, and the pressure reaches 4 times the atmospheric pressure 10 minutes before this stage;

[0067] t3: keep the temperature at 750°C for 10 to 15 minutes, and reach 5 to 7 times the atmospheric pressure before the end of this stage.

[0068] Wherein, in step t3, keep the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com